Abstract

The problems with traditional solar cells are mainly their high cost and low conversion efficiency, which severely restricts the advancement of these cells in real-world uses. Therefore, in order to maximise the efficiency of GaAs/AlGaAs thin-film heterostructures, GaAs/AlGaAs solar cells were numerically simulated along with Mo(S,Se)2 and CH3NH3PbI3 layers in order to determine the most suitable candidate for maximising its power conversion efficiency. Both two dimensional (2D) and three dimensional (3D) solar cells were simulated using COMSOL Multiphysics and it was found that the structure which had the highest efficiency was Mo(S,Se)2/GaAs/AlGaAs. The lowering of the Schottky barrier at the semiconductor–metal electrode interface and the low recombination rates reported in the Mo(S,Se)2 layer may have contributed to its high efficiency rates. The combined effect resulted in a open circuit voltage (VOC) of 0.61 V, short circuit current density (JSC) of 43.65 mA/cm2, fill factor (FF) of 76.6% and power conversion efficiency (PCE) of 20.53%. In addition, the optimum thickness for the Mo(S,Se)2 and the CH3NH3PbI3 layers was found to be 40 and 600 nm, respectively. These results allow for the promotion of highly efficient GaAs/AlGaAs heterostructures and provide an effective strategy and source for the manufacture of high-performance thin-film solar cells.

Article Highlights

-

1.

For the first time Mo(S,Se)2, CH3NH3PbI3 or a combination of both were numerically simulated with a GaAs/AlGaAs solar cell using the software COMSOL Multiphysics.

-

2.

It was found that the addition of the Mo(S,Se)2 layer to GaAs/AlGaAs had the greatest effect resulting in a PCE of 20.53% indicating that it is a suitable addition to such solar cells.

-

3.

For the first time the best thicknesses of the Mo(S,Se)2 and CH3NH3PbI3 layers were studied for the highest efficiency and found to be 40 and 600 nm respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The photovoltaic (PV) or solar cell industry has experienced a marked increase in research and development in the last few decades [1]. This was initially caused by the 1970s energy crisis [2] which then progressed into the climate change crisis of today. The need for alternative sources of sustainable, fossil fuel free energy is of paramount importance as the global effort to limit atmospheric warming to 1.5 °C continues [3]. Underpinning renewable sources of energy is solar energy which is collected by PV cells and converted into electricity using the photoelectric effect [4]. It should be noted that the operation of solar cells is described using semiconductor physics. Incorporating solar cell energy into the national electricity grid allows for energy security as well as lowers a country’s carbon footprint ultimately lowering the global annual carbon emissions of around 34 billion tonnes [5].

Solar cells, work by using light energy from the sun and converting it into electrical energy using a principle defined by the photoelectric effect. The photoelectric effect was discovered by Edmond Becquerel in 1839 which started the long and exciting journey of solar cell evolution [6]. This effect was not explained however, until 1905 by Albert Einstein [7]. This eventually led to the development of the first solar cell in 1954 by Chapin et al. at Bell Labs which was a silicon single crystal solar cell with an efficiency of 6% [8, 9]. From here the use of solar cells expanded into space, private and commercial applications. Solar cells which began in the 1950s mainly consisted of crystalline silicon materials which is still the main type of commercially available solar cells. From the 1990s and early 2000s the second generation of solar cells emerged using semiconducting materials other than silicon. These included CIGS, CdTe and many different types of materials. These type of solar cells have a low cost but also a low efficiency of around 10–15% [10]. Presently, the latest research on solar cells are done on what is referred to as third generation solar cells which comprise of organic solar cells (OSC), dye sensitized solar cells (DSSC), perovskite solar cells (PSC) and quantum dot solar cells (QDSC). There are some in the field that also refer to fourth generation solar cells which combines the advances of the previous generations in order to achieve the highest efficiency and stability and the lowest cost possible. Figure 1 shows the various generations of solar cells and what they consisted of.

The work done in this study uses materials from the 2nd and 3rd generation of solar cells such as GaAs and CH3NH3PbI3 and puts them together to research their behaviour working together.

As stated before, commercially available photovoltaic (PV) cells have around 20% efficiency. Therefore, in order to create a more viable product there are many research teams across the world studying various ways in which the power conversion efficiency (PCE) of PV cells can be improved [1]. One of the tools used to study the enhancement of solar cells are simulations. This utilises software which accurately simulates the behaviour of PV cells as well as its component materials. By simulating PV materials, researchers can understand the behaviour of photo-materials such as perovskite crystals [11] or organic dyes [12] before it is synthesised which may be time consuming and expensive. Additionally, current PV research needs to take into consideration the investment and operating costs as well as the cost of materials and maintenance [13]. Put together, simulation of PV cells can save time, manpower, cost and materials. Therefore, for the first time, Mo(S,Se)2, CH3NH3PbI3 or a combination of both were simulated with a GaAs/AlGaAs solar cell using the software COMSOL Multiphysics in this study.

This research was conducted in stages. First, the GaAs/AlGaAs solar cell was rendered in two dimensional (2D) and then extended by adding a Mo(S,Se)2 layer to it. Next, for the first time, three dimensional (3D) simulations were done by simulating a GaAs/AlGaAs, Mo(S,Se)2/GaAs/AlGaAs and CH3NH3PbI3/GaAs/AlGaAs solar cells where CH3NH3PbI3 is Methylammonium lead iodide, MAPbI3, as shown in Fig. 2.

Although perovskite solar cells have garnered much attention in recent years, there are several issues that must be addressed if it is to reach commercialisation. The main issue is that perovskite is inherently vulnerable to temperature, humidity and UV irradiation [14]. As a consequence, it cannot maintain long term stability. This is especially true for lead halide perovskites such as the one used in this research. Additionally, lead is a harmful compound to humans and the environment and should therefore be avoid wherever possible [15]. There is also a lack of universal protocol of testing standards that impedes research and comparison of various studies [16].

