Abstract

The yttria-stabilized zirconia (YSZ) is added to a bioactive glass coating through the electrophoretic deposition (EPD) method to significantly improve the mechanical properties, in particular the bonding strength of the coating on the Ti substrate. In this study, suspensions of bioactive glass and YSZ powder (at the same ratio, 20 g/l) are prepared in ethanol solvent; and tri-ethanol-amine is used as the stabilizer. The effects of the EPD parameters such as deposition time and voltage are studied. The optimum coating quality is achieved at a voltage of 60 V for 10 min. After coating, sintering is performed at three different temperatures (800, 850, and 900 °C). The XRD is used to identify the structure and phase of yttria-stabilized zirconia powders and the coated samples. FE-SEM is also employed to assess the microstructure of the specimens. The highest adhesion strength (\(\sim\) 4.38 MPa) is obtained at the sintering temperature of 850 °C.

Article Highlights

-

Optimum voltage of coating is obtained at the voltage of 60 V.

-

Optimum time of coating is 10 minutes.

-

The sintering temperature of 850°C is suitable for the produced coatings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Metal implants are usually used as a substitute for bulky bones, due to their high strength, and biocompatibility [1]. However, corrosion resistance of metal implants in biological environments is one of the problems which could be resolved by coating. Titanium implants can be coated with hydroxyapatite and bioactive glasses for biomedical applications with excellent biocompatibility and bone conduction [2].

Different methods have been developed to apply biocompatible coatings including plasma spray [3,4,5], mechanical milling [6], pulse laser [7,8,9], aerosol [10, 11], sol-gel [12, 13], electro-deposition [14], pulse electron [15, 16], EPD method [17]. These methods can be employed as processing techniques for the fabrication of coatings and small parts with complicated shapes [17]. EPD method has several advantages over the conventional coating approaches, including short formation time, low costs, simple instrumentation, production versatility for coating on non-planar substrates such as complex-shaped implants, and capability of mass production [2, 17]. Besides, it has been found that nanostructured coatings fabricated by the EPD process have high chemical uniformity, decreased flaw size, microstructural homogeneity, and require lower sintering temperatures for densification [17]. Compared with other methods, the EPD method can be easily controlled in addition to flexibility in microstructural manipulation, thickness control, and offering uniform coating. Regardless of the coating method, the coating must be physically and mechanically stable in the body [18]. Even partial delamination of the coating can lead to the contamination of the implant site, hence, unwanted side effects [19].

In comparison with metallic implants, the yttria-stabilized zirconia (YSZ) shows minimum ion release and biological inertness [20,21,22]. Some documents [23,24,25] have mentioned that the application of YSZ decreases the risk of reactions in surrounding pre-implant tissues, as it can reduce biofilm aggregation and bacterial adhesion [14, 26]. To the best of the authors' knowledge, this research is the first one addressing the deposition of the yttria-stabilized zirconia-bioactive glass nanocomposite on titanium using the EPD method. The incorporation of the biocompatible YSZ into the bioactive glass coating led to proper matching between the thermal expansion of the coating and the substrate, hence, preventing crack initiation on the surface of the coating.

In the next section of this paper, experimental is considered, Sect. 3 shows results and discussion. In Sect. 4, conclusions are presented. Finally, references are added.

