Abstract

This study focuses on the effect of partial replacement of volcanic ash (VA) by waste iron powder in the synthesis of phosphate inorganic polymers (PIPs) based of volcanic ashes. For this purpose, 0, 5, 10, 15, and 20% of the waste iron powder were substituted for those of two volcanic ash named MaJ and Mbo. Subsequently, all the powders were mixed with a solution of H3PO4 (6 M) with a liquid/solid mass ratio of 0.45. The raw materials were characterized by XRF, BET, XRD and FTIR. In addition to these characterization techniques, the obtained synthesis products were also characterized by Optical Microscopy. The properties of the 28-day old specimens were evaluated by determining the compressive strength, density, percentage water absorption and porosity. The results obtained show that the increase in iron powder waste leads to a decrease in compressive strength and density and, in parallel, an increase in porosity and water absorption. In combination with the BET analyses, the observation of the optical micrographs shows that for a partial replacement of 10% of the ash powder (Mbo) by the iron powder waste leads to an increase in the specific surface of the synthesis products and an increased presence of voids within the Mbo-based specimens. On the other hand, for the same content, we observe an occupation of the pores within the MaJ-based specimens. All these results show that iron powders wastes lead to an expansion of the pore volumes in our materials and make them more fragile. Therefore, iron powders can be used as a pore-forming agent in the synthesis of porous Mbo-based PIPs and as fillers for MaJ based PIPs.

Highlights

-

WIP powders can be used as pore-forming agents.

-

The synthesis products have a high specific surface areas and water absorption percentage can be favorable for adsorption.

-

PIPS can be used for the pre-treatment of used oils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Phosphate inorganic polymers (PIPs) can be considered as binding systems resulting from a polycondensation reaction between metal oxides or an inorganic material and a phosphate acid hardener [1, 2]. In recent years, much of the work aimed at developing these polymers has used aluminosilicate materials with significant iron, magnesium and calcium oxide contents as solid precursors such as laterites, clays, fly ash and volcanic ash [2,3,4,5,6,7]. Some recent works on the synthesis of PIPs show that the specimens obtained have a rapid onset of setting at room temperature [8,9,10,11] and low percentages of water absorption [12, 13]. Thus, recent works carried out by some researchers [14,15,16,17,18,19], Djobo et al. [20], Dimace et al. [21], Djon Li Ndjock et al. [22], Missota et al. [23], Lemougna et al. [24] and Moussa et al. [25] showed that during the synthesis of these polymers, although acid activation favors rapid solidification of the synthesis products, the presence of iron oxide strongly influences the mechanical properties. Strength values ranging from 17.8 to 56.4 MPa for precursors with a low iron oxide content [26], and from 23 to 105 MPa for those with an even higher content [27] are noted. Among the solid precursors favorable for the synthesis of PIPs, Cameroon abounds with large deposits of volcanic ash that were formed during the volcanic eruptions that its various mountains once experienced [28,29,30]. However, very few works contributing to the valorization of these rocks for the synthesis of phosphate inorganic polymers are recorded [31]. Nevertheless, within this range of work, the recent study of Djobo et al. [32] focuses on the setting and hardening mechanism of volcanic-ash-based phosphate inorganic polymers cured at room temperature showed that iron was the main element taking part in the hardening reaction followed by aluminium, calcium and magnesium while silicon remained inert. Other similar studies show that the presence of iron within the precursors favors the solidification of the synthesized products and consequently contributes massively to the improvement of the compressive strengths of the resulting PIPs [21,22,23, 33]. It is necessary to note that in most of these works, the source of iron mentioned comes from the iron oxides contained in the starting solid precursor. In the same time, Djon Li Ndjock et al. [34] conducted a study on the effect of Al and Fe powder on the formation of foamed cement obtained by phosphoric acid activation of volcanic ash. Contrary to the results of the previously listed works, the authors conclude that the incorporation of a commercial iron powder leads not only to a decrease in compressive strength and density, but also and above all to a formation of pores within the various polymers obtained. In order to find out whether the influence of these properties was due to the presence of iron and not iron oxides, the present study investigates the effect of partial replacement of volcanic ash powders MaJ and Mbo by 0, 5, 10, 15, and 20% of iron powder residues from a welding shop on the properties of PIPs. Depending on the precursors and polymers obtained, the following analyses were performed: XRF, XRD, BET analysis, optical microscopy, compressive strength, bulk density, water absorption and porosity.

