Abstract

Metals and metal oxide-based nanocomposites play a significant role over the control of microbes. In this study, antibacterial activity of iron oxide (Fe2O3) nanocomposites based on induction furnace (IF) steel slag has been carried out. IF steel slag is an industrial by-product generated from secondary steel manufacturing process and has various metal oxides which includes Al2O3 (7.89%), MnO (5.06), CaO (1.49%) and specifically Fe2O3 (14.30%) in higher content along with metalloid SiO2 (66.42). Antibacterial activity of iron oxide nanocomposites has been revealed on bacterial species such as Micrococcus luteus, Bacillus subtilis and Staphylococcus aureus. Micrococcus luteus has undergone maximum zone of inhibition (ZOI) of 12 mm for 10 mg/mL concentration of steel slag iron oxide nanocomposite. Growth inhibitory kinetics of bacterial species has been studied using ELISA microplate reader at 660 nm by varying the concentration of steel slag iron oxide nanocomposites. The results illustrate that IF steel slag is a potential material and can be utilized in building materials to increase the resistance against biodeterioration.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Industrial by-products utilization and management is a major challenge among researchers globally, and many solutions have been initiated. In steel industry, steel manufacturing process generates enormous quantity of industrial by-product called ‘slag’ [1]. Land filling of steel slag in industrial sites has not been encouraged due to progressive saturation [2]. The energy and emission associated with natural aggregate extraction, crushing and cleaning can be reduced by utilizing of steel slag as an alternate aggregate [3]. Several research studies have been carried out to utilize steel slag in various fields. Steel slag has been utilized in concrete/mortar [4, 5], cementing material [6], bituminous paving mixtures [7], road construction [8], fire resistance [9], thermal energy storage [10], heavy metal removal [11, 12], organic pollutant and dye removal [13], synthesis of mesoporous nanosilica [14], improvement in soil quality [15], water filter [16], radiation shielding [17], CO2 sequestration [18], crop production [19], green artificial reef [20] and micro-fouling [21].

Historically, it is evident that, iron slag was used in wound healing by Greek physician Aristotle in 350 BC [22]. Antibacterial agents seek considerable attention in health sector for its prevention against bacterial pathogens, and they are also used in various industries including food, textile and as water disinfectant etc., [23]. There is an ever-growing need for prevention of biofilm formation, and different strategies are conferred towards antimicrobial studies [24]. The dimensions of metals/metal oxides nanomaterial are between bulk materials and molecules/atoms/ions which interact with cell to make stable entity with less energy [25]. Iron oxide nanoparticles have been studied for various antimicrobial activities [26, 27].

Iron oxide nanostructures in the phase of hematite (α-Fe2O3) have been synthesized and experimented for its antibacterial activity using Escherichia coli and Staphylococcus aureus. The experimental result shows that 20 μg/μl concentration of α-Fe2O3 delivered the ZOI 45 ± 2 39 ± 2 against the bacterial species E. coli and S. aureus, respectively [28]. Fe2O3 nanoparticles have been functionalized using 3-aminopropyltriethoxysilane (APTES) and studied for its antibacterial activity. The binding of inorganic nanoparticles and organic functional groups (i.e. APTES–Fe2O3) has been studied using spectral analysis (absorption and emission). Pseudomonas aeruginosa and S. aureus are the bacterial species used in this study. The measured zone of inhibition was 21 mm and 11 mm for S. aureus and P. aeruginosa, respectively. The results illustrate that the APTES–Fe2O3 nanocomposites can be used as a potential antibacterial agent [29]. Iron oxide (α-Fe2O3) nanoparticles were synthesized using the extract of S. cordifolia plant and studied for its antibacterial activities using bacterial species such as B. subtilis, S. aureus, E. coli and K. pneumonia. Agar well diffusion procedure has been adopted for antibacterial study, and the obtained zones of inhibition values are 16.00 ± 1.00, 13.67 ± 0.58, 11.33 ± 0.58 and 12.00 ± 1.00 mm for the bacterial species B. subtilis, S. aureus, E. coli and K. pneumonia, respectively. From the results, it can be inferred that B. subtilis shows maximum inhibition (ZOI 16.00 ± 1.00) towards α-Fe2O3 [30].