2 Experimental

First, the titanium grade 2 (ASTM 256) sheet was cut into a thickness of 2 mm, a length of 10 cm, and a width of 1 cm. Then, they were sandblasted to allow the coating to adhere to the substrate. The sheets were placed in acetone for 10 min in an ultrasonic bath to remove the contaminations. YSZ-stabilized zirconia powder with ZrO2-3% Y2O3 composition was purchased from the Chinese company (Jiaozuo Huasu hemical Co.) with a particle size of 50 nm and purity over 99%. Ethanol (99.5%) and Tri-ethanol-amine (TEA) [N (CH2CH2OH)3 Merck Inc.] were used as a solvent and stabilizer, respectively. Figure 1 shows a schematic view of the EPD cell. The EPD cells contained two Ti and stainless steel electrodes at a distance of 10 mm. Electrodes were submerged parallel to each other in the suspension. Stainless steel was used as the anode material, whereas the cathode electrode was made of Ti sheets with a thickness of 2 mm. The steel was precisely cut into rectangular-shaped substrates with dimensions of 10 × 10 cm2. The detail of the EPD cell used in this research can be found in previous works of the authors [23]. A power supply was used with a voltage up to 120 V (Struers model: Polectrol made in Denmark). The bioactive glass powder was prepared by melting the glass (45 SiO2-25.5Na2O -24.5 CaO-6 P2O5 wt. %) at 1400 °C for 2 h in an alumina crucible. A suspension was prepared using 20 g/l of the bioactive glass and YSZ at the ratio of 50%/50% in ethanol containing 0.15 g/l of TEA. The suspension was aged for 45 min and then placed in an ultrasonic bath for 30 min. After the EPD process, the samples were slowly dried at room temperature for 24 h to eliminate the organic solvent. Before and after the coating process, the specimens were weighed by a digital balance (METTLER AT201) with an accuracy of 0.0001 g. The weight of the coating was calculated at 30, 60, and 90 V at an optimum time of 10 min. Then, the samples were sintered (with a heating rate of 2 °C/min) in the furnace under neutral atmospheres of argon at 800, 850, and 900 °C for one hour at atmospheric pressure. The FE-SEM (MRIA3TESCAN-XMU) was used for the microstructural evaluation of the surface of the coating. The structure and phase of the coated samples before and after sintering were assessed by XRD analysis using ULTIMA4-Riguka PHILIPS-binary with a copper lamp with a wavelength of 1.54 Å in the angle range of 5 to 100° and the step size of 0.02°/s). The bonding strength of the coating was determined at different sintering temperatures by a pull-off testing machine (the POSI Test Manual DEFELSKO manual and 14 mm diameter ASTM D4541 standard). The Pull-off test was conducted for the coated samples with a dimension of 2 × 2 cm2.

A schematic view of the EPD cell, including a a thick deposit on the working electrode (WE) and a thin one on the counter electrode (CE), b a basic model of an EPD cell, and c variations of the potential of an EPD cell during deposition [23]

3 Results and discussion

The FE-SEM images and EDS spectra were used to determine the morphology and particle size of the bioactive glass powder as depicted in Fig. 2 shows.

The FE-SEM images indicate the multifaceted particles with dimensions below three microns. The EDS results also reveal the weight percentage of each element in the bioglass powder, confirming the formation of the bioactive glass.

Figure 3 shows the XRD pattern and TEM micrograph of YSZ nano-powder provided by the manufacturer. This powder mainly contains a tetragonal phase as well as a slight amount of monoclinic phase with a mean particle size of \(\sim\) 50 nm.

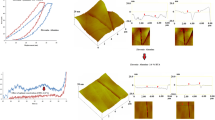

Figure 4 shows the FE-SEM image of the surface of the bioactive glass films on the Ti substrate at different temperatures after the sintering process, a: at 800 °C, b: 850 °C, and c: 900 °C. As seen in the images, the structure is completely interconnected after the sintering. Matching between the sintering shrinkages of the coating and the substrate is an important factor in achieving dense coating [17]. As can be seen in Fig. 4 b, sintering at 850 °C led to nearly optimum coherence and uniformity compared to Figs a and c which are related to the sintering at temperatures of 800 °C and 900 °C, respectively.

The main problem of the EPD method for the bioactive glass coating of titanium substrate is the sintering of these coatings. High-temperature sintering results in the degradation of the substrate. Therefore, the sintering temperature should be ideally below 1000 °C. The mentioned temperature does not, however, suffice to result in a properly strong bioactive glass. As a result, a slight adhesion occurs between bioactive glass and the metal substrate. The sintering shrinkage of bioactive glass coating and the mismatch of the expansion coefficient of the coating with the base metal promote the formation of cracks in the interface of coating- metal substrate [20]. The incorporation of biocompatible ceramics such as zirconia, alumina, and titania into a bioactive glass coating can remarkably improve the mechanical properties without compromising the biocompatibility [21]. Among the biocompatible ceramic materials, zirconia has shown powerful mechanical properties and good biocompatibility. In this research, the addition of YSZ to bioactive glass coating led to a fairly close match between the thermal expansion coefficients of the coating and the substrate, preventing cracks initiation on the coating surface.

Table 1 lists the bonding strength of the bioactive glass–YSZ composite at three different sintering temperatures.

As can be seen, the highest adhesive strength was achieved at 850 °C. Under similar conditions, the bonding strength of the bioactive glass coating was 2.4 MPa. Based on Table 1, the bonding strength of the composite coating was about two times higher than the bioactive glass, due to the higher compatibility of thermal expansion coefficients of the substrate and bioactive glass. The incorporation of YSZ into the bioactive glass led to more adaption of the thermal expansion coefficient of the substrate, as it increases the adhesion strength of the coating to the substrate. The thermal expansion coefficients of the biologically active glass, YSZ and titanium are 16 × 10−6/°K, 10.5 × 10–6/°K, and 8.6 to 10–6/°K, respectively [22].

