Abstract

A dendrimer based on diazine supported heterogeneous Cobalt nanoparticles (NPs) were synthesized by a reduction method whereas the dendrimer was produced between the reaction of 2,4,6-triamino-1,3-diazine and benzoyl chloride at 80 °C for 8 h. The SEM image of the dendrimer supported Co NPs displayed the globular and agglomerate spherical size and EDX assessment noted the existence of necessary cobalt ion while TG and DSC showed excellent thermal stability. XRD revealed that FCC configuration of Co NPs. By using the Debye–Scherrer formula, the average size of these Co NPs was calculated to 18.10 nm likewise it was found 7.00 nm by the TEM analysis. The dendrimer was also evaluated by IR, 1HNMR, 13CNMR, Mass spectrophotometry, and elemental analysis. The catalytic effect of these nanoparticles catalyst has been studied for Heck coupling reactions in tetrabutylammonium bromide solution and observed excellent catalytic efficiency within very short reaction time (45 min) and also reusable.

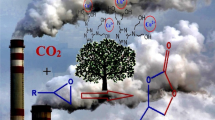

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The cross-coupling reaction for the formation of C–C bond catalyzed by transition metal has been deliberated highly effective synthetic methods [1,2,3,4]. Adversely, the implementation of conventional catalyst palladium complexes for cross-coupling reactions has certain constraints in the case of poisonousness, price, non-reusability, and moisture sensitivity [5,6,7]. Furthermore, a significant decrease in catalytic efficiency of surface-active metal atoms was often induced due to various kinetic complications for instance agglomeration of metal particles during the reaction [8, 9]. These issues can be achieved primarily through heterogeneous catalysts, the application of green reaction solvents and/or other transition metals that have garnered much attention in recent years, such as Ni, Cu, Co and Fe [10,11,12,13,14]. In organic synthesis, furthermore, cobalt-catalyzed couplings are of interest as cobalt is a cheap, easily accessible and one of the most efficient catalyst [15,16,17,18]. Recently some cobalt-based catalysts were recorded for the Heck reaction [19,20,21]. Also, metal nanoparticles of metal play a significant participation as the real catalyst or as a source of catalyst in many synthetic procedures. Recently, nanostructures have become one of the fastest issues owing to their innovative characteristics that are individual from those of their substance counterparts [22]. Due to their exceptional physical and chemical characteristics, which are of concern to fundamental science studies and prospective technological applications in catalysts, magnetic liquids and magnetic recording media, significant focus has been concentrated on the studies of nanosized magnetic materials such as Fe, Co, and Ni over the past decade [23,24,25,26].

In addition, dendrimer encapsulated metal NPs are used in a multitude of implementations notably drug delivery and catalysis [27, 28]. By using the dendrimer template method the synthesis of dendrimer supported nanoparticle for catalysis has considerable advantages: (1) producing well-defined NPs with uniform shape and structure (2) leading in reliable catalytic locations available, (3) embedded NPs in dendrimer are also retained within the dendrimers, (4) restricting agglomeration causing in surface area preservation and a successive boost in the lifetime of the catalyst [29, 30]. Moreover, ionic liquids (ILs) are an appealing solvent for nanoparticles in catalytically efficient transition metal manufacturing and retention. More notably, it is possible to produce ILs that include coordinating groups [31], for instance, with either the nitrile groups of the cation or anion (CN–IL). Palladium nanoparticles have been observed to be greater supported in CN–IL compared to non-functional ionic liquids in various C–C coupling reactions catalyzed by a palladium catalyst; thus, improved catalytic activity and recyclability are achieved [32, 33].

According to these factors into consideration, and as an aspect of ongoing work to improve reliable green catalytic [34,35,36] synthetic method of diazine-based dendrimer supported monometallic Co NPs without phosphine ligand in the presence of tetrabutylammonium bromide (TBAB) solution as ionic solvent and base of tetrabutylammonium acetate (TBAA) for carbon–carbon cross-coupling reaction as revealed by Heck coupling reactions has been established.

2 Results and discussion

2.1 Synthesis and characterization

Dendrimer 3 was synthesized from the reaction of 2,4,6-triamino-1,3,-diazine 1 with benzoyl chloride 2 at 80 °C for 8 h (Scheme 1). The structure of the compound was established by IR, 1H NMR, 13C NMR, Mass spectrophotometry and also elementary analysis (S1-S4 in the supporting information).

Compound 3’s structure was corroborated by the existence of vital peaks in the IR spectrum. The peak at the stretching stripe of 3035 and 1535 cm−1 stated the presence of aromatic C–H and aromatic C=C respectively, while the peak at 1620–1780 cm−1 deliver the C=O band. Furthermore, it is considerable that there is no N–H fetter nigh 3400–3200 cm−1 that has been shown to have transformed 1° amino group of triazine into 3° amido group. The structure of dendrimer 3 was also recommended by the IH NMR and 13C NMR spectra. In the 1H NMR peak, there is no NH or NH2 tie that further characterized the structure of compound 3. The molecular ion peak 748.25 (100) [M]+ by MALDI-TOF MS and the presence of the required element by elementary analysis also ratify the makeup of compound 3.

Typically, dendrimer supported metal NPs were prepared from metal salts or complexes by chemical reduction with LiBH(C2H5)3, N2H4·H2O, NaBH4, H2, etc. [37, 38] or by UV irradiation, [34, 39] or by decomposition (thermal, microwave, ultra-sound, etc.) [35, 36]. Here it was followed very simple chemical reduction method by hydrazine monohydrate as the following Scheme 2.

The dendrimer supported monometallic Co NPs 4 were described by various physicochemical methods such as IR, SEM, EDX, XRD, TEM, TGA, and DSC (Schemes 3 and 4).

All the required peaks of dendrimer 3 were present in the IR spectrum of the dendrimer supported Co NPs 4 (S 5 in the supporting information) and a small change of the peak position of C=O group that might be induced due to steric effect between Co NPs and CO group. However, these observations of IR analysis indicated the formation of dendrimer 3 supported Co NPs 4.

The SEM image of these nanoparticles 4 displayed the agglomerate globular and spherical size of the particles (Fig. 1).