A different issue facing solar cells is the thickness of the layers themselves. For a given cell, the optimal thickness is balanced between opposing needs of high optical absorption and of efficient charge carrier collection [17]. The reason they are opposing is because the thicker the optical layer is for photo-absorption, the lower the efficient collection of carriers can take place. This is because the path length of the carriers would be shorter than the distance they must travel in order to be collected. As a result, there are many types of materials and optimal thicknesses that must be studied so that the most efficient solar cell can be obtained. It is for this reason that various materials and their optimal thicknesses where studied in this work. It is for this reason that the approach done in this study was taken.

Although solar cells have become increasingly popular, there are still aspects that can be improved. For example, the efficiency of thin-film solar cell needs to be increased in order for any possible commercialisation in the future. Additionally, its stability and longevity should also be increased. In this effort, the key benchmarks of the solar cell that are used to characterise its performance are the open-circuit voltage (VOC), short-circuit current (ISC), fill factor (FF) and PCE.

The photogeneration rate is one of the important factors, and its affected by the intensity and wavelength of the input photons, the band structure of the material, and the optical characteristics of the semiconductor. The photo-generation rate integral expression is given as:

where z is the device's depth from the surface, λ is the wavelength, and α(λ) denotes the absorption coefficient described by:

where κ(λ) is the imaginary part of the refractive index of the material and φ(λ) is the photon generation rate defined by:

where F(λ) is the spectral irradiance approximated to be AM 1.5 [18]. In COMSOL the radiation illuminates the whole cell uniformly. As a result, the optical behaviour of a material such as silicon is important to know [19, 20].

It should be noted that the simulation approach to solar cell development, as done in this study, offers reasonable insight into the behaviour of devices. This can then be used to efficiently determine suitable structures to test in the laboratory. Therefore, through simulation of solar cells, there can be improved stability, and efficiency so that they may become more commercially viable and with a greater variety of photovoltaics in the solar cell market.

This paper aims to fill the gap in the research that deals with the improvement of heterojunction solar cells using novel materials. For example, although GaAs/AlGaAs and perovskite solar cells are being widely researched, the performance of the combination of the two have not been demonstrated to the best of the authors’ knowledge. This sort of tandem solar cell behaviour is a field of active research and has the potential to improve the solar cell efficiency limit above the Shockley–Queisser limit of 29.8% [21].

In addition to this, the work presented in this paper demonstrates the usefulness of simulations in the research and development of solar cell technology. Due to the use of the Finite Element Method (FEM) and appropriate material properties, the behaviour of the semiconductor materials can be accurately simulated allowing for an understanding of their performances. Without simulations, these materials would have to be fabricated in the lab which takes a lot of time, energy, manpower and materials. Therefore, the utility of simulations in performing research on solar cell enhancement is another aspect shown in this study. In addition to this, although simulations are sometimes used in solar cell research, to the best of the authors’ knowledge, the specific structures simulated in this work has not been used or published before.

2 Literature review

Since the limiting single junction efficiency of solar cells is 33%, heterostructure solar cells have been increasingly attractive for research especially GaAs and AlGaAs along with other III-IV compound solar cells [22] which demonstrated a record efficiency of 39.2% under one sun and 47.1% under concentrated sun [23]. This discovery has sparked efforts to duplicate it with other materials, such as perovskites, which could result in cheaper production costs. The literature shows that Graphene/GaAs/AlGaAs solar cells have been studied by Shahnooshi et al. which resulted in an efficiency of 14% [24] but more research is needed to boost this value.

In addition the effect of Mo(S,Se)2 on thin-film solar cells has been studied by Zandi et al. who showed that the addition of the Mo(S,Se)2 layer to a CZTSSe solar cell improved the VOC while keeping the JSC constant [25]. This offers promising use of Mo(S,Se)2 which is why it was used and studied in this paper.

Perovskite/GaAs tandem solar cells have also been studied by Zhao et al. who used CsPbIBr2/GaAs tandem solar cells and achieved an efficiency of 30.67% [26]. This high efficiency was due to optimising the doping concentration of the GaAs base and studying the effects of defect density on the structure.

Therefore, this paper aims to combine the effect of Mo(S,Se)2 and CH3NH3PbI3 with GaAs/AlGaAs since to the best of our knowledge it has not been studied and can offer an effective strategy and reference for the manufacture of high-performance thin-film solar cells.

3 Materials and methods

There are several different categories of materials such as one dimensional (1D), 2D and 3D materials. Therefore, there are several emerging 2D materials such as graphene, transition metal dichalcogenides (TMDs), hexagonal boron nitride (hBN), phosphorene, black phosphorus, silicene and MXenes. These 2D materials possess exceptional mechanical, electrical, and thermal properties but are still yet to be thoroughly studied. The maximum efficiencies of solar cells with the use of 1D and 2D materials is shown in Table 1.

Materials that have a full three-dimensional structure and have traits and behaviour that span all three spatial dimensions are referred to as 3D materials. These compounds, which can be both natural and artificial, are frequently found in our daily lives. The creation of 3D materials has become a potential direction in materials research for improving solar cell performance. These materials have complex hierarchical or nanoscale structures, which have many benefits for solar applications. These materials' three-dimensionality enables more light trapping and absorption, maximising the use of incident photons. Additionally, their increased surface area makes efficient charge separation and collection possible, reducing recombination losses. Scientists can optimise the optical, electrical, and chemical properties of 3D materials to increase solar cell performance by adjusting their composition and morphology. As a result, the use of 3D materials in solar cells is crucial for developing renewable energy technologies and making it possible for clean and sustainable energy sources to be used widely. They include metals, ceramics, polymers, composites, glasses and semiconductors.

