Abstract

In this study, a biodegradable spherical adsorbent bead was developed from eggshell (ES) and Bijoypur clay (BC) for the removal of hexavalent chromium from synthetic tannery wastewater. This Eggshell–Clay polymer composite (ES–BC) was made by incorporating them with PVA and alginate. To analyze the morphology and chemical composition of the adsorbent before and after the chromium adsorption, SEM, FTIR, XRD, and EDX were used. The impact of adsorption parameters such as adsorbent dosage (0.67–2.23 g/L), pH of the solution (1.5–9), contact time (10–240 min), initial Cr (VI) concentration (25–100 ppm), and solution temperature (25–65 °C), percentage clay in ES-BC adsorbent (0–40%) for Cr (VI) adsorption were investigated. The optimum value for adsorbent dosage, pH, contact time, initial Cr concentration, temperature, and clay to eggshell ratio was found 1.17 g/L, 1.5, 150 min, 58.2 ppm, 25 °C, and 80/20% respectively. The isotherm model was well-fitted to the Freundlich isotherm suggesting heterogeneous adsorption in multilayer on surface. The adsorption kinetics followed pseudo-second-order kinetics supporting the chemisorption process. Moreover, a decrease in enthalpy (H°) and negative Gibbs free energy (G°) with increased temperature indicated exothermic and spontaneous reaction. Therefore, this research investigated that the composite may serve as a viable option for treating Cr (VI) containing tannery effluent.

Article Highlights

-

An adsorbent comprised of eggshell and clay was prepared and characterized.

-

The adsorbent achieved a maximum adsorption capacity of 122.1 mg/g when applied to wastewater.

-

The composite adsorbent may serve as a viable option for treating tannery effluent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

All living things need access to clean water. A lack of access to clean water, however, is one of the most pressing environmental issues in developing countries [1]. There is a growing concern that water contamination in developing nations poses a threat to public health [2]. Pollutants from tannery effluents are among the worst for the environment compared to other types of industrial waste [3]. The widespread usage of chromium salts in the leather industry raises concerns about the possible transformation of Cr (III) into Chromium (VI), which is toxic to both humans and the environment. Therefore, it is crucial to rapidly eliminate Cr6+ from the tannery effluent. An estimated 90 percent of all leather is tanned with basic chromium sulfate [4,5,6,7]. It is impossible to achieve superior handling performance, excellent stability to hot water, customized qualities for individual users, and adaptability of chrome-tanned leather with any other tanning procedure [8]. The typical leather tanning method uses 8–12% basic chromium sulfate (BCS). However, the tanning process only absorbs around 60–70% of BCS, with the remaining 30–40% of unfixed chromium being released as effluent [9].

Cr (III) and Cr (VI) are the two most stable chromium isotopes [10]. One of the most damaging and carcinogenic water contaminants is chromium (Cr), yet Cr (III) exhibits lower toxicity compared to Cr (VI) and is a nutrition for humans at low concentrations [11]. Even at concentrations of 1 part per billion (ppb), Cr6+ seems to be toxic [12]. Hexavalent chromium compounds have been linked to a variety of health problems after being inhaled or swallowed, including lung cancer in humans, cardiovascular disease, dermatitis, and liver and kidney damage [13]. In humans, Cr (VI) has been shown to induce mutations, it is therefore categorized by the International Agency for Research on Cancer as a category 1 human carcinogen [14]. Chromium has been shown to have harmful effects on the environment, hence tannery effluent containing chromium salts must be cleaned up.

Some of the ways to get rid of chromium are chemical precipitation, reverse osmosis, electrolytic process, membrane systems, ion exchange, adsorption, etc. [15]. There are several drawbacks to the aforementioned methods. These include high operating costs and the generation of excessive sludge. However, these problems may be overcome by using an adsorption approach [16], which is inexpensive, sludge-free, and easy to implement. Natural and synthetic zeolites, [17], organically modified porous silica [18], natural and modified clays [19], macroporous polymeric adsorbents [20], pulp [21], clinoptilolite [22], leaf [23], activated carbon [24], charcoal [25], green walnut shell [26], eggshell [27, 28], etc. have all evolved to serve as adsorbents. The removal of Cr is accomplished with the use of composites because of their low cost, high efficiency, low maintenance, enhanced processability, increased surface area, stability, and adaptability [29]. Since eggshells have a high concentration of calcium carbonate, they can be employed as an effective adsorbent in the purifying of water and soil polluted by metallic ions [30]. Two layers may create numerous circular pores [31, 32], which may be the secret of eggshells’ efficiency. The usage of metal linked with clay minerals, either alone or in conjunction with other synthetic or natural polymers, has a fascinating history [33, 34]. Owing to its significant surface area, layered structure, mechanical stability, and environmental friendliness, clay is a promising candidate as a composite material [35].

In this investigation, bio-composite beads were made using eggshell and Bijoypur clay, a kind of kaolinite clay that may be found in the Bijoypur area. Beads with improved mechanical properties and spherical shapes were made by confining eggshell and Bijapur clay on polymer composites of PVA and Alginate. Boric acid was used to crosslink PVA, while CaCl2 was used to enhance surface properties. To determine whether or not the resulting composite was effective as an adsorbent, it was subjected to a battery of tests. Several factors, including beginning concentration, solution temperature, the ratio of components of bead composition, contact duration, pH, and bead dosage were studied to determine their impacts. A batch experiment was conducted to examine the adsorption of Cr (VI) onto beads. In addition, we conducted research on thermodynamics, kinetics, and isotherms.

2 Materials and methods

2.1 Materials

Chicken egg shells were collected from Jagannath Hall Cafeteria, University of Dhaka, Bangladesh. The raw clay was procured from Bangladesh Insulator & Sanitaryware Factory Limited (BISFL), Mirpur-1, Dhaka, the authorized institution for collection of the clay from Bijoypur, Netrokona, Bangladesh. Hydrochloric Acid (HCl), Polyvinyl Alcohol (PVA), Sodium Hydroxide (NaOH), Acetone, and Calcium Chloride (CaCl2) were supplied by Merck KGaA (64271 Damstadt, Germany). Sodium Alginate was used from Qualikems Fine Chem Pvt. Ltd. (Vadodara-3911340, Gujarat, India). Boric Acid, Potassium Dichromate (K2Cr2O7) (purity 99%) was collected from Merck Limited (Mumbai-400018, India). Deionized water was employed in conducting all experiments. The chemicals employed in this experiment were used without further purification.