The existence of cobalt was 71.25% of mass and 35.25% of atom of the synthesized diazine based dendrimer supported Co NPs 4 (Fig. 2) was found by EDX analysis. It was taken the weight ratio of the prepared dendrimer 3 and cobalt chloride as 1:3.3 ratio as well as it was observed from EDX analysis of the synthesized dendrimer supported Co NPs that the mass ratio between dendrimer and Co NPs was 1: 2.02. Also, no chlorine was observed in the dendrimer supported Co NPs. It was revealed from these observations that the synthetic procedure was successful for the preparation of dendrimer supported Co NPs 4.

The XRD illustration (Fig. 3) also described the particle shape and size of the diazine-based Cobalt NPs. Three notable peaks of FCC Cobalt nanoparticles were associated to (111), (110) and (220) at 43.30°, 54.50° and 75.50° respectively with corresponding to the Cobalt FCC JCPDS #15-0806 standard JCPDS powder diffraction card [40]. From the XRD graph, the average particle size of 18.10 nm calculated by the Debye–Scherrer formula while the average particle size of the NPs was 7.00 nm (Fig. 4b) observed from the TEM analysis.

Thermal constancy is one of the key features of catalyst in order to sustain their activity in long reaction times and high temperature. It was detected from the TG and DSC curves of cobalt NPs 4 (Fig. 5). The substrate of nanoparticles varies with its framework and shape with the increasing of temperature and is evaluated by the thermo-gravimetric diagram according to the weight reduction of these components. It was identified from the TG curve that compound 4’s total weight loss from 220 to 258 °C and the DSC values were just about analogous to the TG values. The melting point from the DSC endothermic curve was indicated at about 220 °C. The final stage of decline disclosed catalyst 4’s 12.10% ash residue.

2.2 Catalytic performance of the dendrimer 3 assisted cobalt NPs 4

The ionic liquid (IL) tetrabutylammonium bromide (TBAB) solution in which metal nanoparticles are dispersed represented as a good solvent as well as co-catalyst for example Heck reaction between aryl bromides and butyl methacrylate catalyzed by Pd-NPs with tetrabutylammonium acetate (TBAA) as a base at 120 °C [41].

At first, a general model reaction between 4-bromoanisol and methyl acrylate to detect the optimized reaction conditions for the Heck reaction catalyzed by Co NPs 4 with a solvent of tetrabutylammonium bromide (TBAB) solution. The outcomes of the different reactions were summarized in Table 1.

Reaction conditions: 4-bromoanisol (1 mmol), methylacrylate (1.2 mmol), base tetrabutylammonium acetate (TBAA) (1.5 mmol), 45 min, temperature 120 °C, Yields% was calculated on the basis of 4-bromoanisol; solvent tetrabutylammonium bromide (TBAB) solution (5 mL), reaction environment- nitrogen atmosphere.

Initially, when a coupling reaction with the use of 3.0 or 4.0 mol% of Co NPs 4 as catalyst, 4-bromo anisol (1.0 mmol) with methyl acrylate (1.2 mmol) with NaOH, Na2CO3 or Et3N, Bu3N (1.2 equivalent) about 70 min was occurred from 80 to 100 °C temperature in the solvent of ionic liquid tetrabutylammonium bromide (TBAB) solution under nitrogen atmosphere, the coupling product was found up to 50% of yield (Table 1, Entries 1–4). Curiously, the reaction has shown a significant increase in the yield of products at 65% or 73% with 5.0 mol% of Co NPs 4 with base TBAA and solvent TBAB solution by increasing temperature at 100 °C or 110 °C with reduced time about 60 or 55 min (Table 1, Entries 5, 6). However, the maximum outcome for the optimized conditions was observed by using 5.0 mol% of the Co NPs 4 and TBAA as a base, and solvent TBAB solution for this above Heck coupling reaction under the nitrogen atmosphere at 120 °C at 45 min (Table 1, Entry 7).

After optimizing the conditions of Heck reaction catalyzed by Co NPs 4, it was carried out the Heck coupling reaction of different aryl halogen derivatives on different olefins catalyzed by this catalyst to study the effect of different substituents of reagents on the yield% of the coupling products. But it was not found any noteworthy variation of yield% of coupling products for different aryl bromide derivatives and different olefins. A little amount of higher yield% of the product was obtained for aryl bromides containing electron-donating substituents methyl and hydroxyl group shown in Table 2.

Many studies have noted that the metal-catalyzed Heck reaction in the ionic fluid can provide an effective and easy path for the preparation of regioselective products by preventing the isomerization of certain conjugated dienes [42]. All the coupling products were found as regioselective trans-products supported by 1HNMR spectra of coupling products and was not obtained any by-products. All the coupling products were analyzed by 1HNMR and 13CNMR spectra (S6-S31 in the supporting information.)

The vigorous sites of transition metal nanoparticles immobilized in ionic liquid are not readily oxidized and settled down due to the fact that all surface atoms are geta table for catalysis whether through the coordination or dislocation of the stabilizing agent or ligands [43].

While the solvent stabilizes the nanoclusters of metal, the base creates fast neutralization of PdH that inhibits the readmission of hydride to the products and avoids interconversion of olefin. As a result of these impact, TBAB and TBAA improve the rate of high output of products and abate the reaction time compared to exact Heck reaction without TBAB and TBAA [44].

Apart from the stabilizing impact of the ionic liquid [41, 45,46,47,48] on the metal nanoparticles and the regulation of the regioselectivity in the coupling mechanism, a further benefit in the usefulness of TBAA is the contain of the question ordinarily observed in the Heck reaction: that is, the sharp deactivation of the catalyst attributable to a arise in inorganic salt or ammonium halide levels obtained from metal hydride neutralization by inorganic or organic bases as tertiary amines [49, 50].

The mechanistic investigations of cobalt catalyzed Heck coupling reaction carried out recently by numerous researchers [51,52,53] described that alkyl halides induce the generation of the corresponding radical intermediates with the catalyst with the cobalt catalyst whereas alkenyl and aryl halides undergo non-radical oxidative addition in the mechanistic pathway. Based on these observations, we have proposed a plausible mechanism of catalyst 4 as following.

2.3 Recoverability and reusability of the catalyst

The recoverability and reusability of the catalyst 4 have been tested utilizing bromoanisol and methyl acrylate as substrates, and the yield% has been included in Table 3. The catalyst was recovered by centrifugation after each catalytic run followed by ethanol and acetone washing (2 × 3 mL), and also recycled to further catalytic run. After being reused four times, the SEM analysis of the recovered catalyst (Fig. 6) has been taken and agglomerated surface morphology was found alike initial morphology and also the catalyst’s constant performance, suggesting that the catalyst is not only effective enough for the Heck reaction but also very stable (Table 4).

