Abstract

This paper presents a study on the structural, morphological and elastic properties of erbium oxide nanoparticles doped bio-silicate borotellurite glass system fabricated using the technique of melt-quenching with chemical compositional formula {[(TeO2)0.7 (B2O3)0.3]0.8 (SiO2)0.2}1−y (Er2O3 NPs)y where 0.01 ≤ y ≤ 0.05. The objective of the work was to study the some elastic and thermal parameters associated with non-destructive ultrasonic technique, with the aim of utilizing the glasses for erbium doped fiber amplifier application. Various measurements and Characterizations techniques which includes density and molar volume measurements, energy dispersive X-ray fluorescence, X-ray diffraction (XRD), Fourier transform infrared (FTIR), Transmission electron microscopy and Pulse-echo technique were carried out in this study. The density values for the glasses increased from 4.1900 to 4.6003 gcm−3 with the addition of 1–5% of Er2O3 NPs in the glass structure. The increase can be ascribed to increase in the overall molar weight of the glass due to incorporation of heavy Er3+ ions. The XRD patterns revealed no presence of sharp peaks with the observed broad hump around 2θ = 20–30° indicating the glassy and amorphous nature of the studied glasses. The FTIR spectra showed absorption with peaks around 1362–1385 cm−1, 1221–1250 cm−1, 655–689 cm−1 and 602–630 cm−1 wave number ranges, indicating the presences of H3BO3, SiO4, BO3, TeO3 and TeO4 structural units in the glass system. The microstructural nature observed in the glass morphology showed nanoparticle agglomerations in the glasses. The ultrasonic velocities, elastic moduli, microhardness, Poisson ratio, softening and Debye’s temperatures, thermal expansion coefficient as well as other important parameters were calculated from the density and ultrasonic data. The values of the ultrasonic velocities, elastic moduli, Debye’s temperature, softening temperature, thermal expansion coefficient and the acoustic impedance increased with increase in the Er2O3 NPs concentration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the last few decades, the need for an increased rice husk commercialization is ever increasing with continued increase in the global rice production above 645 million tonnes annually [1]. The commercialization of the rice milling waste beyond the present 30% becomes necessary so as to solve the environmental pollution problems caused by their continued disposal and also help in solving some the mankind’s problems [1, 2]. One of the areas considered these days for the rice husk is in glass and ceramics fabrications for optical fibre, optoelectronics and other glass and ceramics technological applications [3,4,5]. Many different researchers have worked on the silicate extraction (from the rice husk) for fabrication different glass compositions for various technological and industrial applications [6, 7].

Glass science and technology research in the present days has been giving great attention to the fabrications and utilizations TeO2-based glasses [8]. Tellurium oxide based glasses have demonstrated more advantages over other silicate and phosphate glasses due to their low melting point, high rare RE ions solubility, high effect of stark splitting, high refractive index and high optical transparency in wide spectral region [9,10,11]. Tellurium oxide alone does not form glass on its own, but rather require combination with other glass formers or modifiers. TeO2–B2O3 combination was found to be one of the most favourable combinations for the glass utilization in the area of optical fibre amplifiers, optoelectronics and laser applications [5, 9]. Borotellurite glasses presents a compromising quality against the individual disadvantages of B2O3 and TeO2 by having high chemical durability, high refractive index, high thermal stability, low melting point, and high refractive index [12].

Among the number of rare earth (RE) ions used in the areas of optical fibres, optoelectronic and lasers, Er3+ ions are found to be more suitable for optical signal amplifiers and sometimes laser applications and white-light emitting devices [13]. Since Er3+ ions in glasses possesses two useful emission bands around 1500 nm and 2700 nm, the former is utilized in the EDFA and the 2700 nm band is utilized in medicine and optical sources for sensors [14]. The area of optical transmission in the communication system requires gain bandwidth widening of the optical amplifiers that is utilized in the wavelength division multiplexing (WDM) systems [15].

