Abstract

This article presents a novel approach to address the mining width-constrained open pit mine production scheduling problem in the context of medium-term planning. A mathematical formulation is proposed to incorporate mining width constraints into the production scheduling process, aiming to maximize the NPV of the schedule while ensuring enough room for the operation of mining equipment. To tackle the computational challenges posed by large-scale instances of the problem, we propose a method based on variable fixing and horizontal precedence generation. In this study, we apply the developed model to real-world scenarios from Radomiro Tomic short-term mine planning problems such as optimizing the timing of major truck maintenance and the impact of external factors, like the delay in the production of the Chuquicamata underground project. Remarkable improvements are observed with the mining width-constrained model. Specifically, the mining width satisfiability is enhanced from 2 to 60% compared to the traditional open pit mine production scheduling model, underscoring the significance of incorporating these constraints. The proposed method showed good results reaching optimality gaps within 5%.

Similar content being viewed by others

References

Kozan E, Liu SQ (2018) An open-pit multi-stage mine production scheduling model for drilling, blasting and excavating operations. Advances in Applied Strategic Mine Planning. Springer International Publishing, pp 655–668. https://doi.org/10.1007/978-3-319-69320-0_38

Mousavi, A., Kozan, E., & Liu, S. Q. (2016). Open-pit block sequencing optimization: a mathematical model and solution technique. Open-pit block sequencing optimization: a mathematical model. Engineering Optimization, 0273(July). https://doi.org/10.1080/0305215X.2016.1142080

Alarie S, Gamache M (2002) Overview of solution strategies used in truck dispatching systems for open pit mines. Int J Surf Min Reclam Environ 16(1):59–76. https://doi.org/10.1076/ijsm.16.1.59.3408

Manríquez F, González H, Morales N (2023) Short-term open-pit production scheduling optimizing multiple objectives accounting for shovel allocation in stockpiles. Optim Eng 24(1):681–707. https://doi.org/10.1007/s11081-021-09701-4

Moradi Afrapoli A, Askari-Nasab H (2019) Mining fleet management systems: a review of models and algorithms. Int J Min Reclam Environ 33(1):42–60. https://doi.org/10.1080/17480930.2017.1336607

Upadhyay SP, Askari-Nasab H (2019) Dynamic shovel allocation approach to short-term production planning in open-pit mines. Int J Min Reclam Environ 33(1):1–20. https://doi.org/10.1080/17480930.2017.1315524

Asad MWA, Qureshi MA, Jang H (2016) A review of cut-off grade policy models for open pit mining operations. Resour Policy 49:142–152. https://doi.org/10.1016/j.resourpol.2016.05.005

Eivazy H, Askari-Nasab H (2012) A mixed integer linear programming model for short-term open pit mine production scheduling. Min Tech 121(2):97–108. https://doi.org/10.1179/1743286312Y.0000000006

Jamshidi M, Osanloo M (2018) Multiple destination influence on production scheduling in multi-element mines. Int J Eng Trans A 31(1):173–180. https://doi.org/10.5829/ije.2018.31.01a.23

Blom M, Pearce AR, Stuckey PJ (2019) Short-term planning for open pit mines: a review. Int J Min Reclam Environ 33(5):318–339. https://doi.org/10.1080/17480930.2018.1448248

Blom ML, Pearce AR, Stuckey PJ (2016) A decomposition-based algorithm for the scheduling of open-pit networks over multiple time periods. Manage Sci 62(10):3059–3084. https://doi.org/10.1287/mnsc.2015.2284

Blom M, Pearce AR, Stuckey PJ (2017) Short-term scheduling of an open-pit mine with multiple objectives. Eng Optim 49(5):777–795. https://doi.org/10.1080/0305215X.2016.1218002

Del Castillo MF, Dimitrakopoulos R (2016) A multivariate destination policy for geometallurgical variables in mineral value chains using coalition-formation clustering. Resour Policy 50:322–332. https://doi.org/10.1016/j.resourpol.2016.10.003

Shishvan MS, Benndorf J (2016) The effect of geological uncertainty on achieving short-term targets: a quantitative approach using stochastic process simulation. J South Afr Inst Min Metall 116(3):259–264. https://doi.org/10.17159/2411-9717/2016/v116n3a7

Nelis G, Morales N (2022) A mathematical model for the scheduling and definition of mining cuts in short-term mine planning. Optim Eng 23(1):233–257. https://doi.org/10.1007/s11081-020-09580-1

Dimitrakopoulos R, Jewbali A (2013) Joint stochastic optimisation of short and long term mine production planning: method and application in a large operating gold mine. Min Tech 122(2):110–123. https://doi.org/10.1179/1743286313Y.0000000040

Kumar A, Dimitrakopoulos R, Maulen M (2020) Adaptive self-learning mechanisms for updating short-term production decisions in an industrial mining complex. J Intell Manuf 31(7):1795–1811. https://doi.org/10.1007/s10845-020-01562-5

Paduraru C, Dimitrakopoulos R (2018) Adaptive policies for short-term material flow optimization in a mining complex. Min Tech 127(1):56–63. https://doi.org/10.1080/14749009.2017.1341142

