Abstract

Silica hydrogels are used as fire-retardant materials due to the occurrence of intumescence that limits heat and mass transfer. They act as heat-sink, through continuous endothermic condensation reactions, meantime shrinking to a more connected network, towards the correspondent crystalline compound. Which compositions and treatments amplify this phenomenon is still of interest. To this aim, two silica sols containing two different complexing agents: ethylene glycol and glycerol has been prepared and analyzed. The samples were subjected to different treatments to induce gelation and densification: exposure to ultraviolet or microwave or infrared irradiation. Thermogravimetric analysis coupled with differential scanning calorimetry (TG-DSC) and scanning electron microscopy analyses has been also carried out. Moreover, dynamic mechanical spectroscopy (DMS) let to evaluate simultaneously the mechanical and intumescence behavior of the gels at increasing curing times for each type of irradiation. Intumescence of gels occurs up to 200 °C and appears as an endothermal group of peaks visible on the heat-flux DSC curves. DMS analyses let to assess that a MW cured glycerol-containing gel (GL-0-MW 6d) shows a glass transition above 150 °C, measured as the maximum of damping peak. Accordingly, this sample is a good option for the application: a few bubbles nucleate and grow fast at high temperature.

Article Highlights

-

Transparent fire doors contain silica gel, which absorbs heat and releases water by foaming. Two different silica gels were synthetized using different chelating agents.

-

The foaming depends on the reagents used to produce the gel, on the treatments for stabilizing it and also on ageing.

-

Both foaming and consolidation of the gel were studied with thermogravimetric and dynamic-mechanical analysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The sol–gel method is widely used today for the synthesis of organic–inorganic nanomaterials [1,2,3,4], using a mild process, based on the change of a sol into a gel (sol–gel transition).

In physics and chemistry, “sol” indicates a colloidal system in which the dispersed phase is solid while the dispersant one is fluid, generally liquid. The sols are defined as mono- or poly-dispersed depending on whether the sizes of the solid particles are all the same or not. Gelation occurs with a sudden change in the viscosity due to condensation reactions among the hydroxyl groups on the surface of the colloidal parts that become closest due to the reduction in volume by solvent evaporation, heating, pH changes, addition of electrolytes. The gel state can be characterized by viscosity values ranging from a few hundred mPa to more than 1·1012 Pa s (viscosity at glass transition). This means that they can be very fluid or very rigid and glassy. The viscosity difference is related to the degree of condensation (and therefore connectivity) and complexing agents (substances capable of modifying the reactivity of ions or atoms). The viscosity of the gel is not indifferent to the application and should be defined a priori based on the expected molding technology. The optimal viscosity that the gel should have to be formed is not known a priori, but at the point of gelation it is generally low.

One of the applications of these types of material is their use as a fire-retardant agent, encapsulated in between glass panes of doors and windows. The hydrogel acts as a heat-sink because condensation reactions give rise to intumescence that limits heat and mass transfer [5]. Fire-resistant glass can be used in construction to block flame spreading in a fire, applied in partition walls, fire doors, fire windows, escape routes and stairways [5, 6]. Silica gel has been tested as a flame retardant instead of traditional systems that could produce toxic volatile compounds during thermal decomposition. The use of silica gel leads to a significant reduction in the Heat Release Rate (HRR), besides forming an efficient fire-retardant layer [7, 8].

Gels are always in a metastable state, as they are amorphous. For each application, a certain degree of gel condensation can be assessed as suitable and empirically established. Accordingly, the studies are based both on which is the most appropriate state, in terms of viscosity and modulus, and on how to achieve it, in terms of additives and curing process.

Silica glasses by sol–gel process are formed in kinetically controlled reactions from molecular precursors and sol–gel transition (gelation or gel point) occurs when a continuous silica network is formed, but many structural rearrangements and shrinkage could take place in gels up until the stable crystalline form is reached. Aging is the period when the wet gel increases its stiffness, depending on the curing treatments, as each of them produces a different connectivity of the inorganic macromolecular system.

The sol–gel method leads to the formation of a silica 3D network that can be modified along with its chemical and physical properties, allowing to obtain high thermal stability, purity, pores and increased reactivity due to its large surface [2]. Silica gels are generally produced starting from potassium silicate or from alkoxysilane in alcohol with water and catalysts for accelerating hydrolysis, to give mixtures of silica sol. To control the rate of hydrolysis and condensation, a complexing agent (glycerol or alternatively ethylene glycol) can be also added [9]. Cross-linking of the inorganic macromolecular system occurs by condensation, that releases water and absorbs a lot of heat, but not in a single step, because it requires the proximity of reagent groups. Condensation induces an increase of connectivity of the silica tetrahedra, except for organic or silanol residues. As the shrinkage of the bulk proceeds due to the sol–gel reactions, more groups come closer, becoming available for further condensation. For this reason, the condensation reactions into gels could continue with effects such as shrinkage or intumescence. The residuals give rise to intumescence during heating or even fire, depending on the quantity and type of reagents, the order in which they have been mixed, the time and way in which the heat is absorbed during curing. Accordingly, a lot of combinations with very different behaviors are possible merely by varying the percentages of the components and the mixing conditions.