Figures 5 and 6 show the XRD patterns of green and sintered bioactive glass and the bioactive glass -YSZ composite samples. As seen, the XRD results confirm the amorphous phase of the bioactive glass coating. Of course, a very small amount of crystalline phase can be observed which is related to sodium calcium silicate characterized by angles of 9, 26.7, 33, 34.4, 48.8, and 60.9°. In the composite coating, in addition to this phase, some peaks related to the tetragonal zirconia phase can be detected at 30, 50, and 60°, as well as titanium peaks at 40, 35, and 38° due to the presence of the titanium substrate.

Figure 6 indicates the crystallization of the amorphous phase into silicate phosphorus sodium-calcium (Na3CaPSiO7) with monoclinic structure (8.32, 9.33, 1.35, 6.44 and 49° with code reference of 0485-035-00) and calcium sodium phosphate (Na2Ca (PO4)2SiO4) with hexagonal structure (4.33, 5.31 and 46.46° with code reference of 1229-033-00).

In both coatings, the rutile phase (TiO2) with a tetragonal structure can be detected at the angles of 27, 3.54, and 36°, with a code of 0317-076-01, indicating the partial oxidation of titanium substrate during the coating process. Similar results were reported by Khanali et al. [23].

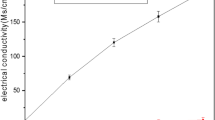

Table 2 shows the weight of coating at different voltages at the constant time of 10 min.

As seen, the weight of the coating increased with the enhancement of the voltage. During the deposition process, the charge of particles affects the density of the deposits. When the particles approach each other, they stick together and tend to agglomerate with the increase of the attraction forces. If the particles have a low surface charge, they will agglomerate even for relatively large inter-particle distances, leading to porous, sponge-like deposits [17, 23]. On the contrary, particles with a high surface charge will repel each other during deposition, leading to higher particle packing density on the surface. However, uniform and crack-free surface coating is important. Figure 7 shows surface images of three samples that were coated at different voltages in 10 min, 7a at 30 V, 7b at 60 V and 7c at 90 V. Images of coating at different voltages show that the voltage of 60 V led to the uniform coating with no cracks (Fig. 7B). Therefore, the optimum voltage of the coating was considered to be 60 V.

The coating weight was measured for 1 to 20 min to determine the optimum time of the coating. Based on Fig. 8, the weight of the coating increases by prolonging the process up to 10 min, beyond which, the deposition rate gradually decreases and flattens at the final stage. This behavior can be explained by the propagated formation of the green coat on the surface of the electrode. The optimal coating time was considered to be 10 min, beyond which, the weight of the coating remained almost constant.

4 Conclusion

Preparation of YSZ-bioactive glass nanocomposite coatings on titanium by different methods has its own difficulties. But YSZ-bioactive glass nanocomposites were successfully deposited using the EPD method. With this research, it was shown that by applying 60 V for 10 min, fairly good coating was applied on titanium by EPD method, so that the adhesive strength of 4.38 MPa was obtained after sintering of this coating at temperature of 850 °C. In the future, improvement of the adhesive strength of these types of coatings could be carried out by the surface treatment of the titanium substrate.

References

Goriainov V, Cook R, Latham JM, Dunlop DG, Oreffo RO (2014) Bone and metal: an orthopaedic perspective on osseointegration of metals. Acta Biomater 10:4043–4057

Campbell AA (2003) Bioceramics for implant coatings. Mater Today 6:26–30

Cattini A, Latka L, Bellucci D, Bolelli G, Sola A, Lusvarghi L et al (2013) Suspension plasma sprayed bioactive glass coatings: effects of processing on microstructure, mechanical properties and in-vitro behaviour. Surf Coat Technol 220:52–59

LeeT-M CEB, Yang C-Y (1996) Characteristics of plasma-sprayed bioactive glass coatings on Ti-6A1-4V alloy: an in vitro study. Surf Coat Technol 79:170–177

Pillai RS, Frasnelli M, Sglavo VM (2018) HA/β-TCP plasma sprayed coatings on Ti substrate for biomedical applications. Ceram Int 44:1328–1333

Davodi R, Ardestani M, Kazemi A (2020) Sinterability and characterization of Ag/Al2O3 metal and ceramic matrix composites processed by mechanical milling. Sci Sinter 52(3):245–255

