Abstract

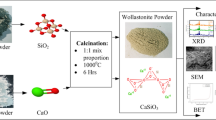

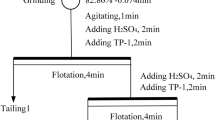

This study aimed to produce magnesium oxide (MgO) particles with different properties from dolomite ore using an experimental procedure comprising four stages: sample preparation (S1), HCl leaching (S2), precipitation (S3), and calcination (S4). Three different base sources (NaOH, KOH, and NH4OH) were used as precipitant in the third stage to obtain magnesium hydroxide [Mg(OH)2] from a leachate solution, which was obtained in the second stage. Next, Mg(OH)2 particles generated by different alkali sources were calcined at various temperatures from 600–1000 °C for different durations (1–5 h). The effect of these base types on the properties of each product was investigated by X-ray diffraction (XRD), scanning electron microscopy (SEM), Brunauer–Emmett–Teller (BET), atomic force microscopy (AFM), and wet chemical analyses. The experimental results indicated that each product was identified as periclase (MgO) mineral, which was produced with a specific surface area (SSA) of 4.49–44.54 m2/g depending on the production conditions. The surface roughness of the MgO particles increased with increasing calcination temperature. SEM analyses showed that MgO particles produced at a temperature of 600 or 800 °C were amorphous, indicating that the process was not influenced by the base type, but MgO crystals were smooth when the calcination temperature was 1000 °C. Finally, it was determined from all experimental findings that MgO particles produced via the addition of NaOH have superior properties (such as higher SSA and lower surface roughness) compared with MgO particles produced with KOH or NH4OH as the alkali source. These properties led to great improvement of its usability in industry.

Similar content being viewed by others

References

European Commission (2017) Study on the review of the list of critical raw materials. Publications Office of the European Union, Luxembourg

Bindhu MR, Umadevi M, Kavin Micheal M, Arasu MV, Abdullah Al-Dhabi N (2016) Structural, morphological and optical properties of MgO nanoparticles for antibacterial applications. Mater Lett 166:19–22

Wang Y, Chen Y, Liu C, Yu F, Chi Y, Hu C (2017) The effect of magnesium oxide morphology on adsorption of U(VI) from aqueous solution. Chem Eng J 316:936–950

Moussavi G, Mahmoudi M (2009) Removal of azo and anthraquinone reactive dyes from industrial wastewaters using MgO nanoparticles. J Hazard Mater 168:806–812

Venkatesha TG, Nayaka YA, Chethana BK (2013) Adsorption of Ponceau S from aqueous solution by MgO nanoparticles. Appl Surf Sci 276:620–627

Mantilaka MMMGPG, De Silva RT, Ratnayake SP, Amaratunga G, de Silva KMN (2018) Photocatalytic activity of electrospun MgO nanofibres: synthesis, characterization and applications. Mater Res Bull 99:204–210

Somanathan T, Krishna VM, Saravanan V, Kumar R, Kumar R (2016) MgO nanoparticles for effective uptake and release of doxorubicin drug: pH sensitive controlled drug release. J Nanosci Nanotechnol 16:9421–9431

Lin YT, Ou SF, Lin MH, Song YR (2018) Effect of MgO addition on the microstructure and dielectric properties of BaTiO3 ceramics. Ceram Int 44:3531–3535

Espuelas S, Omer J, Marcelino S, Echeverría AM, Seco A (2017) Magnesium oxide as alternative binder for unfired clay bricks manufacturing. Appl Clay Sci 146:23–26

Huang T, Yuan Q, Deng D (2019) The role of phosphoric acid in improving the strength of magnesium oxychloride cement pastes with large molar ratios of H2O/MgCl2. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2019.01.013

Chen Y, Wu C, Yu H, Chen W, Chen C, Zheng S, Chen F (2018) Study of using light-burned dolomite ores as raw material to produce magnesium oxysulfate cement. Adv Cem Res 30:437–450

Hu Y, Liu X, Zhou Z, Liu W, Xu M (2017) Pelletization of MgO-based sorbents for intermediate temperature CO 2 capture. Fuel 187:328–337

Hiremath V, Shavi R, Seo JG (2017) Controlled oxidation state of Ti in MgO-TiO 2 composite for CO 2 capture. Chem Eng J 308:177–183

Hiremath V, Shavi R, Gil Seo J (2017) Mesoporous magnesium oxide nanoparticles derived via complexation-combustion for enhanced performance in carbon dioxide capture. J Colloid Interface Sci 498:55–63

Ho K, Jin S, Zhong M, Vu A-T, Lee C-H (2017) Sorption capacity and stability of mesoporous magnesium oxide in post-combustion CO2 capture. Mater Chem Phys 198:154–161

Dong H, Unluer C, Yang E-H, Al-Tabbaa A (2017) Synthesis of reactive MgO from reject brine via the addition of NH4OH. Hydrometallurgy 169:165–172