Non-destructive ultrasonic technique have been used various researchers in the study of elastic properties of non-crystalline and crystalline materials alike [16]. The ultrasonic velocities were used together with density and their molecular/structural data for the calculation of the elastic moduli, microhardness, acoustic impedance, softening temperature, Debye temperature, fractal bond connectivity and the Poisson ratio [16, 17]. In another study, the elastic properties of erbium oxide doped TeO2–ZnO–P2O5–LiNbO3 was reported. The elastic moduli investigated was found to have increased with Er3+ ions concentration increased [18].

In this study a choice was made for SiO2–TeO2–B2O3 composition for erbium oxide nanoparticles’ hosting with the aim of increasing the rice husk commercialization (through SiO2 extraction) in the area of lasers and EDFA applications. The choice of TeO2 was to improve the refractive index and the optical transparency in the IR region. B2O3 was selected to compromise the high phonon energy of the TeO2, lower the glass forming temperature, improve the RE solubility and hardness [19]. SiO2 composition aimed at improving both the thermal and chemical stability as well as the mechanical strength of the glasses [2].

Non-destructive ultrasonic technique was employed in this work for the collection of ultrasonic velocity data. The elastic moduli, Poisson ratio, micro-hardness, Debye temperature, softening temperature, acoustic impedance, thermal expansion coefficient and fractal bond connectivity as well as the morphological and structural properties were studied. The ultrasonic studies provides information on glass structure as well as some thermal and mechanical features of studied glasses [16, 20]. For better utilization of glass material in the EDFA and laser applications, studying the elastic properties of such material is very important especially as some glasses’ elastic properties might not always favour fibre drawing.

1.1 Experiments

From rice milling factory in Malaysia, rice husk (rice milling waste) was obtained. Using the simple cold acid (HCl) leaching technique, 98.548% of SiO2 was extracted. The extracted SiO2 was used with Er2O3 NPs (Alfar Aeser, 99.9%), B2O3 (Alfar Aeser, 99.9%) and TeO2 (Alfar Aeser, 99.9%) for the fabrication of {[(TeO2)0.7 (B2O3)0.3]0.8 (SiO2)0.2}1−y (Er2O3 NPs)y using melt-quenching technique.

For the glass fabrication, powdered chemicals were weighed using electronic weighing balance in accordance with the compositional chemical equation. The weighed chemicals were made homogeneous by stirring for ½ hour in an alumina crucible. The crucible containing the homogeneous mixture is then put into a 400 °C electric furnace for 1 h preheating before transferring to another furnace at around 900 °C for another 2 h for mixture melting. The pre-heating was necessary to enable the evaporation of any possible moisture in the mixture as B2O3 is highly hygroscopic in nature [10]. The molten material was turned into a cylindrical molt and transferred to the 400 °C furnace for 1 h annealing to remove thermal stress and bubbles before being allowed to cool down to room temperature [9]. The cylindrical glasses were finally cut to about 4–5 mm thickness for non-destructive ultrasonic probing and the remaining portion grinded for XRD, TEM and FTIR analyses.

The XRF analysis of the extracted SiO2 was performed using the Energy Dispersive X-ray Spectrometer (Shimadzu model EDX-720) to determine its purity. The density was measured using MD-300S, Alfa Mirage electronic densimeter and using the Archimedes principle. Using Archimedes principle, the glass density (ρ) and molar volume (Vm) were calculated as follows;

where water density was taken to be 1 g/cm3, Mw = molecular weight of glass, Wair = weight of sample in air, and Wwater = sample weight in water [9].

Other characterization performed includes the X-ray diffraction (XRD) using the XRD system {PANalytical (Philips) PW3050/60}, Fourier transform infrared (FTIR) using Perkin Elmer 1650 spectrometer and Transmission Electron Microscopy (TEM) using JOEL transmission electron microscope that operates at 200 kV. Using Ritec Ram-5000 Snap System, ultrasonic pulse-echo technique was performed to determine the ultrasonic (longitudinal and shear) velocities in the samples.