Bao Q, Chen C, Wang D, Ji Q, Lei T (2005) Pulsed laser deposition and its current research status in preparing hydroxyapatite thin films. Appl Surf Sci 252:1538–1544

Man H, Chiu K, Cheng F, Wong K (2009) Adhesion study of pulsed laser deposited hydroxyapatite coating on laser surface nitrided titanium. Thin Solid Films 517:5496–5501

Curcio M, De Stefanis A, De Bonis A, Teghil R, Rau J (2019) Pulsed laser deposited bioactive RKKP-Mn glass-ceramic coatings on titanium. Surf Coat Technol 357:122–128

Hahn B-D, Park D-S, Choi J-J, Ryu J, Yoon W-H, Choi J-H et al (2011) Preparation and in vitro characterization of aerosol-deposited hydroxyapatite coatings with different surface roughnesses. Appl Surf Sci 257:7792–7799

Feng L et al (2020) Preparation and modification of inverse opal zirconia pigment. Sci Sinter 52(3):299–306

Ghorba MM, Golobostanfard MM (2019) Hierarchical porous ZnO films synthesized by sol–gel method using triethylenetetramine stabilizer. SN Appl Sci 1:267. https://doi.org/10.1007/s42452-019-0274-1

Fathi M, Mohammadi AD (2008) Preparation and characterization of sol–gel bioactive glass coating for improvement of biocompatibility of human body implant. Mater Sci Eng A 474:128–133

Joy-anne NO et al (2019) Bioactive glass coatings on metallic implants for biomedical applications. Bioactive Mater 4:261–270

Bellucci D et al (2017) Pulsed electron deposition of nanostructured bioactive glass coatings for biomedical applications. Ceram Int 43:15862–15867

Surmeneva MA et al (2016) Effect of pulsed electron beam treatment on the physico-mechanical properties of hydroxyapatite-coated titanium. Ceram Int 42:1470–1475

Askari M, Yousefpour M, Rajabi M (2015) Electrochemical and biological characterization HA/Al2O3-YSZ nano-composite coatings using electrophoretic process. J Biomed Mater Res Part A. https://doi.org/10.1002/jbm.a.36392

Zhang B et al (2014) Zhang BG, Myers DE, Wallace GG, Brandt M, Choong PF. Bioactive coatings for orthopaedic implants—recent trends in development of implant coatings. Int J Mol Sci 15:11878–11921

Wan H et al (2017) Failure mechanisms of the coating/metal interface in waterborne coatings: the effect of bonding. Materials. https://doi.org/10.3390/ma10040397

Ren Q, Wang L, Huang Q (2017) A micro-test structure for the thermal expansion coefficient of metal materials. Micromachines 8(3):70

Yin X, Liang C, Ge F (2018) Electrodeposition of a YSZ–Yttria stabilized zirconia composite coating on a titanium bone implant. Int J Electrochem Sci 13:822–831

Kulpetchdara K et al (2016) Influence of the nano hydroxyapatite powder on thermally sprayed HA coatings onto stainless steel. Surf Coat Technol 306:181–186

Khanali O, Rajabi M, Baghshahi S (2017) Effect of non - aqueous solvents on deposition properties in electrophoretic deposition process of yttria stabilized zirconia nano powder. J Ceram Process Res 18:735–742

Das R, Bhattacharjee C (2019) 16 - Titanium-based nanocomposite materials for dental implant systems. In: Asiri AM, Inamuddin A, Mohammad A (eds) Applications of nanocomposite materials in dentistry. Wood head Publishing, (2019) 271–284

Silva-Herzog D et al (2020) Glass coatings to enhance the interfacial bond strength between veneering ceramic and zirconia. Odontology 19:115–118

Dimitriadis K, Moschovas D, Tulyaganov DU, Agathopoulos S (2020) Development of novel bioactive glass-ceramics in the Na2O/K2O-CaO-MgO-SiO2-P2O5-CaF2 system. J Non-Cryst Solids 533:119936

Funding

Funding was provided by INSF (Grant No. 94/sad/42699), 2015, Masoud Rajabi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors have no conflicts of interest associated with the publication of the paper with the title of: “Processing of the Yttria Stabilized Zirconia-Bioactive Glass Nano composite Coating Produced by Electrophoretic Deposition Method” to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shirpay, M.R., Askari, N. & Rajabi, M. Processing of the yttria stabilized zirconia-bioactive glass nano composite produced by electrophoretic deposition method. SN Appl. Sci. 4, 284 (2022). https://doi.org/10.1007/s42452-022-05168-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-022-05168-9