Abstract

As indoor positioning provides particular challenges due to the unavailability of GPS signals, various systems such as ultra-wideband (UWB), radio frequency identification (RFID), ultrasound, and wireless local area network (WLAN) have been proposed in recent years. Some of these technologies are currently being marketed and some are still being developed. UWB technology allows for higher precision while also reducing power consumption. Hence, the underground automation and localization systems can use this technology for more accuracy and robustness. This article discusses new robust UWB modules used for underground positioning and collision avoidance with regard to human safety in underground mining operations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The traditional way of determining the localization of people within an underground mine is to use tokens, which the employees leave at the shaft before getting inside the mine, and take them after they come back up. This method, however, proved unreliable with employees forgetting to leave the tokens or taking them back. Radio frequency identification (RFID) tags solved this problem. The tags emit radio signals, which predict whether the miner is still in the mine or has returned to the surface. This immensely reduces the factor of human error. An even more important issue than knowing if the miners are in the mine is the precise determination of their locations. To approach this issue, different technologies try to calculate the exact position of the machinery and miners underground.

Next sections of this paper introduce the UWB technology, which is one of the current technologies used to estimate and track positions in underground mines. One of the most important research areas at the AMT of RWTH Aachen University is localization in indoor areas, pursuing a precise localization of workers and machinery underground to reduce accidents. To approach this, the AMT designs and develops UWB modules, which were successfully tested with a Technology Readiness Level (TRL) of 6 in the area of localization systems and collision avoidance in non-explosive area.

2 Ultra-Wideband Signal

As its name states, ultra-wideband is a radio signal, which has a high bandwidth over a wide spectrum of frequencies. It has a short duration pulse of picoseconds to nanoseconds and a low duty cycle of about 0.5%, which leads the signal carry information with a low energy [1]. The bandwidth allowed to be occupied for authorized use of UWB according to the US Federal Communications Commission (FCC) ranges from 3.1 to 10.6 GHz with a power spectral density emission limit of − 41.3 dBm/MHz for UWB transmitters [2]. This frequency range is from 3.8 to 4.2 GHz and 6 to 8.5 GHz in Europe [3].

One of the most important properties of this radio signal in comparison to other radio technologies is that it can carry a huge amount of data using very little power. Therefore, it is recognized as an adequate technology in indoor positioning with a high accuracy, where Bluetooth, WiFi, Zigbee, or other technologies cannot offer comparable results due to their bandwidth limitations [4]. The properties mentioned above and the low energy consumption of UWB technology led companies to rely on UWB as an accurate and reliable technology for data transfer, positioning and tracking of employees, and machinery in underground mining.

3 An Overview of Methods of Measuring the Distance and Positioning Using UWB

There are different methods used for measuring the distance between two radio modules such as measuring the received signal strength, measuring the angles like the angle of arrival (AoA), and time of flight (ToF) [5].

3.1 Received Signal Strength

In this method, the power of the signal received from the transmitter at the receiver is measured within free space (usually air). The medium, in which the signal is transmitted, can cause an attenuation on the strength of the signal. As this attenuation is dependent on the distance between two antennas, the distance can be calculated considering the attenuation parameters of the medium. To show the attenuation of the signal strength over a distance according to Friis’ transmission formula, the available power at the receiving antenna Pr (dBm) to the power at the transmitting antenna Pt (dBm) for a time harmonic, free-space radio system can be calculated with the Formula 1 [6]:

wherein gr (dB) and gt (dB) are the receiving and the transmitting gains of the antennas, respectively. λ (m) is the wavelength; r (m) describes the distance between the antennas. This equation is valid if the impedances of the antennas match perfectly to their source and the antennas are polarization matched as well [6]. The formula shows a strong dependency of the attenuation of the signal power to the distance the signal is traveling between the antennas. In this method, if the signal propagates through other obstacles like walls and doors, the calculation of the distance will be more complicated.

3.2 Angle of Arrival

AoA or direction of arrival is a method of determining the direction of an object by elevating the azimuth angle of incoming signals. This method needs more than two antennas (antenna array) for 2D and more than three antennas for 3D as receivers. This measures the time of arrival in each receiver to calculate the angle from where the signal is sent. As shown in Fig. 1, the difference in path length p related to the distance d between the antennas can be calculated according to Formula 2 [7]:

wherein θ (rad) is the AoA.