2.2 Egg shell (ES) powder preparation

The egg shells were collected, cleaned to eliminate dirt, and then dried in an oven for 24 h at 105 °C before being ground into powder using a crushing machine. Using a micro-sieve set to a mesh size of 150 µm, the powdered egg shells were prepared for storage.

2.3 Bijoypur clay (BC) powder preparation

The clay was dried at 105 °C for 24 h in an oven to get rid of any wetness, and then it was ground up using a breaking machine to make the fine powder. To activate the clay and wash away the grime, 6 h were spent in a stirrer at a speed of 1500 revolutions per minute while adding 3 M HCl. It was then washed with deionized water until the pH was neutral, filtered, and baked at 105 °C for 24 h to eliminate moisture. After being dried, the clay was ground once again and sieved through a micro-sieve set to a mesh size of 150 µm.

2.4 Eggshell and Bijoypur clay composite powder preparation

Powdered eggshell and Bijoypur clay in various proportions (10:0, 9:1, 8:2, 7:3, 6:4) were combined with deionized water and agitated for 1 h at 200 rpm speed before undergoing drying in an oven set to 105 °C. Then, the powder was made by grinding the combination and heating it in a furnace for 4 h at 550 °C.

2.5 Composite bead preparation

A homogeneous solution of 5% (w/v) clear polyvinyl alcohol (PVA) and 1% (w/v) of sodium alginate (SA) were prepared. Then, 30 mL of distilled water was added to 0.5 g of prepared composite powder and kept in an ultrasonic machine for an hour. The solution of composite powder was unified with a clear PVA and SA mixture. The composition was kept in a stirrer at the temperature of 50 °C and 200 rpm. The solution was thickened by continuous heating. After 2 h, a uniform, sticky polymer material was ready to be used to make beads. A 6% Boric acid solution was heated to 50 °C and mixed at a speed of 200 rpm for 30 min. Then 3% of Calcium chloride (CaCl2) was added into it and stirred again at 50 °C temperature and 200 rpm for the time period of 30 min. The prepared thickened composite solution fell dropwise into the prepared boric acid and CaCl2 solution and stirred gently to form gelation and protect from agglomeration. After the gelation of the beads had been completed, these were thoroughly washed several times with deionized water to eliminate any unbound compounds and then filtrated to remove any remaining water. The beads residue was then dried at 60 °C for 12 h and ready to be used as adsorbent.

2.6 Preparation of synthetic wastewater

To create a Cr (VI) stock solution (200 ppm 1 L), the required quantity of K2Cr2O7 (Molecular weight 294.185 and purity 99%) was dissolved in the exact volume of de-ionized water. After that, de-ionized water was added to dilute the initial solution to provide 5, 10, 15, 25, and 50 ppm standard solutions for a calibration curve. The concentration of Cr (VI) was determined using atomic adsorption spectrophotometer (AAS).

2.7 Batch experiments

To evaluate adsorption, the prepared beads were used. For Cr (VI), adsorption capacity and efficiency were measured for a range of factors including starting concentration, pH, adsorbent dose, contact duration, and temperature as well as the percentage of composite forming materials used. The pH ranged from 1.5 to 9, the adsorbent dosage ranged from (0.67–2.23 g/L), the initial concentrations were in 25, 50, 75, and 100 ppm, the contact period ranged from 10 to 240 min, and the temperature ranged from 25 to 65 °C with a difference of 10 °C, and share of Clay incorporated in Egg-Shell-Clay composite adsorbent (0–40%) were used. A filter was used to remove the beads from the treated Cr (VI) containing solution before the absorbance was measured. Using Eqs. 1 and 2, the adsorption capacity and efficiency in percent were determined.

where C0 (mg/L) and Ce (mg/L) represent the initial and equilibrium concentrations of Cr (VI), respectively. V represents the volume of the solution that was used (in liters), and m (g) represents the weight of the adsorbent that was used [36]. After the adsorption, the Cr (VI) ions were desorbed from the adsorbent with 1 mol L−1 H2SO4 as an eluent. The chromium was then reduced to Cr(III) using Sodium metabisulfite.

2.8 Equipment

The Fourier Transform Infrared (FT-IR) spectrometer (Model: ALPHA II, Platinum-ATR, BRUKER, Germany & Model: IRPrestige-21, Shimadzu Corporation, Japan) was used within the specified range of 4000 to 400 cm−1 wavelength to investigate the functional groups of adsorbent and its interactions with chromium (VI). X-ray diffractometer (Model: Ultima IV, Rigaku, Japan) was used to analyze the crystalline phase in the adsorbent. The measurement was taken in the continuous mode; radiation used: Cu Kα, wavelength used: 1.5406 A°, operated at 8.04 keV, 40 mA; scanning rate of 3.0° min−1 over a 2θ range of 10–70°; and scan width was 0.02°. Thermo gravimetric Analysis (Instrument Model: TGA 8000, PerkinElmer, Netherland) was carried out to know the thermal response of the adsorbent. To regulate the inert atmosphere, nitrogen was used and the temperature ranged from 25 to 800 °C and at a heating rate of 20 °C/min. Field Emission Scanning Electron Microscopy (FESEM) with Energy Dispersive X-ray (EDX) Spectroscopy Analysis (Model: JSM-7610F, JEOL Ltd., Japan) was used to examine the surface of adsorbent before and after adsorption of Cr (VI) in various magnifications and then the elemental composition changes were also analyzed. The amount of chromium present in reference samples was calculated using a UV–visible Spectrophotometer (UV1011M028, Varian Australia PTY LTD, Australia).

