Abstract

The floodable volume of longwall gob can be of great importance in developing accurate coal mine operation plans, particularly for mine water management and environmental control strategies. Given the inaccessibility and difficulty in direct measurement of gob characteristics following gob recompression, hydrologic, geomechanical, and spatial data and principles were used to solve for the porosity and height of the residual gob using a mathematical model framework and bulking-based techniques. Based on this approach, gob porosity of Appalachian longwalls appears to be tighter than previously reported, ranging between 4.99 and 14.31%. Residual gob height, as normalized with respect to mine extraction height, ranges between 1.90 and 2.45. A novel, bedding-based bulking approach is ampliative with respect to existing roof caving and bulking fundamentals, as it has greater explanatory value compared with the traditional, lithologic-based bulking application. The efficacy of using the residual gob characteristics determined by the mathematical model and bedding-based bulking is examined using a causal comparative method, whereby time series prediction of historical groundwater rebound is compared with observed mine pool elevation data. Prediction accuracy is significantly improved using a prototype model to calculate void volume of longwall gob, specifically, the dependence of porosity of the gob material upon the longwall width to overburden depth ratio for movement basins of subcritical and critical panel widths. The potential implication of these findings toward hydrologic, geomechanical, and ventilation studies of longwall gob could be significant.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Underground mining of below drainage coal seams induces groundwater infiltration into active mine workings. Depending on the rate of inflow, pumping can be critical to maintaining dry, working faces, adequate ventilation, and ancillary operations. This is especially important when the floor rock has low bearing capacity and is susceptible to water, as these conditions have potential to impede both mine development and highly efficient longwalls. Vertical inflow of groundwater is derived from overlying aquifers and surface water sources at shallow overburden conditions [1,2,3] but could also be associated with drainage from overmined seams in multiple seam mining scenarios. Inflow has been shown to occur as horizontal seepage across common barriers between contiguous mines [4, 5] and spillage through discrete connections [6] but is typically undifferentiated. Following mine closure or sealing, dewatering pumps are typically deactivated, which leads to resaturation and filling of the abandoned mine voids. Practitioners ordinarily refer to this resaturation process as mine flooding or groundwater rebound.

Groundwater rebound, in the mining context, refers to the gradual flooding of abandoned mine workings up to some level [6]. The initial development of flooding in a coal mine aquifer is the formation of a phreatic surface, or pool, in the lowest elevation of the mine [7]. Pools can also form within mine workings located up-gradient of this main pool due to the physical effects of contour depression and intra-mine barriers. Inflow to these perched pools will transmit to the main pool when the decant of the floor depressions and intra-mine barrier spillage points are encountered. Eventually, these pools coalesce and subsequently transgress as one pool across the remaining, unflooded mine workings. Groundwater rebound occurs until such time that the coal mine aquifer attains groundwater equilibration or is controlled to prevent unwanted discharge or impacts to hydrologic balance. In the United States of America (USA), control of coal mine aquifers is regulated under 30 C.F.R §817 of the Surface Mining Control and Reclamation Act of 1977 and state authority approved through cooperative federalism. Mine water that is pumped to maintain control of the coal mine aquifer is treated prior to discharge in accordance with the National Pollutant Discharge Elimination System permitting programs authorized by §402 of the 1972 Clean Water Act and amendments promulgated thereafter, regardless if the mine water is pumped to maintain dry, working faces, or coal mine aquifer control.

The concept of longwall mining dates to the late nineteenth century, but modern, fully mechanized longwall mining was not recognized as a viable technique until shield supports were introduced in the mid-1970s [8]. Contemporary longwall mining is conducive to high production and subject to strict state and federal safety and health standards. The operation consists of a shearer with two rotating cutting drums, a panline which guides the shearer that runs the length of the working face, and a series of self-advancing hydraulic roof supports that protect the working face and serve to advance the panline. Typical modern longwall panel face widths range from a few hundred meters to well over 450 m, and panel lengths may extend up to 6000 m. As the shearer removes the coal and the shields advance (i.e., as the face retreats), the immediate roof behind the shields fails and caves, and the overburden above the extracted coal seam progressively subsides to the surface [8].

Caving is an unloading process of the rock mass from an original stress state within the immediate roof. As soon as the roof is undermined, the lowest stratum begins to sag downward, breaks, falls to the mine floor and expands in volume relative to its in-situ state. As stratum in the immediate roof fails, the load of the overburden is transferred upward, increasing the stress on the adjacent layer [9]. The caving process continues until the crown of the bulked and caved rock mass, or “gob”, is arrested against the lowest un-caved stratum in the roof. As the face retreats from a given location, the gob gradually reconsolidates and stiffens to support the large loads from the overburden weight. This results in a reduction in the void ratio and associated permeability of the residual gob [10].

Bulking, as it relates to mine-induced caving, describes expansion as the ratio of the volume of the broken rock strata to the original volume of the same strata before the stress state is altered [8]. Bulking factor has been shown to be associated with rock type, such that a gob consisting of broken massive sandstone will have greater expansion (and thus a higher bulking factor, void ratio, and porosity) compared with a gob comprised of delaminated shale [8, 11, 12]. Bulking factor has also been explained through its relationships to rock strength, and particle size, shape, and arrangement. Larger block sizes are prone to leave more void space in a finite volume [10, 11, 13 as cited in 12], especially if the caved rock rotates during the fall and accumulates in a disorderly arrangement [8, 13]. In contrast, lower bulking factors are expected in laminated strata [8, 11, 12, 14, 15 as cited in 12], weaker rock due to more particle breakage [10, 11, 13 as cited in 12], and thinner and wider disk-shaped rock [11].

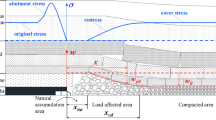

Original and residual bulking factors are differentiated according to the load of the overlying strata acting on the caved rock mass [8, 11]. Original bulking factors are used to determine the strata in the immediate roof that are likely to comprise the caved rock mass accumulation zone (CRMAZ), as these values are associated with unabated rockfall under minimal or no compaction from the overlying strata. Residual bulking factors are used to estimate the height of the residual gob following gob recompression. Residual bulking factors are applied to the same strata that comprise the CRMAZ. The height difference between the CRMAZ and the residual gob can be used to estimate gob compaction (Fig. 1).