Angle of arrival localization technique [7]

Formula 3 [7] can calculate the phase difference of arrival α (rad) considering the signal wavelength λ (m) and the path length p (m):

Hence, the AoA can be calculated from the Formula 4 [7]:

One of the disadvantages of this method is for example issues with multipath components, which are unpreventable in indoor areas. Hence, the accuracy of an angle determination can be affected task [8].

3.3 Time of Flight

The other common method to determine the distance between two antennas is to calculate the time the signal travels from the transmitter to the receiver (so called ToF (s)). Formula 5 estimates the distance d between the transmitter and the receiver:

wherein c \( \left[\frac{m}{s}\right] \) is the propagation speed of the signal. As the UWB signal covers a large bandwidth, which provides a high time resolution, it can resolve the multipath effect; therefore, it shows a robust performance in indoor environments [7]. Thus, positioning and tracking using ToF techniques are more reliable and have better performance in comparison with the other mentioned positioning techniques. There are some techniques using ToF implementing the positioning algorithms, i.e., time difference of arrival and two-way ranging, which are the most common methods in this case.

3.4 Time Difference of Arrival

In the TDoA process, the receiver measures the time at which the transmitted signal from the tag arrives at the anchors. By estimating the TDoA in each anchor pair and using the equation systems considering the tolerances, it is possible to determine the position of the tag. Here, the differential structure of the range measurements leads to construct hyperbolic lines between each pair of anchors [9]. The position of the tag will be on the intersection of two or more hyperbolic lines in a system with more than two anchors. In this method, the anchors should be fully or partly synchronized in their clock signals, which is one of its disadvantages [10].

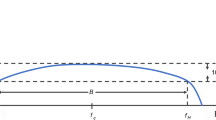

3.5 Two-Way Ranging

In TWR process, the transmitter sends a signal to the receiver and gets it back after tround as shown in Fig. 2:

Two-way ranging scheme [11]

Considering the time treply (s) the receiver needs to send back the signal to the transmitter, the distance d (m) between the sender and receiver can be estimated with Formula 6:

To determine the position of the object, the distances of the object from every anchor, which are calculated in the above formula, is used in an algorithm, i.e., trilateration.

4 Hardware Development for Tracking

At the Institute for Advanced Mining Technologies (AMT), an underground positioning system was developed, which can estimate the position of an object using TWR. Positioning and tracking an object using this method, needs a system with the possibility to send signals from the anchors to the tag. To develop an adequate hardware a transceiver is needed, which can generate and receive the UWB signals. DecaWave is a company, which produces integrated ultra-wideband transceiver IC compliant to IEEE802. It supports 6 radio frequency (RF) bands from 3.5 to 6.5 GHz and can provide a platform for both TDoA and TWR. The transceiver can be used in the real-time localization systems (RTLSs) as a tag or anchor modules [12]. In Fig. 3, the schematic of a basic UWB module is shown.

According to this concept, AMT designed a UWB module and a proper housing for the module as depicted in Fig 4. To design a circuit, which functions in ultra high frequency (UHF) or in super high frequency (SHF), one of the most important factors to consider is the impedance of the high frequency (HF) traces on the board and solutions to eliminate the noise or at least minimizing it. Hence, the board is designed in four layers, in which the direct layer under the components is the ground plane, which makes it possible to define the impedance of the traces and minimize the noise of the HF signals [13]. The important traces on the board are the differential pair traces between the UWB transceiver and the multilayer balun and the single-ended (SE) trace between the balun and the antenna port, which transfer the UWB signals in SHF band and should have the impedance of 50 Ω. A universal synchronous asynchronous receiver transmitter (USART) prepares the communication between a computer and the board. As the board is used in mining environment, a compact antenna instead of a patch antenna is used. This hardware can be installed on the machines or carried by people.

5 Hardware Development for Collision Avoidance

As the hardware described in the last section is large in size and the people cannot install it on the helm easily, another adequate hardware is designed. In this case, the DWM1000 module from DecaWave is used, which is based on mentioned DW1000 UWB transceiver IC (integrated circuit). The module has 4 RF (radio frequency) bands in comparison to DW1000, which has 6 RF bands. It contains an on-board ceramic monopole antenna, which reduces the whole size of the UWB board and reduces the complexity of the design. As the antenna is integrated on the module, the whole module must be encapsulated to prevent damages to the antenna. The IC can be used in cases there is no synchronization of the clock signals needed, as it has no possibility for that. Therefore, it can be used as a UWB tag carried by a person. The developed module and a casing for the module are shown in Fig. 5.