With respect to the materials used in the simulation, Gallium arsenide (GaAs) atoms combine to form a semiconductor. Since GaAs has good electronic characteristics, it is frequently utilised in a wide range of electrical and optoelectronic devices such as solar cells. GaAs effectively emits and absorbs light due to its straight bandgap. This characteristic makes it appropriate for uses in solar cells, lasers, and light-emitting diodes (LEDs). Additionally, GaAs has a greater electron mobility than silicon, enabling faster electron movement within the material [34, 35]. Aluminum Gallium Arsenide (AlGaAs) is a combination of gallium arsenide (GaAs) with varying amounts of aluminum added. The characteristics of AlGaAs can be adjusted to fit certain requirements by altering the aluminium to gallium ratio, e.g. Al0.25Ga0.75As. The presence of aluminium alters the material's bandgap, enabling a larger range of optical and electrical properties. The production of semiconductor devices, especially for optoelectronic purposes, frequently uses AlGaAs. In a single crystal, hetero-structures with various bandgaps can be produced by altering the aluminium content.

GaAs and AlGaAs are combined to create GaAs/AlGaAs semiconductor heterostructures. GaAs and AlGaAs can be combined to form heterojunctions with various bandgaps, which is essential for customising the electrical and optical characteristics of the resulting devices. To obtain particular device features, the energy band structure can be modified by adjusting the composition and thickness of the AlGaAs layers.

Mo(S,Se)2 refers to a family of TMD materials. It is a mixed chalcogenide compound where the sulfur and selenium atoms can be combined in different ratios. Similar to other TMDs like molybdenum disulfide (MoS2) and molybdenum diselenide (MoSe2), materials made of Mo(S,Se)2 have a layered crystal structure. Van der Waals forces between the layers are weak, making exfoliation into thin2D sheets simple. Due to these materials' distinctive electrical and optical characteristics, there has been a lot of interest in them. Tuning of the bandgap and electrical structure is made possible by the inclusion of both sulphur and selenium in Mo(S,Se)2. Depending on the exact composition, the bandgap of Mo(S,Se)2 can be either a direct bandgap (in the case of MoS2) or an indirect bandgap (in the case of MoSe2).

Methylammonium lead iodide (CH3NH3PbI3) has outstanding light-absorbing and charge-transporting abilities, leading it to attract a lot of interest in the field of photovoltaics [36]. It procedures a 3D arrangement in the form of a perovskite crystal structure. A repeating lattice formed by the methylammonium cations, lead ions, and iodide anions results in special electrical and optical properties. Due to its high light absorption coefficient, lengthy carrier diffusion lengths, and inexpensive manufacturing techniques, CH3NH3PbI3 perovskite has received a lot of attention in the field of photovoltaics [36]. Perovskite solar cells made of CH3NH3PbI3 have shown rapid efficiency gains [37] that are comparable to those of conventional silicon-based solar cells.

In this study various simulations were done starting from 2D and then progressing to 3D models as shown in Fig. 2. The model development followed a sequential order starting with the model definition node within COMSOL. Here, the variables and parameters such as bandgap and relative permittivity are defined. Next, the model’s geometry is outlined such as its dimensional length and thickness. After this, the material properties that was outlined in the model definition section are assigned to the correct domain. Once this is done the physics of the model is added. In this study, the semiconductor module [38] is used and therefore semiconductor and solid state physics as well as electromagnetic wave theory are incorporated into the model. Since COMSOL uses FEM to solve problems [39, 40], the optimal mesh is then added to the model. It is important to develop an adequate mesh that balances simulation time with computational accuracy. The study is then appropriately chosen best quality mesh, with equiangular skew of value 1, as shown in (Fig. 3) so that the voltage parameter could be swept accordingly.

The properties of the materials used in the simulations are shown in Table 2 below. It should be noted that these materials were chosen since some of the parametric data were available in the literature as referenced in Table 2. In addition, these materials were used since they are popularly used in solar cells but have never been used together in the simulation environment.

The simulation software used in this research is COMSOL Multiphysics because of its materials library, user friendly interface and its accuracy of results. It was also used because it has the ability to simulate multijunction solar cells in 1D, 2D and 3D unlike SCAPS-1D (another popular solar cell simulator) which can only simulate in 1D. Also, other simulation programs were not suitable for this research due to the fact that COMSOL Multiphysics has a vast online support system to assist in debugging any issues with the simulations.

In addition, COMSOL Multiphysics has thermal, optical and semiconductor simulation capabilities which allows for the simulation of various devices and systems. COMSOL produces precise findings based on the phenomena being studied using well-defined mathematical equations which are computed using the finite element method. It also offers versatility because the user can define their own physics by including custom equations. The Java programming language is used to generate COMSOL simulations, hence all Java syntax and libraries are supported [41].

A numerical method FEM is used in this study to solve the governing equations (such as Poisson equation) of the semiconductor [42]. By breaking down a complicated domain into smaller, interconnected parts, or subdomains, it can represent the geometry of the physical system. The behaviour of these elements is then roughly estimated by FEM using mathematical models, which usually use partial differential equations. FEM offers a potent tool for simulating and analysing the behaviour of semiconductor structures by solving these equations for each element and putting them together into a global system.

FEM is flexible for a wide range of applications due to its many advantages, including its ability to handle complex boundary conditions and irregular geometries. Additionally, it offers an affordable way to forecast system performance and optimise designs before actual prototypes are constructed. But FEM is not without its problems. It can be computationally expensive and can demand a lot of processing power, particularly when dealing with large-scale and complex geometries or systems. Fine meshing is often necessary for accurate simulation, which might result in a large number of equations to solve. Furthermore, the accuracy of FEM results depends on the underlying mathematical models assumptions and boundary conditions, hence it is crucial to validate the results against experimental data. Notwithstanding these drawbacks, FEM is still a vital tool for this study given its versatility and accuracy.

The governing equations for both the 2D and 3D simulations done in this study are the photogeneration equation shown in Eq. (3) as well as the continuity equation and Poisson equation. There are also several assumptions that are made such as that the behaviour of the solar cell reflects reality even though external conditions such as temperature and pressure changes throughout an experiment in laboratory conditions but not in the simulation. The illumination intensity and spectrum can also vary slightly from day to day but for the same simulations, the same solar spectrum shown in Fig. 4 is used for all the simulations. In addition to this, simulations do not take into account the preparation of the materials which can have an effect on its performance. It also assumes that the materials all have the same properties across each study without varying. The dynamic behaviour of solar cells and its stability are also assumed to be negligible in this study. For the 2D simulations the boundary conditions are: the left side of the geometry is grounded while the right side of the boundary has a varying applied voltage to it. All the other sides were isolated. For the 3D boundary conditions the top of the geometry is grounded while the bottom of the cell has a varying potential difference. All the other sides were insulated.