2 Experimental procedure

2.1 Raw materials and activated solution

The two varieties of volcanic ash used in this study, MaJ and Mbo, were collected in the localities of Manjo and Mbouroukou respectively in the Moungo department (Littoral Region, Cameroon). The synthesis process of the latter is that used by Dickson et al. [23, 35]. The iron powder residues were collected in a welding workshop in the city of Douala. In order to maximize the iron content, they were separated by magnetic sorting and only the particles that stuck easily to the magnet were sieved through a 90 µm sieve. A part of these residues will be activated with phosphoric acid and labelled WIPA during the FTIR analysis of the raw materials. As hardener, we used in this work a diluted solution of phosphoric acid (C = 6 M) prepared from a commercial solution H3PO4 whose purity in P2O5 is 85%. The binding liquor (hardener) will be kept for a minimum of 48 h before use.

2.2 Preparation of IPPs

The PIPs were prepared by combining the VA powder (MaJ/Mbo) and iron residue powder with a binding liquor of 6 M concentration in a liquid/solid ratio of 0.45. The partial substitution of VA by iron residue powder was carried out in proportions ranging from 0 to 20% and the different formulations obtained, which are recorded in Table 1, were kept in a corner of the laboratory for a minimum of 28 days before any other use.

2.3 Characterization methods

Chemical analysis of the iron powder residues was carried out using a Panatical Axios Fast PW 2650 X-ray fluorescence apparatus. The chemical composition of the solid precursors MaJ and Mbo had already been given in the previous work of Dickson et al. [23, 35]. The identification of the different mineralogical phases present in the raw materials and polymers was carried out by analysis of the X-ray diffractogram performed by a Bruker apparatus (D2 Phaser) using a copper anti-cathode of wavelength = 0.15418 nm and by comparison with the standard Powder Diffraction Files (PDF) from the International Center for Diffraction Data (ICDD). For the observation of the different vibrational modes within the solid precursors, iron powder residues and polymers obtained, a Thermo Scientific Nicolet IS 5 spectrophotometer operating in ATR mode in a germanium crystal in absorbance in the range of 4000 to 400 cm−1 was used. The evaluation of the specific surfaces and the observation of the morphology of the different samples were experimented by optical microscopy and BET analysis. The BET analysis required the use of a NOVA touch LX4. The optical microscopy was carried out using a Leica DM750 optical microscope with an integrated micro camera. For the determination of the porosity and water absorption rate, the measurements were carried out in accordance with ASTM C-20 [36]. The compressive strength of the different polymers was determined using an electrohydraulic press of the brand M&O, type 11.50, N°21. The compressive strength is the average of the tests performed on five samples for each formulation.

3 Results and discussions

3.1 Characterization of raw materials

3.1.1 XRF, XRD and FTIR

The chemical composition of the raw materials MaJ, Mbo and WIP obtained by X-ray fluorescence is given in Table 2

It was found that the raw materials MaJ and Mbo consist mainly of the oxides SiO2, Al2O3, Fe2O3, CaO, and MgO and therefore can be used for the synthesis of inorganic polymers by acid or alkaline method. For WIP, the chemical composition shows a fairly high content of iron oxide Fe2O3 (i.e. 90.72) and low contents of SiO2 and Al2O3. The presence of aluminium and silicon oxides in low proportions shows that our WIPs are not totally pure and probably come from iron-rich composites. The X-ray patterns of solids precursors at Fig. 1 show the presence of mineralogical phases such as augite [Ca(Mg0,85Al0,15)(Si1,70Al0,30)O6, JCPDS file: 78-1391, 24-0201], anorthite [Na0,33Ca0,67Al1,67Si2,33O8, PDF: 78-1629], Cristobalite [SiO2, PDF: 89-3434, 39-1425], Diopside [Ca(Mg, Fe, Al)(Si, Al)2O6, PDF: 38-0466], Magnesian ferrosilite [(Mg0,463Fe1,537)Si2O6, PDF: 88-1917], Hematite [α-Fe2O3, PDF: 33-0664] and Maghemite [γ-Fe2O3, PDF: 39-01346] for volcanic ash (MaJ and Mbo) and Magnetite [Fe3O4, PDF: 19-0629], Hematite [α-Fe2O3, PDF: 33-0664, 89-8103], Iron [α-Fe, PDF: 06-0696] and Diaspore [β-AlO(OH), PDF: 5-355] in those from WIP. The presences of the mineralogical phases observed in these diffractograms are consistent with the results of the chemical analysis and reveal the presence of favorable reactive phases during the synthesis of the inorganic polymers.

The FTIR spectra of the raw materials MaJ, Mbo, WIP and WIPA observed in Fig. 2 show two main absorption ranges from 441 to 1015 cm−1 and from 1422 to 3348 cm−1 respectively.