Short of limited and site-specific monitoring, and back-calculation from numerical modeling approaches, the mechanical and physical behavior of gob material following gob recompression has received relatively little attention due in part to the inaccessibility of the gob environment for conducting in situ measurements of porosity using conventional tests [10, 11]. Porosity of the gob material is further complicated by possible interaction effects among various influential variables, such as overburden depth, longwall width, extraction height, and geology of the immediate roof. The absence of sufficient data implies an opportunity to learn. This paper seeks to quantify the porosity of the gob material and determine if predictive modeling of gob porosity across the coal mine aquifer, using an innovative approach consisting of water balance and gob bulking principles, is possible. Throughout this paper, the term porosity is used to reference the pore water fraction of the total void volume.

2 Methods and Materials

The intent of this research is to establish, confirm and validate relationships and generalizations that contribute to mine subsidence theory. In particular, this research targets a solution, as derived from hydrologic, geomechanical, and spatial data and principles, to quantify porosity of gob material following gob recompression using an analytical spreadsheet solution as a method of experimental data analysis. A causal comparative method is subsequently used as a competency assessment tool to validate the experimental results and evaluate predictive accuracy relevant to practitioner use.

2.1 Case Studies

To reasonably quantify the porosity of the longwall gob material, a process of elimination (POE) was used to select case studies that would yield testable and verifiable results. Longwall mines were excluded from the study if detailed and reliable mine dewatering and mine pool monitoring records, bottom of coal (BOC) elevation, roof geology, and mine design files could not be obtained. The confidence of determining porosity of the gob material was also improved by removing the confounding effects of adjacent mines. Accordingly, the longwall mines selected for the study were surrounded by intact and thick coal barriers and were not undermined or overmined by multiple seam mining.

The POE was also used to identify longwall mines which contain more than one pool. Coal mines that use the longwall method typically consist of districts of longwall panels, where each district is separated by an intra-mine barrier to isolate ventilation, mitigate the stress effects of mining on one side of the barrier from the other, and, in turn, prevent (or reduce) water seepage from flooded portions of the mine into other mining districts [16]. As a result, a single longwall mine could have several distinct pools that are at various levels of groundwater rebound due to the presence of intra-mine barriers.

The POE ultimately narrowed down the study to eight discrete pools that have developed within six longwall mines located within the USA. Appalachian coalfield. These mining operations retreated longwalls within the Pittsburgh seam of the Upper Pennsylvanian Monongahela Group (n = 5), the Clarion seam of the Middle Pennsylvanian Allegheny Formation (n = 2) and the Pocahontas No. 3 seam of the Lower Pennsylvanian Pocahontas Formation (n = 1). Three of these longwall mines currently operate under coal mining activity permits but include sealed mine workings where groundwater rebound is occurring. The remaining mines are at various stages of closure, with respect to decommissioning and mine reclamation.

The case studies represent a range in average overburden depth conditions of 78 m to 584 m, average longwall widths of 175 m to 377 m, and average coal thicknesses of 1.6 m to 2.5 m (Table 1).

2.2 Experimental Analysis

The floodable volume of a longwall mine consists of the combined void volumes of mine development and longwall gob. Void volume can be represented through application of a mathematical modeling framework to characterize mine development and longwall gob features in three-dimensional space, where XYZ data correspond to mine extraction widths, lengths, and heights, respectively. However, the fraction of the geometric volume of longwall gob capable of storing water is unknown.

Metaphorically, the approach used to quantify the effective porosity of the gob material is akin to how one may determine the void volume of fill rock; place fill rock in a container and pour water from a graduated cylinder into the container of fill rock until it attains full saturation. The void volume of the fill rock would be equal to the change in water volume within the cylinder. For longwall gob, the container, fill rock, and water are analogous to the total volume, solids volume, and interstitial (floodable) volume of the gob material, respectively. Unique to this research is the ability to measure the change in water volume of the cylinder.

The experimental design of this research (Fig. 2) focuses on specific mine workings, or experimental test zone (ETZ), for which accurate mine dewatering and mine pool monitoring data exist, and therefore, the saturation volume required to fully inundate each ETZ can be quantified. The saturation volume (or volume difference within the illustrative “graduated cylinder”) becomes the algebraic solution of the mathematical model. Consequently, the mathematical model is structured as a working backward problem solution, where it is utilized to solve for the average porosity of the gob environment for each case study, herein referred to as experimental porosity.

2.2.1 Saturation Volume

Mine dewatering and mine pool monitoring data were studied to identify historic records where groundwater rebound across a mine working occurred prior to or following steady state control of the mine pool within the same mine working. The product of mine dewatering rate (Q) and length of time for the mine pool to rebound across the same mine working (t) is equal to the saturation volume of the ETZ (Vsat (ETZ)) (Eq. 1). However, there are a few caveats associated with the use, and interpretation, of inflow-related data.

Inflow is responsive to seasonal and annual variations of overlying aquifers and surface water sources. Inflow has also been observed to reduce under lower hydraulic gradients, as potentially explained by Darcian flow through porous media. As a result, inflow during dry season months (June through November) may be less than inflow during the wet season months (December through May). Furthermore, inflow at lower groundwater rebound levels is often greater than inflow at higher groundwater rebound levels, since mine workings examined at the onset of mine flooding are typically subject to higher hydraulic gradient.

To reduce the uncertainty associated with these possible differences in inflow, a minimum of 12 continuous months of mine dewatering and mine pool monitoring data were sought to quantify saturation volume. Data collected prior to mine closure or sealing were used to compute the average inflow for case studies examined at the onset of mine flooding. For case studies where the mine pool aquifer was controlled, inflow was determined by one of two methods:

-

Average mine dewatering rate, if the pool elevation was stable across the period of evaluation; or

-

Regression analysis of the dependence of change in mine pool elevation on mine dewatering rate, if there was a net change in pool elevation across the period of evaluation.

Two types of instruments are used to compute mine dewatering rate; elapsed time meters (ETMs) and totaling meters. ETMs are used in pumping applications with a focus on maintenance schedule, and the volume is calculated as the product of operational run time and pump capacity. Totaling meters, or an electromagnetic flow meter equipped with a totalizer function, measure and display the total volume of fluid that passes by a flow sensor. The mine dewatering rate was calculated as the ETM or totaling meter volume divided by the time between measurements.