The solar spectrum used in the simulations [49]

In addition, simulating in different dimensions is necessary to develop an acute understanding of the behaviour of the model and the physics involved. By simulating in 2D the physics equations are limited only in the x and y directions. As the model is built to the 3D environment the z direction is included in the equations. Such a sequential manner of development allows for a critical understanding of the model which therefore makes troubleshooting bugs in the model easier.

Applying the mesh is also seriously considered since the mesh that is chosen for the 2D model is not the same mesh chosen for the 3D model. For the 2D mesh a mapped mesh is used. As the dimensionality of the model increases so too does the complexity of the mesh. As a result, 3D geometries, have more complex meshes such as the swept mesh. A crucial element of any numerical model of a semiconductor device is the mesh. Grid independence, which is the quality of findings not noticeably changing when the mesh is adjusted, is a crucial consideration when evaluating a numerical solution. The semiconductor equations' finite element formulations get the best results when different meshing techniques are used [41]. The default mesh suggestions in the Semiconductor Module automatically improve the mesh according to the chosen physics features. Sometimes tweaking the default mesh by hand enhances performance and facilitates the problem-solving process.

The mapped mesh was chosen for the 2D models as well as the swept mesh for the 3D models since these were the types of meshes advised to be used in the Semiconductor user’s guide of COMSOL Multiphysics [43]. The skewness which is a measure of mesh quality was checked to make sure that the quality of the mesh was optimal for each simulation. A skewness of 1 is preferred as shown in Fig. 3

The dimensions of GaAs and AlGaAs were guided by the choice of dimensions selected by COMSOL Multiphysics tutorial titled 1D heterojunction [38]. The dimensions of the Mo(S,Se)2 were guided by the thickness of the material used by Zandi et al. [25]. Additionally, the thickness of CH3NH3PbI3 was guided by the work done by Leguy et al. [44]. The 2D simulations were of the order of μm while the 3D simulations were of the order of nm. This is because results agreed with the diode behaviour of a solar cell at these length scales. Additionally, the one of the aims of this study was to enhance the performance of thin-film technology so using nm length scales were ideal.

By studying various multijunction solar cells in diode mode, critical information about the solar cell’s electrical performance can be determined. Losses due to recombination, series resistance and shunt resistance can also be determined. Diode mode studies can also guide optimisation of multijunction solar cells by adjusting thicknesses and other material properties. In addition, diode mode studies can help characterise the individual contribution of each layer to the overall solar cell system.

As stated previously, this work builds a multijunction solar cell using COMSOL which, for the first time, includes a Mo(S,Se)2 or CH3NH3PbI3 layer on a GaAs/AlGaAs multijunction backing. Compared to single-junction solar cells, multijunction solar cells are intended to capture a wider range of the sunlight spectrum. They are composed of numerous p-n junctions constructed of distinct semiconductor materials. Their efficiency can be greatly increased by this design.

The complex refractive index of the materials used in the simulation were found in the materials library of COMSOL Multiphysics. The complex refractive index is written in the form

where n is the real part of the refractive index and describes the refraction of light into a material and k is the imaginary part which describes the absorption of light into the material.

For GaAs the absorption spectrum was obtained from Papatryfonos et al. [45]. The AlGaAs absorption spectra was obtained from Aspnes et al. [46]. The complex refractive index of Mo(S,Se)2 was given by Islam et al. [47] and the complex refractive index of CH3NH3PbI3 was obtained from Leguy et al. [48].

3.1 2D simulations

Figure 2 shows the order in which the models were developed as well as the physics module which was used (Semiconductor). For the 2D models, a mapped mesh was employed. The mesh consisted of 160 elements with an element ratio of 0.01 so that the mesh will be more concentrated at the junctions of the model in order to capture most of the physics taking place. This meant that the largest mesh size was 0.05 µm × 0.125 µm and the smallest mesh size was 0.007 µm × 0.125 µm.

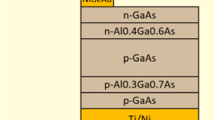

3.1.1 GaAs/AlGaAs multijunction

This model is shown in Fig. 5 and was developed by applying the method as stated earlier. It had a height of 2 μm and a total length of 10 μm. Each segment had a length of 5 μm. The solar spectrum shown in Fig. 4 was used as well as only the Semiconductor module. It is important to know the effect of the solar spectrum on the efficiency of solar modules [50]. The GaAs was n-type and the AlGaAs was p-type. A voltage sweep from 0 to 2 V was performed for this simulation.

3.1.2 Mo(S,Se)2/GaAs/AlGaAs multijunction

This model builds on the work done in Sect. 3.1.1 by introducing a new Mo(S,Se)2 layer to the multijunction as shown in Fig. 6. The Mo(S,Se)2 layer was 0.1 μm thick and had a height of 2 μm to match the rest of the structure. The mesh used here was a mapped mesh similar to what was used previously with 50 additional elements to accommodate the addition of the new layer.

The properties of the Mo(S,Se)2 layer are shown in Table 2 [25]. The Mo(S,Se)2 layer contained p-type doping of 1 × 1015 cm−3. From the simulation perspective it is easy to form a p-type material by selecting acceptor doping (p-type) in the doping selection settings. Physically, Fu et al. constructed a p-type Mo(S,Se)2 layer by in-situ doping of group VB elements (V, Nb and Ta) [51]. In this approach, Mo(S,Se)2 is doped with VB elements. Shallow acceptors (VMo, NbMo, TaMo) are generated, converting Mo(S,Se)2 from weak n-type to p-type conductivity. This processes increases the work function (WF) and hole concentration in Mo(S,Se)2. To achieve p-type Mo(S,Se)2 the aliovalent dopant has to be a shallow acceptor, the dopant formation energy is sufficiently enough and the intrinsic defects cannot undo the holes generated by the extrinsic acceptors [51]. To accomplish this, aliovalent exchange of VIB Mo by VB elements with one less outer electron was done. For the study, a voltage sweep from 0 to 2 V was done.