Iron/iron oxides are also utilized with other metal ion nanoparticles for antibacterial/antimicrobial activities as Cu-Fe [31], Fe/Zn oxide [32], fibreglass-Fe2O3/Ag [33] and γ-Fe2O3@SiO2@TiO2–Ag nanocomposites [34]. In concrete, corrosion occurs by microbes (producing inorganic/organic acids) causing deterioration which degrades the components of concrete and it is a serious issue to be addressed [35]. Induction furnace steel slag has been utilized in concrete by our research team earlier [36] which reveals that it can be used as a partial replacement of natural coarse aggregate. This study aims to provide antibacterial property of induction furnace steel slag on M. luteus, B. subtilis and S. aureus which can be a significant research data in the building environment of concrete constructions under microbial environment, thereby contributing to the sustainable constructions.

2 Materials and methods

2.1 IF steel slag sample collection and characterization

Iron oxide-based slag materials used in the present study have been obtained from Jeppiaar furnace and steels, Pvt. Ltd., Kanchipuram, Tamil Nadu, India. Slag material is subjected to size reduction using ball milling technique. X-ray diffraction (XRD) is operated at 9 kW with CuK-alpha radiations using Bruker D8 to analyse mineral phases of slag material. Surface morphology of IF steel slag has been analysed using field emission scanning electron microscope (FE-SEM) (CARL ZEISS, SUPRA-55, Germany) equipped with energy-dispersive X-ray analysis (EDAX). The presence of various metal oxides in steel slag material has been analysed using X-ray fluorescence spectroscopy (Bruker S8 Tiger).

2.2 Antibacterial experiments

Antibacterial activity of iron oxide nanocomposite has been studied against M. luteus, B. subtilis and S. aureus bacterial species. Microbes were maintained at Marine microbiology laboratory, Centre for Ocean Research, Sathyabama Institute of Science and Technology, Chennai. Agar well diffusion assay has been adopted to determine the zone of inhibition (ZOI) of microbes against iron oxide nanocomposite. Luria Bertani agar (LBA) media plates were made and wells of 5 mm diameter were created using cork borer. Iron oxide nanocomposite of 2, 5 and 10 mg/mL concentrations was added to the wells and incubated for 24 h at 37 °C.

The growth kinetics of bacterial species were studied using ELISA microplate reader (BioTek—ELX 800) to examine the effect of iron oxide nanocomposite in various concentrations (2, 5 and 10 mg/mL) with 106 cells of each individual bacterial species (20 µL) grown in Luria Bertani broth medium (200 µL). A control is maintained in identical conditions. Growth rate of bacterial species was examined by measuring OD values at 660 nm up to 27 h at an interval of 3 h. In this research work, all the experiments were carried out thrice and the mean value has been taken.

3 Results and discussion

3.1 Slag-based iron oxide nanocomposite

Mineralogical phases of components present in steel slag have been identified using XRD analysis (Bruker D8 advance) (Fig. 1). The presence of major mineralogical phases in slag material is quartz (SiO2, 2θ value 26.6), iscorite (Fe7SiO10, 2θ values 50.32 and 60.30), almandine (Fe3Al2Si3O12, 2θ values 22.20 and 68.48) and hematite (ε-Fe2O3, 2θ values 36.7 and 39.94). Also minor peaks with less intensity have been identified and is similar to the results reported [37, 38]. The presence of minor phases in steel slag materials is manganocalcite [(Ca, Mn)CO3, 2θ value 29.73], merwinite [Ca3Mg(SiO4)2, 2θ values 31.69 and 34.92], periclase (MgO, 2θ value 46.12) and mayenite (Ca12 Al14O33, 2θ value 55.07) [37]. Iron silicates such as FeSiO4 (2θ value 35.10) and FesiO10 (2θ value 51.48) are along with MnO2 (2θ value 42.74) and are also present in slag materials, and the similar results have been reported earlier [38].

Surface morphology of slag material is recorded using FE-SEM (SUPRA 55 CARL ZEISS, Germany) and is shown in Fig. 2.a–c. SEM analysis shows that the particles are heterogeneous in nature. Also, the metal oxides of slag material are in dissimilar in size and shape. The slag particles were sub-rounded to angular shape with heterogeneous in nature. The roughness and edges were visible in bulk and angular particles. EDAX analysis was carried out to identify the elemental composition of slag material (Fig. 2d). Among various metals present in slag elemental composition (Fig. 3 and Table 1), iron (Fe—17.25%) and silicon (Si—18.54%) contribute majorly along with aluminium (Al—5.80%), manganese (Mn—3.48%), calcium (Ca—1.58%) and magnesium (Mg—0.65%) with some trace elements. The presence of various metal oxides composition in steel slag has been analysed using XRF technique (Bruker S8 Tiger) and is shown in Table 2. The major metal oxides present in slag are Fe2O3 (14.30%), Al2O3 (7.89%), MnO (5.06) and CaO (1.49%) along with metalloid SiO2 (66.42).