Mine pool monitoring data were evaluated to determine the length of time for the mine pool to rebound across the ETZ. Groundwater rebound was evaluated within boreholes originally installed to support coal mine production and maintenance, such as power and communication services. Following mine closure or sealing, boreholes are sometimes left open to promote drainage of trapped mine air. These boreholes are equipped with flame arrestors (should methane be present) and are often accessible for purposes of mine pool monitoring and mine water management. Mine pool elevation measurements were typically recorded monthly and were collected using portable, hand-operated water level meters.

2.2.2 Floodable Volume

The floodable volume of the ETZ (Vfloodable (ETZ)) is a three-dimensional representation of mine development (Vv dev (ETZ)) and longwall gob (Vv gob (ETZ)) features within the ETZ (Eq. 2). Vfloodable (ETZ) is equal in value to the saturation volume quantified for the same zone.

2.2.3 Void Volume of Mine Development

Three types of mine development (mains, gateroads, and bleeder) were discriminated by differences in number of entries, coal pillar size and perceived loading, and proximity to the gob, as all of these variables can affect void volume.

Untransformed, the void volume of mine development (Vv dev untransformed (ETZ)) is the sum of the product of planimetric area (A), extraction height (H), and extraction ratio (Eratio) of each unique ArcGIS feature (i) located between the lower (LETZ) and upper (UETZ) limits of the ETZ (Eq. 3). Analytical methods and spatial algorithms of ArcGIS were used to measure the area of main, gateroad, and bleeder feature types. Information gathered from personal communication with mine operations was used to estimate extraction height of development. CAD measurement tools were used to derive extraction ratio through assessment of representative development entry widths and coal pillar dimensions.

An advantage of using ArcGIS overlay analysis is its integration of spatial data and attribute data. As a result, feature area is measured between two contiguous BOC contours and discriminated by type of mine development. The use of spatial data to calculate feature volume would be effortless if the coal seam was horizontal. However, calculation of feature volume associated with an inclined coal seam requires modification.

To quantify the distribution of the volume for an individual ArcGIS feature in dipping coal, a hypsometric (or area-height) analysis was performed to determine the percentage of the total ArcGIS feature volume within the ETZ. The analysis relates horizontal cross-sectional area of the ArcGIS feature (Ai) relative to each BOC contour interval (or stage, k) the feature intersects through the derivation of proportionality constants (Pk) (Eq. 4). Proportionality constants are geometrically delineated using attributes of extraction height, coal dip, and BOC contour interval (H).

Once the ArcGIS feature is represented as a sum of the stages, applicability of each stage (xk) is evaluated to quantify the ArcGIS feature volume located between the LETZ and UETZ and thus excludes the portion of feature volume that adjoins the ETZ. The void volume of mine development is transformed from Eq. 3 to Eq. 5 to represent the void volume of mine development inside of the ETZ (Vv dev (ETZ)).

where xk equals applicability constant to note if feature volume k is within (x=1) or outside (x=0) the ETZ.

Custom Microsoft Excel scripts identified features in dipping coal, applied proportionality and applicability constants to distribute the percentage of the total volume to each BOC contour interval the feature intersected, and totaled the type-specific, modified volumes that intersect each BOC contour interval.

As an example of application, Fig. 3 represents mine development within an inclined coal seam where extraction height is 2.29 m (7.5 feet). Without transformation, the total feature volume would be assigned to the BOC interval for which area was measured using ArcGIS (for example, 490–495 ft amsl), but in reality, the volume of a BOC contour interval is the sum of a portion of this feature volume (k = 1) and portions of volumes associated with antecedent BOC intervals (k = 2 of 485–490 ft amsl and k = 3 of 480–485 ft amsl).

Void volume of a 3-entry gateroad development system, as shown in planimetric view at top. Upper cross-section shows the total feature volume of untransformed ArcGIS data. Lower cross-section displays the BOC contour interval volume as transformed using custom workflow scripts. Elevation is shown using the US customary system of measurement

2.2.4 Total Volume of Longwall Gob

The void volume associated with longwall gob (Eq. 6) is the product of area, residual gob height, and porosity of the gob material. ArcGIS overlay analysis was used to derive gob area, and proportionality and applicability constants were used to discriminate the gob area according to intersected BOC contour intervals. However, void volume associated with longwall gob is complicated by the height and porosity of the gob material. Auspiciously, the height of the gob (derivation of m) can be estimated using bulking analysis of the roof caving process [8, 17].

For each of the eight case studies, geologic core log data were used to mechanistically determine the height of the CRMAZ and the residual gob height. Exploratory core log data utilized in this study employ the Ferm coding classification system [18] to identify each stratum, as well as an expanded list of modifiers that provide additional detail of the strata pertinent for geotechnical study. Bulking factors were applied to the geologic data, on a per stratum basis, using a bottom up progression until the difference in bulking thickness and original thickness of the immediate roof strata was equal to the extraction height. Because the characteristics of the strata can be highly variable and lateral changes in roof geology are typically the norm, not the exception [9], the height of the CRMAZ and residual gob height were determined using the minimum, average and maximum bulking factors associated with various coal measure strata, if available. The bulking analysis did not quantify allowable sagging of the lowest un-caved stratum. Consequently, this technique predicted the largest possible height of the caved rock mass.

To determine the height of the CRMAZ and residual gob height, published rock-type bulking factors [8] were utilized. The rock-type, bulking based technique assigned original bulking factors of 1.50–1.80 to sandstone, 1.60–1.80 to sandy shale and 1.40 to clay shale. Residual bulking factors of 1.30–1.35 (sandstone), 1.25–1.35 (sandy shale), 1.10 (shale), and 1.05 (broken coal) were applied to the same strata that comprised the CRMAZ.

To reconcile differences between rock-type bulking and the particle size, shape, and arrangement relationship to bulking, an alternative bulking-based technique was also assessed. With this alternative method, Ferm codes and modifiers were evaluated to determine if the strata of the immediate roof were likely to detach as sheets or blocks. Sheet-like caving should be more prone to compaction during gob recompression and thus, drive the void ratio lower, whereas block-like caving should be less prone to compaction during gob recompression and result in higher bulking. Modifiers associated with sheet-like caving included descriptions such as laminated, very thinly, or thinly bedded strata; sand streaks, coal streaks, and coal spars in shale; and shale streaks, coal streaks, and coal spars in sandstone. Modifiers associated with block-like caving included thickly or massively bedded strata and streaks or coal spars of rare or few occurrence. The bedding-based bulking technique maintained the range (1.05–1.35) in residual rock-type bulking factors [8] but reconfigured its allocation according to the hypothetical response of the roof strata to mine-induced caving (i.e., sheet-like or block-like caving). Residual bulking factors of 1.05–1.10 (sheet-like caving modifiers) and 1.30–1.35 (block-like caving modifiers) were applied to the same strata that comprised the CRMAZ.