3 Results and discussion

3.1 Characterization of composite bead

3.1.1 FT-IR analysis of composite bead

Peaks in the FTIR spectroscopy of adsorbent constructed of eggshell and clay were found at 3433.29, 2929.87, 2380.15, 2274.07, 1627.92, 1429.25, 1111.0, 659.66, and 480.28 cm−1. As shown by the attribution of strong bands between 3400 and 3750 cm−1 to the hydroxyl bond (O–H), Cr (VI) interacted with the OH functional group [37]. Absorption bands at 3433, 693, and 480 cm−1 (rather than 3696, 3622, 3450, 1033, 914, 790, 693, 538, and 468 cm−1) conclusively showed the presence of kaolinite in all samples [38]. Eggshells include organic layers made up of amino acids, as evidenced by bands observed at 2926 cm−1 (C–H vibrations), which were compatible with experimental bands at 2929 cm−1 [39]. For amines and amides in the protein fiber of ES, N–H peaks of 2380.15 cm−1 and 2274.07 cm−1, respectively, have been reported [40]. The stretching of an amide carbonyl group was linked to the experimental bands (1627 cm−1) and the bands at 1645 cm−1 [41]. The wide stretching frequency of the C=O in carbonate ions, 1429 cm−1 was a commonly used approach for detecting carbonate-based goods [42]. 480.28–659.66 cm−1, 1111 cm−1, and 1429.25 cm−1 were possible ranges for the peak in the adsorbent that corresponded to the asymmetric stretching vibrations of the Si–O–Si, Si–O–Al, and Si–O–Mg bonds, including the bending vibrations of the Si–O bond inside the structure. [43]. In Fig. 1, evidence was seen of Cr (VI) adsorption on composite beads in the form of discrepancies between FT-IR spectra recorded before and following the adsorption process. The adsorption peaks showed fine-drawn changes in the range and intensity after the adsorption of Cr (VI) on the adsorbent which exhibited that the adsorption process was physical, to which reciprocal actions between the Cr (VI) ions and the functional groups of the adsorbent were as feeble forces as van der Waals [44].

3.1.2 Composite bead's XRD analysis

The bead’s XRD pattern having both narrow and wide peaks, indicated the polymer was predominantly semi-crystalline. Due to its amorphous nature, the widest peak was found at 21.13° for \(2\uptheta\) shown in Fig. 2, which matched with the peak for quartz minerals present in clay but in sharp form [45]. The crystalline structure of calcium carbonate exhibits a strong, large peak at 29.54° for \(2\uptheta\) which was analogous to calcium carbonate at 29.47° for \(2\uptheta\) [46].

3.1.3 TGA analysis of adsorbent

According to TGA results shown in Fig. 3, it was evident that moisture content retained in the adsorbent and other volatile materials adhered to it was removed at the commencing stage of heating (65–185)°C, and 19% weight was lost. Upon heating on adsorbent from 185 to 415 °C, another 23% of the weight disappeared as the melting temperatures of the adsorbent’s constituents sodium alginate, PVA, and membrane-associated with ES were supposed to be decomposed in this range of temperature. In between 415 and 515 °C temperature, an extra 22% weight was lost and it was not until the temperature hit 515 °C that the weight loss was seen. Most of the adsorbent’s weight was lost before 515 °C as it comprised PVA and sodium alginate in major share.

3.1.4 Composite bead’s FESEM with EDX

Images of the bead surfaces before and after adsorption of chromium (VI) were captured using an FESEM at 5.0 kV and at 25 and 5000 times their usual magnifications. FESEM images at magnification of 25× and 5000× (Fig. 4) showcased the existence of numerous pore structures on the surface of the composite bead adsorbent before adsorption. It was owing to the pore structure of the bead that chromium (VI) was able to be absorbed by it. FESEM images delineated at a magnification of 25× and 5000× after adsorption showed a reduction in porosity and a layer was developed on the bead's surface due to Cr (VI) adsorption (Fig. 5).

Through the analysis of the adsorbent’s EDX, it was determined that Cr (VI) had undergone adsorption on its surface. As shown in Table 1, the amount of Cr (VI) adsorbed from the K2Cr2O7 stock solution was increased on the surface of the bead adsorbent.

An increase in the percentage of different metals after adsorption of Cr (VI) using alginate beads may indicate that there is an ion exchange process occurring between the beads and the solution. This means that some of the metal ions from the beads are released into the solution and replaced by the Cr (VI) ions from the solution. This can enhance the adsorption capacity and stability of the alginate beads.

3.2 Adsorption studies for Cr (VI)

3.2.1 Effect of the ratio of ES (eggshell) and BC (Bijoypur clay) used in adsorbent

It was shown that blending ES with BC in varying proportions produced a composite material with superior performance than utilizing ES alone. The composite was able to soak up a greater quantity of Cr (VI) because it had a greater number of different functional groups with a strong affinity for adsorbing the metal. The absorbent capabilities of the ES-BC composite were enhanced by the incorporation of functional groups such as –OH, –Al–O, –Si–O, N–H, and C=O. In contrast, a too-large increase in the proportion of BC proved ineffectual since only the quantity of functional groups, not types was raised. Figure 6 displayed the results of the adsorption studies, which found that a mixture of 20% BC and 80% ES was the most effective. In this study, a stock solution concentration of 50 ppm, a pH of 5.86 (pH of stock solution of K2Cr2O7, without any modification), a dosage of 1.0 g/L, a rotational speed of 150 rpm, contact time of 120 min, and a temperature of 25 °C were employed.

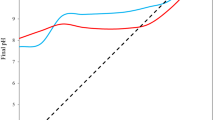

3.2.2 Effect of pH

The pH value is the most important factors that contribute to the adsorption efficiency [47]. The adsorption capability and removal of Cr (VI) caused a shift in the solution pH shown in Fig. 7 which went from 1.5 to 9. During this study, all other variables (ratio of adsorbent’s constituents 20% BC: 80% ES, stock solution concentration of 50 ppm, a dosage of 1.0 g/L, a rotational speed of 150 rpm, contact time 120 min and a temperature of 25 °C) were kept constant. At pH 1.5, maximum % of removal and capacity were observed which were 84.40% and 42.20 (mg/g) respectively. The Cr (VI) ion adsorption efficiency was decreased at higher pH values using the ES-BC composite adsorbent. The handiness of OH− ions concentration increased with the increasing pH which contested with Cr (VI) ions [48]. At elevated pH levels, metal ions, including the Cr (VI) ions, resulted in the formation of precipitates, leading to a reduction in ion concentration [49]. Furthermore, the alteration in the surface charge of the adsorbent, shifting from positive to negative, boosted the electrostatic force of repulsion between ions and the surface of the sorbent and was another cause of low Cr (VI) adsorption [50].

