Abstract

The poor stability of CsPbX3 (X = Cl, Br, I) perovskite nanocrystals is the most impediment to its application in the field of photoelectrics. In this work, monodisperse CsPbBr3/TiO2 nanocrystals are successfully prepared by coating titanium precursor on the surface of colloidal CsPbBr3 nanocrystals at room temperature. The CsPbBr3/TiO2 nanocomposites exhibit excellent stability, remaining the identical particle size (9.2 nm), crystal structures and optical properties. Time-resolved photoluminescence decay shows that the lifetime of CsPbBr3/TiO2 nanocrystals is about 4.04 ns and keeps great stability after lasting two months in the air. Results show that the coating of TiO2 on CsPbBr3 NCs greatly suppressed the anion exchange and photodegradation, which are the main reasons for dramatically improving their chemical stability and photostability. The results provide an effective method to solve the stability problem of perovskite nanostructures and are expected to have a promising application in optoelectronic fields

Article highlights

-

1. Prepared the all-inorganic CsPbBr3/TiO2 core/shell perovskite nanocrystals by an easy method.

-

2. Explored its essences of PL and lifetime of the synthesized CsPbBr3/TiO2 perovskite nanocrystals.

-

3. CsPbBr3/TiO2 nanocrystals show the great thermal stability after the post-annealing.

-

4. The CsPbBr3/TiO2 nanocrystals have a high PLQY and have a promising application in solar cells.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Owing to the high absorption coefficient, long carrier diffusion distance, tunable emission bandgap and high photoluminescence quantum yield, colloidal metal halide perovskite nanocrystals have been intensively explored in laser, photodetector, light-emitting diode (LED) and solar cell [1,2,3,4]. Kojima et al. [5] prepared the earliest perovskite solar cells, selecting organic–inorganic hybrid perovskite materials CH3NH3PbX3 (X = Br, I) as new photosensitizer to replace the dyes in traditional DSSCs. However, due to the large bandgap, the photoelectric conversion efficiency is only about 3.8%, which extremely obstructs their prelude as the light-absorbing material.

Recently, due to particular crystal structure, high energy conversion rate, low cost and mild conditions, organic–inorganic hybrid perovskite nanostructure have attracted much attention of the academic and industry community [6, 7]. Under ongoing efforts, the photoelectric conversion efficiency has rapidly increased to 22.1% [8]. Liu et al. [9] added iodide ions to the organic cation solution and realized the high-efficiency PSC film based on "lead halide perovskite" absorbent and achieved the 22.1% energy efficiency in small batteries. In 2018, École Polytechnique Fédérale de Lausanne (EPFL) refreshed the world efficiency record of CIGS perovskite solar cells to 23.3% [10]. Similarly, Chen et al. [11] designed an inorganic perovskite device by adjusting bandgap at different positions, which increased the film thickness and reduced the charge recombination, behaving 15.2% of the final photoelectric conversion efficiency. Recently, the ground-breaking cell produced by Oxford PV has been proven to convert 29.52% of solar energy into electricity. However, when exposed to moisture, humidity, glare and high temperature, the perovskite nanocrystals would decompose and decrease their environmental stability. These uncontrollable factors block the development of nanocrystals in practical applications [12, 13].

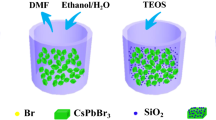

Recently, significant efforts have been committed to increasing the stability of perovskite nanocrystals, by embedding a protective semiconductor matrix, adulterating photocurable fluoropolymer or compounding to molecular sieve material with regular porous structure [14]. Employing a facile solution-phase method, Zhou et al. prepared CsPbX3/ZnS nanocrystal heterodimer with a high quality and enhanced stability, which offers an interesting playground to design and fabricate novel perovskite heterostructures [15]. Zhang et al. [16] successfully prepared high-stability CsPbX3/SiO2 Janus nanoparticles, and the photoluminescence quantum yield reached 80%, and the luminescence lifetime achieved 19.8 ns. The implanting of Janus nanometers particles into the white light-emitting diode devices greatly improved the stability of CsPbX3 (X = Cl, Br, I) nanocrystals in air, water and light environments. However, the stability of these perovskite composites could be only manifested in the short term, and the external protection layers are not uniform and fine. It is well known that the surface passivation could eliminate the defects and dangling bonds and therefore increase their stability. In 2016, Huang et al. proposed a new and efficient surface passivation method, in which a stable mixed-halide passivation layer was formed on the surface of nanocomposites by ion exchange between CsPbX3 (X = Br, I) perovskite nanocrystals and lead selenide quantum dots. Results show that it not only improved the fluorescence quantum yield, but also significantly increased the photoelectric conversion efficiency and air stability of perovskite solar cells [17]. Coincidentally, Dalal et al. firstly demonstrated that some p-type semiconductors could be used as high-efficient perovskite-defective passivation materials, and a passivation mechanism was proposed [18]. Although some new p-type semiconductor showed excellent perovskite depletion passivation effect, the exploration of those good stability passivation agent would be the focal point in the future. It could imagine that if we combining wider band-gap semiconductor materials with perovskite nanostructures and forming an external protective layer around the CsPbX3 (X = Cl, Br, I), the more stable and efficient CsPbX3 nanostructures could be expected to manufacture.