2.2.5 Experimental Porosity

Experimental porosity of the gob material following gob recompression was derived using basic substitution and rearrangement of Eqs. 2 and 6 (Eq. 7).

The most salient component incorporated into the experimental analysis design is the use of bulking analysis to estimate the height of the residual gob following gob recompression. Because two bulking-based techniques (rock-type and bedding-based) are examined to estimate the height of the residual gob following gob recompression, there are potentially two disparate values of experimental porosity for each case study. Consequently, the question becomes: which bulking-based technique is more tangible and pragmatic?

To evaluate the effectiveness of rock-type versus bedding-based bulking techniques to estimate residual gob height, rock-type and bedding-based bulking porosity were calculated through the relation of void ratio, e, to bulking factor, K, (Eq. 8) and effective gob porosity, n, (Eq. 9) [11, 19 as cited in 12].

For each case study, rock-type and bedding-based bulking porosity were compared to the experimental porosity using percent difference. The percent difference indicates the relative proficiency of the two bulking techniques to corroborate the experimental porosity, as well as increase confidence in the use of bulking analysis to determine residual gob height. To determine if any difference exists between the means of experimental porosity and the rock-type and bedding-based bulking porosity, a parametric two-sample t test was performed. Statistical significance was determined by comparing the attained p value to an a priori criterion of 0.05 and fit to a two-tailed test.

2.3 Prediction of Floodable Volume of Longwall Gob

Performance of a predictive model can be examined using backtesting of another independent set of historical or observed data to estimate how accurately a predictive model will perform in practice. Fundamentally, backtesting is a type of retrodiction that assesses the viability of a predictive model. As applied to this research, backtesting works on the assumption that the porosity and height of the residual gob derived from experimental data analysis are viable solutions that can be used to calculate void volume of longwall gob across all levels of groundwater rebound.

However, gob material is anything but a homogeneous and isotropic porous media. Consequently, a data-informed approach was used to assess predictability of the void volume of longwall gob by analyzing potential predictor variables relevant to the distribution of gob porosity. Detail complexity was further reduced to predictor variables that have significant logical relationship to gob porosity, as examined using linear regression and sensitivity analyses.

Prediction accuracy was examined using a causal comparative method, where groundwater rebound predictions were compared with observed mine pool elevation data collected across the same zone. Historical mine dewatering and mine pool monitoring data for each case study were evaluated to determine if a performance test zone (PTZ), hypsometrically distinct from the ETZ, exists. Because groundwater rebound predictions are a function of floodable volume and inflow, it was important to identify PTZ for which inflow stability was known. In addition, to reduce the uncertainty of seasonal variation of inflow, the minimum duration of groundwater rebound used for validation was specified at 12 months. To ensure the entire residual gob was examined, the minimum extent of groundwater rebound used for validation was specified to be equal to or greater than the residual gob height calculated using bulking analysis.

2.3.1 Potential Predictors

Significant research of mine subsidence theory of overburden movement and deformation in the USA began in the late 1970s [9, 16, 20, 21]. These studies resulted in the development of subsidence prediction models in the early 1990s [16]. Subsidence prediction has been shown to be dependent upon the depth, width and length of the gob, as the size of the gob determines the extent that overburden movement reaches the surface and forms a movement basin. Thus, it is logical to investigate the dependence of the physical and mechanical properties of the gob following recompression upon the depth, width, and length of a longwall panel.

The dimensions of a gob are used to determine characteristics of the movement basin (Fig. 4). At a given depth, surface subsidence (S0) within the movement basin generally increases with longwall panel width, until the panel attains a critical value where subsidence reaches its maximum possible value (Smax). For panel width exceeding the critical width, a flat-bottomed, “supercritical” basin is formed. Whereas, the movement beyond panel edge are typically defined by the angle of draw, δ0, the edges associated with the flat-bottomed basin can be demarcated by an angle to critical subsidence, ψ. When the panel width is less than the critical panel width, a smaller and shallower “subcritical” basin is formed. The critical panel width can be calculated according to its linear relationship to depth [16] and typically occurs when the longwall width (w) to overburden depth (h) ratio is approximately 1.2. The movement basin is subcritical when the w/h ratio is less than 1.2 and supercritical when the w/h ratio exceeds 1.2.

adapted from Peng, 2008 [16]

Supercritical and subcritical movement basins and associated subsidence and gob loading components. Redrawn with modifications;

The use of overburden depth to determine the w/h ratio implies the full weight of the overburden acts on a portion of the gob. However, when a longwall panel is subcritical, the upper, unbroken strata will be bridged by the side abutments that develop above and beyond the gateroad chain pillars. This transfer of load from the gob to the side abutments (Ls) results in gob pressure that is less than the full load of the overburden weight [16]. The depth of effective gob loading (heff), which is the weighted average depth that the gob is subject to, is based upon this principle and can be estimated from the w/h ratio of the panel and abutment angle, β [22].

2.3.2 Sensitivity Analysis

The use of a model inevitably involves uncertainty in both the model representation and in the input data [23], as parameter values and assumptions are subject to change and error. Sensitivity analysis aims to investigate these potential experimental errors and their influence on conclusions to be drawn from a model.

Local sensitivity analysis (LSA) is used to determine the relative importance of input parameters (such as gob porosity) according to their influence of the output (floodable volume). LSA is limited in breadth as it analyzes sensitivity around an optimal point in the factor space; however it is informative in so far it guides decisions related to how individual input parameters affect the robustness of a model.

The absolute slope of a regression line is ordinarily used to rank parameters, where the output is most sensitive to the input parameter with the greatest absolute slope. Due to differences in units of measurement (such as liters per minute, meters, percent), the absolute slopes among the different parameters are not necessarily comparable. This common problem can be overcome by calculating elasticities and sensitivity index, as these techniques are alternative means to determine the parameters to which the output is most sensitive. Collectively, absolute slope, elasticity, and sensitivity index were used to determine relative ranking and parameter sensitivity of input parameters within the mathematical model.