3.2.3 Effect of adsorbent dosage

It was shown in Fig. 8 that a higher bead dosage improved Cr (VI) adsorption and the optimum value was found for 1.17 g/L. In fact, with the rise of adsorbent dosage, active sites were also increased and the diffusion of the metal ions was promoted onto the adsorbent which signified higher removal efficiency [51]. As the dosage of beads was increased from 0.67–2.23 g/L, keeping all other variables constant (ratio of adsorbent’s constituents 20% BC: 80% ES, a pH of 1.5, stock solution concentration of 50 ppm, a rotational speed of 150 rpm, contact time 120 min and a temperature of 25 °C), so too did the rate at which Cr (VI) was flushed out of the system. Increasing the dosage, however, decreased adsorption capacities while leaving all other factors the same. A similar trend was reported by some authors that with increasing of adsorbent dose, the adsorption of Cr (VI) was also increased [52] This was attributed to the fact that there was no Cr (VI) available in the solution for further adsorption onto the additional adsorbent [53]. Figure 8 shows that at a dosage of 2.33 g/L, the maximum removal was 90.42 percent and the maximum capacity was 19.38 mg per gram. For optimal performance, maximum doses, clearance rates, and capacities were determined. A maximum capacity of 35.62 mg/g and an optimal removal rate of 82.2% was observed at an optimal dosage of 1.17 g/L.

3.2.4 Effect of contact time

The effect of contact time (10–240 min.) on the adsorption of Cr (VI) ion using ES-BC adsorbent is shown in Fig. 9. It revealed that with increasing contact time, maintaining other variables (ratio of adsorbent’s constituents 20% BC: 80% ES, a pH of 1.5, a dose of 1.17 g/L, stock solution concentration of 50 ppm, a rotational speed of 150 rpm, and a temperature of 25 °C) constant, Cr (VI) adsorption was increased and after 150 min, the capacity showed little growth as most of the active sites were blocked by the deposition of Cr (VI) ions. During equilibrium, the dwindling number of active sites decreased the driving force for adsorption, eventually resulting in negligible or no further adsorption [54]. Shiao-Shinget et al. showed that the highest elimination efficiency occurred in the initial 5 min [55]

3.2.5 Effect of initial concentration

The effect of the initial concentration of Cr (VI) was illustrated in Fig. 10 maintaining all other conditions at their respective values (ratio of adsorbent’s constituents 20% BC: 80% ES, a pH of 1.5, a dose of 1.17 g/L, contact time of 150 min., a rotational speed of 150 rpm, and a temperature of 25 °C). With the increase of initial Cr (VI) concentration, the elimination efficiency was reduced [56]. Higher removal percentages were seen at lower initial concentrations and as the initial concentration rose from 25 to 100%, the % removal declined from 87.34 to 73.35%. The decline in adsorption efficiency may be attributed to a lack of sufficient active sites to accommodate a significantly higher amount of accessible metal in the solution [57] 58.2 ppm concentration of Cr (VI) was found to be optimal in the graph, with elimination of 80.72% and capacity of 46.5 mg/g.

3.2.6 Effect of temperature

The impact of temperature on Cr (VI) adsorption was studied in the temperature range of 25–65 °C and demonstrated in Fig. 11 maintaining all other variables (ratio of adsorbent’s constituents 20% BC: 80% ES, a pH of 1.5, a dose of 1.17 g/L, contact time of 150 min., a rotational speed of 150 rpm, and initial concentration of 58.2 ppm) constant. The percentage removal declined from 84.43 to 69.29% with the temperature elevated from 25 to 65 °C. The highest rate of adsorption was at 25 °C and decreased with increasing temperature. This study explored the adsorption rate above 25 °C, as the experimental setup could not maintain lower temperatures. Adsorption inhibition with increasing temperature indicated that Cr (VI) was adsorbing through an external heating process [58].

3.2.7 Adsorption isotherm study

The sorption isotherm summarizes the relationship between the quantity of solute adsorbed by a unit weight of solid sorbent and the amount of solute still present in the solution at equilibrium [59]. In the current investigation, the sorption behavior of Cr (VI) was measured using the Langmuir, Freundlich, and Temkin models for which data was provided in Table 2. The linear isotherm equation of Langmuir is expressed as follows:

where qe is the absorption capacity at equilibrium (mg/g), qm is the Langmuir maximum adsorption capacity (mg/g), KL is the Langmuir constant, and Ce is the Cr (VI) Concentration at equilibrium (mg/L). Again, RL, a significant parameter of the Langmuir equation, narrates the sorption intensity. The process may be allowed as unfavorable, linear, favorable, and irreversible if RL \(>\) 1, RL = 1, 0 < RL < 1, RL = 0. To know the value of RL, the following equation was used:

where C0 represents the initial concentration of Cr (VI) ion.

To analyze Langmuir’s isotherm, Ce versus Ce/qe graph was plotted in Fig. 12a.

Langmuir isotherm comprises monolayer homogeneous adsorption of the adsorbed substance with some affinity on all binding sites of the adsorbent [60]. The value of the correlation coefficient, R2, was 0.9497, which was slightly far from the theoretical value 1. The Langmuir constant, KL (L/mg) was equal to 0.05879, and the maximal theoretical adsorption capacity qm (mg/g) of the adsorbent was calculated using the slope of a linear equation, and was found to be 122.1. The separation factor RL value was 0.98341, i.e. between 0 to 1 indicating a favorable reaction and nearly close to a linear process.

Freundlich’s adsorption isotherm is typically used to look into the adsorption behavior for the heterogeneous surface and granted multilayer adsorption [61]. The linearized form of Freundlich isotherm can be described as the following equation:

where KF and n are the Freundlich model constants. The values of KF and 1/n were calculated from the slope and intercept of the plot of ln qe versus ln Ce respectively, shown in Fig. 12b. If 1/n \(>\) 1; 0 < 1/n < 1; 1/n = 1; 1/n = 0, the process is unfavorable, favorable, linear, and irreversible respectively [62].