In the first domain, the low intensity absorption bands whose peaks appear between 441 and 1015 cm−1 observable on the different raw materials and WIPAs are characteristic of the vibration modes of elongations and deformations of Si–O–T bonds (T: Si, Al or Fe) [14, 23, 35, 37,38,39,40]. In particular, the bands with peaks at 441, 465, 512 and 576 cm−1 are attributable to Fe–O bonds in iron oxide-rich minerals [21,22,23, 35, 41, 42] while those with peaks at 758 cm−1 (MaJ) and 740 cm−1 (Mbo) are characteristic of Si–O bonds in the silicate lattices within these precursors [23, 35, 43, 44]. The bands observed at 582, 667 and 875 cm−1 seen on the WIP spectrum support the presence of an amorphous silica phase [14, 23, 35]. In addition, the strong absorption bands with peaks at 904, 969, 975, 1007 and 1015 cm−1 are attributable to symmetric deformations of the Si–O–T [43] and Fe–O–Si bonds as these precursors contain high Fe2O3 content [16, 23, 35, 45, 46]. The decrease of the wave number from 1015 cm−1 (WIP) to 1007 cm−1 (WIPA) is due to the change of the chemical environment after the acid activation. However, it is important to mention that the absence of some absorption bands on the IR spectrum of WIPA reveals that these residues are not inert in the acid. In the second absorption region, the bands observed at 3348 and 1640 cm−1 on the WIPA spectra are H–O–H bonds of the water molecules trapped during the acid activation of WIP. As for the peak at 1422 cm−1 on the IR spectrum of WIP, it can be associated with the C=O bond confirming that WIP is not pure and contains carbonaceous impurities.

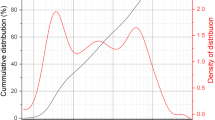

3.1.2 BET analysis

Table 3 shows that the specific surface area values and the total pore volume of the raw materials from the BET analyses. In general, the observed values of the specific surface areas are inversely proportional to the total pore volumes and the largest values are noticeable on MaJ. These values being important, it can be predicted that our samples present a good reactivity and will be favorable to the mineral polycondensation process in the presence of an alkaline or acid hardener. These observations are also made by Diaz et al. [47], Dzoudjo et al. [39] in similar studies.

3.2 Characterization of PIPs

3.2.1 Mineralogical analysis

Figure 3a and b shows the x-ray pattern of volcanic-ash-based phosphate inorganic polymers obtained. Most of the oxides initially present in the raw materials are found in the diffractograms of the synthesis products but their intensity is higher due to the fact that during the synthesis a polycondensation and redox reaction occurs simultaneously. However, the redox reaction is priority over the polymerisation, which can be confirmed by the dome observed in the 2ϴ values between 20° and 35° for the Mbo-based inorganic phosphate polymers and between 18° and 38° for the MaJ-based PIPs. Indeed, the presence of the dome highlights the presence of an amorphous phase in our syntheses. New peaks appear and these peaks reveal the presence of new crystalline phases such as: Brushite [CaHPO4·2H2O, PDF: 02-0085 et 04-0740], aluminium phosphate hydrate [AlPO4·xH2O, PDF: 15-0275], silicon hydrogen phosphate [SiH2P2O8, PDF: 17-0827, 21-1067], potassium magnesium phosphate hydrate [K2MgP2O7·4H2O, PDF: 52-1083]. The disappearance of anorthite, which was present in the raw materials, is also noted. The formation process of the different mineralogical phases obtained can be materialized by redox reactions followed by the acid–base reactions below [2, 34]:

Figure 4a and b shows the FTIR spectra of the different inorganic phosphate polymers based on volcanic ash (MaJ/Mbo) and WIP. Generally speaking, we note the disappearance of several low intensity bands between 441 and 667 cm−1 initially present in the starting precursors and characteristic of Fe–O bonds, confirming that the iron minerals take part in the polymerization reaction. The appearance of new absorption bands whose peaks are perceptible on the various polymers at 3309, 3317, 3345, 3346 cm−1 and those at 1639 and 1640 cm−1, initially absent on the raw materials, characteristic of the modes of vibration of the elongations and deformations of the H–O–H and O–H bonds of the water molecules originating from the activating solution H3PO4 trapped in the cavities of the polymeric framework during their elaborations. These observations are in agreement with those made in previous work aimed at synthesizing phosphated inorganic polymers [34, 35, 40, 48].