The reaction was carried out with bromoanisol (1.0 mmol), methyl acrylate (1.2 mmol) and TBAA (3 mmol) in TBAB solution in the presence of 5 mol% Co NPs catalyst 4 at 120 °C.

Moreover, the catalytic activity of dendrimer supported Co NPs 4 was contrasted with other previously reported Co-NPs catalyst. It is observed that the reaction time in the presence of dendrimer supported Co NPs 4 is much shorter than the reported Co NPs and also cobalt-based catalysts.

3 Conclusion

One of the overwhelmingly dominant goals of our study to find out an eco-friendly green synthetic reaction process for carbon–carbon bond forming reactions catalyzed with novel air-stable diazine based dendrimer supported cobalt nano catalyst in the presence of ionic liquid without any phosphine ligand within a short reaction time. We have developed an environment and eco-friendly novel diazine-based dendrimer supported cobalt NPs catalytic synthetic method for carbon–carbon cross-coupling reactions especially in the case of Heck coupling reactions with ionic liquid (TBAB) solution without any phosphine ligand whereas the cobalt NPs have been characterized with IR, SEM, EDX, XRD, TGA & DSC and also dendrimer has been analyzed by IR, 1HNMR, 13CNMR, Mass spectrophotometry and elemental analysis. The globular and agglomerate spherical size, as well as the presence of cobalt ion, were observed by SEM and EDX analysis while the FCC shape of the Co NPs was confirmed with XRD analysis. The average size of 18.10 nm and 7.00 nm of the Co NPs were determined with Debye–Scherrer formula and the TEM experiment respectively. This novel and ecofriendly dendrimer supported Cobalt nanoparticle (NPs) catalyst are estimated as an effective catalyst for the Heck coupling reactions with very short reactions times with ionic liquid without any hazard solvent as well as recovered and reused. However, this methodology is now investing for various cross-coupling reactions such as Suzuki, Sonogashira, stille etc.

4 Experimental

4.1 Materials and method

All reagents as well as solvents for example tetrabutylammonium bromide (TBAB) solution and, tetrabutylammonium acetate (TBAA), methyl acrylate, butyl acrylate, styrene, 2, 4, 6-triaminopyrimidine; acetyl chloride and CoCl2 have been purchased from Sigma Aldrich and also used without purification. The melting point of all synthesized compounds was determined on Gallenkamp (England) in open capillary tubes. Shimadzu FTIR 8400S Fourier Transformation Spectrophotometer infrared was used for the detection of IR spectrum with KBr pellets (400–4000 cm−1). 1H NMR and 13C NMR spectra had been taken at 500 MHz and 125.76 MHz, respectively, on a JEOL instrument as well as BRUKER DPX-400 MHz and 100 MHz spectrophotometers respectively. Relative to TMS, chemical shifts have been recorded. Silica gel 60 F 254 covered on 25 TCC sheets of aluminum was used for chromatography with a thin layer analysis (TLC). The columns were formed from silica gel 60 N (neutral, 40–100 μM) chromatographic separation. The thermal stability of nanoparticles was detected with thermogravimetric analyzer (NETZSCH STA 449F3) within the range of 26 to 600 °C. Using aluminum oxide crucible, the thermogravimetric (TG) and differential scanning calorimetry (DSC) analysis were recorded at 10 ok/min and at a flow rate of 40 and 60 mL/min under a nitrogen atmosphere. The particle size and phase of Co NPs 4 were measured by PANANALYTICAL X-ray diffractometer (XRD). Scanning electron microscope (SEM), as well as Energy-dispersive X-ray spectroscopy (EDX) of NPs 4, were observed by JEOL-JSM-7600F. Transmission electron microscopy (TEM) analysis was accomplished by Philips CM12 transmission electron microscope (operating at 200 keV).

4.2 Synthesis of 2,4,6-tris(di-benzamido)-1,3-diazine 3

The mixture of 0.2 g (0.00159 mol) 2,4,6-Triaminopyrimidine, 3 mL of benzoyl chloride was stirred at 80 °C temperature in 5 mL of DMF in a 250 mL round bottom flask under a nitrogen atmosphere with reflux condition. At the starting of the reaction, the color of the reaction mixture was a clear solution and gradually it turned into light brown. The progress of the reaction was checked by thin-layer chromatography (TLC) and after 8 h it was completely converted into the light brown solid reaction mixture and was stopped by the addition of distilled water. After cooling the reaction mixture, it was filtered under suction on a Buchner funnel and washed with sufficient distilled water. Then the product was extracted with CHCl3. After the elimination of the solvent, it was crystallized with ethyl acetate and the desired compound 3 was found as light brown crystalline solid. Melting point is 130–132 °C, odorless and 92% of yield. IR (KBr): vmax 3035, 1685, 1675, 1535, 1350 and 1290 cm−1.

1H NMR (400 MHz, CDCl3): 4.49 (s, 1H), 6.75–7.23 (m, 18 H) and 8.45–8.50 (dd, 12H, J = 8.0, J = 8.8 Hz). 13C NMR (125.76 MHz, CDCl3): 128.60, 129.46, 130.34, 133.35 and 172.77 ppm. MALDI-TOF MS: m/z (%) = calcd. for C46H31N5O6: 749.77; found 748.25 (100) [M]+, Anal. Calcd. (%) for C46H31N5O6: C, 73.69; H, 4.17; N, 9.34; Found: C, 73.65; H, 4.10; N, 9.30.

4.3 Synthesis of dendrimer compound 3 supported Co nanoparticles 4

To synthesize dendrimer compound 3 supported Co nanoparticles 4, 0.100 g of 2,4,6-Tris (di-benzamido)-1,3-diazine 3 (0.133 mmol), 0.337 g of CoCl2 (2.6 mmol), NH2–NH2·H2O (1.2 mmol) were stirred in CH3CN (8 mL) in a round bottom flask under reflux conditions. The NaOH solution (0.3 M) was added gradually to the reaction due to keeping up the solution pH 11 and the suspension was forcefully stirred with a magnetic stirring bar at 90 °C for 3 h. After stopping and settling down the reaction, the black residue was obtained. In addition, after centrifugation (3500 rpm for 10 min) of the reaction mixture, the residue was filtered, washed with distilled water and acetone and dehydrated overnight in an oven at 120 °C. IR (KBr): vmax 3032, 1687, 1602, 1577, 1304 and 1299 cm−1.