Although it has less frequency bands in comparison with DW1000 transceiver, it leads to a smaller size of the module, which can be worn by a person. There is an opportunity that a small display can be connected to the module via inter-integrated circuit (I2C) protocol, so that some information about the range can be shown on the display.

6 Measurement Results to Validate the Developed Systems

The UWB modules described above were tested in underground mining. The first mentioned module designed using DW1000 UWB transceiver is installed on the top of a vehicle, which operates in an underground mine. The module is connected to a computer to save the data for further evaluation of the measurement results. The vehicle is driving towards a person standing in the middle of a junction on the way. The person in front of the vehicle holds the personnel tag. According to the defined distances between the vehicle and the person, the personnel tag receives a warning signal from the UWB module to alert the person, who operates the vehicle and the person in front of the vehicle. In Fig. 6, the person and the vehicle are depicted.

In this experiment, a prism is installed near the UWB module on the top of the vehicle. A Geodimeter tracks it from the start point and saves the data to compare the position of the vehicle with the range of the UWB personnel module. The range of the personnel tag matches with a high accuracy of 10 cm to 30 cm, which is shown in the figure below. In this experiment, a distance of 5 m is defined as a minimum distance between the vehicle and the person.

7 Conclusion

The UWB technology is a reliable technology to be used in many applications in underground mining such as communication, positioning, and tracking. The successful experiments in this work show that UWB technology is an adequate tool in underground positioning systems (UPS) in regard to positioning and collision avoidance. Thanks to its high accuracy, robustness, and high immunity to multipath fading [14], it led to achieve progress in industry 4.0, which is now a focus of many researchers. There are many different applications, which use UWB technology. According to the applications, different systems can be designed and diverse adequate hardware with necessary modifications can be developed.

References

Nekoogar F (2005) Ultra-wideband communications: fundamentals and applications. Prentice Hall Press, Upper Saddle River

FCC (2010) Revision of part 15 of the commission’s rules regarding ultrawideband. Federal Communications Commission, Washington, D.C.

European Commission decision on the harmonisation of radio spectrum for equipment using ultra-wideband technology in the Union and repealing Decision, 14 May 2019. [Online]. Available: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2019.127.01.0023.01.ENG&toc=OJ%3AL%3A2019%3A127%3ATOC

Pietrzyk MM, von der Grün T Ultra-wideband technology-based ranging platform with real-time signal processing. Fraunhofer Institute for Integrated Circuits, Nuremberg

Betancur GO, Treven F (2017) A framework for a relative real-time tracking system based on ultra-wideband technology, Gothenburg, Sweden. Chalmers University of Technology, University of Gothenburg

Preradovic S (2011) Advanced radio frequency identification design and applications. InTech, Rijeka

Dotlic I, Connell A, Ma H, Clancy J, McLaughlin M (2017) Angle of arrival estimation using Decawave DW1000 integrated circuits. In: 14th Workshop on Positioning, Navigation and Communications (WPNC), Bremen, p 2

Zafari F, Gkelias A, Leung KK (2019) A survey of indoor localization Ssystems and technologies. IEEE Commun Surv Tutor 21(3):2568–2599

Ahmed S, Zeng Y (2017) UWB positioning accuracy and enhancements, pp 634–638

Zandian R Ultra-wideband based indoor localization of mobile nodes in ToA and TDoA configurations. University of Bielefeld, Bielefeld

Jiang Yi, Leung VCM (2007) An asymmetric double sided two-way ranging for crystal offset, International Symposium on Signals, Systems and Electronics: 525–528

DW1000 datasheet (2015) Decawave Ltd., reland

Park J (2003) Practical embedded controllers: design and troubleshooting with the Motorola 68HC11. Newnes, Lithgow

Darmon L, McLaughlin M, Neirynck D (2012) Designing the first commercial IEEE 802.15.4a chip. IEEE Conference EILAT

Acknowledgments

Open access funding provided by Projekt DEAL. The authors gratefully acknowledge the SIMS project partners for their cooperation in this project.

Funding

The SIMS project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 730302.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kianfar, A.E., Uth, F., Baltes, R. et al. Development of a Robust Ultra-Wideband Module for Underground Positioning and Collision Avoidance. Mining, Metallurgy & Exploration 37, 1821–1825 (2020). https://doi.org/10.1007/s42461-020-00279-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00279-6