In our previous work, we prepared CsPbX3 (X = Cl, Br, I) perovskite nanocrystals by the hot-injection method and studied their optical properties [19, 20]. By varying the amount of PbX2 (X = Cl, Br, I), the prepared CsPbX3 nanocrystals possess high photoluminescence quantum yield (PLQY, about 70%), narrow full width at half-maximum (FWHM) (4–17 nm), tunable band gap (407–680 nm), and highly strong photostability. In this paper, we coated titanium precursor on the outside of the colloidal CsPbBr3 NCs at room temperature and formed perovskite CsPbBr3/TiO2 nanocomposites with high dispersion and high crystallinity. By forming a CsPbBr3/TiO2 nanocomposite, we are trying to improve its PLQY and thermal stability. The optical mechanism, containing microstructure, chemical state and time-resolved decay process, was comprehensively studied.

2 Experimental section

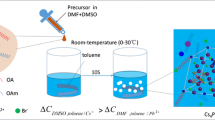

2.1 Synthesis of CsPbBr3/TiO2 nanocrystals

The preparation process of CsPbBr3 has been introduced in our previous papers [19, 20]. To synthesize the CsPbBr3/TiO2 nanocrystals, 15 µL TBOT with 1 mL toluene was added into a 250-mL 3-neck flask containing 20 mL of CsPbBr3 nanocrystal solution under stirring. The solution was placed in a glove box with 30% relative humidity (RH) at room temperature for hydrolysis. After stirring for 3 h, the crude solution was centrifuged at 6,500 rpm for 8 min, and the precipitate was dried in Ar atmosphere at 300 °C for 2 h to obtain CsPbBr3/TiO2 core/shell NCs.

2.2 Characterization

In the experiments, X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), FT-IR spectrometer (FTIR), micro-Raman Spectroscopy (Raman) and high-resolution transmission electron microscopy (HRTEM) were carried out for microstructural characterization of the obtained samples. The absorption properties were conducted on a double UV–Vis absorption spectrophotometer model 727. Room-temperature photoluminescence (PL) spectra were taken on an Edinburgh (FLS920) fluorescence spectrophotometer.

3 Results and discussion

Figure 1 shows X-ray diffraction patterns of the as-prepared CsPbBr3 and CsPbBr3/TiO2 nanocrystals. It can be seen that the diffraction peaks of CsPbBr3 NCs are consistent with the standard data file (JCPDS No. 54–0752), which confirms the accuracy of the cubic phase [21]. Two samples exhibit eight obvious peaks at 15.27°, 21.58°, 26.50°, 30.55°, 34.44°, 37.67°, 43.86° and 46.71°, corresponding to (100), (110), (111), (200), (210), (211), (220) and (300) planes, respectively. For CsPbBr3/TiO2 NCs, two additional diffraction peaks at ~ 23.8° and ~ 46.5° can be observed, which are assigned to (101) and (200) planes for anatase TiO2 (JCPDS No. 89-4921) [22]. Simultaneous appearance of characteristic peaks for TiO2 and CsPbBr3 nanocrystals represents that the TiO2 has successfully deposited on the surface of CsPbBr3 NCs. Compared with CsPbBr3 and TiO2 nanocrystals, CsPbBr3/TiO2 NCs exhibits two additional diffraction peaks at 41° and 56.5°, which may originate from the residue or incomplete existence of TiO2 shell.