4.4 Catalytic application of Co nanoparticles 4 for Heck reactions

General procedure-A mixture of 1.0 mmol of aryl bromides, 1.2 mmol of different substitutes of olefins, 5.0 mol% of Co NPs 4, TBAA as a base (1.5 mL), and TBAB solution (5.0 mL) as a solvent was poured into a round bottom flask. Then at 120 °C under reflux conditions about 45 min, it was stirred as well as the reaction was monitored and controlled by thin-layer chromatography (TLC). At the starting of the reaction, the colored of the reaction mixture was light brown gradually it was changed into brown colored solution of reaction mixture. The progress of the reaction was checked by TLC and after the completion of the reaction, the reaction solution was completely converted into light brown reaction mixture. Then it was cooled at room temperature and after removing the solvent, the product was extracted with CHCl3 (20 ml) and the organic layer was also filtered, dried with MgSO4. Finally, the product was purified through silica gel column chromatography (ethyl acetate: hexane, 5:1).

4.4.1 Synthesis of (E)-1,2-diphenylethene 17 [60]

Yield%-82, Mol. Wt.: 180.25, mp. 76–78 °C, 1H NMR (400 MHz, CDCl3), δ 7.00 (s, 2 H, CH=CH); 7.46–7.50 (m, 4 H, Ar–H); 7.64–7.68 (m, 4H, Ar–H); 7.76 (d, 2 H, J = 7.2 Hz, Ar–H); 13C NMR (100 MHz, CDCl3): δ 127.56 (CH=CH), 128.61 (Ar–C), 128.11 (Ar–C), 129.85 (Ar–C), 138.46 (Ar–C); Anal. Calcd. (%) for C14H12: C, 93.29; H, 6.71; Found: C, 93.20; H, 6.67.

4.4.2 Synthesis of 1-methoxy-4-styrylbenzene 18 [60]

Yield%-85, Mol. Wt.: 210.27, mp. 135–137 °C, 1H NMR (400 MHz, CDCl3), δ 3.50 (s, 3 H, OCH3); 6.38 (d, 2 H, J = 12.0 Hz, Ar–H); 6.57 (d, 1 H, J = 16 Hz, CH=CH); 6.86 (d, 1 H, J = 16 Hz, CH=CH); 7.29–7.38 (m, 1 H, Ar–H); 7.57 (t, 2 H, J = 11.2 Hz, Ar–H); 8.18 (t, 4 H, J = 18.0 Hz, Ar–H). 13C NMR (100 MHz, CDCl3): δ 53.31 (OCH3), 113.29 (Ar–C), 125.32 (Ar–C), 125.76 (Ar–C), 127.56 (CH=CH), 127.66 (Ar–C), 129.53 (Ar–C), 129.83 (Ar–C), 131.25 (Ar–C), 138.34 (Ar–C), 158.40 (Ar–C); Anal. Calcd. (%) for C15H14O: C, 85.68; H, 6.71; Found: C, 85.60; H, 6.68.

4.4.3 Synthesis of (E)-methyl 3-o-tolylacrylate 19 [60]

Yield%-80, Mol. Wt.: 176.21 mp. 120–122 °C, 1H NMR (400 MHz, CDCl3), δ 2.40 (s, 3 H, CH3); 3.83 (s, 3 H, OCH3); 6.48 (d, 1 H, J = 16.0 Hz, CH=CH); 7.33–7.69 (m, 3H, Ar–C); 7.83–7.90 (m, 1 H, Ar–C); 8.34 (d, 1 H, J = 8.0 Hz, CH=CH); 13C NMR (100 MHz, CDCl3): δ 20.66 (CH3), 52.56 (OCH3), 118.46 (CH=CH), 127.16 (Ar–C), 127.62 (Ar–C), 131.11 (Ar–C), 131.75 (Ar–C), 133.56 (Ar–C), 138.66 (Ar–C), 143.46 (Ar–C), 168.36 (CO); Anal. Calcd. (%) for C11H12O2: C, 74.98; H, 6.86; Found: C, 74.90; H, 6.80.

4.4.4 Synthesis of (E)-methyl 3-(2-hydroxy-5-methoxyphenyl) acrylate 20

Yield%-90, Mol. Wt.: 208.21, mp. 135–137 °C; 1H NMR (400 MHz, CDCl3): δ 3.48 (3H, s, OCH3); 3.89 (3H, s, OCH3); 5.09 (1H, s, OH); 5.64 (1H, d, J = 16.0 Hz, CH=CH); 6.66–6.69 (1H, dd, J = 1.5 Hz, J = 8.0 Hz, Ar–H); 7.46 (1H, d, J = 14.0 Hz, Ar–H); 8.58 (1H, d, J = 16.0 Hz, Ar–H); 9.47 (1H, d, J = 16.0 Hz, CH=CH); NMR (100 MHz, CDCl3): δ 51.61 (OCH3), 57.67 (OCH3), 107.67 (Ar–C), 116.26 (Ar–C), 119.16 (CH=CH), 122.20 (Ar–C), 131.09 (Ar–C), 141.21 (Ar–C), 142.20 (CH=CH), 157.67 (Ar–C), 168.22 (CO); Anal. Calcd. (%) for C11H12O4: C, 63.45; H, 5.81; Found: C, 63.40; H, 5.78.

4.4.5 Synthesis of (E)-methyl 3-(5-fluoro-2-hydroxyphenyl) acrylate 21

White solid, Yield%-90, Mol. Wt.: 196.18, mp. 132–134 °C, 1H NMR (400 MHz, CDCl3): δ 3.84 (s, 3H, CH3); 5.29 (s, 1H, OH); 5.46 (d, 1H, J = 16.0 Hz, CH=CH); 7.43 (d, 1H, J = 8.0 Hz, Ar–H); 8.63–8.66 (dd, 1H, J = 8.0 Hz, 4.0 Hz, Ar–H); 9.04 (d, 1H, J = 4. Hz, Ar–H); 9.56 (d, 1H, J = 16 Hz, CH=CH); NMR (100 MHz, CDCl3): δ 22.12 (CH3), 119.26 (CH=CH), 121.16 (Ar–C), 122.22 (Ar–C), 132.12 (Ar–C), 144.43 (CH=CH), 145.43 (Ar–C), 158.11 (C–F), 168.11 (CO), Anal. Calcd. (%) for C10H9FO3: C, 61.22; H, 4.62; Found: C, 61.19; H, 4.60.

