Abstract

This study presents an evaluation of a potential alternative to plastic degradation in the form of organic composting. It stems from the urgent need of finding solutions to the plastic residues and focuses on the compost-based degradation of greenhouse film covers in an important rose exporter company in Ecuador. Thus, this study analyzes the physical, chemical, and biological changes of rose wastes composting, and also evaluates the stability of new and aged agricultural plastic under these conditions. Interestingly, results of compost characterization show a slow degradation rate of organic matter and total organic carbon, along with a significant increase in pH and rise of bacterial populations. However, the results demonstrate that despite these findings, composting conditions had no significant influence on plastic degradation, and while deterioration of aged plastic samples was reported in some tests, it may be the result of environmental conditions and a prolonged exposure to solar radiation. Importantly, these factors could facilitate the adhesion of microorganisms and promote plastic biodegradation. Hence, it is encouraged for future studies to analyze the ecotoxicity of plastics in the compost, as well as isolate, identify, and evaluate the possible biodegradative potential of these microorganisms as an alternative to plastic waste management.

Article highlights

-

The study assesse the stability of agricultural plastic films during real conditions of rose waste composting.

-

Environmental conditions such as a long-term exposure to solar radiation may account in part for the degradation of aged plastic films.

-

After composting, the chemical structure of the new plastic films changed but this finding may correspond to the protective additives.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Plastics are synthetic materials composed of polymeric chains with high molecular weight derived from fossil oil or natural gas. Properties such as low-cost production, durability, resistance, and flexibility have posed plastics as the most popular replacement for related materials, including paper bags, wood, and wool bags [1]. Indeed, statistics have shown that around 6300 million metric tons (Mt) of plastic residues have been generated during 2015 worldwide, of which only 9% have been recycled, while future predictions consider that the world will generate around 230 Mt by 2025 of plastic waste [2, 3]. Consequently, plastic usage translates into high levels of waste, reaching and affecting several ecosystems daily [2, 4]. The resulting accumulation of plastic waste, caused by its slow degradation rate, constitutes a severe environmental problem worldwide [5].

Plastics have been categorized according to their properties and applications. Low-Density Polyethylene (LDPE), in particular, is a type of plastic formed by the polymerization at high pressure of ethylene monomers [6]. It is extensively employed in agriculture as greenhouse covers, mulching, and coating, in which plastic consumption rises to 2 million tons per year [7]. Moreover, greenhouse cover films have a lifetime of two years. After this period, they need to be replaced, leaving deteriorated films as a significant plastic waste source. In Ecuador, for example, the amount of plastic used to cover one hectare (ha) of greenhouse is roughly 1000 kg per year [8].

Ecuador is one of the major floriculture producers for exports worldwide. It occupies the third place after the Netherlands and Colombia in the entire ornamental industry, and it is the number one in exports of roses as a cut flower, being one of the five main economic sectors in the country [9]. By 2019, the flower industry generated about 800 million USD, destining approximately 4900 ha for the production of flowers [9]. In consequence, this sector generates an enormous amount of waste, including plastics and organic wastes with high concentrations of pesticides and agrochemicals.

Ecuadorian regulations in agricultural waste management require the collection and disposal of plastics by authorized environmental managers. Nevertheless, while such regulations exist, plastic-waste management plans in many waste generator companies, including the agricultural, floricultural, and forestry sectors, are still incipient. The apparent lack of effective plans may be, in part, a consequence of the myopic focus on organic waste. Current waste management programs seek to treat and re-incorporate organic residues as soil fertilizers, while plastics (greenhouse films, bags, package films) are sometimes buried in plantation pits, discarded in landfills, or burned uncontrollably in the open fields, especially among small farmers [6]. Additionally, it has been reported that greenhouse plastic films and containers from pesticide packages are dumped in creeks or sold to members of the community [10]. This implies a chronic exposure of the community to toxic chemicals derived from pesticides, including organophosphates, carbamates, and chlorinates, known for being carcinogenic and hormone-disrupters [10]. Managing such an enormous amount of waste will considerably impinge on the environment, whose repercussions are well worth considering. It is, therefore, necessary to emphasize the urgent need to find alternatives to plastic waste management.

Efforts have focused on developing these strategies. Composting is a rather oldmethod for organic waste processing and has become a strategy, amongst many others, for plastic waste management. Polymeric chains can be broken down and fragmented by the formation of biofilms on the polymer's surface. These films will then attract other microorganisms, which will favor plastic degradation by enzymatic processes [11]. Several studies have reported that some microorganisms have the potential to degrade plastics, such as LDPE. For example, many strains of Bacillus sp., Aspergillus sp., Penicillium sp., and Pseudomonas sp., have been identified as potential degraders [12,13,14]. Interestingly, these microorganisms have been isolated from soils, landfills, and compost, highlighting the high potential of composting in plastic waste management.