A silica gel is an amorphous material (i.e. a liquid with high viscosity), a metastable system that tends over a long time towards the only corresponding stable form: SiO2 crystal or quartz at room temperature. During aging, especially if irradiated by sunlight, gel can bleach due to the formation of quartz crystal nuclei that are not transparent to visible light.

For using gel as a fire retardant, acting as a thermal barrier, which delays heat transmission and inhibits flame spread, intumescence should occur in a single large phenomenon and with a large release of water, possibly without releasing alcoholic residues, that could instead fuel a fire. Therefore, a highly condensed gel would not be suitable for application [6]. To slow down the condensation, chelating agents such as glycerol or ethylene glycol can be used to react, through hydrogen bonds, with the hydroxyl groups. Due to their nature, chelating agents can interact with free water molecules or any other present ion [10]. In nature, both molecules are known to modify the surface tension of water present in the organic fluids of animals capable of hibernating, thereby preventing crystallization [11].

According to classical kinetic theory, a reaction can be accelerated both by bringing the reactants together, so that the effective collisions increase (e.g., when the volume of the gel is reduced by evaporation of the solvent), by supplying them enough energy to overcome the EActivation. Condensation can be also accelerated when energy is supplied the oligomers initially present. The amount of energy delivered to gel depends on both the frequency (wavelength) of radiation (UV, IR, MW) and treatment time.

Shorter wavelength radiations are more penetrating but also more energetic [12,13,14,15]. For this reason, they are often absorbed in the most superficial layer, activating the processes too quickly: they start from the most peripheral areas of the gel volume and are not effectively transmitted inside. UV light is applied for top-down processing [16], but laser light [17], X-ray irradiation [18, 19], γ-rays [20], and an electron beam [21, 22], can also induce structural modification and film densification. With electromagnetic radiation exposure, light–matter interaction is particularly effective in a soft state because of the low degree of condensation and the presence of organic compounds. The radiation-induced changes are produced via the reactive species that are created by light irradiation. The effect very much depends on the energy and brilliance of the source.

For a more homogeneous and effective transfer of energy in the entire gel volume, microwaves could be useful [12,13,14]. Microwave irradiation (MW) was a non-conventional energy source at the beginning of sol–gel process development, then this fast technique was largely implemented in industrial applications [23,24,25,26], even on large surfaces. MW generates heating of polar substances, like water and silanol present in gels, producing a reduction of gelation times of silica sol through condensation [27].

In the absence of energetic or evaporative phenomena, condensation can proceed over a long time, giving rise to syneresis: the connectivity of the gel increases, since the free spaces between the inorganic macromolecules reduce. Once triggered, this phenomenon proceeds until the solvent is almost completely expelled. However, syneresis is hardly observed in tightly wrapped systems.

It is already known that silica content affects the evaporation of H2O and the release of volatile compounds [7]. Moreover, the effects on thermal intumescence of the chelating agent ethylene glycol or glycerol, as well as time and type of curing treatment (IR, UV or MW), have been examined from gelation to intumescence on acid-catalyzed silica alcogels by thermal–mechanical analyses and through a systematic collection of data, linking the effects of condensation with the type and not the amount of energy supplied [28, 29].

2 Experimental part

All the samples were prepared according to procedure reported in reference [7]: a commercial silica sol (Snowtex containing a potassium salt, Japan), stabilized by glycerol (GL, 10 wt% of silica) or ethylene glycol (GE, 5 wt% of silica) as complexing agents, was mixed with an aqueous solution of potassium silicate. The transparent gel containing silica is suitable for pouring into the cavity between glasses as a fireproof interlayer or, as in this study, in molds to obtain shaped samples for thermal and mechanical analyses.

Both the commercial colloidal silica and the potassium silicate sols, along with the gels obtained from their mixing, were analysed via Delsa Nano-Dynamic light scattering (DLS, Backman and Coulter, California, USA).