In the present study, the value of the adsorption intensity, 1/n was 0.62602, which divulged the favorable nature of the adsorption process. The R2 value for the Freundlich isotherm was 0.9825, which was very close to 1, and suggested that the Freundlich isotherm model was of superior fit for Cr (VI) adsorption compared to Langmuir isotherm model using the ES-BC adsorbent. Yusuff et al. [63] obtained a similar outcome using an anthill-eggshell composite (AEC) for Cr(VI) adsorption, demonstrating initial concentrations from 34.2 to 165.8 mg/L, with Freundlich model as the best fit and AEC having a maximum adsorption capacity of 12.99 mg/g. Compared to this study, the maximum adsorption capacity of ES-BC showed better results. In another study, a composite of bentonite clay and MnFe2O4 was employed for the adsorption of Cr (VI), demonstrating conformity with the Freundlich model and showcasing a maximum adsorption capacity of 178.57 mg/g [44]. Therefore, a composite comprising clay forms a heterogeneous surface and facilitates multilayer adsorption processes.

The Temkin isotherm model is built relying on the hypothesis of a multi-layer adsorption process [64]. The linear form of the Temkin isotherm equation is expressed as follows [62].

where KT = \(\frac{\mathrm{R T}}{{{\text{b}}}_{{\text{T}}}}\); T is the absolute temperature of the solution in Kelvin (K), R is the universal gas constant (8.314 Jmol−1 K−1), KT is the equilibrium binding constant related to maximum binding energy (L mg−1), aT is the Temkin isotherm constant (L/g), and bT is the Temkin constant associated with the adsorption heat (J/mol). Evaluation of Temkin’s isotherm with plotting ln Ce versus qe graph was shown in Fig. 12c.

The calculated values for KT and BT were 0.60174 L mg−1 and 26.3482 J mol−1, with an R2 value of 0.9692. The correlation coefficient value (R2) revealed that Temkin isotherm was not faithfully suitable for Cr (VI) adsorption.

3.2.8 Kinetics study

In this current investigation, to anticipate the rate of Cr (VI) binding onto composite bead adsorbent, the compatibility of equilibrium data was assessed by employing pseudo-first-order and pseudo-second-order kinetic models. The linear forms of rate equations are stated as:

where adsorption capacity at time t is represented by qt (mg/g), the pseudo-first-order and pseudo-second-order rate constants, respectively [g/(mg/min)], are denoted by K1 and K2. The graphical representations for the pseudo-first-order and pseudo-second-order kinetics were used to derive the k1, k2, qe, and correlation coefficients (R2) [40]. At 25, 50, 75, and 100 ppm, a pseudo-first-order reaction rate was observed for the adsorption of Cr (VI). The model was evaluated by plotting ln (qe − qt) against time which was shown in Fig. 13a. Furthermore, at the same concentrations, the findings were found consistent with the pseudo-second-order reaction rate by plotting t/qt against time (t) shown in Fig. 13b.

The rate at which adsorption took place was observed using data shown in Table 3. As the value of correlation coefficient (R2) in the case of pseudo-second-order reaction was very close to 1, the investigation revealed that the adsorption of Cr (VI) could be better fitted with the experimental data and suggested a tendency towards the chemisorption process. Research by Ahmadi et al. [44], Yusuff et al. [63], and Hasan et al. [65] found that when using eggshell composite and clay composite, the adsorption of Cr(VI) followed a kinetic model that supported the pseudo-second-order model.

3.2.9 Thermodynamics study

Thermodynamic parameters in adsorption study are crucial because these provide insights into the energy changes and feasibility of the adsorption process. The adsorption of Cr (VI) on the adsorbent was assessed by determining various thermodynamic parameters including changes in the enthalpy (ΔH°), entropy (ΔS°), and Gibbs free energy (ΔG°) which could be stated as follows:

where R is the universal gas constant (8.314 Jmol−1 K−1); T is the absolute temperature of the solution in Kelvin (K); KL is the equilibrium constant; and the changes in enthalpy (J/mol), entropy (J/mol K), and Gibbs free energy (J/mol) are represented by the values of ΔG°, ΔH°, and ΔS°, respectively.

In the course of the study, adsorption experiments were executed at temperatures of 25 °C (298° K), 35 °C (308° K), 45 °C (318° K), 55 °C (328° K), and 65 °C (338° K).

A graph of 1/ T vs ln KL was plotted shown in Fig. 14. In Table 4 data for the thermodynamic investigation of Cr (VI) adsorption and in Table 5 thermodynamic parameters for Cr (VI) adsorption were shown.

It was evident that the process was exothermic because of the negative value of enthalpy. Since the reaction was unfavorable at higher temperatures, and the negative Gibbs free energy values dropped as the temperature rose, the process was spontaneous.

3.3 Comparison with other studies

The value of the adsorption capacity (mg/g) found in this study was compared with other studies reported in Table 6 and was found quite competitive.

4 Conclusion

Evaluating the efficacy of biocomposite beads in adsorbing Cr (VI) from a synthetic waste solution was the key motivation for this research. Bead composites were successfully created based on eggshell and Bijoypur clay, as their form, supporting qualities, and basic compositions were determined by FTIR, XRD, TGA, and FESEM with EDX analyses. The most favorable conditions for Cr (VI) adsorption were identified as 25 °C temperature, a pH of 1.5, composite adsorbent comprised of 20% clay and 80% eggshell with a dose of 1.17 g/L, 150 min of contact time (2.5 h), and initial concentration of 58.2 ppm. According to the findings of the study on the equilibrium isotherm, the Freundlich model offered a better fit to the sorption data than both the Langmuir and Temkin models, which indicated the information about surface heterogeneity of the adsorbent. The value of 1/n was found to be 0.62602, which divulged the favorable nature of the adsorption process. The kinetic data was well-fitted to the pseudo-second-order kinetic model, suggesting a tendency towards chemisorption. It was found that 122.1 mg/g was the maximum monolayer Cr (VI) adsorption capacity at 25 °C and as the enthalpy (H°) and Gibbs free energy (G°) changes were negative, it was apparent that the biosorption was an exothermic, practical, and spontaneous process. So, the egg-shell and clay composite holds significant potential for efficient utilization as an adsorbent for the treatment of Cr (VI) containing aqueous solution.