Composting is a dynamic four-step process undergoing the following phases: mesophilic, thermophilic, cooling, and maturation. In each of these phases, microbial growth and composition vary continuously due to temperature changes, promoting organic matter degradation [15]. The mesophilic phase reaches 40 °C due to metabolic activity. Specifically, the labile compounds and simplest carbon and nitrogen sources are used up by the microorganisms, releasing heat. A mixture of bacteria, actinomycetes, and fungi contributes to the decomposition process [16]. As temperature increases to 45 °C, the system turns from a mesophilic to a thermophilic stage, where mainly thermophilic bacteria, Bacillus in particular, and actinomycetes are favored. The metabolic activity of these microorganisms facilitates the decomposition of more complex carbon sources such as lignin and cellulose polymers. The thermophilic phase ends once the substrates are not available, whose gradual decrease in temperature induces mesophilic microorganisms to reappear, especially fungi, fond of the remaining lignin and cellulose substrates. On the other hand, it takes some weeks for the compost to cool down to 20 °C, a step that in turn indicates the starting point of the maturation phase. At this stage, actinomycetes can proliferate and induce the formation of humic substances [16].

Finally, given the increasing interest in plastic degradation, this study evaluates agricultural LDPE film stability during rose waste composting in an ornamental farm in Ecuador. It is important to note that this study worked with two plastic types; a new or virgin film and an aged one used for two years as greenhouse cover. Moreover, the research focused on two aspects: (1) a physical–chemical and biological characterization of composting; and (2) an evaluation of the physical and chemical changes in LDPE after being inserted into the composting process. Therefore, in the next section, the preparation of methods and materials are discussed for both compost and plastics. After that, in Sect. 3, the results are analyzed along with the discussion and, finally, in Sect. 4 we present the conclusions drawn from this study.

2 Materials and methods

2.1 Materials and preparation of samples

Two different types of LDPE were used: aged and new. The former was a two-year-aged plastic of 7 mils of thickness (“Agrolene Transparente AT”), previously used as greenhouse cover, while the latter was a new agricultural film of 7 mils thick (“Infralene Transparente Rosa Roja”). Both were cut into 25 sheets of 21 cm long × 14.7 cm wide. All samples were disinfected with 5% sodium hypochlorite, then with 1% sodium dodecyl sulfate (SDS), and rinsed three times with distilled water for 15 min each. Finally, all samples were dried in a desiccator.

2.2 Location

This study was performed in Agroplantas Cia. Ltda., a company located in Ecuador, Itulcachi-Pichincha, at 2600 m above sea level (− 0.2779; − 78.339). This company produces, selects, and exports various types of roses. Unsatisfactory roses are discarded whose residues include petals, stems, and leaves, which are then managed through the composting process.

2.3 Experimental design

We worked with a total of 50 samples. As described in Sect. 2.1, twenty-five sheets of both new and aged LDPE were cut, yet just twenty-four of each were placed in the compost. While the entire composting process lasted for four months, six new and aged plastic samples were taken out for analysis monthly. The remaining two samples, absent in the composting system, were used as the control. Heat treatment simulated the composting period in these samples (see Table 1).

2.4 Compost unit preparation and compost sampling

An open compost wooden bin of 240 cm long, 140 cm wide, and 110 cm high was built. Roses residues were crushed and placed inside, filling almost 70% of the container (73 cm high). The LDPE samples (new and aged) were placed randomly at this level with an average distance between samples of 20 cm. As for compost sampling, every week, a total of 5 compost samples were collected at random positions, immediately stored in airtight plastic bag covers (26.8 cm × 27.3 cm) and then transported into containers to the laboratory for physical, chemical, and microbiological compost analyses.

2.5 Physical and chemical compost characterization

2.5.1 Temperature measurements in the compost unit

The compost temperature was measured in situ with a digital thermometer type K thermocouple of about 40 cm long. Measurements were taken at four different points in the compost pile for four months.

2.5.2 pH measurements

For pH value determination, 20 g of sample was diluted in 100 ml of distilled water in a 500 ml flask, shaken for 30 min on a rotary shaker (Shaker Orbit 3525), and filtered to proceed with pH value reading using a Mettler Toledo FiveEasy FE30 pH meter [17].

2.5.3 Moisture content, organic matter, and total organic carbon

Moisture content analyses were performed in triplicates and calculated with the gravimetric method. 5 g of sample was oven-dried at 105 ℃ for 24 h, placed in a desiccator for a day, and reweighed. For organic matter (OM), dried samples were calcinated at 550 ℃ for six hours [18]. The total organic carbon (TOC) content was calculated dividing the volatile solids by 1.83 [19].

2.5.4 Total nitrogen content

The content of total nitrogen (TN) was measured in triplicates using the Kjeldahl method with a VELP Scientifica DK 6 Unit Digester and UDK 129 Distillation Unit [20].

2.6 Microbiological analysis of compost

A stock solution was prepared by diluting 25 g of compost sample into 225 ml of the sterile water solution and stirred for 20 min for homogenization. Ten-fold serial dilutions (10–1 to 10–9) were made from this stock for bacterial and fungal counts.