The presence of absorption bands between 965 and 1005 cm−1 observed on the IR spectra of the synthesis products are attributable to the vibration modes of the Si–O–Al and Fe–O–Si bonds [49] and confirm the presence of an amorphous phase due to the partial replacement of Al by Fe(II)/Fe(III) in the tetrahedral network of the AlO4 network and which could have reacted with the PO4 units coming from the activating solution. These observations are in agreement with the results obtained in several research works [5, 18, 50]. The observation of these different absorption bands confirms the presence of mineralogical phases such as: magnesium and iron phosphate, hydrated aluminium and iron phosphate and hydrated potassium and magnesium phosphate observed after the X-ray diffractograms (Fig. 3a, b).

3.2.2 Morphological change and BET analysis

Figure 5 shows the optical micrographs of the solid precursors (MaJ and Mbo) and the different 28 days old syntheses.

The observation of these shows that the simple activation by phosphoric acid already generates a quantity of voids within the polymers GMaJ0 and GMbo0, due to the evaporation of the water molecule because the reaction is exothermic. This is in agreement with the work of Ping et al. [51] on the synthesis of a porous geopolymer by phosphoric acid activation.

In addition, the higher the level of WIP that replaces the VA powder, the higher the cavities within the tested specimens. Indeed, during the synthesis of WIPs, iron will oxidize in the presence of the phosphoric acid solution, forming the cations Fe2+, Fe3+. This leads to the release of hydrogen as described in Eq. (1). This release of hydrogen added to that of the departure of water from the fresh polymer paste leaves larger voids (pores) in the latter [52]. This observation is similar to that made by Djon Li Ndjock et al. [34] who showed in their study that the incorporation of a certain level of commercial iron leads to the formation of pores within the resulting products. Comparing these results with those presented in Table 3, it is noted that for a partial replacement of 10% of the volcanic ash powder by WIP and in acid medium (C = 6 M), the specific surface of the Mbo based synthesis products increases (i.e. 26.8719 to 49.4881 m2/g) as well as the total pore volume, but the pore size does not vary. This result is in agreement with that observed by Dzoudjo et al. [39] who showed in a study on the synthesis of a pozzolan-based geopolymer that the addition of a pore-forming agent such as hydrogen peroxide improves the textural properties of pozzolans. On the other hand, for a 10% WIP content during the preparation of the MaJ-based specimens, the specific surface area, the total volume and the pore size decrease. This leads to the conclusion that during the synthesis of Mbo-based polymers, WIP plays the role of pore-forming agent whereas during the elaboration of MaJ-based PIPs, WIP plays the role of fillers.

3.2.3 Mechanical and physicochemical properties

3.2.3.1 Compressive strength and water adsorption

The results of the compressive strengths and water absorption rates are presented in Figs. 6 and 7 and Table 4.

The observation of these shows that in general, the partial replacement of volcanic ash powders by WIP leads to a decrease in compressive strength and conversely, an increase in the percentage of water absorption. Compressive strength values ranging from 28.88 to 2.55 MPa for MaJ-based polymers (GMaJ0, GMaJ5, GMaJ10, GMaJ15 and GMaJ20) and between 16 and 2.24 MPa for Mbo-based polymers (GMbo0, GMbo5, GMbo10, GMbo15 and GMbo20) are noted. Indeed, the presence of an additional iron source leads to the formation of cavities in the resulting products and consequently weakens them: hence the progressive decrease in values [21, 26, 34, 53, 54]. This behavior is favorable for the use of these polymers in the recycling of used waste oils.

In addition, it is worth noting that the activation being of the acid type, a redox reaction takes place between the iron and the acid, which results in a release of dihydrogen as mentioned in Eqs. (1) and (2). This release leads to voids (pores) within the material and consequently to a reduction in mechanical values. Such observations have also been made when using other pore forming agents such as aluminium powder [34, 35, 51]. However, beyond a partial replacement of 10% of the volcanic ash powder, the compressive strength values no longer vary for the Mbo-based specimens (i.e. 2.23 MPa for GMbo15 and GMbo20) and decrease slightly for those based on MaJ. On the other hand, in terms of water absorption percentage, beyond 5% of partial VA replacement, the value of the absorption rate does not vary anymore for MaJ-based specimens, but continues to increase for Mbo-based specimens. This confirms the hypothesis mentioned in paragraph 3.2.2 according to which, during the mineral polycondensation reaction, beyond 10% substitution of the MaJ ash, the WIPs obstruct the open pores and behave as fillers. During the synthesis of Mbo-based polymers, however, regardless of the substitution rate, WIPs always behave as a pore-former. The observations made on these two properties (compressive strength and absorption rate) are in agreement with those from BET analysis and microscopic observation.