Data availability

This article includes all the data generated or analyzed during the study.

References

Parvin F, Haque MM, Tareq SM. Recent status of water quality in Bangladesh: a systematic review, meta-analysis and health risk assessment. Environ Challenges. 2022;6: 100416. https://doi.org/10.1016/j.envc.2021.100416.

Schwarzenbach RP, et al. Global water pollution and human health. Annu Rev Environ Resour. 2010;35:109–36. https://doi.org/10.1146/annurev-environ-100809-125342.

Moysés FS, et al. Effect of tannery effluent on oxidative status of brain structures and liver of rodents. Environ Sci Pollut Res. 2017;24:15689. https://doi.org/10.1007/s11356-017-9149-4.

Ahmed MD, Maraz KM. Benefits and problems of chrome tanning in leather processing: approach a greener technology in leather industry. Mater Eng Res. 2021;3(1):156–64. https://doi.org/10.25082/MER.2021.01.004.

Hedberg YS, Liden C, Wallinder IO. Chromium released from leather—I: exposure conditions that govern the release of chromium (III) and chromium (VI). Contact Dermatitis. 2015;2(4):206–15. https://doi.org/10.1111/cod.12329.

Thanikaivelan P, et al. Recent trends in leather making: processes, problems, and pathways. Crit Rev Environ Sci Technol. 2005;35(1):37–79. https://doi.org/10.1080/10643380590521436.

Beghetto V, et al. The leather industry: a chemistry insight part I: an overview of the industrial process. Sci Ca’Foscari. 2013;1:13–22. https://doi.org/10.7361/SciCF-448.

Zhang C, et al. A salt-free and chromium discharge minimizing tanning technology: the novel cleaner integrated chrome tanning process. J Clean Prod. 2016;112:1055–63. https://doi.org/10.1016/j.jclepro.2015.07.155.

Zhang J, Chen W. A rapid and cleaner chrome tanning technology based on ultrasound and microwave. J Clean Prod. 2020. https://doi.org/10.1016/j.jclepro.2019.119452.

Jiang B, et al. Synergetic transformations of multiple pollutants driven by Cr (VI)–sulfite reactions. Environ Sci Technol. 2015;49(20):12363–71. https://doi.org/10.1021/acs.est.5b03275.

Bin H, et al. Research progress of heavy metal pollution in China: sources, analytical methods, status, and toxicity. Chinese Sci Bull. 2013;58:134–40. https://doi.org/10.1007/s11434-012-5541-0.

Pradhan D, et al. Recent bioreduction of hexavalent chromium in wastewater treatment: A review. J Ind Eng Chem. 2017;55:1–20. https://doi.org/10.1016/j.jiec.2017.06.040.

Tchounwou PB, et al. Heavy metal toxicity and the environment. Mol Clin Environ Toxicol Springer Basel. 2012;101:133–64. https://doi.org/10.1007/978-3-7643-8340-4_6.

Dayan AD, Paine AJ. Mechanisms of chromium toxicity, carcinogenicity and allergenicity: review of the literature from 1985 to 2000. Hum Exp Toxicol. 2001;20(9):439–51. https://doi.org/10.1191/096032701682693062.

Hu X, et al. Adsorption of chromium (VI) by ethylene diamine-modified cross-linked magnetic chitosan resin: isotherms, kinetics and thermodynamics. J Hazard Mater. 2011;185:306–14. https://doi.org/10.1016/j.jhazmat.2010.09.034. (ISSN 0304-3894).

Samiey B, et al. Organic-inorganic hybrid polymers as adsorbents for removal of heavy metal ions from solutions: a review. Materials. 2014;7(2):673–726. https://doi.org/10.3390/ma7020673.

Wang S, Peng Y. Natural zeolites as effective adsorbents in water and wastewater treatment. Chem Eng J. 2010;156(1):11–24. https://doi.org/10.1016/j.cej.2009.10.029.

Jang EH, Pack SP, Kim I, et al. A systematic study of hexavalent chromium adsorption and removal from aqueous environments using chemically functionalized amorphous and mesoporous silica nanoparticles. Sci Rep. 2020;10:5558. https://doi.org/10.1038/s41598-020-61505-1.

Gui CX, et al. Sandwich like magnesium silicate/reduced graphene oxide nanocomposite for enhanced Pb2+ and methylene blue adsorption. ACS Appl Mater Interfaces. 2014;6(16):14653–9. https://doi.org/10.1021/am503997e.

Pan B, et al. Development of polymeric and polymer-based hybrid adsorbents for pollutants removal from water. Chem Eng J. 2009;151(1–3):19–29. https://doi.org/10.1016/j.cej.2009.02.036.

USBR Hexavalent Chromium Treatment Technologies; U.S. Department of the Interior Bureau of Reclamation Research and Development Office: Denver, CO, USA. 2018.

Faghihian H, Bowman RS. Adsorption of chromate by clinoptilolite exchanged with various metal cations. Water Res. 2005;39:1099–104. https://doi.org/10.1016/j.watres.2004.12.010.

Rengaraj S, et al. Removal of chromium from water and wastewater by ion exchange resins. J Hazard Mater. 2001;87(1–3):273–87. https://doi.org/10.1016/s0304-3894(01)00291-6.

Wang Y, et al. Cr (VI) adsorption on activated carbon: Mechanisms, modeling and limitations in water treatment. J Environ Chem Eng. 2020. https://doi.org/10.1016/j.jece.2020.104031.

Gode F, Pehlivan EA. comparative study of two chelating ion-exchange resins for the removal of chromium (III) from aqueous solution. J Hazard Mater. 2003;100(1–3):231–43. https://doi.org/10.1016/S0304-3894(03)00110-9.

Faust SD, Aly OM. Chemistry of water treatment. 2nd ed. Taylor & Francis Group: CRC Press; 2018. https://doi.org/10.1201/9781315139265.