Several silica gels were analyzed by DMS and DSC after the following curing treatments: (IR) by using a muffle and leaving the samples for 5 min at 50 °C; (UV) by using a low-pressure mercury UV lamp (60 s under a 60 W lamp with emission at 254 nm wavelength), and MW (at a power of 640 W microwave oven for 10 s). Since it is not possible to calculate how much effective energy is absorbed by the samples due to the diversity of the diffusion process, the treatment conditions were chosen considering a reduced duration and the easy implementation of the process, without producing visible alterations of the gel state, such as shrinkage and intumescence. The samples have been accordingly labelled IR-GE, MW-GE, UV-GE or IR-GL, MW-GL, UV-GL. The gels must be stored in sealed vessel, otherwise they become white, no longer transparent and increasingly rigid and brittle. The bleaching is due to the nucleation and growth of water bubbles and/or crystalline quartz, with size varying from 5 to 27 nm, as evidenced through Dynamic Light Scattering measurements (see Supplementary Materials).

Finally, two new samples (GE-0 and GL-0) were prepared and studied systematically using DSC and DMS at different aging times. The six days aged samples were observed under the SEM COXEM EM30AX (Coxem, Daejeon, Korea) with 15 kV electron acceleration.

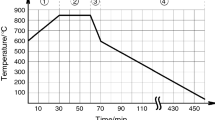

Differential scanning calorimetric (DSC) analyses, recorded simultaneously with thermo-gravimetric analysis (TG), was carried out using Labsys SETARAM thermobalance (Caluire, France) with a heating ramp of 5 °C/min from room temperature up to 600 °C in nitrogen atmosphere.

The behavior of each type of gel (GE-0 and GL-0) was then observed during heating in oil up to intumescence (foaming). At the end the extremely fragile residues were observed under the SEM, described before.

The shear modulus and glass transition temperature of the samples were investigated using an EXSTAR DMS6100 thermo-mechanical analyzer (Seiko Instruments Inc. Chiba, Japan). All the samples were analyzed using the shear modulus and a heating rate of 5 °C/min from room temperature (around 25 °C) up to 200 °C with a load of 50 mN at a frequency of 1 Hz.

The residues of the DMS were then observed under the SEM, described before.

3 Results and discussion

The gels as prepared were completely transparent except for a few bubbles visible in some of them. DLS analysis neglected any presence, if not sporadic and statistically irrelevant, of nanometric aggregates. The refractive indices measured on all the samples were homogeneously slightly lower than the value of the standard consisting of pure silica glass. Accordingly, the silica gels are completely free of metal impurities, which would have made the index rise. Moreover, in pure silica glass, the degree of connectivity is close to the theoretical maximum value of four oxygen bridges for each silicon atom. Those bonds speed up the linear transmission of the light beam, while in gels, consisting of amorphous macromolecular silica produced by reactions of hydrolysis and condensation of the reactants, connectivity decreases.

Dynamic mechanical spectroscopy in shear stress configuration is the best technique for studying amorphous and polymeric materials, subjected to cyclic mechanical stress in a temperature range up to 200 °C. G′ is the conservative modulus, the rigidity related to the domains having high connectivity, whereas G″, the dissipative modulus, indicates the amount of disordered terminal chains, which are going to condensate massively giving rise foaming with a strong loss of solvent or water. The samples immediately after preparation are soft because of low connectivity. In laboratory conditions, samples can be considered “mature” after at least 6 days. In fact, in Fig. 1a–c, the DMS analyses of 2 days aged samples are reported. The curves of IR-GL stopped at around 100 °C, due to the shrinkage induced already at a low temperature during the test. The IR radiation has reached during the thermal curing the innermost points of the sample more evenly, promoting a greater condensation reactivity since the beginning of the DMS test. In fact, it can be observed that G’ curve increases slowly up to about 40 °C, suggesting an increase of connectivity by condensation, meantime also G” curve grows up to the value of about 60 °C, indicating an improved mobility of terminal chains. This can be due presumably to foregoing hydrolysis and condensation reactions. According to many authors, the temperature of the peak of G″ curve is a measure of Tg, glass transition temperature [30, 31]. The other two samples, MW-GL and UV-GL, managed to complete DMS run. In these two other samples, the curing irradiation with shorter wavelength couldn’t provide a deep penetration and the release of water occurred slowly during DMS test. However, the MW-GL sample shows, similarly to IR-GL an initial growth of G’ and G” curves, although in a narrower temperature range, and a following collapse of the two moduli, corresponding to the peak of tan delta above 100 °C. This event modified gel structure and it is followed by a second growth of the two moduli curves up to 140 °C. For UV-GL sample, it can be observed that although G” curve grows up to the maximum value 60 °C, G’ one is always decreasing. Moreover, UV-GL sample shows similarly a peak of tan delta above 110 °C, but after that the two curves do not grow significantly. DMS analyses confirm that in the samples IR-GL and MW-GL the endothermal phenomena, which consent the heat absorption during fire, occur mainly by condensations both at lower and higher temperatures, up to 200 °C, whereas UV-GL release mainly free water in conjunction with hydrolysis. The data allow us to hypothesize that a good intumescence must occur in a single large event at high temperature and it does not consist only in the release of free water from a “wet”gel, but also and above all of condensation water.