3.2.3.2 Bulk density and apparent porosity

Figure 8 and Table 4 present the bulk density and apparent porosity of volcanic-ash phosphate inorganic polymers. As well as the percentage of water absorption and compressive strength, the results obtained show that the partial replacement of VA with WIP leads to a decrease in density and conversely, an increase in apparent porosity. In terms of density, values ranging from 2.85 to 1.49 g/cm3 for Mbo-based polymers and from 2.35 to 1.17 g/cm3 for MaJ based polymers are noted. While the apparent porosity values are respectively between 17.23 and 30.85% for MaJ-based polymers and 13.71 to 37.77% for Mbo-based polymers. It is noted that at 5% of partial replacement of VA by WIP the apparent density of the synthesis products decreases sharply and the porosity equally increases. Above this rate, the density of all polymers and the apparent porosity of the MaJ-based specimens varies very little. The increase in porosity observed above 10% VA substitution on Mbo-based polymers is closely related to its water absorption rate and the presence of pores observed on the micrographs of these formulations. Indeed, as the water absorption rate of a polymer increases, its porosity increases [35, 55].

These results corroborate with those presented by the BET analyses and the observation of the micrographs in Fig. 5.

4 Conclusion

The aim of this study was to evaluate the effect of partial replacement of MaJ and Mbo volcanic ash powders by WIP on the properties of phosphate inorganic polymers. The result shows that:

-

The exothermic redox reaction caused by contact between dilute acid (6 M) and the iron supplement from WIP creates pores in our synthetic products, making them more fragile;

-

Compressive strengths decrease with the addition of iron powder and, for a 5% WIP content, this characteristic may be acceptable for subsequent use of the polymer as an oil filter membrane;

-

Conversely, the water absorption rate and porosity increase.

-

Furthermore, above 5% WIP, the physical–chemical and mechanical properties of the MaJ-based polymers vary very little, but those based on Mbo are continuously affected.

The same observations made on the specific surface area of the different samples tested show that WIPs can be used as a pore forming agent in the synthesis of Mbo-based polymers and as fillers after a 10% substitution in the synthesis of inorganic phosphate-based MaJ polymers. The Mbo-based polymers can be used later for the treatment of used engine oils.

Data availability

Not applicable.

References

Wagh A. Recent progress in chemically bonded phosphate ceramics. Int Sch Res Not. 2013. https://doi.org/10.1155/2013/983731.

Wagh AS, Jeong SY. Chemically bonded phosphate ceramics: III, reduction mechanism and its application to iron phosphate ceramics. J Am Ceram Soc. 2003;86(11):1850–5.

Tome S, Etoh MA, Kumar S. Improved reactivity of volcanic ash using municipal solid incinerator fly ash for alkali-activated cement synthesis. Waste Biomass Valoriz. 2020;11:3035–44. https://doi.org/10.1007/s12649-019-00604-1.

Grace A, Tatiane M, Noel J, Djobo Y, Tome S, Cyriaque R, Giogetti J, Deutou N. Lateritic soil based-compressed earth bricks stabilized with phosphate binder. J Build Eng. 2020;31: 101465. https://doi.org/10.1016/j.jobe.2020.101465.

Obonyo EA, Kamseu E, Lemougna PN, Tchamba AB, Melo UC, Leonelli C. Sustainable approach for the geopolymerization of natural iron-rich aluminosilicate. Materials. 2014;6:5535–53. https://doi.org/10.3390/su6095535.

Davidovits J. Geopolymers chemistry and applications. 5th ed. Saint Quentin: Institut Géopolymères; 2020. p. 674.

Gualtieri ML, Romagnoli M, Gualtieri AF. Preparation of phosphoric acid-based geopolymer foams using limestone as pore forming agent–thermal properties by in situ XRPD and Rietveld refinements. J Eur Ceram Soc. 2015. https://doi.org/10.1016/j.jeurceramsoc.2015.04.030.

Tchakouté HK. Elaboration et caractérisation de ciments géopolymères à base de scories volcaniques. PhD. Thesis, Univ. Yaounde I, Fac. Sci. 2013;170.

Noël J, Djobo Y, Elimbi A, Kouamo H, Kumar S. Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr Build Mater. 2016;124:606–14. https://doi.org/10.1016/j.conbuildmt.2016.07.141.

Kioupis D, Zisimopoulou A, Tsivillis S, Kakali G. Development of porous geopolymers foamed by aluminium and zinc powders. Ceram Int. 2021. https://doi.org/10.1016/j.ceramint.2021.06.037.

