Abstract

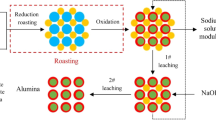

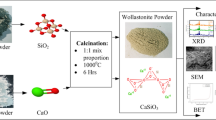

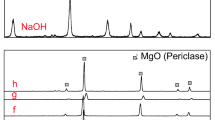

This work describes a leaching process for the conversion of high-magnesium peridotite rock, which is a chromite ore overburden, into two valuable products: magnesium salts and micro silica. Under normal leaching conditions, residue remaining after leaching is of a gelatinous nature and thus hinders the filtration process. To address this issue, oxidative leaching with the addition of H2O2 was employed, and it significantly improved the filtration kinetics. Four different approaches for H2O2 addition were tried, and they all proved effective in controlling gelation. The optimum oxidative leaching condition was 70 °C, 2 h time, 2 M H2SO4, 0.5 M H2O2 and 400 RPM; under these conditions, 92% magnesium leaching efficiency was achieved. After leaching, the leach liquor obtained was purified and dried into Mg(OH)2 and MgSO4 salts. The leach residue contained mainly silica particles, with size in the 10–30 μm range. This material thus represents an attractive candidate for the production of high-performance concrete for the construction industry. The oxidative leaching process described here enabled the complete conversion of peridotite into valuable products, magnesium salts and micro silica.

Similar content being viewed by others

References

Mishra H, Sahu HB (2013) Environmental scenario of chromite mining at Sukinda Valley—a review. Int J Environ Eng Manag 4:287–292

Ledin M, Pedersen K (1996) The environmental impact of mine wastes—roles of microorganisms and their significance in treatment of mine wastes. Earth Sci Rev 41:67–108. https://doi.org/10.1016/0012-8252(96)00016-5

Worldwide EL (2010) Guidebook for evaluating mining project EIAs. Environmental Law Alliance Worldwide, Eugene

Calvo G, Mudd G, Valero A, Valero A (2016) Decreasing ore grades in global metallic mining: a theoretical issue or a global reality?. Resources 5:36. https://doi.org/10.3390/resources5040036

Matinde E, Simate GS, Ndlovu S (2018) Mining and metallurgical wastes: a review of recycling and re-use practices. J South Afr Inst Min Metall 118:825–844. https://doi.org/10.17159/2411-9717/2018/v118n8a5

Murthy YR, Rao BC, Kapure G, Tathavadkar V (2010). New prospective for the utilisation of Indian lateritic chromite overburden. Proc. XI Int. Sem. Miner. Process. Technol. India.158–165

Habashi F (2005) A short history of hydrometallurgy. Hydrometallurgy 79:15–22. https://doi.org/10.1016/j.hydromet.2004.01.008

Mohanty JK, Rao DS, Paul AK, Khaoash S (2009) Characterization of high magnesian rocks for suitability as flux in iron and steel industry. Journal of Geology and Mining Research 1:149–155

Baldauf-Sommerbauer G, Lux S, Aniser W, Siebenhofer (2017) Synthesis of carbon monoxide from hydrogen and magnesite/dolomite. Chemie Ingenieur Technik 89:172–179. https://doi.org/10.1002/cite.201600078

Hansgirg FJ (1945) Process for manufacturing metallic magnesium from magnesium silicates United States patent US 2,372,571

Ghazy SE, Kabil MA, Abeidu AM, El-Metwally NM (1996) Selective separation of magnesium from olivine minerals. Sep Sci Technol 31:829–838. https://doi.org/10.1080/01496399608001327

Gee EA, Pawel MT (1951) Production of magnesium chloride from magnesium silicate ore. United States patent US 2,549, 798

Butt CA, Hallman AO, Bowden CL, Whitlow EP, Finley PP (1946) Production of magnesium chloride from serpentine. United States patent US 2,398, 493

Harris GB, Peacey JG (1992) Production of pure magnesium chloride solution from siliceous magnesium minerals United States patent US 5091161

Zhang Q, Sugiyama K, Saito F (1997) Enhancement of acid extraction of magnesium and silicon from serpentine by mechanochemical treatment. Hydrometallurgy 45:323–331. https://doi.org/10.1016/S0304-386X(96)00087-4

Bodas MG (1996) Hydrometallurgical treatment of zinc silicate ore from Thailand. Hydrometallurgy 40:37–49. https://doi.org/10.1016/0304-386X(94)00076-F

Yang Z, Rui-lin M, Wang-dong N, Hui W (2010) Selective leaching of base metals from copper smelter slag. Hydrometallurgy 103:25–29. https://doi.org/10.1016/j.hydromet.2010.02.009

He S, Wang J, Yan J (2010) Pressure leaching of high silica Pb–Zn oxide ore in sulfuric acid medium. Hydrometallurgy 104:235–240. https://doi.org/10.1016/j.hydromet.2010.06.011