For bacterial counts, 0.1 ml of each dilution was aseptically transferred onto the culture media Nutrient Agar (NA) in triplicates and incubated for 24 h at 28 °C for mesophiles and at 50 °C for thermophiles. Fungal counts were performed in equal conditions yet they were incubated on Potato Dextrose Agar for a week. All colonies were counted by the direct method and the number of Colony Forming Units (CFU/g) of bacteria and fungi was calculated (adapted from Gebeyehu and Kibret) [21].

2.7 Characterization of low-density polyethylene

Every month, polyethylene degradability was evaluated by taking six random samples of new LDPE and six random samples of aged ones from the compost (Table 1). Three samples, subject to weight loss, FTIR analysis and mechanical strength, were washed following the protocol described in Sect. 2.1. The remaining three samples of each LDPE were used for Scanning Electron Microscopy (SEM) analysis (2.7.4) and, as a control, a film of each type was treated with heat to simulate compost conditions for four months.

2.7.1 Weight loss analysis

This analysis is one of the easiest methods to quantify plastic degradation. Thus, three samples (Table 1) monthly taken and washed as described in Sect. 2.1., were weighed using a five-digit analytical balance AUW120D, Shimadzu Corp., and the respective percentage of weight loss was calculated applying the following equation [22].

2.7.2 Fourier-transform infrared spectroscopy analysis

Fourier-transform infrared spectroscopy (FTIR) analysis was performed using an Agilent Technologies Cary 630 FTIR spectrometer. Structural changes in LDPE samples were identified based on the emitted spectrum, with sample spectra being set between [4000 cm−1 and 650 cm−1] [23].

2.7.3 Mechanical properties

Tensile strength measurements through elongation at break were carried out to evaluate deterioration in LDPE samples during the composting process (Table 1) using Lloyd Instruments LFPlus 1kN single column tester. This measurement was performed in triplicates using the ASTM method D882 to determine changes in the elongation percentage of both types of LDPE (aged and new) in parallel direction (PD) and transverse direction (TD). The material was considered degraded if more than 50% of its mechanical properties were lost [6].

2.7.4 Scanning electron microscopy analysis

Scanning electron microscopy analysis (SEM) was used to observe changes in the polymer's morphology caused by the different conditions to which the LDPE samples were subjected, and to identify microbial adherences to the polymer [23]. Subsamples (0.5 × 0.5 cm) were cut from each LDPE type as detailed in Table 1 and washed with 1% SDS for 10 min to remove impurities. Then, following fixation with 3.7% formaldehyde in Phosphate Buffer Saline (PBS) for 1 h 30 min at 4 °C, they were rinsed with distilled water first, with PBS after, and then by a dehydration gradient with ethanol (50%, 70%, 95%, 100%) for 15 min each. After washing, the samples were dried in a vacuum hood [1, 24]. A JSM-IT300 Scanning Electron Microscope (JEOL Ltd.) was employed to observe the sample surface at different points.

3 Results and discussions

As mentioned earlier, this study focused on two aspects: (3.1) characterization of physical–chemical and biological composting parameters that influence the decomposition of organic matter; and (3.2) evaluation of biodegradability of new and aged LDPE under conditions of rose composting.

3.1 Characterization of physical, chemical and biological parameters of roses residues composting

3.1.1 Determination of temperature and pH value during the composting process of rose residues

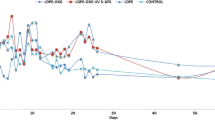

Temperature is a key indicator of microbial activity [25, 26]. Figure 1a, shows the variation of temperature during composting. Mesophilic phase began at 21.53 ± 1.36 °C, and after eight days, the temperature reached the thermophilic phase, which lasted about twenty days, with a maximum value of 56.50 ± 1.55 °C registered at the twelfth day of composting. The heat generated resulted from the labile and carbon-rich sources metabolized by different microorganisms [16]. The thermophilic phase is an essential step in the composting process since proteins, fats, and complex compounds such as cellulose and hemicellulose are broken down [27]. The maintenance of high temperatures depends mainly on the composition of the waste, the compost system's design, moisture, and adequate aeration [28, 29]. In this study, the cooling phase began with a constant decrease in temperature from day 22 of composting until day 60. At this point, the temperature recorded was 19.55 ± 2.16 °C (maturation phase).

Physical–chemical and biological characterization of composting of rose residues during 124 days. a Evolution of temperature and pH during composting. b Evaluation of total solids content (%TS), organic matter (%OM), moisture (% moisture), total organic carbon (% TOC); c C/N ratio and total nitrogen (%N) during composting; d: Counting of (CFU/g) of bacterial and fungal populations during composting

Figure 1a, also shows the variation in pH value, an indicator of microbial environment which influences biological activities and hence the decomposition process. The initial value was about 5.3, and a neutral pH value of 7.20 was observed after the 8th day (thermophilic phase), possibly due to the formation of carbonates, bicarbonates, and strong bases such as KOH [16, 19]. Together with the release of ammonia/ammonium by the breakdown of proteins, these compounds tend to neutralize and even alkalinize the compost [30, 31]. The pH value is, therefore, an important parameter to evaluate compost maturity and stability [32]. This statement supports the observation that pH was maintained between 8.20, 8.40, and 8.35 at the maturation phase (final step of compost).