1.2 Results and discussions

Table 1 presents the XRF analysis result of the SiO2 extracted from rice husk using cold HCl leaching method. Unlike the hot leaching technique presented by Mustapha et al. [21] which requires heating, the present SiO2 extraction require no heating during leaching and is cost effective as well. About 98.548% pure SiO2 was achieved as shown in Table 1.

The XRD patterns for the studied glasses are presented in Fig. 1. XRD result study is used for identification of amorphous nature and crystalline phase presences in samples [22]. The patterns in Fig. 1 showed the spectra recorded between 20° ≤ 2θ ≤ 80° observed at lower scattering angles is a broad diffusion indicating the presence of long range structural disorder in the glasses [23]. The presence of a broad hump around 2θ = 27° indicates the glassy/amorphous nature of the studied glasses. As observed in the Figure, as the Er2O3 NPs are increased in concentration, the broad hump continue to narrow, suggesting the tendency of crystallization with continued increase in the Er2O3 NPs concentration [24].

The density and molar volume variation with Er2O3 NPs concentration is presented in Fig. 2. The density value increased from 4.1900 to 4.6004 gcm−3 as the concentration of Er2O3 NPs increased from 0.01 to 0.05 Molar. The high density value observed might be due to the high material compactness resulting from to the presence of nanoparticle of Er2O3. The increase in the density value with dopant increase might be associated to decrease in the non-bridging oxygen number which can be confirmed by the TeO4/TeO3 concentration variations in Fig. 4. The increase in the density might also be due to increased substitution of lighter B3+, Si4+,and Te4+ ions with comparatively much heavier ions of Er3+, resulting in the overall glass molecular weight increase [19]. The molar volume increased from 28.8196 to 29.0061 cm3 and then decreased down to 28.6456 cm3 as the dopant’s concentration raised from 0.01 to 0.03 and down to 0.05 M respectively. The initial value increase can be attributed to a decrease in atomic compactness in the glasses network due to breakage one of the double bonds of oxygen atoms in the network (decreased connectivity) resulting from the formation of TeO3 structural units [9]. The decrease in the glasses’ molar volume with addition of more dopant can be due the increase in the concentration TeO4 units suggesting more cross-linkage between the oxygen atoms and the cations in the glass network [17].

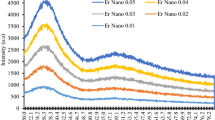

The FTIR spectra for the studied Er2O3 NPs doped silica borotellurite glasses are presented in Fig. 3. Various IR peak positions observed and recorded include the absorption peaks around wave number range of 602–630 cm−1, 655–689 cm−1, 950–1150 cm−1, 1221–1250 cm−1 and 1362–1385 cm−1. The assignment of each absorption peak is presented in Table 2.

Table 3 and Fig. 4 present the variation of the trigonal pyramidal (TeO3) and trigonal bipyramidal (TeO4) structural units against the Er2O3 NPs molar concentration. Increase in the TeO4 concentration is associated with increase in oxygen atoms bonding in the glass network while the TeO3 concentration increase relates to the increase in the oxygen atoms bond breakage. BO3 concentration presented in Table 2 is from the area under the curve around 1221 cm−1 and 12,250 cm−1 [26]. While the increase in the Bʘ3 concentration represents the area under the curve around 1362–1385 cm−1 [27]. Thus, with TeO4 concentration increase we have more bridging oxygen atoms created and TeO3 creates more non-bridging oxygen atoms in the glass network [28].

The TEM microstructure of the studies Er2O3 NPs doped rice husk silicate borotellurite glass system is presented in Fig. 5. Er2O3 NPs of various sizes can be observed in the diagram with lager particles of micro-sizes. The larger particles might have formed from the fusion of small nanoparticles through Oswald ripening effect in the glass network, which happened after the formation of glass [28].