3.2 Antibacterial studies of iron oxide slag nanocomposites

3.2.1 Zone of inhibition

Antibacterial efficacy of slag-based iron oxide nanocomposite against M. luteus, B. subtilis and S. aureus was evaluated by agar well diffusion assay. Iron oxide nanocomposite-introduced bacterial species have undergone bactericidal effect with respect to the amount of IF steel slag taken. The antibacterial effect of bacterial species increases with increasing concentrations of iron oxide nanocomposite (Fig. 4). It was observed that M. luteus has high receptive of antibacterial activity of iron oxide nanocomposite with ZOI of 12.1 mm (10 mg/mL), 9.1 mm (5 mg/mL) and 6.5 mm (2 mg/mL) followed by B. subtilis of ZOI of 10 mm (10 mg/mL), 8.2 mm (5 mg/mL) and 6.2 mm (2 mg/mL). S. aureus exhibits least ZOI among the microbes studied with 8, 6.7 and 5.9 mm for 10 mg/mL, 5 mg/mL and 2 mg/mL of iron oxide nanocomposite concentrations, respectively. Iron oxide of slag material inhibits microbial growth and can be utilized in concrete related to microbial attack [39].

3.2.2 Growth kinetics and cell death

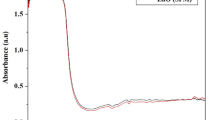

Growth inhibitory kinetics of bacterial species has been studied using ELISA microplate reader. Accuracy in determination, usage of less chemicals/time saving is the reason behind this method [40]. Optical density (OD) values were measured with respect to time at 660 nm, for different species with various concentration of iron oxide nanocomposite (2, 5 and 10 mg/mL), and are plotted in a graph (Fig. 5a–c). Antibacterial activity increases with increasing concentration of iron oxide with respect to time in the order of 10 > 5 > 2 mg/mL.

Iron oxide nanoparticles are capable of extending reactive oxygen species (ROS) in the media culture possessing antimicrobial activity [41]. IF steel slag iron oxide nanocomposite involved in the growth inhibition of M. luteus, B. subtilis and S. aureus bacterial species. Oxido-reduction reactions involve in ROS generation via Fe3+ and Fe2+ [42] present in slag-based iron oxide. The free radicals formed via oxido-reduction process are adequate to deposit stress on the bacterial cell causing death [41].The rupturing of cell wall is due to the production of ROS such as hydroxyl radicals (OH·), singlet oxygen (HO2·) [41, 43]. Microbial-influenced biocorrosion occurs when suitable conditions are present in the environment [44]. In concrete, corrosion occurs by microbes (producing inorganic/organic acids) causing deterioration which degrades the components of concrete. Metabolic process of microorganisms generates ammonia and hydrogen sulphide causes which can also cause corrosion of concretes; these metabolites of microorganisms are aggressive in nature and reacts with the components of concrete leading to the formation of non-binding calcareous salts, and degradation of sulphate causes expansion of concrete results destruction of structural elements in concrete [45]002E Blast furnace slag has been utilized in concrete, and the results show positive impact on deterioration of concrete [46, 47]. Iron oxide nanocomposite of IF steel slag exhibits inhibitory effect against microbial growth and can be utilized in building materials to increase the resistance against biodeterioration [39].

4 Conclusion

Antibacterial potential of IF steel slag-based iron oxide nanocomposite on M. luteus, B. subtilis and S. aureus bacterial species is effective. IF steel slag is available widely as an industrial by-product at very low cost and can be used as an active antimicrobial agent in building materials. Induction furnace slag-based iron oxide nanocomposites can improve the safety measures of concretes to increase the resistance against biodeterioration. This initiative will lead to utilization of IF steel slag in concrete on large scale under microbial environment.