3.1.2 Determination of Moisture Content, Organic Matter and Total Organic Carbon

Compost moisture promotes microbial activity, survival, and facilitates the transport of nutrients which highly influeces OM decomposition [15]. Figure 1b illustrates some physical parameters such as the moisture content trend during 124 days of composting, whose initial value was 67.07% ± 0.82. Notably, similar research elsewhere has also reported initial values of 70–80% in moisture content for floral waste [19, 33, 34]. In this study, moisture content decreased periodically down to a final value of 16.21 ± 0.53%. This indicates low metabolic activity and suggests that the compost reached its mature phase [35].

In composting, microbial activity drives OM degradation with higher rates in the thermophilic phase where labile organic compounds are mineralized [31]. However, Fig. 1b showed no significant reduction in this parameter. The initial content was 91.19 ± 0.66%, and after 124 days of composting, 88.03 ± 0.58%. Importantly, this low degradation rate was due to feedstock decomposition as it is entirely made of rose wastes which possess high amounts of cellulose and lignin, compounds hard to depolymerize [33]. The final amount of OM in the compost depends therefore on its initial value and the transformation of its components during the process [36]. Hence, decomposition rates are inversely proportional to the amount of cellulose, hemicellulose, and lignin [33]. These polymers will be decomposed from the thermophilic phase to the cooling phase and even at the curing phase [37].

Furthermore, the TOC content was expected to change the same as organic matter during composting due to the mineralization of organic compounds and compost maturation [38]. In this study, however, the TOC content remained almost constant (Fig. 1b). These findings are supported by Sharma et al.; Shouche, Pandey, and Bathi [33, 34], who recommended that cow dung or chicken manure should be incorporated into the compost to promote the further reduction of organic matter.

3.1.3 Total nitrogen and C/N ratio

Total nitrogen content during composting ranged from 1.19 ± 0.10% to 2.93 ± 0.07% (Fig. 1c). In line with results obtained by Sharma and Yadav [19] this increasing trend was observed at the mesophilic and thermophilic phases due to mineralization of organic matter, the loss of carbon, perhaps in the form of CO2, and the action of nitrogen-fixing bacteria [34].

The C/N ratio is an essential indicator of OM decomposition and stabilization in the compost. This parameter should decrease during composting due to the loss of carbon and TN content per unit material [27, 39]. Moreover, the initial C/N ratio highly influences the composting process as it directly affects the degradation of materials mediated by microorganisms [31]. In this study, the initial C/N ratio was 43 (Fig. 1c). Although this value disagrees with similar studies in which initial values of 28 to 33 are reported for floral wastes [19, 34], it can be speculated that such differences may just reflect the heterogeneity of the initial compost of this study, which contained petals, stems, and leaves from different varieties of flowers. Finally, the value dropped down to 12 in the first 22 days, followed by a period of small fluctuations before reaching a final value of 17 (Fig. 1c) and it could indicate the compost maturity [40].

3.1.4 Bacteria and fungi communities during composting

The environmental conditions during composting, such as temperature, moisture content, pH value, and the nature of organic substrates, strongly affect the structure and diversity of the microbial community, which plays a fundamental role in composting by promoting OM decomposition [15, 41]. Hence, monitoring the evolution of such communities may provide vital information to effectively manage the process and assess OM stabilization [42]. This study determined the total bacterial and fungal communities at different phases of rose residues composting.

As shown in Fig. 1d, both mesophilic and thermophilic bacteria populations were in a higher proportion than the fungal population, primarily at the mesophilic phase and thermophilic phase. According to Shilev et al. [27], bacteria are the most active microorganisms during the thermophilic phase due to high temperatures, pH conditions, and drastic humidity changes. Mesophilic bacterial population was around 109 CFU g−1 in all the period of composting (Fig. 1d). In comparison, the thermophilic bacteria population present at the beginning of the composting was 107 CFU g−1 and then reached 1010 CFU g−1 in 14 days (thermophilic phase). After, the number was reduced to a range of 108 to 107 CFU g−1, reaching a plateau at this value (Fig. 1d). In contrast, no thermophilic fungi were found in this study as fungi may be less tolerant to high temperatures [42]. Nevertheless, the population of mesophilic fungi were maintained throughout the composting process in a range of 106 to 108 CFUg−1 (Fig. 1d). These results reflect that fungi populations at different phases of composting play an essential role because they are actively involved in the decomposition of recalcintrant substrates such as cellulose, lignin, hemicellulose and low-nitrogen containing substrates [25, 26].

3.2 Characterization of new and aged low density polyethylene under conditions of rose composting

As mentioned in Sect. 2.3., LDPE films were subjected to rose residues composting during 124 days, yet 6 samples for each type (new and aged) were collected monthly (Table 1). To assess changes in physical and chemical properties, four methods were employed: Weight loss, FTIR, mechanical properties by tensile test, and Scanning Electron Microscopy (SEM). Moreover, one sample of each LDPE underwent heat treatment to simulate the compost temperature, and after 124 days FTIR was performed.