4.4.6 Synthesis of (E)-methyl 3-(2-hydroxy-4-methylphenyl) acrylate 22

White solid, Yield%-90, mp. Mol. Wt.: 192.21, mp. 137–137 °C, 1H NMR (400 MHz, CDCl3): δ 2.20 (s, 3H, CH3), 3.84 (s, 3H, OCH3); 5.09 (s, 1H, OH); 6.23 (d, 1H, J = 16.0 Hz, CH=CH); 6.54 (s, 1H, Ar–H); 7.48 (d, 1H, J = 8.0 Hz, Ar–H); 8.66 (d, 1H, J = 8.0 Hz, Ar–H); 9.46 (d, 1H, J = 16.0 Hz, CH=CH); NMR (100 MHz, CDCl3): δ 21.10 (CH3), 51.10 (OCH3), 101.12(Ar–C), 116.11 (Ar–C), 118.16 (CH=CH), 121.121 (Ar–C), 131.18 (Ar–C), 140.11 (Ar–C), 142.10 (CH=CH), 156.10 (Ar–C), 161.12 (CO); Anal. Calcd. (%) for C11H12O3: C, 68.74; H, 6.29; Found: C, 68.74; H, 6.20.

4.4.7 Synthesis of (E)-butyl 3-(2-hydroxy-5-methoxyphenyl) acrylate 23

White crystalline solid, Yield%-85, Mol. Wt.: 250.29, mp. 135–137 °C, 1H NMR (400 MHz, CDCl3): δ 0.97 (t, 3H, J = 16.4 Hz, CH3); 1.39–1.57 (m, 2H, CH2); 1.66–1.76 (m, 2H, CH2); 3.81 (s, 3H, OCH3), 4.24 (t, 2H, J = 16.4 Hz, CH2); 5.45 (s, 1H, OH); 6.60 (d, 1H, J = 16.4 Hz, CH=CH); 6.88 (d, 1H, J = 16.4 Hz, Ar–H); 7.15 (d, 1H, J = 16.0 Hz, Ar–H); 7.54 (s, 1H, Ar–H); 8.05 (d, 1H, J = 13.6, CH=CH). NMR (100 MHz, CDCl3): δ 13.83(CH3), 16.81(CH2), 30.15 (CH2), 35.36 (CH2), 66.24 (CH2), 118.37 (CH=CH), 119.36 (Ar–C), 123.22 (Ar–C), 126.10 (Ar–C), 127.59 (Ar–C), 137.78 (Ar–C), 138.34 (CH=CH), 155.13 (Ar–C), 167.12 (CO). Anal. Calcd. (%) for C14H18O4: C, 67.18; H, 7.25; Found: C, 67.10; H, 7.20;

4.4.8 Synthesis of (E)-butyl 3-(5-amino-2-hydroxyphenyl) acrylate 24

Light brown crystalline solid, Yield% 86, mp. 135–137 °C, 140–142 Mol. Wt.: 235.28, 1H NMR (400 MHz, CDCl3): δ 0.96 (t, 3H, J = 14.8 Hz, CH3); 1.39–1.48 (m, 2H, CH2); 1.66–1.73 (m, 2H, CH2); 3.58 (s, 2H, NH2); 4.23 (t, 2H, 16.0 Hz, CH2); 5.58 (s, 1H, OH); 6.60 (d, 1H, J = 16.0 Hz, CH=CH); 6.87 (d, 1H, J = 12.4 Hz, Ar–H); 7.16 (d, 1H, J = 16 Hz, Ar–H); 7.52 (s, 1H, Ar–H); 7.94 (d, 1H, J = 16.0 Hz, CH=CH). NMR (100 MHz, CDCl3): δ 16.63 (CH3), 18.62 (CH2), 31.65 (CH2), 64.26 (CH2), 116.66 (CH=CH), 119.65 (Ar–C), 121.12 (Ar–C), 127.80 (Ar–C), 129.99 (Ar–C), 136.80 (Ar–C), 138.33 (CH=CH), 157.60 (Ar–C), 167.77 (CO). Anal. Calcd. (%) for C13H17NO3: C, 66.36; H, 7.28; N, 5.95; Found: C, 66.30; H, 7.20; N, 5.90.

4.4.9 Synthesis of (E)-butyl 3-(5-chloro-2-hydroxyphenyl) acrylate 25

White crystalline solid, Yield%-84, mp. 148–150 °C; Mol. Wt.: 254.71, 1H NMR (400 MHz, CDCl3): δ 0.96 (t, 3H, J = 16 Hz, CH3); 1.32–1.49 (m, 2H, CH2); 1.45–1.92 (m, 2H, CH2); 4.33 (t, 2H, J = 16.0 Hz, CH2); 5.11 (s, 1H, OH); 6.60 (d, 1H, J = 16.0 Hz, CH=CH); 6.77 (d, 1H, J = 14 Hz, Ar–H); 7.25 (d, 1H, J = Hz, Ar–H); 7.59 (s, 1H, Ar–H); 7.96 (d, 1H, J = 14.8 Hz, CH = CH). NMR (100 MHz, CDCl3): δ 14.13 (CH3), 19.82 (CH2), 31.66 (CH2), 64.66 (CH2), 117.16 (CH=CH), 119.16 (Ar–C), 123.82 (Ar–C), 125.10 (Ar–C), 128.79 (Ar–C), 130.08 (Ar–C), 139.64 (CH=CH), 154.61 (Ar–C), 168.72 (CO); Anal. Calcd. (%) for C13H15ClO3: C, 61.30; H, 5.94; Found: C, 61.25; H, 5.90;