The values of the ultrasonic velocities of the system of Erbium NPs doped RHSBT glasses were presented in Table 4. The ultrasonic wave velocities were calculated as;

where v is the longitudinal (VL) or shear (Vs) velocity, t is time of travel of the ultrasonic wave to and fro inside the glass sample and x is the sample thickness and \(v_{m}\) is the mean ultrasonic velocity [29]. The longitudinal, shear and the mean ultrasonic velocities for the studied glasses increased from 3722.15 to 4087.26 m/s, 2214.38 to 2345.19 m/s and 2994.21 to 3190.21 m/s respectively as Er2O3 NPs concentration was increased 1–5% molar composition. The velocities are directly related to the material density and hence increase in material density may cause an increase in the values of the ultrasonic velocities [30]. The increase in the values may also be associated with the increased compactness in the glass network which resulted from increase in the number of bridging oxygen (BO) in the network [31].

Table 4 and Fig. 6 present the elastic moduli of the Erbium NPs doped RHSBT glasses. The elastic [Longitudinal (L), Shear (G), Young (E) and Bulk (K)] moduli were calculated using the data of density (ρ), longitudinal (VL) and Shear (Vs) velocities as reported by [17] as;

The longitudinal, shear, young and bulk moduli increased from 58.050 to 76.853 GPa, 20.546 to 25.302 GPa, 31.801 to 37.720 GPa and 30.656 to 43.117 GPa respectively. The increase in the elastic moduli has a connection to the fact that the material connectivity in the glass system increased with the increase in Er2O3 NPs content. This is due to the formation of more TeO4 units in the glass network which suggests a decrease in the formation of NBO and hence more rigid network formation [32, 33]. The elastic moduli increase might also result from the increase in the overall stretching force constant of the glasses. This might be attributed to the modifier role of the Er3+ ions in the glass network. The Er3+ ions increase can cause an increase in the coulomb contribution to the lattice energy in the glass system [34].

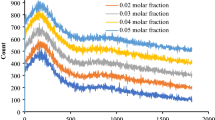

The micro-hardness and fractal bond connectivity values for different Nano Er2O3 concentrations in the Nano Erbium Doped RHSBT Glass System are presented in Fig. 7 and Table 5. The micro-hardness (H), Poisson (σ) and the fractal bond connectivity (d) were calculated as follows;

The variation in the micro-hardness as can be observed shows direct proportionality with the fractal bond connectivity in Fig. 7 and inverse proportionality with the Poisson ration in Fig. 8. By definition, micro-hardness refers to material’s resistance to penetration or indentation [29]. The increase observed in the micro-hardness value is an indication of an increased rigidity and network connectivity in the glasses and the decrease indicates the opposite [17]. The fractal bond connectivity value changed from 2.6808 to 2.7880 and then to 2.3472 as the Nano Er2O3 concentrations increased from 1 to 5% in the glass network. This is an indication of the structural change from tetrahedral structure (3D) to a 2D layer or structure [29].

The Poisson’s ratio of a material gives a measure of the resistance of the material to volume change as well as to shape change. It can also be defined as the negative of the ratio of contraction of transverse strain to extension of longitudinal strain in the applied force direction [35, 36]. Poisson’s ratio is small for shear resistant but compressible materials such as cellular solids and can reach 0.5 for incompressible bodies such as rubber. Glasses fall in between these two and have values from 0.1 to 0.4 and specifically for oxide glasses mainly in the 0.16–0.3 with highly polymerized silica rich glass having the lowest value of theoretical volume occupied (V) and the highest for glass networks consisting of chains and cluster units [37].

The Poisson ratio relation with the concentration of Er2O3 NPs in an erbium NPs doped RHBT glass system is presented in Fig. 8. The relation showed a decrease in the value from 0.22609 to 0.217202 as the Er2O3 NPs molar concentration increased from 1 to 2%. The value then increased to 0.257384 when the Er2O3 NPs molar concentration was increased to 4% which the decreased to 0.25459 when the Er2O3 NPs molar concentration reached 5%. The decrease in the Poisson’s ratio value with increase in Er2O3 NPs molar concentration may be due to an increase in the glass ionicity which is caused by more polar bonding presence in the modifiers [34]. The increase in the Poisson ratio may be associated to increase in the crosslink density in the glass network [38].