Chen Q, et al. One-step synthesis of carbon quantum dot-carbon nanotube composites on waste eggshell-derived catalysts for enhanced adsorption of methylene blue. J Environ Chem Eng. 2021. https://doi.org/10.1016/j.jece.2021.106222.

Rajoriya S, et al. Adsorption of methyl red dye from aqueous solution onto eggshell waste material: Kinetics, isotherms and thermodynamic studies. Curr Res Green Sustain Chem. 2021. https://doi.org/10.1016/j.crgsc.2021.100180.

Islam MM, et al. A comprehensive review of the current progress of chromium removal methods from aqueous solution. Toxics. 2023;11(3):252. https://doi.org/10.3390/toxics11030252.

Lee JI, et al. Restoring phosphorus from water to soil: using calcined eggshells for P adsorption and subsequent application of the adsorbent as a P fertilizer. Chemosphere. 2022;287(Pt 3): 132267. https://doi.org/10.1016/j.chemosphere.2021.132267.

Pettinato M, et al. Eggshell: a green adsorbent for heavy metal removal in an MBR system. Ecotoxicol Environ Saf. 2015;121:57–62. https://doi.org/10.1016/j.ecoenv.2015.05.046.

Mashangwa TD, et al. Determination of the efficacy of eggshell as a low-cost adsorbent for the treatment of metal laden effluents. Int J Environ Res. 2017;11:175–88. https://doi.org/10.1007/s41742-017-0017-3.

Gu S, et al. Clay mineral adsorbents for heavy metal removal from wastewater: a review. Environ Chem Lett. 2019;17:629–54. https://doi.org/10.1007/s10311-018-0813-9.

Biswas S, et al. Application of chitosan-clay biocomposite beads for removal of heavy metal and dye from industrial effluent. J Compos Sci. 2020;4(1):16. https://doi.org/10.3390/jcs4010016.

Shirzad-Siboni M, et al. Preparation, characterization and application of a CTAB-modified nanoclay for the adsorption of an herbicide from aqueous solutions: Kinetic and equilibrium studies. C R Chim. 2015;18:204–14. https://doi.org/10.1016/j.crci.2014.06.004.

Chen Y, et al. Reduction and removal of chromium VI in water by powdered activated carbon. Materials (Basel). 2018;11(2):269. https://doi.org/10.3390/ma11020269.

Balan E, et al. First-principles modeling of the infrared spectrum of kaolinite. Am Miner. 2001;86(11–12):1321–30. https://doi.org/10.2138/am-2001-11-1201.

Yousefi B, et al. Assessing the reliability of an automated system for mineral identification using LWIR hyper spectral infrared imagery. Miner Eng. 2020;155(4): 106409. https://doi.org/10.1016/j.mineng.2020.106409.

Tizo MS, et al. Efficiency of calcium carbonate from eggshells as an adsorbent for cadmium removal in aqueous solution. Sustain Environ Res. 2018;28:326–32. https://doi.org/10.1016/j.serj.2018.09.002.

Praipipat P, et al. Chicken and duck eggshell beads modified with iron (III) oxide-hydroxide and zinc oxide for reactive blue 4 dye removal. Arab J Chem. 2022. https://doi.org/10.1016/j.arabjc.2022.104291.

Coates J. Interpretation of infrared spectra, a practical approach. In: Meyers RA, editor. Encyclopedia of Analytical Chemistry. Chichester: John Wiley & Sons Ltd.; 2000. p. 10815–37. https://doi.org/10.1002/9780470027318.a5606.

Hassen AA, et al. Utilization of chicken eggshell waste as a bio-filler for thermoplastic polymers: thermal and mechanical characterization of polypropylene filled with naturally derived CaCO3. Polym Polym Compos. 2015;23(9):653–62. https://doi.org/10.1177/096739111502300908.

Thue PS, et al. Synthesis and characterization of a novel organic-inorganic hybrid clay adsorbent for the removal of acid red 1 and acid green 25 from aqueous solutions. J Clean Prod. 2018;171:30–44. https://doi.org/10.1016/j.jclepro.2017.09.278.

Ahmadi A, Foroutan R, Esmaeili H, Tamjidi S. The role of bentonite clay and bentonite clay@MnFe2O4 composite and their physico-chemical properties on the removal of Cr(III) and Cr(VI) from aqueous media. Environ Sci Pollut Res Int. 2020;27(12):14044–57. https://doi.org/10.1007/s11356-020-07756-x.

Kłosek-Wawrzyn E, Małolepszy J, Murzyn P. Sintering behavior of Kaolin with Calcite. Procedia Engineering. 2013;57:572–82. https://doi.org/10.1016/j.proeng.2013.04.073.

Hamdi WJ, Habubi NF. Preparation of epoxy chicken eggshell composite as thermal insulation. J Aust Ceram Soc. 2018;54:231–5. https://doi.org/10.1007/s41779-017-0145-4.

Abshirini Y, et al. Enhancement removal of Cr (VI) ion using magnetically modified MgO nanoparticles. Mater Res Expr. 2019. https://doi.org/10.1088/2053-1591/ab56ea.

Zhanh LH, et al. Magnetic hollow carbon nanospheres for removal of chromium ions. Journal of Materials Chemistry A. 2013. https://doi.org/10.1039/c3ta10430c.

Geetha P, et al. Green synthesis and characterization of alginate nanoparticles and its role as a biosorbent for Cr(VI) ions. J Mol Struct. 2016;1105:54–60. https://doi.org/10.1016/j.molstruc.2015.10.022.

Du Y, et al. Flower-, wire-, and sheet-like MnO2-deposited diatomites: Highly efficient absorbents for the removal of Cr (VI). J Environ Sci. 2015;29:71–81. https://doi.org/10.1016/j.jes.2014.06.047.

Bedemo A, Chandravanshi BS, Zewge F. Removal of trivalent chromium from aqueous solution using aluminum oxide hydroxide. Springer Plus. 2016. https://doi.org/10.1186/s40064-016-2983-x.

Owalude SO, Tella AC. Removal of hexavalent chromium from aqueous solutions by adsorption on modified groundnut hull Beni-Suef University. J Basic Appl Sci. 2016;5(4):377–88. https://doi.org/10.1016/j.bjbas.2016.11.005.