3.2 3D simulations

Extending the 2D models into the 3D environment followed next. This was done in largely the same way apart from a few details such as using swept and mapped meshes instead of just a mapped mesh. Here, each face was separated into 5 horizontal segment and 10 vertical segments as shown in Fig. 7. This means that for the 3D models, the AlGaAs mesh size was 20 nm × 10 nm, the GaAs mesh size was 20 nm × 10 nm, the Mo(S,Se)2layer mesh size was 20 nm × 10 nm and the CH3NH3PbI3 layer had a mesh size of 20 nm × 130 nm.

3.2.1 GaAs/AlGaAs multijunction

The geometry of the first 3D model is shown in Fig. 8. The wafer had a length of 200 nm, width of 200 nm and a total height of 50 nm for each layer. The additional layers were placed on top of the GaAs/AlGaAs base shown in Fig. 8. The area for this model as well as all the other 3D models was \(4\times {10}^{4}\) nm2.

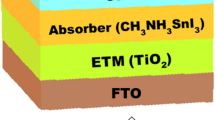

3.2.2 Mo(S,Se)2/GaAs/AlGaAs & CH3NH3PbI3 /GaAs/AlGaAs multijunction

The third layer was added to the geometry as shown in Fig. 9. The third layer was situated atop the GaAs layer and was set to either be Mo(S,Se)2 or CH3NH3PbI3. The properties of each are shown in Table 2. The Mo(S,Se)2 layer had a height of 50 nm while the CH3NH3PbI3 layer had a height of 650 nm. The effect of the height of each of these layers are also investigated later on.

This simulation method is advantageous in that it can be used to simulate both the Mo(S,Se)2/GaAs/AlGaAs multijunction and the CH3NH3PbI3/GaAs/AlGaAs multijunction using the same model development by simply swapping the material’s properties.

The investigation that was conducted for these simulations, involved sweeping the voltage from 0 to 2 V and analysing the J–V and P–V curves as well as the recombination graphs.

4 Results and discussion

4.1 2D simulation results

4.1.1 GaAs/AlGaAs multijunction

Figure 10 shows the I–V characteristics from the simulated model shown in Fig. 5. From the graph it can be seen that the VOC is 0.85 V and the ISC is 0.46 nA. For this model, the J–V graph resembles that done by Horio et al. [52]. Such agreement with experimental data ensure greater confidence that the simulation is accurate and can therefore be trusted.

The concentrations of electrons and holes inside the cell are visualized in Figs. 11 and 12. From the graphs it can be seen that the electrons were concentrated at the first layer of the cell while the holes were concentrated in the second layer of the cell. The depletion region can also be seen. This is where the junction voltage gets its value since only after the junction voltage is exceeded can a current begin to flow. Since various materials have different junction voltages for now we can say that it is sufficient that we can see it being illustrated in the figures since it is not shown in Fig. 10. However, Table 3 shows the VOC values for the 3D models.

4.1.2 Mo(S, Se)2/GaAs/AlGaAs multijunction

Figure 13 shows the I-V curve when the Mo(S,Se)2 layer is added. A preliminary comparison shows that the addition of the layer restricts the current as compared to the layer without the Mo(S,Se)2 compound. Here, the VOC is 0.82 V and the ISC is 0.174 nA. Figure 14 shows the carrier concentration of the electrons in the assembly. The hole concentration is the inverse of the electron concentration. As can be seen, the model is set up as a p–n–p type structure. The electrons are focused in the middle layer while the first and second layers possessed the holes.

4.2 3D simulation results

4.2.1 GaAs/AlGaAs multijunction

Figure 15 displays the carrier concentration distribution with the electrons being concentrated in the top layer while the holes are focused in the bottom layer. This is similar to the 2D models shown in Fig. 12. This was especially useful in ensuring that each model was set up correctly and debugging any errors during the building of the simulations.

4.2.2 Mo(S,Se)2/GaAs/AlGaAs multijunction

Figure 16 shows the I-V graph for the Mo(S,Se)2/GaAs/AlGaAs multijunction. The values for VOC and ISC are shown in Table 3 and are 0.6137 V and 17.46 pA respectively. From the graph it can also be seen that the voltage was swept from − 0.75 to + 0.75 V. This allowed for a better illustration of the semiconductor behaviour of the solar cell.

4.2.3 CH3NH3PbI3/GaAs/AlGaAs multijunction

Figure 17 shows the energy level diagram of the CH3NH3PbI3/GaAs/AlGaAs multijunction in the. The understanding of the energy levels makes it easier to understand how the absorbed photons produce electron–hole pairs (excitons) within each layer and how these excitons flow across the layers to produce a photocurrent. The bandgap is also crucial in understanding the values of VOC and ISC. When photons with energies over the bandgap are absorbed, electrons are excited from the valence band to the conduction band. Electricity is produced as a result of the flow of these energised electrons and holes as current. Electron and hole quasi fermi levels overlap here.

4.2.4 CH3NH3PbI3/Mo(S,Se)2/GaAs/AlGaAs multijunction

The final model produced was a combination of all the layers used as shown in Fig. 18.

This model incorporated the combined effect of the Mo(S,Se)2 and the CH3NH3PbI3 layers. Analysis of the current densities from each model are shown in Fig. 19 which reveals that the addition of the Mo(S,Se)2 and CH3NH3PbI3 layers increased the overall efficiency from 12.40 to 20.53% and 12.40 to 15.70% respectively. A possible explanation for this improvement is because the Mo(S,Se)2 layer improved the electrical connection between the metal contact and the device by lowering the Schottky barrier as explained by Zandi et al. [25]. The Schottky barrier is a potential energy barrier that is formed at the interface between a metal and a semiconductor. It is created due to the equalisation of the Fermi level between the metal and semiconductor which causes charge to move from one material to the other. This leads to the formation of an energy barrier which must be overcome in order for charges to easily flow. The value of the barrier depends of the metal and semiconductor that forms the interface which reduces the value of the VOC. The layer of Mo(S,Se)2 boosted the carrier collection at the junctions which lead to a reduction of the Schottky barrier and subsequent increase in the VOC that was seen [25].