The gels form through the condensation of the silica domains in the starting sol with potassium silicate. Both the complexing agents, glycerol (GL) and ethylene glycol (GE), can change the further condensation paths, controlling and slowing them down. Ethylene glycol inhibits aggregations within the silica network, that high percentage can prevent the formation of a three-dimensional silica lattice, and drive to obtain controlled porous materials [32]. Therefore, a percentage of GE higher than 5%, as in the present study, may completely hinder foaming. The two species (GL and GE) can also interact with free water molecules or any other type of ion [10, 11].

The condensation reactions (within the silicate and between this and the silica nano-domains) occur accompanied by thermal exchanges, accordingly thermal analyses can detect these processes. However, as discussed before, condensation between close groups will take place partially already in the preparation step and during curing. The residual groups, that in the beginning are far away, approach with the shrinkage and condense at higher temperature (within 200 °C) giving rise to intumescence. Accordingly, it depends on the quantity and type of reagents or the order in which they are mixed, but mostly on the curing treatment, which could be considered an accelerated aging process. Those described in the experimental part have been designed considering the needs of an industrial plant. Several tests have been carried out in laboratory on very thin samples to understand if differences are due to the depth of penetration of the used electromagnetic radiation (IR, MW and UV). The higher the energy provided by electromagnetic waves, the higher the degree of connectivity of the silica-based material, the lower the intumescence.

In Figs. 2a–c and 3a–c, the TG-DSC curves of the 2 days aged samples IR/MW/UV GE and GL, respectively, are shown. The samples lost about 40% of their initial mass up to 200 °C; those with glycerol (IR-GL, MW-GL, UV-GL) at about 350 °C showed a further loss due to combustion/pyrolysis of the glycerol.

The DSC curves of samples mainly show a group of peaks very close and partially overlapping, indicating endothermic processes between 105° and 157 °C, involving evaporation of water simply entrapped or deriving from the condensation of silanols in different macromolecular species. The peaks are mainly two, but in some cases a third peak appears at the end of temperature range. Looking at the DSC curves, it is seen that there are two main endothermic peaks present, and similarities appear between the heat treatments, IR and MW on one side and UV on the other, with both GE and GL. In Fig. 2a and b, IR-GE and MW-GE curves show at lower temperature a peak with a maximum at about 110 °C smaller than the second at about 135 °C, whereas the curve of UV-GL shows a wide peak at lower temperature and a pronounced shoulder at higher temperature. In Figs. 3a and b, the peak at lower temperature is wider and more intense than the second in IR-GL and MW-GL curves, on the contrary in the UV-GL curve the shoulder at higher temperature is slightly reduced. Since the peaks at lower temperatures correspond to the release of free water molecules or from the condensation of very close silanols, while those at higher temperatures correspond to the condensation of silanols which have come together after shrinkage, the ratio between the two types of peaks (at low and high temperatures) is indicative of the effectiveness of the curing treatment, with respect the intumescence. It should be remembered that intumescence should occur in a single large heat absorption event which favors the release of water at a temperature not too low. The release of water occurred during preparation and curing is subtracted to the intumescence during application as a fire-resistant material. As discussed above, most of the condensation take place within 100 and 160 °C, where endothermal peaks are visible in TG-DSC curves: the more intense the peaks, the more suitable the gel as fire retardant. In Fig. 2a and b, the curves of IR and MW cured samples similarly show a main narrow peak at higher temperature: if the endothermal peaks are low in that range, condensation must be occurred mainly during curing. At this regard it appears that UV curing provide a similar behavior, irrespective of the complexing agent, but the peak of foaming takes place just above 100 °C. This is presumably due to the low penetration depth of UV radiation, which avoids water can be released already during curing. Furthermore, the lower gel connectivity, the lower its viscosity. Accordingly, the most suitable viscosity for casting and the intumescence at higher temperatures derive mainly from the research and development activity within the production plant [6]. Acidic catalyzed sol–gel compounds tend to have higher density than the base-catalyzed ones [28]. The solvent used for the synthesis, generally the parent of the used silicon alkoxide (so that the gel is typically called alcogel), together with water molecules, is initially confined in the dead space between the oligomeric forming macromolecules [33]. As the number of Si–O–Si bridges increases by condensation up to gelation, with the formation of branched clusters, discrete species, the solvent, is gradually expelled out the gel (syneresis). The further condensation occurs during curing and lets to a denser packing of inorganic oligomeric domains until the shrinkage and the structural collapse reduces dead space to nanometric size [31]. Of course, during the intumescence no alcoholic solvent should be released in order not to feed the flame and possibly only water should be released, but, although heating favors water release, bubbles must nucleate and grow.