Tchakouté HK, Rüscher CH. Mechanical and microstructural properties of metakaolin-based geopolymer cements from sodium water glass and phosphoric acid solution as hardeners: a comparative study. Appl Clay Sci. 2017;140:81–7.

Tchakouté KH, Ruscher CH, Kamseu E, Fernanda A, Leonelli C. Influence of the molar concentration of phosphoric acid solution on the properties of métakaolin-phosphate-based geopolymer cements. Appl Clay Sci. 2017;147:184–94.

Tchakouté KH, Ruscher CH, Kamseu E, Djobo JNY, Leonelli C. The influence of gibbsite in kaolin and the formation of berlinite on the properties of métakaolin-phosphate-based geopolymer cements. Mater Chem Phys. 2017;199:280–8.

Kaze CR, Lecomte-Nana GL, Kamseu E, Comacho PS, Yorkshire AS, Provis JL, Duttine M, Wattiaux A, Melo UC. Mechanical and physical properties of inorganic polymer cement made of iron-rich laterite and lateritic clay: a comparative study. Cem Concr Res. 2021;140: 106320. https://doi.org/10.1016/j.ce,conres.2020.106320.

Kaze CR, Beleuk LM, Djouka MLF, Nana A, Kamseu E, Melo UFC, Leonelli C. The corrosion of kaolinite by iron minerals and the effects on geopolymerization. Appl Clay Sci. 2017;138:48–62. https://doi.org/10.1016/j.clay.2016.12.040.

Kaze R, Beuleuk à Moungam L, Cannio M, Rosa R, Kamseu E, Melo UC, Leonelli C. Microstructure and engineering properties of Fe2O3(FeO)–Al2O3–SiO2 based geopolymers composites. J Clean Prod. 2018;199:849–59. https://doi.org/10.1016/j.jclepro.2018.07.171.

Essaidi N, Samet B, Baklouti S, Rossignol S. The role of hematite in aluminosilicate gels based on metakaolin. Ceram-Silik. 2014;58(1):1–11.

Davidovits J, Davidovits R. Ferro-silialate geopolymers, technical papers # 27, Géopolymer Institute Library; 2020. https://doi.org/10.13140/RG.2.2.25792.89608/2.

Ma S, Zhang Z, Liu X. Comprehensive understanding of aluminosilicate phosphate geopolymers: a critical review. Materials. 2002;15:5961. https://doi.org/10.3390/ma15175961.

Baenla J, Bike Mbah JB, Djon Li Ndjock IB, Elimbi A. Partial replacement of low reactive volcanic ash by cassava pell ash in the synthesis of volcanic ash based geopolymer. Constr Build Mater. 2019;227: 116689. https://doi.org/10.1016/j.conbuildmater.2019.116689.

Ngnintedem DLV, Lampe M, Tchakouté HK, Ruuscher CH. Effects of iron minerals on the compressive strengths and microstructural properties of metakaolin-based geopolymer materials. Gels. 2022;8:525. https://doi.org/10.3390/gels8080525.

Djon Li Ndjock BI, Baenla J, Bike Mbah JB, Elimbi A, Cyr M. Amorphous phase of volcanic ash and microstructure of cement product obtained from phosphoric acid activation. SN Appl Sci. 2020;2:720. https://doi.org/10.1007/s42452-020-2496-7.

Missota BPD, Dika JM, Pougnong TE, Baenla J, Ebongue LN, Elimbi A. Effects of kinetic parameters on initial setting time, microstructure and mechanical strength of volcanic ash-based phosphate inorganic polymers. SILICON. 2021. https://doi.org/10.1007/s12633-021-01140-1.

Lemougna PN, MacKenzie KJD, Melo UFC. Synthesis and thermal properties of inorganic polymers (geopolymers) for structural and refractory applications from volcanic ash. Ceram Int. 2011;37:3011–8.

Largeau MA, Mutuku R, Thuo J. Effect of iron powder (Fe3O4) on strength, workability, and porosity of the binary blended concrete. Open J Civ Eng. 2018;8:411–25.

Bewa CN, Tchakouté HK, Banenzoué C, Cakanou L, Mbakop TT, Kamseu E, Rüscher CH. Acid-based geopolymers using waste fired brick and different metakaolin as raw materials. Appl Clay Sci. 2020;198: 105813. https://doi.org/10.1016/j.clay.2020.105813.

Bewa CN, Valentini L, Tchakouté HK, Kamseu E, Djobo JN, Dalconi MC, Garbin E, Artioli G. Reaction kinetic and microstrutural characteristics of iron-rich-laterite-based phosphate binder. Constr Build Mater. 2022;320: 126302. https://doi.org/10.1016/j.conbuildmat.2021.126302.