In addition to this, Fig. 21 shows that the Mo(S,Se)2 layer has the lowest recombination in the Mo(S,Se)2/GaAs/AlGaAs multijunction. This means that charge carriers are recombining the least and therefore able to reach to the electrodes and deliver current.

The additional layers could also have altered the energy bands to become preferential for charge transportation as explained by Torabi et al. [53]. By altering the energy bands to allow charges to flow easier, the performance of the solar cell can be improved as shown in Fig. 20. This is because there is greater agreement between the energy bands across the interfaces of the different layers which promotes the transportation of the carriers.

The CH3NH3PbI3 (perovskite) layer also did not have the accompanying layers that makes it operate optimally such as a hole transport layer (HTL) and electron transport layer (ETL). The absence of these layers as well as suitable electrodes such as fluorine-doped tin oxide (FTO) and gold (Au). Due to this reason the Mo(S,Se)2 layer outperformed the CH3NH3PbI3 layer. It should also be noted that their purposes are different since the Mo(S,Se)2 layer is used for enhanced charge transportation [25] while the CH3NH3PbI3 layer functions as the optical layer generating electron hole pairs [36].

When looking at the CH3NH3PbI3/Mo(S,Se)2/GaAs/AlGaAs multijunction it is shown that the addition of the Mo(S,Se)2 layer resulted in the VOC increasing a lot while the JSC remained somewhat the same. These results exactly matched those produced by Zandi et al. [25] and is explained by the Mo(S,Se)2 layer reducing the Schottky barrier. In the paper, the application the Mo(S,Se)2 layer lead to an increase in the VOC of the heterojunction by 0.513 V while in this study the VOC increased by 0.5 V. The GaAs/AlGaAs solar cell used material properties provided by the materials library of COMSOL.

The CH3NH3PbI3/GaAs/AlGaAs ( red line) of Fig. 19 shows a high series resistance when compared to the others. This is because the addition of the CH3NH3PbI3 layer without the ETL and HTL layers reduces its ability to effectively transport charge and therefore increases its resistance. Therefore, with the addition of the Mo(S,Se)2 layer to the structure (black line) the series resistance decreased allowing for a higher VOC since the Mo(S,Se)2 layer reduced the Schottky barrier allowing increased charge transport.

Figure 20 shows a comparative P–V plot for the 3D models. It shows that the highest peak was achieved by the Mo(S,Se)2/GaAs/AlGaAs multijunction, which also had the highest PCE. The second highest power was achieved by the CH3NH3PbI3/Mo(S,Se)2/GaAs/AlGaAs multijunction.

The values of the short-circuit current (ISC) and open-circuit voltage (VOC) are shown in Table 3. From the table, it can be seen that the highest VOC was achieved by the GaAs/AlGaAs multijunction which could be due the concentrations of the conduction and valence band as a result of the orientation of the energy bands. A similar explanation can be given for the Mo(S,Se)2/GaAs/AlGaAs model achieving the highest ISC. By combining the effect of the Mo(S,Se)2 and GaAs/AlGaAs layers, the highest efficiency was observed at 20.53%.

Figure 21 shows a comparison of the recombination rates of the multijunctions. The graph shows that for the 3 layered multijunctions, there is a peak in recombination that occurs in the GaAs layer. For the Mo(S,Se)2/GaAs/AlGaAs multijunction, the recombination of charge carriers drops in the Mo(S,Se)2 layer but in the CH3NH3PbI3/Mo(S,Se)2/GaAs/AlGaAs multijunction the recombination remains relatively high in the CH3NH3PbI3 layer. For the CH3NH3PbI3/Mo(S,Se)2/GaAs/AlGaAs multijunction, the recombination rate is high in the GaAs layer but peaks in the Mo(S,Se)2 layer and slowly attenuates in the CH3NH3PbI3 layer. The recombination in the Mo(S,Se)2/GaAs/AlGaAs multijunction was the lowest in the Mo(S,Se)2 layer which could have also contributed to have it perform the best.

The effect of the layer’s thickness is also taken into account because it is essential in maximising solar cell performance. If the active layer is excessively thick, charge carrier recombination will take place before the charge carriers exit the layer because of the great distance the charge carriers must travel. However, if the layer is too thin, photon absorption will not generate the optimal amount of electron–hole pairs required to obtain the highest efficiency possible [54]. As a result, there is an optimal layer which must be applied in order for optimal performance of the solar cells.

For the CH3NH3PbI3/Mo(S,Se)2/GaAs/AlGaAs multijunction, the optimal thickness of the Mo(S,Se)2 and CH3NH3PbI3 layers were found to be 40 and 600 nm respectively as shown in Fig. 22. By optimising the thickness, the highest efficiency could be achieved by taking into consideration the path length of the charge carriers. The thickness of the layer should not exceed the path length of the charge carrier or else the carrier will be unable to reach the interface of the layer. For this simulation the efficiency increased as shown in Table 3 however it was a marginal increase in efficiency since the starting thicknesses (50 and 650 nm respectively) were close to the optimal thicknesses already used.

If the models are to be enhanced, there are some other factors to take into account. This includes incorporating the COMSOL Heat Transfer module to add thermal effects. This module allows for the investigation of the heat produced when the model is exposed to electromagnetic radiation. Shockley–Read–Hall heating as well as the consequences of heat generation and a study on heat flow through the model can be done.

To reduce the computational time of the simulation, the meshing of the model can also be enhanced which balances accuracy with time taken for the FEM solver to complete its calculations.

Moreover, by including additional layers and comparing it to what has previously been evaluated, the model can also be expanded. Other models can use gold metal anodes or carbon substrates like graphene.