Since the TG-DSC analyses of the samples aged two days before curing did not allow to reach a definitive conclusion, it was decided to investigate the question using new samples that were left to age on their own and with a curing treatment by IR, MW and UV. The latter can be therefore considered as accelerated aging treatments. In the laboratory conditions, the gels maintained in sealed vessel became “mature”, i.e. it reaches a glassy state that is no longer subject to large variations by heating, after 6–9 days from preparation. Although the TG-DSC curves have not been reported in the paper, it is observed that with natural or accelerated aging the foaming endothermic peaks shift to higher temperatures within the range indicated before. It is also observed that the gels become increasingly glassy and dense, such that it can no longer be of any use from the point of view of application as a fire-resistant material. To study the phenomena, two gels (GE-0 and GL-0), containing GE and GL, respectively, were cast in molds and 48 h after preparation were moved into a beaker containing high temperature oil and heated at constant rate (20 °C⁄min). At the beginning, sample GE-0 was “soft and wet”, presumably because some of the reagents were still unreacted. It had the consistency of a low modulus polymer and deformed under its own weight when removed from the mold, which therefore acted as a support. During the heating in oil in the range 40–50 °C, the sample “settled” into the shape of the container. Meantime, some condensed moisture appeared on the glass beaker, due to the release of water from the sample. At 80–90 °C, some cracks formed on the edges of the still vitreous sample, which stuck to the beaker. Above 100 °C, blisters became visible in the sample, still rubbery. Increasing the temperature, the sample hardened and at 120 °C became completely white. At 140 °C the sample began to “swell” due to a large intumescence. At 160 °C the observations were stopped, and the final sample resulted fragile even under small stresses.

Similar observation was carried out on sample GL-0. Two days after preparation, it was still fluid as honey. Transferred into the beaker containing thermally resistant oil, at 40 °C, the gel resulted sticky, thickened to the point that poking the surface left a mark. At 70 °C, the sample reached such a thick consistency that, after poking, marks became persistent, but, underneath the surface film, it seemed to be still fluid. No moisture condensed on the beaker’s wall. At 90–110 °C the sample appeared solid and numerous small-diameter bubbles began to form beneath the surface. At 120 °C foaming, whitening and volume increase started up until 140 °C. By continuing the heating, the white solid started to release smoke, probably due to glycerol combustion.

According to the observations during the heating in oil, intumescence appears different depending on the complexing agent. GE is highly efficient as complexing agent and a high amount could even stop foaming. However, in the extent of 5 wt% of silica in GE-0 sample, nucleation of very small moisture bubbles, hardly visible to the naked eye, occurs already at low temperature as testified by released moisture. None of initial bubbles can grow preferentially with respect to the others, therefore resulting in uniform and constant foaming. Instead, moisture bubbles nucleation in GL-0 occurs at higher temperature when their growth is easier, giving rise to the so-called “popcorn” effect.

In Figs. 4 and 5 are reported both TG-DSC and DMS curves for all the samples GE-0 and GL-0 at six days of aging before and after thermal curing treatment. The samples lost the same percentage of weight, which means the TG-DSC analysis always ended with intumescence within 200 °C.

As regards DSC curves, it is worth noting that all the samples, quite irrespective of the used complexing agent, show a pronounced main peak with a maximum above 110 °C. This confirms the aging is useful to condense gels and let the intumescence occur in a single phenomenon. Only GE-0 6d, GE-0-IR 6d and GE-0-MW 6d show also a minor second peak at above 130 °C, whereas GL-0 6d and GL-0-IR 6d show just a shoulder. In DSC curve of sample GE-0 the first peak has a maximum of approximately 113 °C, and the second at about 138 °C (Fig. 4a). All the curing treatments on 6 days aged samples promote a single peak with a maximum of approximately 125 °C and, if anything, a shoulder at higher temperature. The latter indicate that the silica lattice is already well interconnected and the residual condensation reactions take place only when new groups keep in touch.