2.3.3 Causal Comparison of Time Series Prediction

A causal comparison method is used to assess profile alignment, where time series prediction of historical groundwater rebound is compared with observed mine pool elevation data collected across the PTZ. Time series prediction is based on floodable volume and inflow, where floodable volume of the PTZ consists of the combined void volume of mine development and longwall gob determined for each BOC contour interval within the zone (Eq. 10).

where t (PTZ) is the duration of groundwater rebound across the PTZ.

Two techniques are used to calculate the void volume of longwall gob; a basic application using an elemental model progressing toward experimental implementation of a prototype model. The competing techniques use the same design elements (i.e., Q, Vv dev, and Vt gob) specific to the PTZ but differ in how porosity of the gob material is used to calculate void volume of longwall gob within the PTZ. The elemental model assumes experimental porosity determined for the ETZ can accurately predict groundwater rebound across the PTZ (ne gob (PTZ) = ne gob (ETZ)). The more sophisticated prototype model examines the influence of predictor variables (i.e., x-variables) upon porosity of the gob material (ne gob (PTZ) as a f (x)) to determine the comparative effect of time series prediction on profile alignment against the standard (observed data).

Furthermore, falsifiability of causality is assessed. If time series prediction using the prototype model does not align with the observed values of the validation dataset, or at least improve the predictive accuracy relative to the element model, then the causal inference associated with prototype modeling is invalid.

3 Results

3.1 Characteristics of Residual Gob

The results of experimental data analysis, using the analytical spreadsheet solution and bulking analysis to quantify the experimental porosity of the gob following gob recompression (per §2.2.), are listed in Table 2. Using the rock-type bulking technique, the average experimental porosity of gob ranges from 4.83 to 13.55; the height of the CRMAZ and residual gob, normalized with respect to H, ranges from 2.60 to 3.22 and 2.03 to 2.67, respectively; and gob compaction, as a percent of H, ranges from 55 to 72%. With the use of the bedding-based bulking technique, the average experimental porosity of gob ranges from 4.99 to 14.31; the height of the residual gob, normalized with respect to H, ranges from 1.90 to 2.45; and gob compaction, as a percent of H, ranges from 69 to 87%.

In comparison, the range in estimated bulking-based porosity associated with the rock-type and bedding-based bulking techniques is 12.09–21.48% and 6.38–15.64%, respectively. The percent difference between experimental porosity and rock-type, bulking-based porosity ranges from 20.5 to 100.8% (M = 60.1%). The bedding-based bulking technique has greater comparative efficiency, as the percent difference between experimental porosity and bedding-based bulking porosity is significantly less, ranging from − 16.3 to 35% (M = 5.8%).

A statistically significant difference exists between rock-type, bulking-based porosity of gob (M = 0.1554; SD = 0.0362) and experimental porosity of gob (M = 0.0859; SD = 0.0315) derived using rock-type bulking analysis; t(14) = − 4.10, p < 0.01. The independent samples t test indicates there is not enough evidence to support the claim that a difference exists between the means of bedding-based bulking porosity of gob (M = 0.0940; SD = 0.0313) and experimental porosity of gob (M = 0.0909; SD = 0.0343) derived using bedding-based bulking analysis; t(14) = 0.19, p > 0.05. Accordingly, experimental porosity of the gob derived using bedding-based bulking analysis was used for predictive modeling, as a consequence of the greater comparative efficiency and significance of statistical examination.

3.2 Potential Predictors

Linear regression was used to explore relationships between the experimental porosity of gob following gob recompression and characteristics of the movement basin (per §2.3.1.), such as extraction height, gob compaction, panel width, overburden depth, effective gob loading depth and associated w/h ratios. Experimental porosity appears to be dependent upon extraction height (r = 0.964, n = 8) and gob compaction (r = 0.972, n = 8), as very strong correlations exist between these paired data (Fig. 5). Longwall panel width (r = 0.665), n = 8), overburden depth (r = 0.351, n = 8) and effective gob loading depth (r = 0.570, n = 8) cannot be singularly used to predict experimental porosity, as the results of univariate linear regression suggest these relationships are very weak.

Regression trendlines showing extraction height (a) and gob compaction (b) versus experimental porosity of the gob material. Extraction height (H) regression line is a best-fit linear function: n = − 0.1123(H) + 0.3195, r2 = 0.930. Gob compaction (∆him) regression line is a best-fit linear function: n = − 0.0952(∆him) + 0.2481, r2 = 0.946

Overburden depth and effective gob loading depth are used to calculate the w/h ratio for each case study. The w/h ratios range from 0.30 to 3.11 and generally indicate three case studies (2, 6, and 8) are associated with subcritical panel widths, four case studies (1, 3, 4, and 5) are associated with supercritical panels widths and case study 7 is at critical panel width. Smax was not attained for case studies 2, 6, and 8. Experimental porosity appears to be dependent upon w/h ratio (r = 0.941, n = 8). Figure 6 shows the relation between these paired data using a univariate quadratic polynomial function.

3.3 Sensitivity Analysis

Assessment of absolute slope, elasticity and sensitivity index (per §2.3.2.) generally indicate floodable volume is most sensitive to inflow and effective porosity of the gob material and less sensitive to extraction height, residual gob height, and extraction ratios of gateroad and bleeder development systems (Table 3).

3.4 Performance of Predictive Modeling

Inflow stability is observed for case studies 1 and 2, as determined by measured mine dewatering rates at the lower and upper limits of their respective PTZ. Case studies 1 and 2 also attained the minimum specifications of duration and extent of groundwater rebound to be used for validation. Groundwater rebound predictions are not possible for the remaining six case studies due to continuous mine pool management practices or insufficient information, such as inflow records, associated with a higher level of groundwater rebound. As such, backtesting of a second, independent set of historical data could not be completed to validate performance of a time series prediction model.

To determine accuracy of the elemental and prototype models to calculate the void volume of longwall gob (per Sect. 2.3.3.), prediction of historical groundwater rebound is compared with observed mine pool elevation data collected across the PTZ of case studies 1 and 2. As depicted in Fig. 7, performance of the elemental prediction model appears to trend well with the observed values, although it overestimates groundwater rebound of case study 1 and underestimates groundwater rebound of case study 2. Performance of the prototype model, where effective porosity of the gob is a function of w/h ratio, is comparatively more accurate, as indicated by the improved convergence in profile alignment with respect to the observed values. Both models show improvement in predictive capability compared to the alternative portmanteau of guessing and estimation, or “guesstimate,” of a possible value in the range of experimental porosity.