4.4.10 Synthesis of (E)-ethyl 3-(2-hydroxy-5-methoxyphenyl) acrylate 26

White solid, Yield-88%, mp. 141–143 °C, Mol. Wt.: 222.24, 1H NMR (400 MHz, CDCl3): δ 1.37 (t, 3H, J = 16 Hz, CH3); 3.17 (s, 3H, OCH3); 4.23–4.33 (q, 2H, CH2); 5.18 (s, 1H, OH); 6.83 (d, 1H, J = 16.4 Hz, CH=CH); 6.89 (s, 1H, Ar–H); 6.95 (d, 1H, J = 8.0, Ar–H); 7.32 (d, 1H, J = 14.0 Hz, Ar–H), 7.83 (d, 1H, J = 16.4 Hz, CH=CH); NMR (100 MHz, CDCl3): δ 15.25 (CH3), 30.36 (OCH3), 60.99 (CH2), 117.84 (Ar–C), 117.49 (Ar–C), 122.45 (C=C), 129.09 (C=C), 142.22 (Ar–C), 143.12 (Ar–C), 156.21 (Ar–C), 169.23 (CO). Anal. Calcd. (%) for C12H14O4: C, 64.85; H, 6.35; Found: C, 64.80; H, 6.30.

4.4.11 Synthesis of (E)-ethyl 3-(5-fluoro-2-hydroxyphenyl) acrylate 27

White solid, Yield-85%, mp. 150–152 °C, Mol. Wt.: 210.2, 1H NMR (400 MHz, CDCl3): δ 1.36 (t, 3H, J = 16.8 Hz, CH3), 4.20–4.33 (q, 2H, CH2); 5.10 (s, 1H, OH); 6.87 (d, 1H, J = 15.6 Hz, CH=CH); 6.94 (d, 1H, J = 9.6, Ar–H); 7.38 (d, 1H, J = 12.0 Hz, Ar–H); 7.89 (d, 1H, J = 4.0 Hz, Ar–H); 8.45 (d, 1H, J = 17.2 Hz, CH=CH); NMR (100 MHz, CDCl3): δ 15.71 (CH3), 60.19 (CH2), 119.14 (Ar–C), 121.41 (Ar–C), 122.23 (Ar–C), 124.33 (C=C), 128.38 (C=C), 142.44 (Ar–C), 144.45 (Ar–C), 158.21 (Ar–C), 170.10 (CO). Anal. Calcd. (%) for C11H11FO3: C, 62.85; H, 5.27; Found: C, 62.79; H, 5.20.

4.4.12 Synthesis of (E)-ethyl 3-(5-chloro-2-hydroxyphenyl) acrylate 28

White solid, Yield-87%, mp. 144–146 °C, Mol. Wt.: 226.66, 1H NMR (400 MHz, CDCl3): δ 1.38 (t, 3H, J = 16.0 Hz, CH3); 4.14 (q, 2H, CH2); 5.17 (s, 1H, OH); 6.83 (d, 1H, J = 16.0 Hz, CH=CH); 6.89 (s, 1H, Ar–H); 6.97 (d, 1H, J = 16.8, Ar–H); 7.35 (d, 1H, J = 16.0 Hz, Ar–H); 7.73 (d, 1H, J = 16.0 Hz, CH=CH); NMR (100 MHz, CDCl3): δ 15.75 (CH3), 60.19 (CH2), 119.94 (Ar–C), 120.49 (Ar–C), 123.83 (Ar–C), 125.33 (C=C), 128.98 (C=C), 142.54 (Ar–C), 143.42 (Ar–C), 157.11 (Ar–C), 171.12 (CO). Anal. Calcd. (%) for C11H11ClO3: C, 58.29; H, 4.89; Found: C, 58.20; H, 4.80.

4.4.13 Synthesis of (E)-ethyl 3-(2-hydroxy-5-methylphenyl) acrylate 29

White solid, Yield-90%, mp. 141–143 °C, Mol. Wt.: 206.24, 1H NMR (400 MHz, CDCl3): δ 1.35 (t, 3H, J = 17.2 Hz, CH3); 2.18 (s, 3H, Ar-CH3); 4.29 (q, 2H, CH2); 5.18 (s, 1H, OH); 6.67 (d, 1H, J = 16.8 Hz, CH=CH); 6.95 (d, 1H, J = 8.0 Hz, Ar–H); 7.31 (d, 1H, J = 8.0, Ar–H); 7.81 (s, 1H, Ar–H), 8.02 (d, 1H, J = 16.0 Hz, CH=CH); NMR (100 MHz, CDCl3): δ 14.25 (CH3), 21.36 (Ar–CH3), 60.69 (CH2), 116.80 (Ar–C), 116.99 (Ar–C), 118.87 (Ar–C), 121.45 (C=C), 129.09 (C=C), 141.19 (Ar–C), 142.32 (Ar–C), 155.71 (Ar-C), 169.12 (CO). Anal. Calcd. (%) for C12H14O3: C, 69.88; H, 6.84; Found: C, 69.80; H, 6.79.

References

Sobhani S, Zarifi F (2015) Pd-isatin Schiff base complex immobilized on γ-Fe2O3 as a magnetically recyclable catalyst for the Heck and Suzuki cross-coupling reactions. Cuihua Xuebao Chin J Catal 36:555–563

Bagherzadeh M, Amini M, Derakhshandeh PG, Haghdoost MM (2014) An efficient glucose-based ligand for Heck and Suzuki coupling reactions in aqueous media. J Iran Chem Soc 11:441–446

Nadri S, Joshaghani M, Rafiee E (2009) Biphenyl-based phosphine: a well-defined, air-stable, and efficient ligand for the Mizoroki–Heck reaction. Appl Catal A Gen 362:163–168

Heck RF (1979) Palladium-catalyzed reactions of organic halides with olefins. Acc Chem Res 12:146–151

Nabid MR, Bide Y, Tabatabaei Rezaei SJ (2011) Pd nanoparticles immobilized on PAMAM-grafted MWCNTs hybrid materials as new recyclable catalyst for Mizoraki–Heck cross-coupling reactions. Appl Catal A Gen 406:124–132

Guo CS, Weng CM, Hong FE (2010) Preparation of cobalt-containing ligands with NHC- and/or P-coordinating sites and their application in heck reactions: the formation of an unexpected cobalt-containing zwitterionic complex. Eur J Inorg Chem 2010:3220–3228