In Figs. 4 and 5 the DMS curves of GE and GL samples, respectively, are shown and give the measure of the gel rigidity. It is worth noting that, differently from Fig. 1, the G′ and G″ curves of all the samples show the same trend: this suggests the gel after six days aging behaves as a quasi-solid (d ≤ 45°) homogeneous material. If in all these cases, DSC curves simplified showing a main single peak, on the contrary, their G′, G″ and tan d curves showed many phenomena both at lower and at higher temperatures. Moreover, GE-0 6d and GE-0-IR 6d samples show many spikes at temperatures above 110 °C whereas GE-0-UV 6d and GE-0-MW 6d above 120 °C, respectively. The presence of spikes after the temperature of the maximum of the DSC peak and related to the intumescence suggests that it is accompanied by dimensional changes that allow movements of the sample inside the clamps. This also indicates that within the gel there still are several groups able to condense releasing water or solvent, much more in the uncured sample (GE-0 6d) than in the cured ones, as expected. Moreover, the presence of spikes makes difficult to read the glass transition events. The G′ and G″ curves of the GL samples do not show spikes, unless very few negligible ones both in the uncured and UV cured samples: glycerol seems to stabilize the gel and make much easier to control condensation, which occurs, as reported before, not only and mainly in a single phenomenon, but also without significant shrinkage, which can cover glass transitions. When G′, G″ and tan δ are plotted against temperature, the presence of glass transition can be assessed and the corresponding temperature (Tg) easily read off either at the maximum of loss tangent peak or at the maximum of loss modulus peak [31, 33]. Of course, the two values cannot be the same and the second is always lower than the first. Alternatively, Tg could be also evaluated from the storage modulus curve as the onset of the step or at its inflection point (the value is about that measured at the maximum of loss modulus peak). These two latter evaluations are not very common and sometimes are not immediately detectable, as could be the case for the maxima of G″ and tan d curves. Moreover, the damping peak could be used to evaluate the thermal wideness of transition(s) and it is measured as the width at half height of the peak. The narrower the peak, the higher the homogeneity. On the other hand, a wider damping peak is somewhat representative of more heterogeneous domains and the co-existence of several transitions due to the chemical interactions between the components in the materials. To compare the different materials, the same value must be considered [31, 33, 34]. As discussed before, the evaluation of the presence of glass transitions of GE-0 samples is very difficult and therefore we will focus on GL-0 samples. The uncured (GE-0 6d) has a pronounced narrow damping peak at about 70 °C, a negligible one above 110 °C and even a third above 140 °C. All of them indicate that the gel is still able to condense, but the major events occurred at lower temperature before intumescence. The cured samples typically show two main wide damping peaks before and after intumescence. GE-0-IR 6d and GE-0-UV 6d show the first both at 70 °C, whereas the second at 130 and 140 °C, respectively. The most interesting result was observed for GE-0-MW 6d sample, which lower damping peak has a maximum at about 80 °C, then above about 120 °C the tan d curve slowly increases up to a maximum above 150 °C, whereas the descendant part of the peak is out of the measurement temperature range. The higher the Tg, the better the application.

Figures 6 and 7 show the SEM images of GE-0 and GL-0 sample, respectively, 6 days aged at room temperature before any treatment (a) and the two residuals of the thermal treatment at 160 °C in oil (b) and of the DMS analyses of the MW cured samples (c). The latter (Figs. 6c, 7c) both appear to be solid foams: the MW curing treatment promote stiffness of gel, leaving the residual condensation during intumescence occurring at higher temperature. However, glycol containing sample shows much greater evenly spread porosity (Figs. 6b, c, 7b, c). Moreover, looking at the images of the samples 6 days aged at room temperature (Figs. 6a, 7a), it could be found some porosity already formed in GE-0 6d (Fig. 6a), but not in GL-0 6d (Fig. 7a). If bubbles nucleate at higher temperature, they must grow fast.

4 Conclusion

Some transparent gels containing silica was considered among those used between two sheets of glass as fire-retardant. They exhibit interesting intumescent characteristics according to composition and curing treatments, so that we have provided a systematic investigation into their thermal behavior up to 200 °C. The effects on thermal intumescence of the complexing agent—ethylene glycol vs. glycerol—as well as the curing treatment—IR, UV, MW—were examined using thermal-calorimetric (TG-DSC) and dynamic-mechanical spectroscopy (DMS) analyses before and after aging/curing.

