Abstract

Copper mine operations consistently generate a large quantity of tailings after their concentration processing. These tailings are either piled up or stored in a dam, where both alternatives of disposal lead to environmental impacts. The dam copper tailings have a huge potential for by-product production thus improving sustainability and profitability in industrial operations. This paper describes a study aiming at producing a magnetite pellet feed as a by-product from a dam chalcopyrite flotation tailings and generating free magnetite non-magnetic rougher tailings. The chemical assay and mineralogy analysis of dam copper flotation tailings indicate low Fe grade (6.34 wt%), high SiO2 grade (63.14 wt%), low magnetite (3.6 wt%), and high iron silicates content (22.72 wt%). The complex mineralogy of these tailings leads to the need of grinding the rougher magnetite pellet feed as fine as 80% of particles smaller than 20 µm (P80) aiming at improving magnetite liberation. The proposed process route comprises a scalping screen, low field rougher, and cleaner magnetic separations using a drum magnetic separator (80 kA/m or 1000 Gauss), followed by silicates reverse cationic flotation as a recleaner step. With this process route, it was possible to produce a high-quality magnetite pellet feed reaching 68.00 wt% of Fe, 2.13 wt% of SiO2, 0.51 wt% of Al2O3, and 95.1 wt% of magnetite. The Blaine specific surface area was 2300 cm2/g, being in the range recommended for pelletizing (1900 up to 3000 cm2/g). The total mass, Fe, SiO2, Al2O3, and magnetite recoveries were 2.77%, 29.71%, 0.09%, 0.12%, and 73.17%, respectively. Most of the magnetite losses, around 20% of total magnetite fed, occurred in the oversize of the scalping screen. Additionally, it generated non-magnetic rougher tailings with less than 1.0 wt% of magnetite that could be used as by-products and reduced the amount of tailings disposal in a dam. This study contributes toward the sustainability of operation, minimizing tailings disposal.

Graphical Abstract

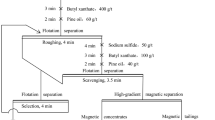

Block diagram of process route to generate magnetite pellet feed from dam copper flotation tailings.

Highlights

• Magnetite pellet feed recovery from chalcopyrite dam copper flotation tailings.

• Process route comprises scalping screen, low field rougher, and cleaner magnetic separations and silicates reverse cationic flotation as recleaner step.

• High-quality magnetite pellet feed reaching 68.00 wt% of Fe, 2.13 wt% of SiO2, and 95.1 wt% of magnetite.

• The total mass, Fe, SiO2, Al2O3, and magnetite recoveries of 2.77%, 29.71%, 0.09%, 0.12%, and 73.17%, respectively.

Similar content being viewed by others

References

Mazzinghy DB, Figueiredo RAM, Parbhakar-Fox A, Yahyaei M, Vaughan J, Powell, MS (2022) Trialling one-part geopolymer production including iron ore tailings as fillers. Int J Min Reclam Environ. https://doi.org/10.1080/17480930.2022.2047271

Hamza MF, El-Assay IE, Guibal E (2019) Integrated treatment of tailing material for the selective recovery of uranium, rare earth elements and heavy metals. Miner Eng 133:138–148. https://doi.org/10.1016/j.mineng.2019.01.008

Zhang Y, Shen W, Wu M, Shen B, Li M, Xu G, Zhang B, Ding Q, Chen X (2020) Experimental study ion the utilization of copper tailing as micronized sand to prepare high performance concrete. Constr Build Mater 244:118312. https://doi.org/10.1016/j.conbuildmat.2020.118312

Gordon RB (2002) Production residues in copper technological cycles. Resour Conserv Recycl 36(2):87–106. https://doi.org/10.1016/S0921-3449(02)00019-8

Lan ZQ, Lan ZY (2015) The progress of comprehensive utilization of copper tailings resource. Conserv Util Miner Resour 10(5):51–56. https://doi.org/10.13779/j.cnki.issn1001-0076.2015.05.011

Lane DJ, Cook NJ, Grano SR, Ehrig K (2016) Selective leaching of penalty elements from copper concentrates: a review. Miner Eng 98:110–121. https://doi.org/10.1016/j.mineng.2016.08.006

Zhu JL, Song JW, Wang L, Xiong RR, Feng SL, Ouyang Y (2018) Research progress on application of copper tailing in cement-based materials. Bull Chin Ceram Soc 37(11):3492–3497. https://doi.org/10.16552/j.cnki.issn1001-1625.2018.11.021

Liu S, Wang L, Li Q, Song J (2020) Hydration properties of Portland cement-copper tailing power composite binder. Constr Build Mater 251:118882. https://doi.org/10.1016/j.conbuildmat.2020.118882

Silva R, Couto D, Tavares A, Guimarães L (2021) Enhanced process route to remove fluorine and Uranium from copper concentrates by selective sulfuric acid leaching. Miner Eng 170:107039. https://doi.org/10.1016/j.mineng.2021.107039

Silva R, Silva JM, Souza TC, Bianchetti M, Guimarães L, Reis L, Oliveira E (2021) Enhanced process route to produce magnetite pellet feed from copper tailing. Miner Eng 173:107195. https://doi.org/10.1016/j.mineng.2021.107195

Zhu B, Tian J, Zhu Y, Tian J, Shen S (2015) Current situation and prospect of comprehensive utilization of copper mine tailings. World Build Mater 5:84–87 (in Chinese)

Jia T, Wang R, Chai B (2019) Various phyllosphere and soil bacterial communities of natural grasses and the impact factors in a copper tailings dam. Curr Microbiol 76:7–14. https://doi.org/10.1007/s00284-018-1575-0

Nikolic N, Böcker R, Nikolic M (2016) Long-term passive restoration following fluvial deposition of sulphidic copper tailings: nature filters out the solutions. Environ Sci Pollut Res 23(14):13672–13680. https://doi.org/10.1007/s11356-015-5205-0

Edraki M, Baumgartl T, Manlapig E, Bradshaw D, Franks DM, Moran CJ (2014) Designing mine tailings for better environmental, social and economic outcomes: a review of alternative approaches. J Clean Prod 84:411–420. https://doi.org/10.1016/j.jclepro.2014.04.079

Jian-jun F, Guan-zhou Q, Tao J, Yu-feng G, Mei-xia C (2011) Roasting properties of pellets with iron concentrate of complex mineral composition. J Iron Steel Res Int 18(7):01–07

Parker G (2001) Encyclopedia of materials: Science and technology. In Guide-wave optical communications: Materials. Elsevier, pp 3703–3707

Fan J-j, Qiu G-z, Tao J, Guo Y-f, Cai M-x (2011) Roasting properties of pellets with iron concentrate of complex mineral composition. J Iron Steel Res Int 18(7):01–07

Krause CA (2018) Campbell Chibougamau mines limited magnetite bay iron ore deposit review of costs and profitability. Ressources naturelles et Faune, Québec, GM69608. https://gq.mines.gouv.qc.ca/documents/examine/GM69608

Acknowledgements

The authors would like to thank Vale S.A. especially Patrice Mazzoni and Keila Gonçalves for authorizing the publication of this work. The authors are also thankful to the CDM’s staff at Vale Mineral Development Centre, who were dutifully engaged in this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silva, R., Silva, J.M., Guimarães, L. et al. Selective Process Route to Recover Magnetite from Chalcopyrite Dam Copper Flotation Tailings. Mining, Metallurgy & Exploration 39, 2517–2528 (2022). https://doi.org/10.1007/s42461-022-00681-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00681-2