Figure 2 shows HRTEM images of the monodisperse CsPbBr3/TiO2 NCs. From Fig. 2a, it can be seen that cube-shaped CsPbBr3 NCs arranged neatly in nonpolar solvent and exhibited a high degree of crystallinity and stability. The average size is about 8.8 nm. From Fig. 2b, c, one can see that the plurality of CsPbBr3 NCs is wrapped by one core–shell TiO2 structure, which caused by the incomplete hydrolysis of high-concentration TBOT on the surface of CsPbBr3 NCs. Figure 2d is the lattice fringe pattern of CsPbBr3/TiO2 nanocomposites, which reflects the 0.58 nm lattice fringe of CsPbBr3 NCs and 0.29 nm of TiO2 NCs, corresponding to the (200) and (101) planes, respectively. More importantly, there is a clearance exist between CsPbBr3 and TiO2, meaning that a tight interface is formed between CsPbBr3 and TiO2.

To test the optoelectronic and electronic properties, the absorption and emission spectra of CsPbBr3/TiO2 nanocrystals were carried out, as shown in Fig. 3a. It exhibits an obvious slight of 9-nm Stokes shift between absorption edge and fluorescence peak, demonstrating the origin of direct band-gap bound exciton recombination, which could be attributed to the strong quantum confinement effect. After lasting in the air for one and two months, the photoluminescence and optical absorption spectra are measured to identify the stability of CsPbBr3/TiO2 nanocrystals, as shown in Fig. S1. Two patterns exhibit a similar small Stokes shift of 9 nm, showing high fluorescence and strong stability. Figure 3b shows the emission spectra of CsPbBr3 and CsPbBr3/TiO2 NCs. Both of them show the analogous emission peak at about 510 nm, which demonstrate the similar size and uniform distribution, corresponding to the exhibition in Fig. 2. More precise observation reveals that the FWHM is about 15 nm, illustrating a favorable crystallinity and stability [23]. By further comparison, it can be observed that there is an obvious increase in PL intensity of CsPbBr3/TiO2 nanocomposites. That means the as-prepared heterocomposites effectively inhibit the recombination of photogenerated charge carriers [24, 25]. From Fig. 3c, it can be seen that the absorption spectra of CsPbBr3 NCs and CsPbBr3/TiO2 nanocomposites are broadcast. It can catch a strong sharp absorption peak at about 500 nm for CsPbBr3 NCs and the absorption edge of the CsPbBr3/TiO2 nanocomposites blue-shifts to 498 nm for CsPbBr3/TiO2 NCs. In the range of 460 to 500 nm, the absorption capacity of CsPbBr3/TiO2 NCs is larger than that of CsPbBr3, which is caused by the existence of amorphous TiO2.

To explore the origin of emission for CsPbBr3 and CsPbBr3/TiO2 nanocomposites, the PL and PLE spectra were carried out, as shown in Fig. 4. From the PLE spectra, as shown in Fig. 4a, a low-intensity broad peak at about 310 nm and a high-intensity broad peak at about 430 nm could be observed. Based on the PLE spectra, we measured the PL spectra under the center wavelength of 310 nm and 430 nm, as shown in Fig. 4b, c, respectively. Both of the two curves show a sharp peak at 508 nm, indicating that the emission at 508 nm is intrinsically linked with the excitation of 310 nm and 430 nm. To further research the origins of emission of CsPbBr3/TiO2 nanocomposites, we also measured the PL and PLE spectra CsPbBr3/TiO2 at room temperature, as shown in Fig. 4d, e. It can be found that the PLE peak intensity increases with increasing the emission wavelength and reaches a maximum value when monitored at 510 nm. Additionally, the broad PLE band confirms that the perovskite nanocrystals can be excited under a broad wavelength. Compared with the PLE spectra of CsPbBr3 and CsPbBr3/TiO2, they all show a peak at about 430 nm. However, the peak at 310 nm disappears for CsPbBr3/TiO2 nanocomposites, proving the successful compound of CsPbBr3 with TiO2. Combined with the above results, PL spectra of CsPbBr3/TiO2 nanocomposites under the excitation wavelength around 430 nm were implemented, as shown in Fig. 4e. One can see that all curves exhibit a sharp emission peak at 509 nm and do not shift with changing the excitation wavelengths, which exhibits the uniform size distribution of nanocrystals, matching the images in Fig. 2. With increasing the excitation wavelength, the PL intensity increases and shows the maximum value at 450 nm, illustrating that the emission at 509 nm is intrinsically linked with the excitation at 430 nm. The PLE spectra of CsPbBr3/TiO2 nanocrystals after lasting one and two months in the air by monitoring at 510 nm as center wavelength were carried out, as shown in Fig. S2 and Fig. S3. Both of them show a maximum absorption under monitoring at 510 nm, which exhibit the same behaviors with the original CsPbBr3/TiO2 nanocomposites. It is interesting that the curves measured after lasting in the air for a month present two saturation excitation peaks at 380 nm and 430 nm. The PLE curves show the fixed single emission peak at 508 nm, illustrating the excellent stability of CsPbBr3/TiO2 nanocrystals. Similarly, as shown in Fig. S3, the absorption peak shifts to 350 nm, which is caused by the surface passivation. The emission peak pinned at 508 nm, further demonstrating the excellent chemical stability and photostability of CsPbBr3/TiO2 nanocrystals.