Chen Q, Gao K, Peng C, Xie H, Zhao ZK, Bao M (2015) Preparation of lignin/glycerol-based bis(cyclic carbonate) for the synthesis of polyurethanes. Green Chem 17:4546–4551

Kim SW, Kim M, Lee WY, Hyeon T (2002) Fabrication of hollow palladium spheres and their successful application to the recyclable heterogeneous catalyst for Suzuki coupling reactions. J Am Chem Soc 124:7642–7643

Metin Ö, Mazumder V, Özkar S, Sun S (2010) Monodisperse nickel nanoparticles and their catalysis in hydrolytic dehydrogenation of ammonia borane. J Am Chem Soc 132:1468–1469

Hammann JM, Haas D, Knochel P (2015) Cobalt-catalyzed Negishi cross-coupling reactions of (hetero)arylzinc reagents with primary and secondary alkyl bromides and iodides. Angew Chem Int Ed 54:4478–4481

Qi H, Zhang W, Wang X, Li H, Chen J, Peng K, Shao M (2009) Heck reaction catalyzed by flower-like cobalt nanostructures. Catal Commun 10:1178–1183

Chang CP, Pradiuldi SV, Hong FE (2009) Synthesis of coumarin derivatives by palladium complex catalyzed intramolecular Heck reaction: preparation of a 1,2-cyclobutadiene-substituted CpCoCb diphosphine chelated palladium complex. Inorg Chem Commun 12:596–598

Affo W, Ohmiya H, Fujioka T, Ikeda Y, Nakamura T, Yorimitsu H, Oshima K, Imamura Y, Mizuta T, Miyoshi K (2006) Cobalt-catalyzed trimethylsilylmethylmagnesium-promoted radical alkenylation of alkyl halides: a complement to the Heck reaction. J Am Chem Soc 128:8068–8077

Pal A, Sevonkaev I, Bartling B, Rijssenbeek J, Goia DV (2014) Dipentaerythritol: a novel additive for the precipitation of dispersed Ni particles in polyols. RSC Adv 4:20909–20914

Di LX, Chen H, Liu SS, Ye LQ, Li YP (2015) Hydrothermal synthesis of superparamagnetic Fe3O4 nanoparticles with ionic liquids as stabilizer. Mater Res Bull 62:217–221

Lu W, Yao K, Wang J, Yuan J (2015) Ionic liquids-water interfacial preparation of triangular Ag nanoplates and their shape-dependent antibacterial activity. J Colloid Interface Sci 437:35–41

Darwich W, Gedig C, Srour H, Santini CC, Prechtl MHG (2013) Single step synthesis of metallic nanoparticles using dihydroxyl functionalized ionic liquids as reductive agent. RSC Adv 3:20324–20331

Pachón LD, Rothenberg G (2008) Transition-metal nanoparticles: synthesis, stability and the leaching issue. Appl Organomet Chem 22:288–299

Evano G, Blanchard N, Toumi M (2008) Copper-mediated coupling reactions and their applications in natural products and designed biomolecules synthesis. Chem Rev 108:3054–3131

Chen A, Zhao G, Chen J, Chen L, Yu Y (2013) Selective hydrogenation of phenol and derivatives over an ionic liquid-like copolymer stabilized palladium catalyst in aqueous media. RSC Adv 3:4171–4175

Lozinskaya EI, Shaplov AS, Kotseruba MV, Komarova LI, Lyssenko KA, Antipin MY, Golovanov DG, Vygodskii YS (2006) “One-pot” synthesis of aromatic poly (1, 3, 4-oxadiazole) s in novel solvents—ionic liquids. J Polym Sci, Part A: Polym Chem 44:380–394

McAtee JR, Martin SES, Cinderella AP, Reid WB, Johnson KA, Watson DA (2014) The first example of nickel-catalyzed silyl-Heck reactions: direct activation of silyl triflates without iodide additives. Tetrahedron 70:4250–4256

Wagner ML, Schmidt LD (1995) Model catalytic oxidation reactions: oxygen with H2, NH3, and N2H4 on Rh(111). J Phys Chem 99:805–815

Bridger K, Watts J, Chien CL (1988) The dependence of coercivities of ultrafine Fe particles on packing fraction and microstructure. J Appl Phys 63:3233–3235

Martın JI, Nogues J, Liu K, Vicent JL, Schuller IK (2003) Ordered magnetic nanostructures: fabrication and properties. J Magn Magn Mater 256:449–501

Kuroda CS, Maeda M, Nishibiraki H, Matsushita N, Handa H, Abe M (2005) Styrene-coated iron nanobeads for medical use. IEEE Trans Magn 41:4117–4119

Myers VS, Weir MG, Carino EV, Yancey DF, Pande S, Crooks RM (2011) Dendrimer-encapsulated nanoparticles: new synthetic and characterization methods and catalytic applications. Chem Sci 2:1632–1646

Peng X, Pan Q, Rempel GL (2008) Bimetallic dendrimer-encapsulated nanoparticles as catalysts: a review of the research advances. Chem Soc Rev 37:1619–1628

Andrés R, De Jesús E, Flores JC (2007) Catalysts based on palladium dendrimers. New J Chem 31:1161–1191

Crooks RM, Zhao M, Sun L, Chechik V, Yeung LK (2001) Dendrimer-encapsulated metal nanoparticles: synthesis, characterization, and applications to catalysis. Acc Chem Res 34:181–190

Fei Z, Geldbach TJ, Zhao D, Dyson PJ (2006) From dysfunction to bis-function: on the design and applications of functionalised ionic liquids. Chem Eur J 12:2122–2130

Zhao D, Fei Z, Geldbach TJ, Scopelliti R, Dyson PJ (2004) Nitrile-functionalized pyridinium ionic liquids: synthesis, characterization, and their application in carbon-carbon coupling reactions. J Am Chem Soc 126:15876–15882

Wan H, Li S, Konovalova TA, Zhou Y, Thrasher JS, Dixon DA, Street SC (2009) Experimental and theoretical studies of the photoreduction of metal ion - dendrimer complexes: observation of a delocalized organic radical. J Phys Chem C 113:5358–5367

Luo X, Imae T (2007) Photochemical synthesis of crown-shaped platinum nanoparticles using aggregates of G4-NH 2 PAMAM dendrimer as templates. J Mater Chem 17:567–571