5 Future work

Biodeterioration and biodegradation of concrete causes serious impacts on construction structures. The results of this research study will make an impact to work with IF steel slag as an alternative. Our research team has already incorporated IF steel slag in concrete, and the mechanical properties of concrete were admissible. Hence, antibacterial efficacy of IF steel slag paves a way to study the concrete specimens incorporated with IF steel slag under microbial environment. This initiative will lead to lesser microbial attack in concrete structures.

References

Repo E, Warchoł JK, Westholm LJ, Sillanpää M (2014) Steel slag as a low-cost sorbent for metal removal in the presence of chelating agents. J Ind Eng Chem 27:115–125. https://doi.org/10.1016/j.jiec.2014.12.025

Petruzzelli D, Passino JR, Tiravantit G (1995) Ion exchange process for chromium removal and recovery from tannery wastes. Ind Eng Chem Res 34:2612–2617

Grubeša NI, Barisic I, Fucic A, Bansode SS (2016) Characteristics and uses of steel slag in building construction. eBook ISBN: 9780081003763

Palankar N, Ravi Shankar AU, Mithun BM (2016) Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates. J Clean Prod 129:437–448. https://doi.org/10.1016/j.jclepro.2016.04.033

Padmapriya R, Bupesh Raja VK, Ganesh Kumar V, Baalamurugan J (2015) Study on replacement of coarse aggregate by steel slag and fine aggregate by manufacturing sand in concrete. Int J Chem Tech Res 8:266–270

Chen Z, Tu K, Li R, Liu J (2020) Study on the application mechanism and mechanics of steel slag in composite cementitious materials. SN Appl Sci. https://doi.org/10.1007/s42452-020-03644-8

Sorlini S, Sanzeni A, Rondi L (2012) Reuse of steel slag in bituminous paving mixtures. J Hazard Mater 209–210:84–91. https://doi.org/10.1016/j.jhazmat.2011.12.066

Maghool F, Arulrajah A, Du YJ, Horpibulsuk S, Chinkulkijniwat A (2017) Environmental impacts of utilizing waste steel slag aggregates as recycled road construction materials. Clean Technol Environ Policy 19:949–958. https://doi.org/10.1007/s10098-016-1289-6

Netinger I, Varevac D, Bjegovi D, Mori D (2013) Effect of high temperature on properties of steel slag aggregate concrete. Fire Saf J 59:1–7. https://doi.org/10.1016/j.firesaf.2013.03.008

Agalit H, Zari N, Maaroufi M (2017) Thermophysical and chemical characterization of induction furnace slags for high temperature thermal energy storage in solar tower plants. Sol Energy Mater Sol Cells 172:168–176. https://doi.org/10.1016/j.solmat.2017.07.035

Baalamurugan J, Kumar VG, Govindaraju K, Prasad BSN, Raja VKB, Padmapriya R (2017) Slag-based nanomaterial in the removal of hexavalent chromium. Int J Nanosci. https://doi.org/10.1142/S0219581X17600134

Forsido T, McCrindle R, Maree J, Mpenyana-Monyatsi L (2019) Neutralisation of acid effluent from steel manufacturing industry and removal of metals using an integrated electric arc furnace dust slag/lime process. SN Appl Sci 1:1–6. https://doi.org/10.1007/s42452-019-1649-z

Luan F, Xie L, Sheng J, Li J, Zhou Q, Zhai G (2012) Reduction of nitrobenzene by steel convert slag with Fe(II) system: the role of calcium in steel slag. J Hazard Mater 217–218:416–421. https://doi.org/10.1016/j.jhazmat.2012.03.047

Fakhar H, Jiang J (2020) A zero-waste approach to blast furnace slag by synthesis of mesoporous nanosilica with high surface area. Int J Environ Sci Technol 17:309–318. https://doi.org/10.1007/s13762-019-02492-3

León-Romero MA, Soto-Ríos PC, Nomura M, Nishimura O (2018) Effect of steel slag to improve soil quality of tsunami-impacted land while reducing the risk of heavy metal bioaccumulation. Water Air Soil Pollut 229:12. https://doi.org/10.1007/s11270-017-3666-0

Anjali MS, Shrihari S, Sunil BM (2019) Experimental studies of slag filter for drinking water treatment. Environ Technol Innov 15:100418. https://doi.org/10.1016/j.eti.2019.100418

Maslehuddin M, Naqvi AA, Ibrahim M, Kalakada Z (2013) Radiation shielding properties of concrete with electric arc furnace slag aggregates and steel shots. Ann Nucl Energy 53:192–196. https://doi.org/10.1016/j.anucene.2012.09.006