a PLE spectra of CsPbBr3 nanocrystals monitored at different wavelengths around 510 nm. b PL spectra of CsPbBr3 nanocrystals taken under different excitation wavelengths around 310 nm. c PL spectra of CsPbBr3 nanocrystals taken under different excitation wavelengths around 430 nm. d PLE spectra of CsPbBr3/TiO2 nanocrystals monitored at different wavelengths around 510 nm. e PL spectra of CsPbBr3/TiO2 nanocrystals taken under different excitation wavelengths around 430 nm

To explore the molecular structure and surface bonds of CsPbBr3/TiO2 nanocrystals, the FTIR spectroscopy for the samples was performed, as shown in Fig. 5. Compared with the CsPbBr3 and CsPbBr3/TiO2 NCs, the decrease in two fundamental sharp peaks at 2923 and 2856 cm−1 suggests the loss of carbonaceous residues and dehydroxylation process. The decrease in another two peaks at 1468 and 1380 cm−1 indicates the losing of COO− and –CH3 groups. Besides, there is an increased intensity of surface-adsorbed water (H–O–H) at 3432 cm−1 and hydroxyl groups (O–H) at 1652 cm−1, plus a slight increase at about 730 cm−1 for Ti–O–Ti bonds, stating the coating of titanium matrix on CsPbBr3 nanocrystals.

To achieve the surface states and compositions of the samples, the X-ray photoelectron spectrum XPS is conducted, as presented in Fig. 6. Compared with the CsPbBr3, two additional peaks of Ti and O are observed in CsPbBr3/TiO2 NCs, indicating a successfully forming of CsPbBr3/TiO2 nanocomposites. The lower intensity of CsPbBr3/TiO2 NCs is caused by the existence of TiO2 shell. Figure S4 is the fine XPS of CsPbBr3/TiO2 NCs. From Fig. S4a, it can be seen that there are only Cs, Pb, Br, Ti, N and O elements in the sample and no other elements are detected, showing good purity of as-prepared samples. The Cs, Pb and Br elements are contributed by the perovskite nanocrystals, while the N and part of O elements are related to the chemical adsorption of OA and OAm ligands [26]. From Fig. S4b, one can see two rough symmetrical peaks at 738.2 and 724.3 eV, corresponding to Cs 3d 5/2 and Cs 3d 3/2, respectively. Figure S4c shows the spin–orbit splitting energy of 4.8 eV from two sharp peaks at 138.2 and 143.0 eV for Pb 4f 7/2 and Pb 4f 5/2, respectively, which are characteristic for Pb2+ in CsPbBr3/TiO2 nanocrystals. Similarly, in Fig. S4e, the strong peak at 458.6 eV matches with Ti 2p 1/2, while the low peak at 464.2 eV matches with Ti 2p 3/2, which confirms the Ti4+ valence. In particular, Fig. S4d shows one single broad peak and can be deconvoluted into two subpeaks. The binding energy at 69.3 eV can be ascribed to the bromine in [PbBr6]4− octahedron, and the peak at 68.3 eV can be ascribed to the bromine in CsPbBr3/TiO2 NCs. Figure S4f is the O1s meticulous scan spectrum, which could be deconvoluted into two subpeaks. The main separation peak at 531.9 eV corresponds to lattice oxygen in the hydroxyl groups and another minor separation peak at 529.9 eV corresponding to adsorption oxygen in the Ti–O of TiO2. Figure S5 and Fig. S6 are the XPS of samples lasting in the air for one and two months. Compared with the original samples, the similar phenomenon of the element meticulous scan spectrogram except oxygen is presented. By analyzing the characteristic profiles in Fig. S5(f) and S6(f), one can see that the main separation peak related to O–H functional groups decreases with lasing in the air, which is caused by the loss of hydroxyl groups for the dehydration with the time.