Lemougna PN, Wang K, Tang Q, Nzeukou AN, Bilong N, Melo UC, Ciu X. Review on the use volcanics ashes for engineering applications. Res Conserv Recycl. 2018;137:177–90.

Djobo YJN, Elimbi A, Tchakouté HK, Kumar S. Volcanic ash-based geopolymer cements/concretes: the current state of the art and perspectives. Environ Sci Pollut Res. 2016. https://doi.org/10.1007/s11356-016-8230-8.

Ayris P, Delmelle P. Volcanic and atmospheric controls on ash iron solubility: a review. Phys Chem Earth. 2012;45–46:103–12. https://doi.org/10.1016/j.pce.2011.04.013.

Njoya D, Elimbi A, Fouejio D, Hajjaji M. Effects of two mixtures of kaolin-talc-bauxite and firing temperatures on the characteristics of cordierite- based ceramics. J Build Eng. 2016;8:99–106. https://doi.org/10.1016/j.jobe.2016.10.004.

Djobo JNY, Stephan D, Elimbi A. Setting and hardening behavior of volcanic ash phosphate cement. J Build Eng. 2020;31: 101427. https://doi.org/10.1016/j.jobe.2020.101427.

Djon Li Ndjock BI, Robayo-Salazar RA, Mejia R, Baenla J, Mbey JA, Cyr M, Elimbi A. Phosphoric acid activation of volcanic ashes: influence of the molar ratio R = (MgO + CaO)/P2O5 on reactivity of volcanic ash and strength of obtained cementitious material. J Build Eng. 2020;33: 101879. https://doi.org/10.1016/j.jobe.2020.101879.

Djon Li Ndjock BI, Baenla J, Bike Mbah JB, Souaibou, Elimbi A. Effects of Al and Fe powders on the formation of foamed cement obtained by phosphoric acid activation of volcanic ash. Mater Lett. 2022;308: 131147. https://doi.org/10.1016/j.matlet.2021.131147.

MissotaPriso Dickson B, MawéNoussi C, NdongoEbonguè L, DikaManga J. Physical and mechanical properties of porous material obtained by low replacement of volcanic ash by aluminum beverage cans. Adv Res. 2021;22:1–11. https://doi.org/10.9734/AIR/2021/v22i130279.

American Society for Testing Materials (ASTM). standard test methods for apparent porosity, water absorption, apparent specific gravity and bulk density of burned refractory brick and shapes by boiling water, Pennsylvania, ASTMC 20-74; 1979. p. 3.

Nkwaju RY, Djobo JNY, Nouping JNF, Huisken PWM, Detou JGN, Couard L. Iron-rich laterite-bagasse fibers based geopolymer composite: mechanical, durability and insulating properties. Appl Clay Sci. 2019;183: 105333. https://doi.org/10.1016/j.clay.2019.105333.

Louati S, Baklouti S, Samet B. Geopolymers based on phosphoric acid and Illito-Kaolinitic clay. Adv Mater Sci Eng. 2016. https://doi.org/10.1155/2016/2359759.

Hermann DT, Tomé S, Shikuku VO, AKiri S, Nadine MK, Soheil A, Janiak C, Etoh MA, Dina D. Enhanced performance hydrogen peroxide modified pozzolan-based geopolymer for abatement of methylene blue from aqueous medium. Silicon. 2022;14:5191–5206. https://doi.org/10.1007/s12633-021-01264-4

Dzoujo TH, Tomé S, Shikuku VO, Baela J, Tchuigwa AS, Janiak C, Etoh MA, Dina D. Synthesis of pozzoloan and Sugarcane bagasse derived geopolymer-biochar composites for methylene blue sequestration from acqueous medium. J Environ Manag. 2022;318: 115533. https://doi.org/10.1016/j.jenvman.

Khabbouchi M, Hosni K, Srasra E. Physico-chemical characterization of modified Tunisian kaolin by phosphoric acid. Surf Eng Appl Electrochem. 2018;54:219–26. https://doi.org/10.3203/S1068375518020072.

Leogodi MA, De Waal D. The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste. Dyes Pigm. 2007;74:161–8. https://doi.org/10.1016/j.dyepig.2006.01.038.

Djobo JNY, Elimbi A, Tchakouté HK, Kumar S. Reactivity of volcanic ash in alkaline medium, microstructural and strength characteristics of resulting geopolymers under differents synthesis conditions. J Mater Sci. 2016;51:10301–17. https://doi.org/10.1007/s10853-016-0257-1.