The Debye and softening temperatures’ variation with concentration of Er2O3 NPs are presented in Fig. 9 and Table 5. The softening temperature (\(T_{s}\)) and the Debye temperature (\(\theta_{D}\)) were calculated using the following standard relations as follows;

where Mw is the glass molecular weight, vm is the mean ultrasonic velocity, h is the Plank’s constant, P is the number of atoms in the chemical formula, k is the Boltzmann constant, c = 1.35 × 109 cm5 K−1s is constant, Na is the Avogadro’s number, ρ is the density of the given sample and \(V_{s}\) is the ultrasonic shear velocity inside the glass [17, 18].

As the concentration of Er2O3 NPs increased from 1 to 5% in the glass system, the values of the softening temperature and Debye temperature increased from 1046.78 to 1162.97 K and 536.984 to 576.050 K respectively. Debye temperature provides the description properties related to atomic vibrations in a solid material; it represents the excitation temperature of high frequency lattice in any material understudy. In glassy materials, network vibrational spectrum are considered as a diffuse version of the lattice spectrum of the equivalent crystal nearest to it [39]. The increase in the value of the Debye temperature recorded can be ascribed to stronger packing and increase connectivity in the glass system arising from more bonding of single bonded oxygen atoms as well as increased lattice vibrations in the glass network [40]. Whereas the softening temperature represents the temperature at which viscous flow translates to plastic flow in a material. The increase in Ts value with Er2O3 NPs composition increase might be associated with increase in the rigidity and connectivity because of increased connectivity. The increased connectivity might as well be attributed to the observed TeO4 concentration increase and TeO3 concentration decrease in the glass structure, which signifies more bonding of oxygen atoms in the glasses [17].

The variation of thermal expansion coefficient (αp) and acoustic impedance (Z) with Er2O3 NPs concentration is presented in Fig. 10 and Table 6. The acoustic impedance and the thermal expansion coefficient were determined from the longitudinal ultrasonic data using the following expressions as reported by Marzouk and Gafaar [31] as follows;

In glasses, the thermal expansion coefficient value and its transition temperature are interdependent. The value is also dependent on other parameters which includes the composition and nature of glass modifier, temperature region as well as thermal history of the glasses [41].The increase in the linear thermal expansion coefficient represents a decrease in the thermal stability of the glasses with increase in Er2O3 NPs composition [42]. Acoustic impedance is a parameter responsible for both reflection and transmission of sound energy inside a material [31]. Increase in the value recorded for the studied glass system can be ascribed to atomic compactness and glass network rigidity [43].

The variation of the fugacity value with Er2O3 NPs molar concentration is presented in Fig. 11. This is the proportion of free volume at the temperature of glass transition. The variation in the fugacity as shown in the figure indicates increase and then a decrease in the value. This is because of an interstitial space increase in the beginning with increase in the Er2O3 NPs molar concentration resulting from the formation of more NBOs. The decrease in the value afterwards indicates an increase in material compactness as the Er2O3 NPs molar concentration is increase. The decrease in the fugacity may as well be considered to be due to an increase in the concentration of bridging oxygen (BO) in the glass network [44]. This parameter also related to the Poisson ratio and is a factor of material permeability in the glass network [45].

The calculations of the latent heat of melting (ΔHm) and the diffusion constant (Di) were carried out using the expressions as reported by Chinnamat et al. [29], as presented in Eqs. (16) and (17) as follows;

The Variation of diffusion constant and latent heat of melting with concentration of Er2O3 NPs in the studied glass system is presented in Fig. 12. The diffusion constant value for the studied glasses increased from 3.3412 × 10−9 to 3.9482 × 10−9 m−2 s−1 when the concentration of Er2O3 NPs was increased from 1 to 5 mol%. The increase in the value might be connected to increase in the ionic bond length resulting from the substitution of other oxides with shorter bond length with longer bonds of Er2O3 NPs, making the overall bond length of the glasses longer [29]. The increase might also be connected to increase in the number of vibrating atoms in the glass network [31]. The latent heat of melting increased in value from 33.397 to 42.7104 kJ as the Er2O3 NPs composition increased from 1 to 5 mol%. Increase in the value together with increase in the diffusion constant confirmed the increase in the Debye’s and softening temperatures [31, 46].