Qhubu MC, et al. Preparation, characterization and application of activated clay biochar composite for removal of Cr(VI) in water: isotherms, kinetics and thermodynamics. Mater Chem Phys. 2021. https://doi.org/10.1016/j.matchemphys.2020.124165.

Wu Y, et al. Adsorption of hexavalent chromium from aqueous solutions by graphene modified with cetyltrimethylammonium bromide. J Colloid Interface Sci. 2013;394:183–91. https://doi.org/10.1016/j.jcis.2012.11.049.

Chen S, et al. Reduction of chromate from electroplatingwastewater from pH 1 to 2 using fluidized zero valentiron process. J Hazard Mate. 2007;142:362–7. https://doi.org/10.1016/j.jhazmat.2006.08.029.

Ngah WSW, Hanafiahin MA. Removal of heavy metal ions from wastewater by chemically modified plant wastes as adsorbents: a review. Bioresour Technol. 2008;99(10):3935–48. https://doi.org/10.1016/j.biortech.2007.06.011.

Adebisi GA, Chowdhury ZZ, Alaba PA. Equilibrium, kinetic, and thermodynamic studies of lead ion and zinc ion adsorption from aqueous solution onto activated carbon prepared from palm oil mill effluent. J Clean Prod. 2017;148:958–68. https://doi.org/10.1016/j.jclepro.2017.02.047.

Chen L, et al. Study on removal of Microcystis aeruginosa and Cr (VI) using attapulgite-Fe3O4 magnetic composite material (MCM). Algal Res. 2021. https://doi.org/10.1016/j.algal.2021.102501.

Al-Sou’od K. Adsorption isotherm studies of chromium (VI) from aqueous solutions using Jordanian pottery materials. APCBEE Proc. 2012;1(1):116–25. https://doi.org/10.1016/j.apcbee.2012.03.020.

Marques JL Jr, et al. Removal of Al (III) and Fe (III) from binary system and industrial effluent using chitosan films. Int J Biol Macromol. 2018;120(Pt B):1667–73. https://doi.org/10.1016/j.ijbiomac.2018.09.135. (Epub 2018 Sep 23).

Darweesh MA, et al. Adsorption isotherm, kinetic, and optimization studies for copper (II) removal from aqueous solutions by banana leaves and derived activated carbon. S Afr J Chem Eng. 2022;40:10–20. https://doi.org/10.1016/j.sajce.2022.01.002.

Borhade AV, Kale AS. Calcined eggshell as a cost effective material for removal of dyes from aqueous solution. Appl Water Sci. 2017;7:4255–68. https://doi.org/10.1007/s13201-017-0558-9.

Yusuff AS, et al. Synthesis and characterization of anthill-eggshell composite adsorbent for removal of hexavalent chromium from aqueous solution. Environ Sci Pollut Res. 2018;25:19143–54. https://doi.org/10.1007/s11356-018-2075-2.

Wang J, Guo X. Adsorption isotherm models: classification, physical meaning, application and solving method. Chemosphere. 2020. https://doi.org/10.1016/j.chemosphere.2020.127279.

Hasan AF, et al. Enhanced adsorption of chromium (VI) from aqueous medium by basic nanohydroxyapatite/chitosan composite based on egg shell. Desalin Water Treat. 2020;206:235–49. https://doi.org/10.5004/dwt.2020.26306.

Abatan OG, et al. Performance of eggshells powder as an adsorbent for adsorption of hexavalent chromium and cadmium from wastewater. SN Appl Sci. 2020. https://doi.org/10.1007/s42452-020-03866-w.

Ashour EA, Tony MA. Eco-friendly removal of hexavalent chromium from aqueous solution using natural clay mineral: activation and modification effects. SN Appl Sci. 2020. https://doi.org/10.1007/s42452-020-03873-x.

Adebayo GB, Adegoke HI, Fauzeeyat S. Adsorption of Cr(VI) ions onto goethite, activated carbon and their composite: kinetic and thermodynamic studies. Appl Water Sci. 2020;10:213. https://doi.org/10.1007/s13201-020-01295-z.

Krishna Mohan GV, et al. Removal of chromium (VI) from water using adsorbent derived from spent coffee grounds. Int J Environ Sci Technol. 2019;16:101–12. https://doi.org/10.1007/s13762-017-1593-7.

Kumar ASK, et al. Application of cellulose-clay composite biosorbent toward the effective adsorption and removal of chromium from industrial wastewater. Ind Eng Chem Res. 2012;51(1):58–69. https://doi.org/10.1021/ie201349h.

Weng C, Sharma YC, Chu S. Adsorption of Cr(VI) from aqueous solutions by spent activated clay. J Hazard Mater. 2008;155:65–75. https://doi.org/10.1016/j.jhazmat.2007.11.029.

Akar ST, Yetimoglu Y, Gedikbey T. Removal of chromium (VI) ions from aqueous solutions by using Turkish montmorillonite clay: effect of activation and modification. Desalination. 2009;244:97–108. https://doi.org/10.1016/j.desal.2008.04.040.

Acknowledgements

The authors are grateful to the Institute of Leather Engineering and Technology (ILET), University of Dhaka, Bangladesh, and BCSIR (Bangladesh Council of Scientific and Industrial Research) for providing the necessary support to conduct this research.

Funding

This research was funded by the Ministry of Science and Technology, People’s Republic of Bangladesh, (grant no. 39.00.0000.012.02.007.22.160).

Author information

Authors and Affiliations

Contributions

Prashanta Talukder: Methodology, Writing-original draft preparation, review and editing, funding acquisition; Razia Sultana: Writing-original draft preparation, review and editing; Mustafizur Rahman Naim: Writing review and editing, Resources; Plabon Islam Turzo: Writing-review and editing; Umme Habiba Bodrun Naher: Conceptualization, Methodology, Formal analysis and investigation, Writing—review and editing, Resources, and Supervision. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Talukder, P., Sultana, R., Naim, M.R. et al. Optimization of batch process parameters for chromium (VI) removal from synthetic wastewater using eggshell–clay composite. Discov Appl Sci 6, 291 (2024). https://doi.org/10.1007/s42452-024-05865-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05865-7