Rushendra Revathy TD, Palanivelu K, Ramachandran A (2016) Direct mineral carbonation of steelmaking slag for CO2 sequestration at room temperature. Environ Sci Pollut Res 23:7349–7359. https://doi.org/10.1007/s11356-015-5893-5

Humaria M (2014) Impact of iron and steel slag on crop cultivation: a review. Curr World Environ J 9:216–219. https://doi.org/10.12944/cwe.9.1.31

Huang X, Wang Z, Liu Y, Hu W, Ni W (2016) On the use of blast furnace slag and steel slag in the preparation of green artificial reef concrete. Constr Build Mater 112:241–246. https://doi.org/10.1016/j.conbuildmat.2016.02.088

Nandakumar K, Matsunaga H, Takagi M (2003) Microfouling studies on experimental test blocks of steel-making slag and concrete exposed to seawater off Chiba. Jpn Biofouling 19:257–267. https://doi.org/10.1080/0892701032000077158

Geiseler J (1996) Use of steelworks slag in Europe. Waste Manag 16:59–63. https://doi.org/10.1016/S0956-053X(96)00070-0

Li Q, Mahendra S, Lyon DY, Brunet L, Liga MV, Li D, Alvarez PJJ (2008) Antimicrobial nanomaterials for water disinfection and microbial control: potential applications and implications. Water Res 42:4591–4602. https://doi.org/10.1016/j.watres.2008.08.015

Shi Z, Neoh KG, Kang ET (2005) Antibacterial activity of polymeric substrate with surface grafted viologen moieties. Biomaterials 26:501–508. https://doi.org/10.1016/j.biomaterials.2004.02.060

Sunitha S, Rao AN, Abraham LS, Dhayalan E, Thirugnanasambandam R, Kumar VG (2015) Enhanced bactericidal effect of silver nanoparticles synthesized using marine brown macro algae. J Chem Pharm Res 7:191–195

Behera SS, Patra JK, Pramanik K, Panda N, Thatoi H (2012) Characterization and evaluation of antibacterial activities of chemically synthesized iron oxide nanoparticles. World J Nano Sci Eng 02:196–200. https://doi.org/10.4236/wjnse.2012.24026

Kamaraj M, Kidane T, Muluken KU, Aravind J (2019) Biofabrication of iron oxide nanoparticles as a potential photocatalyst for dye degradation with antimicrobial activity. Int J Environ Sci Technol 16:8305–8314. https://doi.org/10.1007/s13762-019-02402-7

Pallela PNVK, Ummey S, Ruddaraju LK, Gadi S, Cherukuri CSL, Barla S, Pammi SVN (2019) Antibacterial efficacy of green synthesized α-Fe2O3 nanoparticles using Sida cordifolia plant extract. Heliyon 5:e02765. https://doi.org/10.1016/j.heliyon.2019.e02765

Saravanan P, Jayamoorthy K, Anandakumar S (2016) Fluorescence quenching of APTES by Fe2O3 nanoparticles: sensor and antibacterial applications. J Lumin 178:241–248. https://doi.org/10.1016/j.jlumin.2016.05.031

Rufus A, Sreeju N, Vilas V, Philip D (2017) Biosynthesis of hematite (α-Fe2 O3) nanostructures: size effects on applications in thermal conductivity, catalysis, and antibacterial activity. J Mol Liq 242:537–549. https://doi.org/10.1016/j.molliq.2017.07.057

Bakina OV, Glazkova EA, Svarovskaya NV, Rodkevich NG, Lerner MI (2019) «Janus»-like Cu-Fe bimetallic nanoparticles with high antibacterial activity. Mater Lett 242:187–190. https://doi.org/10.1016/j.matlet.2019.01.105

Bhushan M, Kumar Y, Periyasamy L, Viswanath AK (2018) Facile synthesis of Fe/Zn oxide nanocomposites and study of their structural, magnetic, thermal, antibacterial and cytotoxic properties. Mater Chem Phys 209:233–248. https://doi.org/10.1016/j.matchemphys.2018.02.002

Nangmenyi G, Li X, Mehrabi S, Mintz E, Economy J (2011) Silver-modified iron oxide nanoparticle impregnated fiberglass for disinfection of bacteria and viruses in water. Mater Lett 65:1191–1193. https://doi.org/10.1016/j.matlet.2011.01.042