4 Discussion

This research targets an innovative solution, as derived from hydrogeomechanical data and principles, to quantify porosity of gob material following gob recompression. Whereas the analytical spreadsheet solution was used to solve for experimental porosity of the gob material, causal inference was used to determine if predictive modeling of gob porosity across the coal mine aquifer is practical.

Most theoretically derived hypotheses implicitly assume causal relationships. Although causality is difficult to prove, a compelling case to support the inference of practical causality is posited based on the following evidence: coherence with existing knowledge; strong, empirical correlation; supportive causal mechanism; and performance of predictive modeling.

4.1 Contribution to Existing Knowledge

The bedding-based bulking technique indicates that the height of the residual gob, normalized with respect to H, ranges from 1.90 to 2.45. These results are reasonable given the conclusions drawn by other researchers. Esterhuizan and Karacan [24] speculate that the caved rock mass accumulation zone contains a lower, fully caved zone and an upper, partially caved zone. The lower and upper caved zones are separated by a distinct change in permeability, such that the high permeability of the fully caved zone extends to a height of 1.5H and rapidly decreases to the permeability range of jointed rock within the upper caved zone to a height of about 3.5H. Peng [8] suggests the lower limit of the height of the residual gob is 2H, but the upper limit could approach 6H.

The experimental porosity of the gob material, as derived using the analytical spreadsheet solution and bedding-based bulking technique presented herein, ranges from 4.99 to 14.31%. The range in gob porosity is commensurate with the low to mid-range estimates of gob porosity concluded by other academic research. According to Peng [8], the residual, bulking-based porosity for various coal measure strata ranges from 4.76 to 25.93%. Pappas and Mark [11] estimate residual, bulking-based porosity as high as 23.08% based on a scaled down gradation curve of simulated gob material, where simulated gob recompression is representative of the averaged overburden depth for USA longwall mines. They conclude that the gradation curves determined from photo-analysis accurately estimate the actual gradation curve of the gob material except for the smaller particle sizes, which are underestimated. It has been indicated, however, that material with fine particles removed tends to exhibit larger bulking factor, and thus greater bulking-based porosity, compared with similar materials with fine particles retained [12]. Das [25] concludes that the ultimate in-situ bulking-based porosity of coal measure strata at a longwall face is less than 5% and decreases exponentially with increasing caving height. Zhu et al. [26] investigated the influence of mining-induced unloading on the development of bed separation in the overburden, presumably within the composite bending deformation zone. Their experiment indicated that the bulking-based porosity of the CRMAZ and residual gob following stress reestablishment are greater than 16.67 and 2.91%, respectively.

4.2 Statistical Correlation

Statistical analysis suggests porosity of the gob material correlates with longwall extraction height (Fig. 5a) and gob compaction (Fig. 5b). However, these relationships appear to follow the classic statistical adage, “correlation does not [necessarily] imply causation”.

Conceptually, the effect of block rotation during mine-induced caving results in a disorderly arrangement of the caved rock fragments [8, 24]. As such, the potential for block rotation should increase under greater longwall extraction heights, thereby resulting in higher bulking, and thus higher porosity, of the caved rock mass. Conversely, as fall height reduces, the potential for rock fragments to rotate should be inhibited, thereby reducing bulking. Therefore, a direct (positive) correlation should exist between porosity and longwall extraction height, which is contrary to the statistical assessment findings.

On the other hand, the direct (negative) relationship between porosity of the gob and gob compaction is logical, as it is expected that a lower porosity would result from greater gob recompression. Nevertheless, case studies herein with low experimental porosity (1, 3, and 7) are neither associated with the greatest overburden or effective gob loading depth. Moreover, the case study with the greatest overburden and effective gob loading depth (8) is associated with the highest experimental porosity determined by the analytical spreadsheet solution.

Experimental porosity of the gob material appears to be dependent upon the longwall width to overburden depth ratio (w/h ratio), as a very strong correlation exists between these paired data (Fig. 6). The quadratic relationship between experimental porosity of the gob material and w/h ratio is intriguing from a practitioner perspective, as this relationship has a logical association with existing subsidence prediction models. The dependence of porosity of the gob material upon w/h ratio can be supported by a sum of the parts (SOTP) analysis using surface subsidence monitoring data.

4.3 Causal Mechanism

Surface subsidence monitoring data can be used to validate existing subsidence prediction models or provide data for model development in new ground. Maximum subsidence, S0, is obtained through the collection and processing of these surface subsidence monitoring data. The ratio of maximum possible subsidence, Smax, to longwall extraction height, H, is called the subsidence factor, a. The subsidence factor is a key parameter used in subsidence prediction models involving critical or supercritical panel widths [8]. For subcritical width, it is called apparent subsidence factor, S0/H.

Whereas subsidence factors represent subsidence at the center of a movement basin, weighted average subsidence across the entire movement basin should be more indicative of overall gob loading and gob recompression. Surface subsidence monitoring data were used to calculate the weighted average, xw, subsidence of movement basins involving subcritical (xw of S0), and critical or supercritical (xw of Smax) panel widths. Panel widths ranged from 232 to 310 m and overburden depths ranged from 95 to 213 m.

As shown in Fig. 8, the weighted average subsidence, as a percent of H, is inversely related to porosity of the gob material following gob recompression. As indicated by the vertices of the polynomial trendlines, the weighted average subsidence is greatest for longwall panels at a w/h ratio of 1.9, whereas the porosity of the gob material is least for longwall panels at this same longwall panel width to overburden depth ratio.

A SOTP analysis was used to distribute the longwall extraction height across the zones of overburden movement and surface deformation. Hasenfus et al. [21] presented results of a hydrological and geomechanical monitoring program and proposed four zones of overburden response resulting from longwall mining, including a gob zone, a highly fractured zone, a composite beam, and a surface zone. Kendorski [20] identified five zones of strata movement based on groundwater effect and changes in vertical transmissivity and storativity: caved zone, fractured zone, dilated zone, constrained zone (composite beam zone), and surface fracture zone. Of these five zones, the caved, dilated, and surface fracture zones are associated with increases in storativity.