Gels lose about 50 wt% up to 200 °C: in this range of Temperature an endothermal group of peaks are visible on the heat-flux DSC curves, attributable to intumescence. DMS analysis let to assess that a MW cured glycerol-containing gel shows a glass transition above 150 °C, so that it results the best option for application: bubbles nucleate at high temperature and grow fast. Thus, glycerol could be a better choice in a gel as a fire-retardant material, given that intumescence starts and completes at higher temperatures. The microwave treatment was assessed to heat homogeneously and fast the gel, also before the casting between glass sheets, so that residual condensation/intumescence could occur only at a higher temperature. This is beneficial from the point of view of both application and durability of the window. The latter cannot easily whiten due to residual condensation activated by absorbing sunlight or due to other occasional sources of heat.

Data and code availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Graham T (1864) XXXV: on the properties of silicic acid and other analogous colloidal substances. J Chem Soc 17:318–327

Fonseca BT, D’Elia E, Siqueira Júnior JM et al (2021) Study of the characteristics and properties of the SiO2/TiO2/Nb2O5 material obtained by the sol–gel process. Sci Rep 11:1106. https://doi.org/10.1038/s41598-020-80310-4

Singh LP, Bhattacharyya SK, Kumar R, Mishra G, Sharma U, Singh G, Ahalawat S (2014) Sol-Gel processing of silica nanoparticles and their applications. Adv Coll Interface Sci 214:17–37. https://doi.org/10.1016/j.cis.2014.10.007

Klein LC, Aparicio M, Jitianu A (2017) Handbook of sol–gel science and technology. Springer, p 570

Camino G, Costa L, Cortemiglia ML (1991) Overview of fire-retardant mechanisms. Polym Degrad Stab 33:131–154

Liu W, Ge X, Zhou X, Tang Y (2015) Thermal intumescent behaviour of a gel containing silica. RSC Adv 5(42):33208–33211. https://doi.org/10.1039/C5RA00558B

Morgan AB, Wilkie CA (2014) Non-halogenated flame retardant handbook. Scrivener Publishing, USA, pp 169–199. https://doi.org/10.1002/9781118939239.ch5

Kuprin DS (2017) Physical–chemical explanation of fire-fighting efficiency of FHF (fast-hardening foam) based on structured silica particles. J Sol-Gel Sci Technol 81:36–41. https://doi.org/10.1007/s10971-016-4285-8

Jeffrey BC, Scherer G (1990) Sol–gel science the physics and chemistry of sol–gel processing. Elsevier, pp 108–215

Di Maggio R, Dirè S, Callone E, Bergamonti L, Lottici PP, Albatici R, Rigon R, Ataollahi N (2020) Super-adsorbent polyacrylate under swelling in water for passive solar control of building envelope. SN Appl Sci 2(1):1–13

Dashnau JL, Nucci NV, Sharp KA, Vanderkooi JM (2006) Hydrogen bonding and the cryoprotective properties of glycerol/water mixtures. J Phys Chem B 110:13670–13677

Díaz-Ortiz Á, Prieto P, de la Hoz A (2019) A critical overview on the effect of microwave irradiation in organic synthesis. Chem Rec 19(1):85–97. https://doi.org/10.1002/tcr.201800059

Cao Yuan WEI, Hong-Juan X-N (2009) Advances in microwave assisted synthesis of ordered mesoporous materials. Trans Nonferrous Met Soc China 19:656–664

Kim DS, Chang J-S, Kim WY, Kim HY, Park S-E (1999) Beneficial role of ethylene glycol in the synthesis of MCM-41 material under microwave irradiation. Bull Korean Chem. Soc. 20(4):408–410

Innocenzi P, Malfatti L (2015) The sol–gel handbook. Wiley, pp 165–194. https://doi.org/10.1002/9783527670819.ch05

Alemdar N, Karagoz B, Erciyes AT, Bicak N (2007) A method for polymethymetacrylate coating via self-curable unsaturated polyester primer on metal and glass surfaces. Prog Org Coat 60(1):69–74. https://doi.org/10.1016/j.porgcoat.2007.06.005

Lasagni AS, Seyler M, Holzapfel C, Maier WF, Mucklich F (2005) Periodical gratings in mixed-oxide films by laser-interference irradiation. Adv Mater 17(18):2228–2232. https://doi.org/10.1002/adma.200402074

Innocenzi P, Malfatti L, Kidchob T, Costacurt S, Falcaro P, Marmiroli B, Cacho-Nerin F, Amenitsch H (2011) Densification of sol–gel silica thin films induced by hard X-rays generated by synchrotron radiation. J Synchrotron Radiat 18(2):280–286. https://doi.org/10.1107/S0909049510051666

Romanato F, Guglielmi M (2008) Design of hybrid sol–gel films for direct X-ray and electron beam nanopatterning. Nanotechnology 19(17):175306. https://doi.org/10.1088/0957-4484/19/17/175306