Bienstock D, Zuckerberg M (2009) A new LP algorithm for precedence constrained production scheduling. Working Paper. Columbia University, New York. http://www.columbia.edu/~dano/papers/newSuperblockPaper.pdf. Accessed 2 Jul 2023

Letelier OR, Espinoza D, Goycoolea M, Moreno E, Muñoz G (2020) Production scheduling for strategic open pit mine planning: a mixed-integer programming approach. Oper Res 68(5):1425–1444. https://doi.org/10.1287/opre.2019.1965

Muñoz G, Espinoza D, Goycoolea M, Moreno E, Queyranne M, Letelier OR (2018) A study of the Bienstock-Zuckerberg algorithm: applications in mining and resource constrained project scheduling. Comput Optim Appl 69(2):501–534. https://doi.org/10.1007/s10589-017-9946-1

Chicoisne R, Espinoza D, Goycoolea M, Moreno E, Rubio E (2012) A new algorithm for the open-pit mine production scheduling problem. Oper Res 60(3):517–528. https://doi.org/10.1287/opre.1120.1050

Lerchs H, Grossmann IF (1965) Optimum design of open pit mines. Canadian Institute of Mining and Metallurgy Bulletin 58(633):47–54

Deutsch M (2019) Open-pit mine optimization with maximum satisfiability. Min Metall Explor 36(1):757–764

Deutsch M, Dağdelen K, Johnson T (2023) A dynamic programming algorithm for selecting evenly spaced pushbacks from nested pits. In: Proceedings of the 41st application of computers and operations research in the mineral industry (APCOM) symposium. pp 683–691

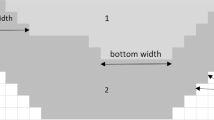

Nancel-Penard P, Morales N (2022) Optimizing pushback design considering minimum mining width for open pit strategic planning. Eng Optim 54(9):1494–1508

Yarmuch JL, Brazil M, Rubinstein H, Thomas DA (2021) A model for open-pit pushback design with operational constraints. Optim Eng 24:623–639. https://doi.org/10.1007/s11081-021-09699-9

Yarmuch JL, Rubinstein H (2023) Developing and testing an optimization algorithm for practical open-pit pushback design. In: Proceedings of the 41st application of computers and operations research in the mineral industry (APCOM) symposium. pp 674–682

Morales N, Nelis G, Amaya J (2023) An efficient method for optimizing nested open pits with operational bottom space. Int Trans Oper Res. https://doi.org/10.1111/itor.13390

Nancel-Penard P, Jelvez E (2023) A direct block scheduling model considering operational space requirement for strategic open-pit mine production planning. Optim Eng. https://doi.org/10.1007/s11081-023-09875-z

Wharton, C., & Whittle, J. (1997). The effect of minimum mining width on NPV. Optimizing with Whittle, 173–178.

Acknowledgements

We would like to express our thanks to Ryan Goodfellow and Connor Meagher for sharing their insights on the sinking rate constraints, as well as to Gonzalo Nelis for sharing his expertise on short-term planning models. Additionally, we extend our gratitude to the anonymous reviewers whose thoughtful comments and suggestions greatly contributed to the improvement of this manuscript.

Funding

This research has been funded by the Chilean National Research and Development Agency ANID through the programs PIA/Basal Grants AFB220001 (J.Y.) and FONDECYT Iniciación Grant 11240385 (J.Y.).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• New formulation that integrates mining width constraints into open-pit production scheduling.

• Adaptation of algorithms and heuristics to manage large-scale instances.

• Scenario analysis based on Radomiro Tomic real dataset offers practical insights for medium-term mine planning optimization.

• The new formulation boosts mining width satisfiability to 60% compared to the 2% obtained with traditional models, with minimal optimality gaps.

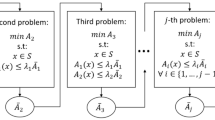

Appendix. Formulation of \({\mathcal{P}}^{*}\)

Appendix. Formulation of \({\mathcal{P}}^{*}\)

The following describes the formulation of the subproblem \({\mathcal{P}}^{*}\); we use the same notation and sets described in Sect. 2.

Variables.

The set of variables are associated with the extraction of the blocks.

Objective Function

The objective function aims to maximize the discounted cashflow or net present value.

Constraints

Constraint (8) represents the resource constraint per destination per period; in our case, the resource associated with each block consists of its tonnage. This constraint can directly be extended to multiple resource constraints per destination. Constraint (9) ensures that, to extract a block b by period t, all its vertical and horizontal predecessors must also be extracted by period t. Constraint (10) forces that if a block is mined by a period t, then it will continue as mined for all subsequent periods. Constraint (11) is analogue to Constraint (10) but regarding the destinations. Constraint (12) ensures that no blocks can be extracted at period 0. Constraint (13) ensures that all the blocks that could violate the sinking rate constraint from block i are extracted at least a period earlier than block j itself. Constraint (14) ensures that the blocks are selected on at most one period one destination.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yarmuch, J.L., Sepulveda, G. Application of Mining Width-Constrained Open Pit Mine Production Scheduling Problem to the Medium-Term Planning of Radomiro Tomic Mine: A Case Study. Mining, Metallurgy & Exploration 41, 681–693 (2024). https://doi.org/10.1007/s42461-024-00970-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-024-00970-y