Raman spectroscopy is a powerful technique to identify the molecular structure of perovskite nanocrystals. Figure 7 shows the Raman spectrum of TOBT, CsPbBr3 and CsPbBr3/TiO2 NCs. From the figure, we can see that CsPbBr3/TiO2 NCs contain two sharp peaks in CsPbBr3 NCs and four weak peaks in TOBT armamentarium. The peaks at about 70 and 120 cm−1 are ascribed to the vibrational mode of [PbX6]4− octahedron and motion of Cs+ cations, respectively [27]. The peaks at about 175, 420 and 620 cm−1 are ascribed to the stress change of O–Ti–O variable angle vibration. Both of them indicate the formation of TiO2 core/shell with an anatase-like structure.

Figure 8 and S7 reveals the time-resolved photoluminescence decay spectrum for CsPbBr3 and CsPbBr3/TiO2 nanocomposites. A radiative emission decay with about 4.04 ns average lifetime of CsPbBr3/TiO2 NCs can be obtained. However, the radiative emission decay time of CsPbBr3 NCs is about 2.52 ns, indicating that the energy transfer happens between CsPbBr3 and TiO2. After lasting months in the air, the lifetime of CsPbBr3/TiO2 NCs keeps at about 3.98 ns and 3.81 ns, meaning the high stability of perovskite nanocomposites after coating with the TiO2. Deposition of TiO2 shell reduces the surface defects of nanocrystals and increases the non-radiative transitions, thereby improving the lifetimes of CsPbBr3/TiO2 nanocrystals. The defect tolerance of CsPbBr3 NCs offers a long lifetime and high PLQY, causing improved stability for CsPbBr3/TiO2 perovskite nanocomposites.

To further check the thermal stability of perovskite nanostructures, we tested CsPbBr3/TiO2 nanocrystals annealing at 80 °C, as shown in Fig. S8-S11. The XRD characteristic diffraction peaks after annealing were similar to the original sample, illustrating the stability of CsPbBr3. In Fig. S9, there was a Stokes shift of 10 nm, demonstrating the emission originated from the exciton recombination. Figure S10 is the fluorescence spectroscopy of CsPbBr3/TiO2 NCs under different excitation wavelengths. One could see an excitation peak at about 400 nm and an emission peak at about 508 nm in PLE and PL spectra. Unchanged emission peaks present the uniform size distribution of nanocrystals and robust stability of the sample after annealing. Figure S11 is the time-resolved PL decay curves of CsPbBr3/TiO2 nanocrystals before and after post-annealing. The PL decaying time of about 3.13 ns indicates a high thermal stability of perovskite nanocrystals.

4 Conclusions

In summary, we successfully prepared monodispersed colloidal CsPbBr3/TiO2 core/shell nanocomposite. The CsPbBr3/TiO2 nanocomposite exhibits a uniform size distribution of about 9.2 nm. A narrow FWHM indicates good crystallinity and favorable stability. The time-resolved photoluminescence decay lifetime of CsPbBr3/TiO2 nanocrystals increases to 4.04 ns which that of CsPbBr3 is 2.52 ns, which leads to a high PLQY. After a post-annealing at 80 °C, it was found that the emission peak and fluorescence lifetime of CsPbBr3/TiO2 nanocrystals remained unchanged, indicating the prepared composite nanocrystals have a strong thermal stability. The results provide an effective method to improve the stability of perovskite nanostructures and are expected to have a practical application in optoelectronic fields.

References

Wang X et al (2018) High-quality in-plane aligned CsPbX3 perovskite nanowire lasers with composition-dependent strong exciton-photon coupling. ACS Nano 12(6):6170–6178

Liu TJ et al (2020) High charge carrier mobility in solution processed one-dimensional lead halide perovskite single crystals and their application as photodetectors. Nanoscale 12(17):9688–9695

Wang Y et al (2018) White LED based on CsPbBr3 nanocrystal phosphors via a facile two-step solution synthesis route. Mater Res Bull 104:48–52

Ji L et al (2020) Large organic cation incorporation induces vertical orientation growth of Sn-based perovskites for high efficiency solar cells. Chem Eng J 402:125133

Kojima A et al (2009) organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J Am Chem Soc 131(17):6050–6051