5 Conclusion

COMSOL Multiphysics was used in this study to numerically simulate several heterojunction solar cells in both 2D and 3D. These included GaAs /AlGaAs and Mo(S,Se)2/GaAs/AlGaAs for the 2D simulations and GaAs/AlGaAs, Mo(S,Se)2/GaAs/AlGaAs, CH3NH3PbI3/GaAs/AlGaAs and CH3NH3PbI3/Mo(S,Se)2/GaAs/AlGaAs for the 3D simulations attempting to maximise the power conversion efficiency. At each step the different factors that contribute to the electrical properties of the solar cell such as carrier concentration and energy bands have been analysed. The thicknesses of the materials in the final simulation were also altered to determine the optimum thickness for that model. The model with highest efficiency was the Mo(S,Se)2/GaAs/AlGaAs. This high efficiency could have been caused by the reduction of the Schottky barrier at the semiconductor–metal electrode interface. The high efficiency could also be due to the fact that the recombination in the Mo(S,Se)2 layer for this model was the lowest. This lead to obtaining a VOC of 0.61 V, JSC of 43.65 mA/cm2, FF of 76.6% and PCE of 20.53%. The optimum thickness for the Mo(S,Se)2 layer and the CH3NH3PbI3 layers was found to be 40 nm and 600 nm, respectively. As a result of these findings, a highly efficient Mo(S,Se)2/GaAs/AlGaAs solar cell structure can be made in order to maximise the efficiency of GaAs/AlGaAs heterostructures.

Data availability

No datasets were generated or analysed during the current study.

References

NRE Laboratory. Best research-cell efficiency chart. Photovoltaic Research (2022).

Roeder JL. What we learned from the oil crisis of 1973: a 30-year retrospective. Bull Sci Technol Soc. 2005;25(2):166–9.

Matemilola S, Fadeyi O, Sijuade T. Paris agreement. Encycl Sustain Manag. 2020;2020:1.

Wheaton BR. Photoelectric effect. In: Greenberger D, Hentschel K, Weinert F, editors. Compendium of quantum physics. Berlin: Springer; 2009. p. 472–5. https://doi.org/10.1007/978-3-540-70626-7_143.

Ritchie H, Roser M, Rosado P. CO2 and greenhouse gas emissions. Our world in data (2020).

Tsakalakos L. Introduction to photovoltaic physics, applications, and technologies. In: Nanotechnology for photovoltaics. CRC Press; 2010. p. 19–66.

Whittaker ET. Albert Einstein, 1879–1955. The Royal Society London; 1995.

Chapin DM, Fuller CS, Pearson GL. A new silicon p-n junction photocell for converting solar radiation into electrical power. J Appl Phys. 1954;25(5):676.

Fraas L, Partain L. Solar cells: a brief history and introduction. In: Fraas L, Partain L, editors. Solar cells and their applications. Wiley; 2010. p. 1–15. https://doi.org/10.1002/9780470636886.ch1.

Anissimov M. What are the different generations of solar cells? Solar Panel Guide (2024).

Chen Z, et al. Thin single crystal perovskite solar cells to harvest below-bandgap light absorption. Nat Commun. 2017;8(1):1890.

Sharma K, Sharma V, Sharma S. Dye-sensitized solar cells: fundamentals and current status. Nanoscale Res Lett. 2018;13:1–46.

Benda V, Černá L. PV cells and modules—State of the art, limits and trends. Heliyon. 2020;6(12):e05666. https://doi.org/10.1016/j.heliyon.2020.e05666.

Wu M, Haji Ladi N, Yi Z, Li H, Shen Y, Wang M. Stability issue of perovskite solar cells under real-world operating conditions. Energy Technol. 2020;8:1900744.

Beepat KG, Sharma DP, Pathak D, Mahajan A. COMSOL multiphysics-based modeling approach to solar cell development. Int J Mod Phys B. 2023;37(12):2350114.

Beepat K, Kumar S, Sharma A, Sharma DP, Pathak D, Nunzi J-M. Perovskite materials for photovoltaics: a review. Eur Phys J Appl Phys. 2023;98:43.

Andreani LC, Bozzola A, Kowalczewski P, Liscidini M, Redorici L. Silicon solar cells: toward the efficiency limits. Adv Phys X. 2019;4(1):1548305.

COMSOL Multiphysics. Si Solar Cell 1D (2024).

Green MA. Self-consistent optical parameters of intrinsic silicon at 300 K including temperature coefficients. Sol Energy Mater Sol Cells. 2008;92(11):1305–10.

Green MA, Keevers MJ. Optical properties of intrinsic silicon at 300 K. Prog Photovoltaics Res Appl. 1995;3(3):189–92.

Futscher MH, Ehrler B. Efficiency limit of perovskite/Si tandem solar cells. ACS Energy Lett. 2016;1(4):863–8.

Yamaguchi M. High-efficiency GaAs-based solar cells. In: Rahman MM, Asiri AM, Khan A, Inamuddin TT, editors. Post-transition metals. IntechOpen; 2021.

Yamaguchi M, Dimroth F, Geisz JF, Ekins-Daukes NJ. Multi-junction solar cells paving the way for super high-efficiency. J Appl Phys. 2021. https://doi.org/10.1063/5.0048653.

Shahnooshi F, Orouji AA, Abbasi A. Enhanced performance of Graphene/AlGaAs/GaAs heterostructure Schottky solar cell using AlGaAs drainage. J Mater Sci Mater Electron. 2022;33(7):4617–27.

Zandi S, Saxena P, Razaghi M, Gorji NE. Simulation of CZTSSe thin-film solar cells in COMSOL: three-dimensional optical, electrical, and thermal models. IEEE J Photovoltaics. 2020;10(5):1503–7.

Wang J, et al. An exploration of all-inorganic perovskite/gallium arsenide tandem solar cells. Solar RRL. 2021;5(7):2100121.