Hikemet RAM, Thomassen R (2003) Electron-beam-induced crosslinking of electroluminescent polymers to produce multicolour patterned devices. Adv Mater 15(2):115–117. https://doi.org/10.1002/adma.200390021

Tirumala VR, Divan R, Mancini DC, Caneba GT (2005) Fabrication of high-aspect-ratio hydrogel Microstructures. Microsyst Technol 11(4):347–352. https://doi.org/10.1007/s00542-004-0453-9

Di Maggio R, Campostrini R, Guella G (1998) Gels from modified zirconium N-butoxide: a pyrolysis study by coupled thermogravimetry, gas chromatographic, and mass spectrometric analyses. Chem. Mater. 10(12):3839–3847

Flores-López SL, Villanueva SF, Montes-Morán MA, Cruz G, Garrido JJ, Arenillas A (2020) Advantages of microwave-assisted synthesis of silica gels. Colloids Surf A Physicochem Eng Asp. https://doi.org/10.1016/j.colsurfa.2020.125248

Das B, Mandal AK (2022) A comparative study on copper doped sodium alumina-phosphate glass with conventional and microwave heating. Opt Mater Part A. https://doi.org/10.1016/j.optmat.2022.113146

Chen K, Li X, Lv D, Yu F, Yin Z, Wu T (2011) Study on microwave absorption properties of metal-containing foam glass. Mater Sci Eng B 176(15):1239–1242. https://doi.org/10.1016/j.mseb.2011.06.010

Siddiquey IA, Furusawa T, Hoshi Y-i, Ukaji E, Kurayama F, Sato M, Suzuki N (2008) Silica coating of CeO2 nanoparticles by a fast microwave irradiation method. Appl Surf Sci 255(5):2419–2424. https://doi.org/10.1016/j.apsusc.2008.07.112

Ghosh SS, Sil A (2022) Effect of microwave processing on Mn doped ZnO diluted magnetic semiconductor characteristics. Mater Today Commun 32:103941. https://doi.org/10.1016/j.mtcomm.2022.103941

Hamulić D, Medoš G, Korte D, Rodič P, Milošev I (2023) The effect of curing temperature and thickness of polybutyl methacrylate siloxane coatings on the corrosion protection of structural steel S355. Coatings 13(4):675. https://doi.org/10.3390/coatings13040675

Kim TH, Song KC (2022) Low-temperature preparation of superhydrophilic coatings using tetraethoxysilane and colloidal silica by sol-gel method. Colloids Surf A 647:129105. https://doi.org/10.1016/j.colsurfa.2022.129105

Graziola F, Girardi F, Di Maggio R, Callone E, Miorin E, Negri M, Müller K, Gross S (2012) Three-components organic–inorganic hybrid materials as protective coatings for wood: optimisation, synthesis, and characterisation. Prog Org Coat 74(3):479–490. https://doi.org/10.1016/j.porgcoat.2012.01.013

Di Maggio R, Fambri L, Mustarelli P, Campostrini R (2003) Physico-chemical characterization of hybrid polymers obtained by 2-hydroxyethyl (methacrylate) and alkoxides of zirconium. Polymer 44(24):7311–7320. https://doi.org/10.1016/j.polymer.2003.09.025

Takahashi R, Nakanishi K, Soga N (2000) Aggregation behavior of alkoxide-derived silica in sol–gel process in presence of poly (ethylene oxide). J Sol-Gel Sci Technol 17:7–18

Buckley AM, Greenblatt M (1994) The sol–gel preparation of silica gels. J Chem Educ 71(7):599. https://doi.org/10.1021/ed071p59

Besbes M, Fakhfakh N, Benzina M (2009) Characterization of silica gel prepared by using sol–gel process. Phys Procedia 2(3):1087–1095. https://doi.org/10.1016/j.phpro.2009.11.067

Acknowledgements

We wish to thank Mr. Sai and Dr. Poletti of Doors&More for the gel samples for characterization.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Conceptualization: RDM; Data curation: OC, NA and RDM; Formal analysis: RDM, OC; Funding acquisition: RDM; Investigation: RDM, OC and NA; Methodology: RDM, OC; Resources: RDM; Software: OC; Validation: RDM, OC and NA; Visualization: OC; Writing—original draft: RDM, OC; Writing—review and editing: RDM, OC and NA; All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript. The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cotini, O., Ataollahi, N. & Di Maggio, R. Curing treatments of silica gel for fire-retardant glass by intumescence. SN Appl. Sci. 5, 319 (2023). https://doi.org/10.1007/s42452-023-05532-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-023-05532-3