Xu H, Wei C, Li C, Fan G, Deng Z, Li M, Li X (2010) Sulfuric acid leaching of zinc silicate ore under pressure. Hydrometallurgy 105:186–190. https://doi.org/10.1016/j.hydromet2010.07.014

He S, Wang J, Yan J (2011) Pressure leaching of synthetic zinc silicate in sulfuric acid medium. Hydrometallurgy 108:171–176. https://doi.org/10.1016/j.hydromet.2011.04.004

Ahmed IM, Nayl AA, Daoud JA (2016) Leaching and recovery of zinc and copper from brass slag by sulfuric acid. Journal of Saudi Chemical Society 20:S280–S285. https://doi.org/10.1016/j.jscs.2012.11.003

Alkan G, Yagmurlu B, Cakmakoglu S, Hertel T, Kaya Ş, Gronen L, Stopic S, Friedrich B (2018) Novel approach for enhanced scandium and titanium leaching efficiency from bauxite residue with suppressed silica gel formation. Sci Rep 8:5676. https://doi.org/10.1038/s41598-018-24077-9

Fedoročková A, Hreus M, Raschman P, Sučik G (2012) Dissolution of magnesium from calcined serpentinite in hydrochloric acid. Miner Eng 32:1–4. https://doi.org/10.1016/j.mineng.2012.03.006

Roorda HJ, Queneau PE (1973) Recovery of nickel and cobalt from limonites by aqueous chlorination in sea water. Trans. IMM C 82:79–87

Hellmann R, Penisson JM, Hervig RL, Thomassin JH, Abrioux MF (2003) An EFTEM/HRTEM high-resolution study of the near surface of labradorite feldspar altered at acid pH: evidence for interfacial dissolution-reprecipitation. Phys Chem Miner 30:192–197. https://doi.org/10.1007/s00269-003-0308-4

Putnis CV, Ruiz-Agudo E (2013) The mineral–water interface: where minerals react with the environment. Elements 9:177–182. https://doi.org/10.2113/gselements.9.3.177

Wang F (2013) Silicate Mineral Dissolution and Associated Carbonate Precipitation at Conditions Relevant to Geologic Carbon Sequestration

Teir S, Revitzer H, Eloneva S, Fogelholm CJ, Zevenhoven R (2007) Dissolution of natural serpentinite in mineral and organic acids. Int J Miner Process 83:36–46. https://doi.org/10.1016/j.minpro.2007.04.001

Apostolidis CI, Distin PA (1978) The kinetics of the sulphuric acid leaching of nickel and magnesium from reduction roasted serpentine. Hydrometallurgy 3:181–196. https://doi.org/10.1016/0304-386X(78)90019-1

Matthew IG, Elsner D (1977) The hydrometallurgical treatment of zinc silicate ores. Metall Trans B 8:73–83. https://doi.org/10.1007/BF02656354

Iler KR (1979) The chemistry of silica. Solubility, Polymerization, Colloid and Surface Properties and Biochemistry of Silica

Crundwell FK (2013) The dissolution and leaching of minerals: mechanisms, myths and misunderstandings. Hydrometallurgy 139:132–148. https://doi.org/10.1016/j.hydromet2013.08.003

Crundwell FK (2014) The mechanism of dissolution of forsterite, olivine and minerals of the orthosilicate group. Hydrometallurgy 150:68–82. https://doi.org/10.1016/j.hydromet.2014.09.006

Teir S, Revitzer H, Eloneva S, Fogelholm CJ, Zevenhoven R (2007) Dissolution of natural serpentinite in mineral and organic acids. Int J Miner Process 83(1–2):36–46. https://doi.org/10.1016/j.minpro.2007.04.001

Luce R. W, Bartlett R. W, Parks G. A (1972) Dissolution kinetics of magnesium silicates. Geochim Cosmochim Acta 36(1):35–50. https://doi.org/10.1016/0016-7037(72)90119-6

Jonckbloedt RCL (1998) Olivine dissolution in sulphuric acid at elevated temperatures—implications for the olivine process, an alternative waste acid neutralizing process. J Geochem Explor 62(1–3):337–346. https://doi.org/10.1016/S0375-6742(98)00002-8

FactSage 7.2 software, CRCT-thermfact inc., and GTT-technologies

Acknowledgements

The authors would like to thank Tata Steel management and Dr. Sanjay Chandra, Chief Research and Development, Tata Steel Limited, for their encouragement during the project and permission to publish the paper. The authors also wish to thank Ranjeet Singh, Alok Pandey, Chandra Kumar Murmu and Ravi Shankar Pathak of Tata Steel, Jamshedpur for their help at different stages of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Reddy, K.V.K., Sanjana, V., Singh, V. et al. Processing of Peridotite Rocks of Chromite Ore Overburden into Magnesium Salts and Micro Silica. Mining, Metallurgy & Exploration 37, 1253–1263 (2020). https://doi.org/10.1007/s42461-020-00211-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00211-y