Statista (2019) Magnesite reserves worldwide as of 2018. https://www.statista.com/statistics/264953/global-reserves-of-magnesium-by-major-countries/. Accessed Mar 2019

Dong H, Unluer C, Yang E-H, Al-Tabbaa A (2018) Recovery of reactive MgO from reject brine via the addition of NaOH. Desalination 429:88–95

Mustafa AMK, Al-Dahan DK, Khachik TV (2014) Laboratory study of MgO preparation from Iraqi dolomite by leach-precipitation-pyrohydrolysis process. Iraqi Bulletin of Geology and Mining 10:83–107

Sierra C, Chouinard S, Pasquier L-C, Mercier G, Blais J-F (2018) Feasibility study on the utilization of serpentine residues for Mg(OH)2 production. Waste and Biomass Valorization 9:1921–1933

Tamilselvi P, Yelilarasi A, Hema M, Anbarasan R (2013) Synthesis of hierarchical structured MgO by sol-gel method. Nano Bulletin 2:1–5

Hazra Chowdhury A, Hazra Chowdhury I, Kanti Naskar M (2015) A facile synthesis of grainy rod-like porous MgO. Mater Lett 158:190–193

Ercan I, Kaygili O, Ates T, Gunduz B, Bulut N, Koytepe S, Ozcan I (2018) The effects of urea content on the structural, thermal and morphological properties of MgO nanopowders. Ceram Int 44:14523–14527

Nemade KR, Waghuley SA (2014) Synthesis of MgO nanoparticles by solvent mixed spray pyrolysis technique for optical investigation. Int J Met 2014:1–4

Demirci S, Öztürk B, Yildirim S, Bakal F, Erol M, Sancakoğlu O, Yigit R, Celik E, Batar T (2015) Synthesis and comparison of the photocatalytic activities of flame spray pyrolysis and sol–gel derived magnesium oxide nano-scale particles. Mater Sci Semicond Process 34:154–161

Abdel-Aal ESA (1995) Possibility of utilizing Egyptian dolomite ores for production of magnesium oxide by acid leaching. Fizykochemiczne Problemy Mineralurgii 29:55–65

Mantilaka MMMGPG, Pitawala HMTGA, Karunaratne DGGP, Rajapakse RMG (2014) Nanocrystalline magnesium oxide from dolomite via poly(acrylate) stabilized magnesium hydroxide colloids. Colloids Surf A Physicochem Eng Asp 443:201–208

Yildirim M, Akarsu H (2010) Preparation of magnesium oxide (MgO) from dolomite by leach-precipitation-pyrohydrolysis process. Physicochem Probl Miner Process 44:257–272

Zhu K, Hu J, Kubel C, Richards R (2006) Efficient preparation and catalytic activity of MgO(111) nanosheets. Angew Chem Int Ed Engl 45:7277–7281

Dong H, Yang E-H, Unluer C, Jin F, Al-Tabbaa A (2018) Investigation of the properties of MgO recovered from reject brine obtained from desalination plants. J Clean Prod 196:100–108

Alvarado E, Torres-Martinez L, Fuentes A, Quintana P (2000) Preparation and characterization of MgO powders obtained from different magnesium salts and the mineral dolomite. Polyhedron 19:2345–2351

General Directorate of Mineral Research and Exploration. Exploration, Research report. Access date 21 November 2016

S.P. Organization, 9th Development Plan Report (2007–2013), Ankara, 2007, pp 192

Altiner M, Yildirim M (2017) Preparation of periclase (MgO) nanoparticles from dolomite by pyrohydrolysis-calcination processes. Asia Pac J Chem Eng 12:842–857

Altiner M, Yildirim M, Yilmaz T (2016) Leaching of mersin/aydincik dolomite ore in hydrochloric acid. Dissolution rates. Physicochemical Problems of Mineral Processing 52:536–550

Ling Z, Zheng M, Du Q, Wang Y, Song J, Dai W, Zhang L, Ji G, Cao J (2011) Synthesis of mesoporous MgO nanoplate by an easy solvothermal–annealing method. Solid State Sci 13:2073–2079

Mo L, Deng M, Tang M (2010) Effects of calcination condition on expansion property of MgO-type expansive agent used in cement-based materials. Cem Concr Res 40:437–446

Itatani K, Shiobara M, Howell FS (2002) Effect of bimodal particle size distribution on the sintering of magnesium oxide powder. Journal of the Society of Inorganic Materials, Japan 9:498–504

Morga R (2011) Changes of semifusinite and fusinite surface roughness during heat treatment determined by atomic force microscopy. Int J Coal Geol 88:218–226

Acknowledgments

This study was supported by Cukurova University (project no: FBA-2019-10123). The author would like to thank the anonymous reviewers for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 843 kb)

Rights and permissions

About this article

Cite this article

Altiner, M. Effect of Base Types on the Properties of MgO Particles Obtained from Dolomite Ore. Mining, Metallurgy & Exploration 36, 1013–1020 (2019). https://doi.org/10.1007/s42461-019-00122-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-00122-7