Gob porosity, gob compaction, and weighted average subsidence were used to allocate the extraction height amongst the caved, dilated and surface fracture zones, and surface movement basin. The dilated and surface fracture zones are not distinguishable based on the limits of this research and were, therefore, combined into one part. Porosity and height of the residual gob were used to determine the void fraction of the extraction height that represents the caved zone. Gob compaction represents the void fraction of the extraction height above the caved zone. The void fraction associated with the surface dimensions of the movement basin is equal to the weighted average subsidence. Therefore, the difference between gob compaction and weighted average subsidence represents the void fraction of the dilated and surface fracture zones.

At a w/h ratio of 1.9, the caved zone, dilated and surface fracture zones, and surface movement basin account for approximately 13, 40, and 47% of the longwall extraction height, respectively. As the w/h ratios become more subcritical, the void fraction associated with the caved zone increases and surface subsidence becomes less. This increase in porosity of the gob can be attributed to side abutment loading for longwall panels of subcritical width. As the w/h ratios become more supercritical, the void fraction associated with the caved zone increases. Based upon the limitations of surface subsidence monitoring data used for this study, the increase in gob porosity for movement basins of supercritical width cannot be reasonably concluded, but it could be associated with a decrease in gob recompression for longwall panels retreated in shallow cover environments. Further study may be warranted. That said, the SOTP analysis implies the dependence of gob porosity on w/h ratio is plausible for gob influenced by longwall panel width to overburden depth ratios less than 2.0.

4.4 Performance of Predictive Modeling

To authenticate the relationship between gob porosity and w/h ratio, prediction of historical groundwater rebound is compared to observed mine pool elevation data collected across the PTZ of case studies 1 (Figs. 7a) and 2 (Fig. 7b). Whereas the elemental model assumed a constant value of gob porosity across the coal mine aquifer, the prototype model leverages the best-fit polynomial regression line (per §3.2.) to quantify the porosity of the gob as a function of w/h ratio.

To reduce potential errors and their influence on conclusions to be drawn from the comparison of the elemental and prototype models, ArcGIS was used to create a w/h ratio raster. The mine features, BOC contour data, and ground surface contour data were conditioned and rasterized to execute a spatial analysis in the form of comparative mathematical overlay. Once rasterized, raster math tools were used to create overburden values across the study area and to divide those values into longwall panel widths. To use the w/h ratio information in a statistically meaningful way, an analysis of weighted average of the w/h ratio was performed, where acreage serves as the weighting factor.

As demonstrated in Fig. 7, the prototype model is more accurate at predicting groundwater rebound than the elemental model. With time, the elemental predictions overestimate groundwater rebound of case study 1 by 9.8% and underestimate groundwater rebound of case study 2 by 24.5%, whereas the prototype predictions underestimate groundwater rebound of case studies 1 and 2 by 0.5 and 0.9%, respectively.

4.5 Case for Causality

Causality subsumes prediction but it infers, as suggested by this research, that the w/h ratio is the reason for the relative differences in porosity of the gob material among the case studies. The ability to accurately predict groundwater rebound using backtesting of the prototype model demonstrates that porosity of the gob is dependent on the w/h ratio and the inference of practical causality appears to be valid. It is theorized that the causal mechanism inducing the range in experimental porosity is, in and of itself, related to gob loading, where the weighted average subsidence within a movement basin is inversely related to the porosity of the gob material under the same longwall width and overburden depth conditions. If the cause is removed, as is the circumstance associated with the elemental model, the accuracy of predictive modeling is reduced.

The weight of evidence supports the use of the prototype model to determine void volume of longwall gob and, in turn, improve proficiency with predicting depletion schedules of floodable volume. These schedules can be used to develop operational plans associated with mine water management and environmental control strategies. Proof of concept may also have practical value regarding ventilation and degasification systems as they relate to gob porosity.

5 Conclusions

Roof caving induced by longwall retreat results in a broken, bulked rock mass commonly referred to as gob. This paper examines an innovative approach consisting of water balance and gob bulking principles to estimate characteristics of the residual gob, such as porosity and height, as these physical properties are inaccessible to study in situ. Water balance measurement methods that accurately account for both mine development and longwall extraction voids can be used to back calculate gob void ratio and effective porosity on a macroscopic scale. Gob porosity of Appalachian longwalls is found to fit a bedding-based (massive versus laminated) bulking model better than the traditional rock-type based model.

Utilizing bedding-based bulking, effective gob porosity appears to trend well with longwall width to overburden depth ratio, such that gob porosity of longwall panels at subcritical width tends to be greater than gob porosity of longwall panels at critical and supercritical width. The exception appears to be gob influenced by longwall panel width to overburden depth ratios greater than 2.0 for which higher porosities are observed. This observation is likely due to the relatively shallower overburden depths (< 120 m) of such cases, which result in significantly less loading and gob compaction.

Comparison of competing groundwater rebound prediction models is used to demonstrate the dependence of gob porosity upon the longwall width to overburden depth ratio. The prototype model, which quantifies gob porosity as a function of the longwall width to overburden depth ratio, has greater efficiency resulting in significant improvement in prediction capability for gob influenced by longwall panel width to overburden depth ratios less than 2.0.

Depending on the site-specific nature of overburden depth, longwall width and geologic strata of the immediate roof, the effective gob porosity within this study range from approximately 5–15%. Such values fall within the lower range of many prior studies, indicating that initial gob bulking and subsequent compaction may produce much tighter longwall gobs than previously thought.

As the need for prediction resolution increases, modeling becomes more sophisticated and resource intensive. It follows that, other things being equal, accuracy using the prototype model is proportionate to the reliability and accuracy of mine dewatering and mine pool monitoring data, as inflow has the greatest relative ranking and parameter sensitivity of input parameters within the mathematical model.

6 Conflict of Interest

The authors have no relevant financial or non-financial interests to disclose.

Data Availability

Supplemental data that support the summary findings of this study are available from the corresponding author, upon reasonable request.

Code Availability

Not applicable.