3.2.1 Weight loss analysis

As a preliminary physical test, weight loss average was calculated for both new and aged LDPE samples collected in the same month. A significant reduction of 0.639% was registered in new LDPE after 31 days of composting (Fig. 2a), whereas in aged LDPE, the maximum average weight loss was about 1.92% after 91 days of composting. However, this trend is variable as after 124 days of composting, an average weight loss of 0.028% was registered (Fig. 2b). Moreover, the negative values represent an increase of weight (Fig. 2b). This suggests that the microorganisms adhered and accumulated on the plastic forming biofilms, or that the samples were not cleaned properly, and it was remaining waste and impurities that adhered to the plastic [1]. Finally, these results reflect that although weight loss analysis is a simple method, it is not a direct evidence of degradation [23].

3.2.2 FTIR analysis of LDPE

To identify chemical changes on the plastic samples after being subjected to the compost or to the heat treatment, FTIR studies were performed. Figure 3a shows the spectrum of both LDPE types (new and aged) under heat treatments and without any treatments. Figure 3b illustrates the spectrum of new LDPE samples composted during 31, 61, 91, and 124 days, and Fig. 3c represents the spectrum of aged LDPE samples composted during the same intervals.

FTIR Analysis of new LDPE and aged LDPE (used in greenhouse covering for two years). a New LDPE and aged LDPE without treatments and samples under heat treatment; b New LDPE composted during 30 days (30 d), 61 days (61 d), 91 days (91 d) and 124 days (124 d); c Aged LDPE composted during 30 days (30 d), 61 days (61 d), 91 days (91 d) and 124 days (124 d)

The new sample undergoing heat treatment showed a slight peak formation at 1615 cm−1 (corresponding to bonds -C = C-), also observed in new samples composted for 61 days (Fig. 3b). This could indicate the oxidation of polyethylene due to thermal processes [23]. Moreover, in the FTIR spectrum for composted new samples, peaks at 864 cm−1 (CH2 groups) and 1548 cm−1 (vibration of amino groups of additives) seemed to gradually disappear in 30, 61, 91, and 124 days, compared to new LDPE with heat treatment and no treatments (Fig. 3b). These changes coud be caused by the microbial diversity and abiotic factors such as temperature. Moreover, the agrochemicals present in rose residues could react with LDPE additives and accelerate degradation because they contain compounds such as halogens and sulfides, chlorides that attack the UV stabilisers [6].

When comparing aged LDPE (used in greenhouse covers for 2 years) with new one, no peaks associated with CH2 groups were observed at 864 cm−1, nor the peak at 1548 cm−1, (Fig. 3a). The study of Cristofoli et al. [43], reported the reduction of a peak at 1534 cm−1 which corresponds to amine groups of the amine light stabilizer additives after exposing LDPE to UV radiation. Furthermore, authors explain that several factors could cause the decrease in the absorption band at 1534 cm−1. These factors include additive consumption during the exposure period, stabilization of free radicals, loss of additives by diffusion to the polymer surface or by chemical reactions, evaporation and leaching [43]. Additionally, a slight peak at 1735 cm−1 corresponding to C = O bonds was observed in aged LDPE samples (Fig. 3a) which could represent either ester or carbonyl groups. These are formed by exposure to UV radiation and are an indicator of degradation [5, 44]. The formation of peaks at 3000 and 3500 in the aged sample, composted for 91 days, (Fig. 3c) corresponds to alcohols’ -OH groups vibrations, which may have been formed by solar radiation or by plastic biodegradation processes [45]. This sample corresponds to the one that presented a higher percentage of weight loss. No further FTIR changes were observed in the other aged composted samples.

To conclude, the formation and reduction of the peaks mentioned above may indicate structural changes in the polymer additives such as amine light stabilizers (1548 cm−1). This can be corroborated with the composted aged LDPE samples since, except for one sample, no changes were observed in the FTIR spectra. This indicates that polyethylene additives protect the plastic by increasing its strength, stability and durability.

3.3 Analysis of mechanical properties

Elongation at break was the tensile test employed to determine the index deterioration since the degraded material is more brittle and unable to retain its initial elongation at break [6]. As mentioned in Sect. 2.7.3., elongation at break tests for each type of LDPE after composting were carried out in triplicates following ASTM method D882, for both parallel (PD) and transverse direction (TD). Figure 4a shows the average of elongation at break at PD and TD of new samples after composting, whereas Fig. 4b illustrates the average of elongation at break in samples of aged LDPE composted during 30, 60, 124 days.