Bewa CN, Tchakouté HK, Ruscher CH, Kamseu E, Leonelli C. Influence of the curing temperature on the properties of poly (phospho-ferro-siloxo) networks from laterite. SN Appl Sci. 2019;1:1–12. https://doi.org/10.1007/s42452-019-0975-5.

Vempati RK, Loeppert RH. Influence of structural and adsorbed Si on the transformation of synthetic ferrihydrite, clays. Clay Min. 1989;37:273–9. https://doi.org/10.1346/CCMN.1989.0370312.

Gallup LD, Reiff WM. Characterization of geothermal scale deposits by Fe-57 Mossbauer spectroscopy and complementary x-ray diffraction and infrared studies. Geothermics. 1991;20(4):207–24. https://doi.org/10.1016/0375-6505(91)90033-R.

Diaz EI, Allouche EN, Eklund S. Factors affecting the suitability of fly ash as source material for geopolymers. Fuel. 2010;89:992–6. https://doi.org/10.1016/j.fuel.2009.09.012.

Djobo JNY, Elimbi A, Stephan D. Phase and dimensional stability of volcanic ash-based phosphate inorganic polymers at elevated temperatures. SN Appl Sci. 2020;2:828. https://doi.org/10.1007/s42452-020-2616-4.

Gomes KC, Lima GS, Torres SM, De Barros S, Vasconalos LF, Barbosa NP. Iron distribution in geopolymer with ferromagnetic rich precursor. Mater Sci Forum. 2010;643:131–8.

Park JT, Lee KJ, Kang M-S, Kang YS, Kim JH. Nanocomposite polymer electrolytes containing silica nanoparticles: comparison between polyethylene glycol and polyethylene oxide dimethyl ether. J Appl Polym Sci. 2007;106:4083–90.

Le-Ping L, Xue-Min C, Qiu Shu-Heng Yu, Jun-Li ZL. Preparation of phosphoric acid-based porous geopolymers. Appl Clay Sci. 2010;50:600–3. https://doi.org/10.1016/j.clay.2010.10.004.

Mandel S, Tas AC. Brushite (CaHPO4·2H2O) to octa calcium phosphate (Ca8(HPO4)2(PO4)45H2O) transformation in DMEM solutions at 365 C. Mater Sci Eng C. 2010;30:245–54.

Dan SP, Cashion JD, Blackford MG, Zhang Z, Vance ER. Fe speciation in geopolymers with Si/Al molar ratio of ~2. J Eur Ceram Soc. 2006;27:2697–703. https://doi.org/10.1016/j.jeurceramsoc.2006.10.006.

Lemougna PN, Mackenzie KJD, Rahier H, Melo UFC. The role of iron in the formation of inorganic polymers (geopolymers) from volcanic ash: a Fe Mössbauer spectroscopy study. J Mater Sci. 2013;48:5280–6. https://doi.org/10.1007/s10853-013-7319-4.

Kamseu E, Nait-Ali B, Bignozzi MC, Leonilli C, Rossignol S, Smith DS. Bulk composition and microstructure dependence of effective thermal conductivity of porous inorganic polymers cements. J Eur Ceram Soc. 2012;32:1593–603. https://doi.org/10.1016/j.jeurceramsoc.2011.12.030.

Acknowledgements

The WIP used for sample preparation was provided by Douala Town of Cameroon. The authors thankful Mrs. Alex Spiess and Samuel Wabo are acknowledge for the assistance during the XRD and BET analysis of VA, WIP and different specimens obtained. The authors thank B. Ateba and C. M. Kede for fruitful discussion during the course of this work.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

This work was carried out in collaboration between all the authors. Joseph Dika Manga: one co-supervisor of this study. Louise Ndongo Ebongue: carried out the experimental part of this study and interpreted the results of mechanical and physicochemical properties. This co-author wrote the first version of this manuscript. Raadmadje DJimtibaye: prepare the sample for mechanical testing. Frank hervé Nelle Nelle: ground and sieve the raw materials. Christoph Janiak: carried out the XRD analysis. Bernard Missota Priso Dickson: other co-supervisor, prepare the methodology, interpreted the XRD, FTIR analysis, revised the proposal manuscript and corrected before submitting the final version.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ebongue, L.N., Dickson, B.M.P., Nelle, F.H.J. et al. Effect of partial replacement of volcanic ashes by waste iron powder on the properties of phosphate inorganic polymers. Discov Appl Sci 6, 155 (2024). https://doi.org/10.1007/s42452-024-05799-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05799-0