Jiang N, Zheng Z, Qin C, Liang R, Li Z, Ye Z, Zhu L. Enhanced power conversion efficiency of perovskite solar cells using dopant-free carbon nanotubes-Spiro-OMeTAD. Ceram Int. 2023;49(6):9502–11. https://doi.org/10.1016/j.ceramint.2022.11.117.

Wang Z, Liu Y, Li L, Gao S, Zhu D, Xiangxiang Y, Cheng S, Zheng D, Xiong Y. An investigation of the effects of ZnO inverse opal pore size in the composite of ZnO nanorods/ZnO inverse opal on the performance of quantum dot-sensitized solar cells. Dalton Trans. 2023;52(1):81–9.

Fu HC, et al. MXene-contacted silicon solar cells with 11.5% efficiency. Adv Energy Mater. 2019;9:1900180.

Nassiri Nazif A, Daus A, Hong J, Lee N, Vaziri S, Kumar A, Nitta F, Chen ME, Kananian S, Islam R, Kim KH, Park JH, Poon ASY, Brongersma ML. High-specific-power flexible transition metal dichalcogenide solar cells. Nat Commun. 2021;12:7034.

Meng J-H, et al. Interface engineering for highly efficient graphene-on-silicon Schottky junction solar cells by introducing a hexagonal boron nitride interlayer. Nano Energy. 2016;28:44–50.

Borah CK, Tyagi PK, Kumar S, Patel K. Few-layer p-type phosphorene sheet: an efficient transparent conducting electrode in silicon heterojunction solar cell. Comput Mater Sci. 2018;151:65–72.

Fu N, Huang C, Lin P, Zhu M, Li T, Ye M, Lin S, Zhang G, Du J, Liu C, Xu B, Wang D. Black phosphorus quantum dots as dual-functional electron-selective materials for efficient plastic perovskite solar cells. J Mater Chem A. 2018;6(19):8886–94.

Ruch J, Kino G. Transport properties of GaAs. Phys Rev. 1968;174(3):921.

Ludwig G, Watters R. Drift and conductivity mobility in silicon. Phys Rev. 1956;101(6):1699.

Yun S, Zhou X, Even J, Hagfeldt A. Theoretical treatment of CH3NH3PbI3 perovskite solar cells. Angew Chem Int Ed. 2017;56(50):15806–17.

Sha WE, Ren X, Chen L, Choy WC. The efficiency limit of CH3NH3PbI3 perovskite solar cells. Appl Phys Lett. 2015. https://doi.org/10.1063/1.4922150.

COMSOL Multiphysics. Heterojunction 1D (2024).

COMSOL Multiphysics. The Finite Element Method (FEM) (2022).

Pomplun J, Burger S, Zschiedrich L, Schmidt F. Adaptive finite element method for simulation of optical nano structures. Phys Status Solidi (B). 2007;244:3419–34.

COMSOL Multiphysics. Application Builder Features and Funtionality (2022).

Markowich PA, Ringhofer CA, Schmeiser C. Semiconductor equations. Springer Science & Business Media; 2012.

COMSOL Multiphysics. Semiconductor Module Users Guide (2024).

Leguy AM, et al. The dynamics of methylammonium ions in hybrid organic–inorganic perovskite solar cells. Nat Commun. 2015;6(1):7124.

Papatryfonos K, et al. Refractive indices of MBE-grown AlxGa(1–x) As ternary alloys in the transparent wavelength region. AIP Adv. 2021. https://doi.org/10.1063/5.0039631.

Aspnes D, Kelso S, Logan R, Bhat R. Optical properties of AlxGa1−xAs. J Appl Phys. 1986;60(2):754–67.

Islam KM, Synowicki R, Ismael T, Oguntoye I, Grinalds N, Escarra MD. In-plane and out-of-plane optical properties of monolayer, few-layer, and thin-film MoS2 from 190 to 1700 nm and their application in photonic device design. Adv Photonics Res. 2021;2(5):2000180.

Leguy AM, et al. Reversible hydration of CH3NH3PbI3 in films, single crystals, and solar cells. Chem Mater. 2015;27(9):3397–407.

Wehrli C, Fröhlich C. Solar Spectral Irradiance Measurements at 368 nm, 500 nm and 778 nm. Metrologia. 1991;28(3):285.

Rodziewicz T, Rajfur M, Teneta J, Świsłowski P, Wacławek M. Modelling and analysis of the influence of solar spectrum on the efficiency of photovoltaic modules. Energy Rep. 2021;7:565–74.

Fu J, et al. Defect engineering enabling p-type Mo(S,Se)2: TM (TM= V, Nb, Ta) towards high-efficiency kesterite solar cells. Chem Eng J. 2023;457:141348.

Horio K, Yanai H. Numerical modeling of heterojunctions including the thermionic emission mechanism at the heterojunction interface. IEEE Trans Electron Devices. 1990;37(4):1093–8.

Torabi N, et al. Analysis of CdSe as an alternative buffer layer for Sb2Se3 solar cells. Sol Energy. 2023;264:111990.

Bouazizi S, Tlili W, Bouich A, Soucase BM, Omri A. Design and efficiency enhancement of FTO/PC60BM/CsSn0.5Ge0.5I3/Spiro-OMeTAD/Au perovskite solar cell utilizing SCAPS-1D Simulator. Mater Res Express. 2022;9:096402.

Author information

Authors and Affiliations

Contributions

Kevin Gurbani Beepat; Draft manuscript preparation, data collection, investigation, analysis and interpretation of results. Davinder Pal Sharma; Conceptualization, methodology, review and editing, project administration, software supply, resources, supervision, corresponding author. Aman Mahajan; Conceptualization, methodology, resources. Dinesh Pathak; Supervision, Conceptualization, review and editing, analysis and interpretation of results. Vinod Kumar; Review and editing, analysis and interpretation of results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Beepat, K.G., Sharma, D.P., Mahajan, A. et al. Simulation of multijunction solar cell interfaces for enhancement of the power conversion efficiency. Discov Appl Sci 6, 283 (2024). https://doi.org/10.1007/s42452-024-05930-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05930-1