Percentage of elongation at break in LDPE samples in parallel direction (PD) and transversal direction (TD). a On new LDPE samples without treatment; with heat treatment during 124 days (heat treatment); and composted samples during 30 days (30d) and 124 days (124d). b On aged LDPE samples. It shows initial properties*; samples without treatments; with heat treatment during 124 days (heat treatment); and composted samples during 30 days (30d) and 124 days (124d). *Initial properties of aged LDPE (used for greenhouse covering) are values obtained from the sheet with technical information of the material

To consider deterioration, the films should lose more than 50% of their initial properties on elongation at break [46]. In this study, no significant differences were found between elongation at break of new samples after composting nor in new sample under heat treatment. Although these results suggest that composting had no influence on the mechanical properties of the material, deterioration in some samples of aged LDPE was determined (Fig. 4b) which may be attributed to environmental factors such as wind, temperature variations, and exposure to long periods of solar radiation [7]. These factors, primarily sunlight UV, cause polymer photodegradation and formation of free radicals on its surface with the ability to attack polymer structures and hence affect plastic properties [1, 47]. Meanwhile, variations in greenhouse factors such as temperature, moisture, wind, and structural anchors can accelerate and intensify deterioration and photodegradation [6]. Additionally, the presence of aged samples with no deterioration, elongation at break lower than 50% of its initial value, (Fig. 4b) can be explained by the position in which those were located on the greenhouse. Therefore, the chosen samples probably correspond to greenhouse cover borders where environmental factors do not affect their mechanical properties.

3.4 Scanning electron microscope analysis

SEM analyses were performed to identify morphological changes on new and aged LDPE film. In aged samples, some morphological changes were observed such as surface rupture, voids, erosions, and cracks (Fig. 5c, d). This indicates deterioration of the aged plastic compared to the new one Fig. 5a, b in which a smooth surface was observed, despite the presence of adhering particles to the film [14, 48].

Similarly, these morphological changes, also identified in aged samples composted during 61 and 91 days, Fig. 6a and b, respectively, could be explained by the exposure of the material to solar radiation, temberpature variations, and other environmental factors that affected the structure and properties of the plastic. In the study of Nikafshar et al. [47], it was established that exposure to UV radiation causes small cracks on the polymer surface, in line with those found in this investigation, as seen in Fig. 6b. Additionally, in samples of aged LDPE composted for 124 days, the adherence of microorganisms Fig. 6c and the formation of a possible biofilm Fig. 6d was observed, as the previous deterioration due to environmental factors could facilitate microbial adhesion for subsequent biodegradation. However, it is important to consider that it may be residual material adhered to the sample.

4 Conclusions

This study found that composting had a limited role in plastic degradation. After subjecting the new and aged LDPE samples to composting for 124 days, small weight loss changes were observed yet insignificant. FTIR analysis determined the formation and reduction of peaks that could indicate structural changes in polyethylene film additives. As for the mechanical tests performed on the samples, deterioration in the two-year-aged LDPE, previously used in greenhouse covers, was determined due to the loss of elongation percentage at break in more than 50% respecting its initial properties. SEM analysis determined the formation of cracks, holes, erosions, voids and surface ruptures in aged films that indicates polymer deterioration.

The physicochemical analyses of composting performed in this study showed a slow degradation rate of organic matter and total organic carbon. Moreover, in this study, no thermophilic but mesophilic fungi were found in all the composting period. At the same time, the bacterial population were in a higher proportion than fungal population during composting.

In terms of the management of plastic greenhouse waste, compliance with the regulation of discarded plastics is necessary after their useful life. Furthermore, beyond its management, it is essential to look for circular economy alternatives to greenhouse plastics that are discarded annually, because the incorporation of plastics into compost piles is not sufficient for their degradation although the potencial showed in the study. In addition, for future it require studies on the ecotoxicity of plastics with additives for greenhouses on the compost, as well as isolation, identification, and evaluation the possible microorganisms biodegradaters as an alternative to plastic waste management.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Das MP, Kumar S (2015) An approach to low-density polyethylene biodegradation by Bacillus amyloliquefaciens. 3 Biotech 5:81–86. https://doi.org/10.1007/s13205-014-0205-1

Greene J (2018) Biodegradation of biodegradable and compostable plastics under industrial compost, marine, and anaerobic digestion. Ecol Pollut Environ Sci Open Access 1:13–18

Lebreton L, Andrady A (2019) Future scenarios of global plastic waste generation and disposal. Palgrave Commun 5:1–11. https://doi.org/10.1057/s41599-018-0212-7

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3:25–29. https://doi.org/10.1126/sciadv.1700782

Zahra S, Abbas SS, Mahsa MT, Mohsen N (2010) Biodegradation of low-density polyethylene (LDPE) by isolated fungi in solid waste medium. Waste Manag 30:396–401. https://doi.org/10.1016/j.wasman.2009.09.027

Dilara PA, Briassoulis D (2000) Degradation and stabilization of low-density polyethylene films used as greenhouse covering materials. J Agric Eng Res 76:309–321. https://doi.org/10.1006/jaer.1999.0513

Kyrikou I, Briassoulis D (2007) Biodegradation of agricultural plastic films: A critical review. J Polym Environ 15:125–150. https://doi.org/10.1007/s10924-007-0053-8

Cazar MA (2010) Evaluación del grado de deterioro y el nivel de contaminación de los residuos plásticos de cubiertas de invernaderos provenientes de las florícolas del Distrito Metropolitano de Quito. Dissertation, Escuela Politécnica Nacional