Juttukonda V, Paddock RL, Raymond JE, Denomme D, Richardson AE, Slusher LE, Fahlman BD (2006) Facile synthesis of tin oxide nanoparticles stabilized by dendritic polymers. J Am Chem Soc 128:420–421

Shi X, Wang S, Meshinchi S, Van Antwerp ME, Bi X, Lee I, Baker JR Jr (2007) Dendrimer-entrapped gold nanoparticles as a platform for cancer-cell targeting and imaging. Small 3:1245–1252

Antonietti M, Wenz E, Bronstein L, Seregina M (1995) Synthesis and characterization of noble metal colloids in block copolymer micelles. Adv Mater 7:1000–1005

O’Brien JM, Hoveyda AH (2011) Metal-free catalytic C–Si bond formation in an aqueous medium. Enantioselective NHC-catalyzed silyl conjugate additions to cyclic and acyclic α, β-unsaturated carbonyls. J Am Chem Soc 133:7712–7715

Wan H, Li S, Konovalova TA, Zhou Y, Thrasher JS, Dixon DA, Street SC (2009) Experimental and theoretical studies of the photoreduction of metal ion - dendrimer complexes: observation of a delocalized organic radical. J Phys Chem C 113:5358–5367

Ahmed K, Tariq I, Siddiqui SU, Mudassir M (2016) Green synthesis of cobalt nanoparticles by using methanol extract of plant leaf as reducing agent. Pure Appl Biol 5:453

Caló V, Nacci A, Monopoli A, Detomaso A, Iliade P (2003) Pd nanoparticle catalyzed Heck arylation of 1, 1-disubstituted alkenes in ionic liquids. Study on factors affecting the regioselectivity of the coupling process. Organometallics 22:4193–4197

Beccaria L, Deagostino A, Prandi C, Zavattaro C, Venturello P (2006) Heck reaction on 1-alkoxy-1, 3-dienes in ionic liquids: a superior medium for the regioselective arylation of the conjugated dienic system. Synlett 18:2989–2992

Zhang Z, Wang Z (2006) Diatomite-supported Pd nanoparticles: an efficient catalyst for Heck and Suzuki reactions. J Org Chem 71:7485–7487

Dupont J, Scholten JD (2010) On the structural and surface properties of transition-metal nanoparticles in ionic liquids. Chem Soc Rev 39:1780–1804

Begouin JM, Gosmini C (2009) Cobalt-catalyzed cross-coupling between in situ prepared arylzinc halides and 2-chloropyrimidine or 2-chloropyrazine. J Org Chem 74(8):3221–3224

Pachon LD, Rothenberg G (2008) Transition-metal nanoparticles: synthesis, stability and the leaching issue. Appl Organometal Chem 22(6):288–299

Ott LS, Hornstein BJ, Finke RG (2006) A test of the transition-metal nanocluster formation and stabilization ability of the most common polymeric stabilizer, poly (vinylpyrrolidone), as well as four other polymeric protectants. Langmuir 22(22):9357–9367

Hornstein BJ, Finke RG (2003) Transition-metal nanocluster catalysts: scaled-up synthesis, characterization, storage conditions, stability, and catalytic activity before and after storage of polyoxoanion-and tetrabutylammonium-stabilized Ir (0) nanoclusters. Chem Mater 15(4):899–909

Prechtl MH, Scholten JD, Dupont J (2010) Carbon–carbon cross coupling reactions in ionic liquids catalysed by palladium metal nanoparticles. Molecules 15(5):3441–3461

Shan S, Wu J, Kang N, Cronk H, Zhao Y, Zhao W, Skeete Z, Joseph P, Trimm B, Luo J, Zhong CJ (2015) Nanoscale alloying in electrocatalysts. Catalysts 5(3):1465–1478

Ikeda Y, Nakamura T, Yorimitsu H, Oshima K (2002) Cobalt-catalyzed Heck-type reaction of alkyl halides with styrenes. J Am Chem Soc 124:6514–6515

Cahiez G, Moyeux A (2010) Cobalt-catalyzed cross-coupling reactions. Chem Rev 110(3):1435–1462

Kreyenschmidt F, Meurer SE, Koszinowski K (2019) Mechanisms of cobalt/phosphine-catalyzed cross-coupling reactions. Chem A Eur J 25(23):5912–5921

Qi H, Zhang W, Wang X, Li H, Chen J, Peng K, Shao M (2009) Heck reaction catalyzed by flower-like cobalt nanostructures. Catal Commun 10(8):1178–1183

Iyer S, Thakur VV (2000) The novel use of Ni Co, Cu and Mn heterogeneous catalysts for the Heck reaction. J Mol Catal A: Chem 157(1–2):275–278

Zhou P, Li Y, Sun P, Zhou J, Bao J (2007) A novel Heck reaction catalyzed by Co hollow nanospheres in ligand-free condition. Chem Commun 14:1418–1420

Zhu Z, Ma J, Xu L, Xu L, Li H, Li H (2012) Facile synthesis of Co–B amorphous alloy in uniform spherical nanoparticles with enhanced catalytic properties. ACS Catal 2(10):2119–2125

Hajipour AR, Khorsandi Z (2016) Multi walled carbon nanotubes supported N-heterocyclic carbene–cobalt (ΙΙ) as a novel, efficient and inexpensive catalyst for the Mizoroki–Heck reaction. Catal Commun 77:1–4

Hajipour AR, Khorsandi Z, Karimi H (2015) Cobalt nanoparticles supported on ionic liquid-functionalized multiwall carbon nanotubes as an efficient and recyclable catalyst for Heck reaction. Appl Organometal Chem 29(12):805–808

Wakabayashi K, Yorimitsu H, Oshima K (2001) Cobalt-catalyzed tandem radical cyclization and cross-coupling reaction: its application to benzyl-substituted heterocycles. J Am Chem Soc 123:5374–5375

Acknowledgements

We would like to express our deepest appreciation to the Ministry of Science and Technology, Government of the Peoples’ Republic of Bangladesh (Grant No.: 39.00.0000.012.02.009.17-474/23.2018-2019) for providing the financial assistance to perform the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Islam, M.S., Mia, M.A.S. Synthesis of dendrimer assisted cobalt nanoparticles and catalytic application in Heck coupling reactions in ionic liquid. SN Appl. Sci. 2, 679 (2020). https://doi.org/10.1007/s42452-020-2448-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-2448-2