Cui B, Peng H, Xia H, Guo X, Guo H (2013) Magnetically recoverable core–shell nanocomposites c-Fe2O3@SiO2@TiO2–Ag with enhanced photocatalytic activity and antibacterial activity. Sep Purif Technol 103:251–257. https://doi.org/10.1016/j.seppur.2012.10.008

Wei S, Jiang Z, Liu H, Zhou D, Sanchez-Silva M (2013) Microbiologically induced deterioration of concrete: a review. Braz J Microbiol 44:1001–1007. https://doi.org/10.1590/S1517-83822014005000006

Baalamurugan J, Ganesh Kumar V, Chandrasekaran S, Balasundar S, Venkatraman B, Padmapriya R, Bupesh Raja VK (2019) Utilization of induction furnace steel slag in concrete as coarse aggregate for gamma radiation shielding. J Hazard Mater 369:561–568. https://doi.org/10.1016/j.jhazmat.2019.02.064

Yildirim IZ, Prezzi M (2015) Steel slag: chemistry, mineralogy and morphology. In: proceedings of the international foundations congress and equipment expo. pp. 2816–2825

Nicolae M, Vîlciu I, Zǎman F (2007) X-ray diffraction analysis of steel slag and blast furnace slag viewing their use for road construction. UPB Sci Bull Ser B Chem Mater Sci 69:99–108

Strigáč J, Števulová N, Mikušinec J, Varečka L, Hudecová D (2018) Antimicrobial efficiency of metallurgical slags for application in building materials and products. Buildings 8:33. https://doi.org/10.3390/buildings8020033

Horáková K, Greifová M, Seemannová Z, Gondová B, Wyatt GM (2004) A comparison of the traditional method of counting viable cells and a quick microplate method for monitoring the growth characteristics of Listeria monocytogenes. Lett Appl Microbiol 38:181–184. https://doi.org/10.1111/j.1472-765X.2004.01448.x

Arakha M, Pal S, Samantarrai D, Panigrahi TK, Mallick BC, Pramanik K, Mallick B, Jha S (2015) Antimicrobial activity of iron oxide nanoparticle upon modulation of nanoparticle-bacteria interface. Sci Rep 5:1–12. https://doi.org/10.1038/srep14813

Auffan M, Rose J, Wiesner MR, Bottero JY (2009) Chemical stability of metallic nanoparticles: a parameter controlling their potential cellular toxicity in vitro. Environ Pollut 157:1127–1133. https://doi.org/10.1016/j.envpol.2008.10.002

Fang M, Chen JH, Xu XL, Yang PH, Hildebrand HF (2006) Antibacterial activities of inorganic agents on six bacteria associated with oral infections by two susceptibility tests. Int J Antimicrob Agents 27:513–517. https://doi.org/10.1016/j.ijantimicag.2006.01.008

Strigac J, Stevulova N, Mikusinec J, Varecka L, Hudecova D (2017) Comparative study of antimicrobial efficiency of metallurgical slags suitable for construction applications. IOP Conf Ser Earth Environ Sci 92:012057. https://doi.org/10.1088/1755-1315/92/1/012057

George RP, Vishwakarma V, Samal SS, Mudali UK (2012) Current understanding and future approaches for controlling microbially influenced concrete corrosion: a review. Concr Res Lett 3:491–506

Strigáč J (2016) Fungistatic properties of granulated blastfurnace slag and related slag-containing cements. Ceram Silikaty 60:19–26. https://doi.org/10.13168/cs.2016.0003

Berndt ML (2011) Evaluation of coatings, mortars and mix design for protection of concrete against sulphur oxidising bacteria. Constr Build Mater 25:3893–3902. https://doi.org/10.1016/j.conbuildmat.2011.04.014

Acknowledgements

We thank Atomic Energy Regulatory Board, Government of India, for the financial grant (AERB/CSRP/Proj. No. 65/07/ 2016) of induction furnace steel slag studies. DST-FIST financial support is gratefully acknowledged. The authors thank the management of Sathyabama Institute of Science and Technology, Chennai, India for its strong support in research activities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Baalamurugan, J., Ganesh Kumar, V., Stalin Dhas, T. et al. Utilization of induction furnace steel slag based iron oxide nanocomposites for antibacterial studies. SN Appl. Sci. 3, 295 (2021). https://doi.org/10.1007/s42452-021-04299-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04299-9