Expoflores (2019) Informe anual de exportaciones de rosas (Accessibility view). Rev Investig Agrar y Ambient 1:1–22

Breilh J (2012) Ecohealth research in practice. Ecohealth Res Pract. https://doi.org/10.1007/978-1-4614-0517-7

Vaverková M, Adamcová D, Klapsiová V (2014) Do the Degradable/Biodegradable plastic materials decompose in domestic compost bin? Proc ECOpole 8:11. https://doi.org/10.2429/proc.2014.8(1)011

Muhonja CN, Makonde H, Magoma G, Imbuga M (2018) Biodegradability of polyethylene by bacteria and fungi from Dandora dumpsite Nairobi-Kenya. PLoS ONE 13:1–17. https://doi.org/10.1371/journal.pone.0198446

Shrestha JK, Joshi DR, Regmi P, Badahit G (2019) Isolation and identification of low density polyethylene (LDPE) Degrading Bacillus spp. from a soil of landfill site. Acta Sci Microbiol 2:30–34

Kumar Sen S, Raut S (2015) Microbial degradation of low density polyethylene (LDPE): A review. J Environ Chem Eng 3:462–473. https://doi.org/10.1016/j.jece.2015.01.003

Villar I, Alves D, Garrido J, Mato S (2016) Evolution of microbial dynamics during the maturation phase of the composting of different types of waste. Waste Manag 54:83–92. https://doi.org/10.1016/j.wasman.2016.05.011

Smith JL, Collins HP (2007) Management of Organisms and Their Processes. In: Eldor AP (ed) Soil Microbiology, Ecology and Biochemistry, Third. Academic Press, Elsevier, pp 483–485

Piper C. (2019) Hidrogen Ion Concentration, Conductivity and Water Soluble Salts. In: Soil and Plant Analysis, 2nd ed. Scientific Publishers, pp 7–8

Huang TH, Almeida Streitwieser D (2015) Estudio comparativo de la compostabilidad de fundas plásticas de PEBD, oxo-biodegradables y de papel distribuidas en el Distrito Metropolitano de Quito. ACI Av en Ciencias e Ing. https://doi.org/10.18272/aci.v7i1.233

Sharma D, Yadav KD (2017) Bioconversion of flowers waste: Composing using dry leaves as bulking agent. Environ Eng Res 22:237–244. https://doi.org/10.4491/eer.2016.126

AOAC International (2012) Official Methods of Analysis of AOAC INTERNATIONAL. Gaithersburg, MD, USA, Official Method 2008:01

Gebeyehu R, Kibret M (2013) Microbiological and physico-chemical analysis of compost and its effect on the yield of kale ( Brassica oleracea ) in Bahir Dar, Ethiopia. Ethiop J Sci Technol 6:93–102

Gajendiran A, Krishnamoorthy S, Abraham J (2016) Microbial degradation of low-density polyethylene (LDPE) by Aspergillus clavatus strain JASK1 isolated from landfill soil. 3 Biotech 6:1–6. https://doi.org/10.1007/s13205-016-0394-x

Shah AA, Hasan F, Hameed A, Ahmed S (2008) Biological degradation of plastics: a comprehensive review. Biotechnol Adv 26:246–265. https://doi.org/10.1016/j.biotechadv.2007.12.005

Bonhomme S, Cuer A, Delort AM et al (2003) Environmental biodegradation of polyethylene. Polym Degrad Stab 81:441–452. https://doi.org/10.1016/S0141-3910(03)00129-0

Shouche S, Bhati P, Nema Z, Jain SK (2014) Mycobiota of decomposing floral waste materials. Asian J Microbiol Biotechnol Environ Sci 16:417–422

Goyal S, Dhull SK, Kapoor KK (2005) Chemical and biological changes during composting of different organic wastes and assessment of compost. Maturity 96:1584–1591. https://doi.org/10.1016/j.biortech.2004.12.012

Shilev S, Naydenov M, Vancheva V, Aladjadjiyan A (2007) Composting of Food and Agricultural Wastes. In: Oreopoulou V., Russ W. (eds) Utilization of By-Products and Treatment of Waste in the Food Industry. pp 283–301

Pérez Méndez MA, Hernández S, Rufo Palma-López DJ, Salgado García S (2011) Caracterización química del compostaje de residuos de caña de azúcar en el Sureste de México. Interciencia 36:45–52

Makan A, Assobhei O, Mountadar M (2013) Effect of initial moisture content on the in-vessel composting under air pressure of organic fraction of municipal solid waste in Morocco. Iran J Environ Heal Sci Eng 10:3. https://doi.org/10.1186/1735-2746-10-3

Sundberg C (2005) Improving Compost Process Efficiency by Controlling Aeration , Temperature and pH. Dissertation, Swedish University ofAgricultural Sciences

Ekinci K, Tosun I, Bıtrak B, Kumbul B, Şevik F, Sülük K (2018) Effects of initial C / N ratio on organic matter degradation of composting of rose oil processing solid wastes. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-018-1947-9