Pistor P et al (2018) Thermal stability and miscibility of co-evaporated methyl ammonium lead halide (MAPbX3, X=I, Br, Cl) thin films analysed by in situ X-ray diffraction. J Mater Chem A 6(24):11496–11506

Liu P et al (2017) Organic–inorganic hybrid perovskite nanowire laser arrays. ACS Nano 11(6):5766–5773

Green MA et al (2015) Solar cell efficiency tables (Version 45). Prog Photovolt 23(1):1–9

Liu Y et al (2016) Thinness- and shape-controlled growth for ultrathin single-crystalline perovskite wafers for mass production of superior photoelectronic devices. Adv Mater 28(41):9204–9209

Bian H et al (2018) Graded bandgap CsPbI2+xBr 1–x perovskite solar cells with a stabilized efficiency of 14.4%. Joule 2(8):1–11

Chen Q et al (2020) Co-solvent controllable engineering of MA0.5Pb0.8Sn0.2I3 lead-tin mixed perovskites for inverted perovskite solar cells with improved stability. Energies 13(10):2438

Shan Q et al (2017) All-inorganic quantum-dot light-emitting diodes based on perovskite emitters with low turn-on voltage and high humidity stability. J Mater Chem C 5(18):4565–4570

Hu H et al (2018) Interfacial synthesis of highly stable CsPbX3/oxide janus nanoparticles. J Am Chem Soc 140(1):406–412

Wang HC et al (2016) Mesoporous silica particles Integrated with All-inorganic CsPbBr3 perovskite quantum-dot nanocomposites (MP-PQDs) with high stability and wide color gamut used for backlight display. Angew Chem Int Ed 55(28):7924–7929

Chen W et al (2017) Enhanced stability and tunable photoluminescence in perovskite CsPbX3/ZnS quantum dot heterostructure. Small 13(21):1604085

Zhang Z et al (2017) A new passivation route leading to over 8% efficient PbSe quantum-dot solar cells via direct ion exchange with perovskite nanocrystals. Adv Mater 29(41):3214–3321

Ye S et al (2017) A breakthrough efficiency of 19.9% obtained in inverted perovskite solar cells by using an efficient trap state passivator Cu(thiourea)I. J Am Chem Soc 139(22):7504–7512

Abbas HA et al (2015) High efficiency sequentially vapor grown n-i-p CH3NH3PbI3 perovskite solar cells with undoped P3HT as p-type heterojunction layer. APL Mater 3:016105

Chen HT et al (2019) Tunable photoluminescence of CsPbBr3 perovskite quantum dots for their physical research. Appl Suf Sci 465:656–664

Chen HT et al (2019) Highly luminescent CsPbX3 (X=Cl, Br, I) perovskite nanocrystals with tunable photoluminescence properties. J Alloys Compd 789:392–399

Gao L et al (2017) Passivation of defect states in anatase TiO2 hollow spheres with Mg doping: realizing efficient photocatalytic overall water splitting. Appl Catal B 202:127–133

Kim Y et al (2015) Efficient luminescence from perovskite quantum dot solids. ACS Appl Mater Interfaces 7(45):25007–25013

Li C et al (2017) Enhanced photoresponse of self-powered perovskite photodetector based on ZnO nanoparticles decorated CsPbBr3 films. Sol Energy Mater 172:341–346

Liu X et al (2018) Enhanced X-ray photon response in solution-synthesized CsPbBr3 nanoparticles wrapped by reduced graphene oxide. Sol Energy Mater 187:249–254

Chen H et al (2011) Defect-related energy structures of aln nanotips probed by photoluminescence. J Phys D Appl Phys 44(50):505304

Xia H et al (2018) High binding ability ligand controlled formation of CsPbX3 (X = Cl/Br, Br, I) perovskite nanocrystals with high quantum yields and enhanced stability. RSC Adv 8(63):35973–35980

Chen D et al (2018) CsPbX3 (X= Br, I) perovskite quantum dots embedded low-melting phosphosilicate glasses: controllable crystallization, thermal stability and tunable emissions. J Mater Chem C 6(25):6832–6839

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 11004170).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, H., Li, R., Guo, A. et al. Highly fluorescent CsPbBr3/TiO2 core/shell perovskite nanocrystals with excellent stability. SN Appl. Sci. 3, 654 (2021). https://doi.org/10.1007/s42452-021-04648-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04648-8