References

Wyrick GG Borchers JW 1981 Hydrologic effects of stress-relief fracturing in an Appalachian valley. Water-Supply Paper 2177. Washington, DC: United States Geologic Survey

Winters RW, Capo RC (2004) Ground water flow parameterization of an Appalachian coal mine complex. Groundwater 42(5):700–710. https://doi.org/10.1111/j.1745-6584.2004.tb02724.x

Donovan, J.J.; Perry, E. F. 2019. Mine flooding history of a regional below-drainage coalfield dominated by barrier leakage. Geofluids. Volume 2019, Article ID 5703108, 16pp. https://doi.org/10.1155/2019/5703108.

Leavitt BR 1999 Mine flooding and barrier pillar hydrology in the Pittsburgh basin. In Proceedings of the Sixteenth Annual International Pittsburgh Coal Conference, Pittsburgh, PA, October 11–14

McCoy KJ, Donovan JJ, Leavitt BR (2006) Horizontal hydraulic conductivity estimates for intact coal barriers between closed underground mines. Environ and Eng Geoscience 12(3):273–282. https://doi.org/10.2113/gseegeosci.12.3.273

Burke SP, Younger PL (2000) Groundwater rebound in the south Yorkshire coalfield: a first approximation using the GRAM model. Q J Eng Geol Hydrogeol 33(2):149–160

Donovan JJ Fletcher J 1999 Hydrogeological and Geochemical Response to Mine Flooding in the Pittsburgh Coal Basin, Southern Monongahela River Basin. Report to the United States Environmental Protection Agency. Project WV-132. Morgantown, WV: West Virginia University

Peng SS (2020) Longwall Mining, 3rd edn. CRC Press/Balkema, London

Hasenfus GJ Su DWH 2006 Horizontal stress and coal mines: Twenty-five years of experience and perspective. In Proceedings of the Twenty-fifth International Conference on Ground Control in Mining, Morgantown, WV, August 1–3. p. 256–267

Karacan CÖ (2010) Prediction of porosity and permeability of caved zone in longwall gobs. Transp Porous Media 82(2):413–439. https://doi.org/10.1007/s11242-009-9437-7

Pappas DM Mark C 1993 Behavior of simulated longwall gob material. RI 9458. Pittsburgh, PA: Bureau of Mines

Ofoegbu GI Read RS Ferrante F 2008 Bulking Factor of Rock for Underground Openings (Draft). U.S. Nuclear Regulatory Commission Contract NRC 02-07-006. San Antonio, TX: Center for Nuclear Waste Regulatory Analyses

Yavuz H (2004) An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int J Rock Mech Min Sci 41(2):193–205. https://doi.org/10.1016/S1365-1609(03)00082-0

Unrug KF 1982 Roof falls and caving in longwall mining operations. In Proceeding of the Second Conference on Ground Control in Mining, Morgantown, WV, July. p. 45–52

Sweby G 1997 Review the Caving Mechanisms Around High Extraction Systems and Determine the Effect of the Mechanisms on the Safety of the System. SIMRAC Project Report COL 327. Johannesburg, South Africa: CSIR Miningtek

Peng SS (2008) Coal Mine Ground Control, 3rd edn. Peng, publisher, Syd S

Palchik V (2002) Influence of physical characteristics of weak rock mass on height of caved zone over abandoned subsurface coal mines. Environ Geology 42(1):92–101. https://doi.org/10.1007/s00254-002-0542-y

Ferm JC, Smith GC (1980) A guide to cored rocks in the Pittsburgh basin. University of Kentucky, Lexington, KY

Duncan JM Witherspoon PA Mitchell JK Watkins DJ Hardcastle JH Chen JC 1972 Seepage and Groundwater Effects Associated with Explosive Cratering. Report No. TE-72-2., Berkeley, CA: University of California

Kendorski FS 2006 Effect of full-extraction underground mining on ground and surface waters: A 25-year retrospective. In Proceedings of the Twenty-fifth International Conference on Ground Control in Mining, Morgantown, WV, August 1–3. p. 425–430

Hasenfus GJ Johnson KL Su DWH 1988 A hydrogeomechanical study of overburden aquifer response to longwall mining. In Proceedings of the Seventh International Conference on Ground Control in Mining, Morgantown, WV, August 3–5. p. 149–162

Mark C Chase FE 1997 Analysis of Retreat Mining Pillar Stability. In Proceedings of New Technology for Ground Control in Retreat Mining. Information Circular IC-9446. Pittsburgh, PA: National Institute for Occupational Safety and Health. p. 17-34

Lilburne L Gatelli D Tarantola S 2006 Sensitivity analysis on spatial models: A new approach. In Proceedings of the Seventh International Symposia on Spatial Accuracy Assessment in Natural Resources and Environmental Sciences, Lisbon, Portugal, July 5–7. p. 329–338

Esterhuizen G Karacan C 2007 A methodology for determining gob permeability distributions and its application to reservoir modeling of coal mine longwalls. In Proceedings of the 2007 SME Annual Meeting, Denver, CO, February 25–28. 2007. p. 7–78

Das SK (2000) Observations and classification of roof strata behaviour over longwall coal mining panels in India. Int J Rock Mech Min Sci 37(4):585–597. https://doi.org/10.1016/S1365-1609(99)00123-9

Zhu W, Yu S, Xu J (2018) Influence of the elastic dilatation of mining-induced unloading rock mass on the development of bed separation. Energies 11:785. https://doi.org/10.3390/e11040785

Acknowledgements

The authors wish to thank the following colleagues for their contributions to this paper: Brianne Constable (preliminary phase of ArcGIS spatial analysis), Brianne Hastings (technical review of the analytical spreadsheet solution), Benjamin Blasingame (technical review of the analytical spreadsheet solution and equation editor), and Ryan St. Peter (field data collection and reporting). The authors also thank all internal reviewers and anonymous MMEX advisors whose suggestions and comments helped improve the overall quality of this manuscript.

Funding

No funds, grants, or other support were received.

Author information

Authors and Affiliations

Contributions

All authors contributed to conceptual design and methodology. Material preparation, investigation, and formal analysis of hydrologic and geomechanical data were performed by Josh Silvis and Greg Hasenfus. Material preparation, investigation and formal analysis of spatial data were performed by Allison Haines. The first draft of the manuscript was written by Josh Silvis and all authors reviewed, edited and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Silvis, J.M., Hasenfus, G.J. & Haines, A.M. Bulking Based Porosity Method to Predict Floodable Volume of Longwall Gob. Mining, Metallurgy & Exploration 38, 1845–1859 (2021). https://doi.org/10.1007/s42461-021-00464-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-021-00464-1