Ameen A, Ahmad J, Raza S (2016) Effect of pH and moisture content on composting of Municipal solid waste. Int J Sci Res Publ 6:35–37

Shouche S, Pandey A, Bhati P (2011) Study about the changes in physical parameters during vermicomposting of floral wastes. J Environ Res Dev 6:63–68

Sharma D, Varma VS, Yadav KD, Kalamdhad AS (2017) Evolution of chemical and biological characterization during agitated pile composting of flower waste. Int J Recycl Org Waste Agric 6:89–98. https://doi.org/10.1007/s40093-017-0155-9

Román, P., Martínez, M. and Pantoja A (2013) Manual de compostaje del agricultor. Organ. las Nac. Unidas para la Aliment. y la Agric. Of. Reg. la FAO para América Lat. y el Caribe 1–112

Navarrón Izquierdo L (2015) Compostaje de Tronco Palmera con lodos de depuracón de aguas residuales urbanas. Dissertation, Universidad Miguel Hernández de Elche. Escuela Politécnica Superior de Orihuela

Zhu N, Changyan D, Yuanzhu X, Huiyue Q (2004) Performance characteristics of three aeration systems in the swine manure composting. Bioresour Technol 95:319–326. https://doi.org/10.1016/j.biortech.2004.02.021

Yadav A, Gupta R, Garg VK (2013) Organic manure production from cow dung and biogas plant slurry by vermicomposting under field conditions. Int J Recycl Org Waste Agric 2:1. https://doi.org/10.1186/2251-7715-2-21

Insam H, de Bertoldi M (2007) Chapter 3 Microbiology of the composting process. Waste Manag Ser 8:25–48. https://doi.org/10.1016/S1478-7482(07)80006-6

Antil RS, Raj D, Abdalla N, Inubushi K (2014) Physical, chemical and biological parameters for compost maturity assessment: A. Review. https://doi.org/10.1007/978-3-319-08004-8_5

Bhatia A, Rajpal A, Madan S, Kazmi AA (2015) Techniques to analyze microbial diversity during composting-A mini review. Indian J Biotechnol 14:19–25

Varma V, Kalamdhad A (2014) Stability and microbial community analysis during rotary drum composting of vegetable waste. Int J Recycl Org Waste Agric. https://doi.org/10.1007/s40093-014-0052-4

Cristofoli K, Brandalise RN, Zeni M (2012) Photostabilized LDPE Films with UV Absorber and HALS as Protection against the Light for Rosé. Sparkling Wine. https://doi.org/10.4172/2157-7110.1000166

Hamzah M, Khenfouch M, Rjeb A et al (2018) Surface chemistry changes and microstructure evaluation of low density nanocluster polyethylene under natural weathering: A spectroscopic investigation. J Phys Conf Ser. https://doi.org/10.1088/1742-6596/984/1/012010

Adelhafidi A, Babaghayou IM, Chabira SF, Sebaa M (2015) Impact of solar radiation effects on the physicochemical properties of polyethylene (PE) plastic film. Procedia - Soc Behav Sci 195:2210–2217. https://doi.org/10.1016/j.sbspro.2015.06.302

Briassoulis D (2005) The effects of tensile stress and the agrochemical Vapam on the ageing of low density polyethylene (LDPE) agricultural films. Part I. Mechanical Behav Polym Degrad Stab 88:489–503. https://doi.org/10.1016/j.polymdegradstab.2004.11.021

Nikafshar S, Zabihi O, Ahmadi M et al (2017) The effects of UV light on the chemical and mechanical properties of a transparent epoxy-diamine system in the presence of an organic UV absorber. Materials (Basel) 10:1–18. https://doi.org/10.3390/ma10020180

Corcoran PL, Biesinger MC, Grifi M (2009) Plastics and beaches: A degrading relationship. Mar Pollut Bull 58:80–84. https://doi.org/10.1016/j.marpolbul.2008.08.022

Acknowledgements

This research received support from Universidad San Francisco de Quito (USFQ). Thanks to Poli grants USFQ for their financial support. The authors are also thankful to Agroplantas Company Cia. Ltda, Plastilene S.A. company and Andes Spirulina S.A. for their assistance provided.

Funding

This work was supported by Chancellor grants and Poli Grants USFQ under the number 0012.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Conceptualization: AL-R, DAS, JAB, CA; Methodology: JAB, CA AL-R. Formal analysis and investigation: CA. Writing—original draft preparation: CA. Writing—review and editing: AL-R, DAS. Funding acquisition: DAS, AL-R. Resources: AL-R, DAS, JAB. Supervision: AL-R, DAS, JAB. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare no conflict of interests regarding sources of funding, financial or personal interests. This research did not involve humans and/or animals, nor required consent of involved human participants.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alvarez-Vega, C., Streitwieser, D.A., Álvarez-Barreto, J. et al. Characterization of low density polyethylene greenhouse films during the composting of rose residues. SN Appl. Sci. 4, 275 (2022). https://doi.org/10.1007/s42452-022-05155-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-022-05155-0