2 Conclusion

Using the agricultural waste (rice husk), silica was extracted with 98.584% purity and was used in the fabrication of a system of erbium doped silica borotellurite glasses with chemical composition {[(TeO2)0.7 (B2O3)0.3]0.8 (SiO2)0.2}1−y (Er2O3 NPs)y using the method of melt-quenching. The aim was to improve the rice husk commercialization from its current 30% in the area of Erbium doped fiber amplifier technology. The glasses were subjected to various measurements and characterizations which include density and molar volume, EDX, XRD, TEM, FTIR and the pulse-echo non-destructive ultrasonic technique for the study of the glasses’ structural and elastic properties. The measured density values increased from 4.1900 to 4.6004 gcm−3 and the XRD patterns revealed the amorphous nature of the glasses. FTIR spectral study showed the presence of TeO4, TeO3, SiO4, H2BO3, and two different structural units of BO3, with the TEM revealing the presence of Er2O3 NPs and larger particles of agglomerated NPs of Er2O3 were formed through Oswald ripening effect. The ultrasonic velocities as well as elastic moduli increased with increased Er2O3 NPs concentration. The microhardness, softening temperature, Debye temperature, thermal expansion coefficient, acoustic impedance, diffusion constant, fractal bond connectivity, fugacity as well as the latent heat of melting were determined for the studied glasses. Based on the studied parameters, the glasses proved to be strong enough to stand fiber drawing and thermal stress.

References

Prasad R, Pandey M (2012) Rice husk ash as a renewable source for the production of value added silica gel and its application: an overview. Bull Chem React Eng Catal 7(1):1–25. https://doi.org/10.9767/bcrec.7.1.1216.1-25

Umar SA, Halimah MK, Hamza AM, Abdulbaset AA (2018) The structural, physical and optical properties of borotellurite glasses incorporated with silica from rice husk. J Sci Math Lett 6:32–46

Kaewkhao J, Limsuwan P (2012) Utilization of rice husk fly ash in the color glass production. Proc Eng 32(32):670–675. https://doi.org/10.1016/j.proeng.2012.01.1325

Lee CS, Matori KA, Ab Aziz SH, Kamari HM, Ismail I, Zaid MHM (2017) Fabrication and characterization of glass and glass-ceramic from rice husk ash as a potent material for opto-electronic applications. J Mater Sci Mater Electron 28(23):17611–17621. https://doi.org/10.1007/s10854-017-7699-3

Umar SAA, Halimah MKK, Chan KTT, Latif AAA (2017) Physical, structural and optical properties of erbium doped rice husk silicate borotellurite (Er-doped RHSBT) glasses. J Non Cryst Solids 472:31–38. https://doi.org/10.1016/j.jnoncrysol.2017.07.013

Hamza AM, Halimah MK, Muhammad FD, Chan KT (2019) Physical properties, ligand field and Judd-Ofelt intensity parameters of bio- silicate borotellurite glass system doped with erbium oxide. J Lumin 207:497–506. https://doi.org/10.1016/j.jlumin.2018.11.038

Mohanta K, Kumar D, Parkash O (2012) Properties and industrial applications of rice husk: a review. Int J Emerg Technol Adv Eng 2(10):86–90

Halimah MK et al (2019) Effect of erbium nanoparticles on structural and spectroscopic properties of bio-silica borotellurite glasses containing silver oxide. Mater Chem Phys 236:121795. https://doi.org/10.1016/j.matchemphys.2019.121795

Alazoumi SH et al (2018) Optical properties of zinc lead tellurite glasses. Resul Phys 9:1371–1376. https://doi.org/10.1016/j.rinp.2018.04.041

Azlan MN, Halimah MK, Umar SA, Azlina Y, El-Mallawany R, Najmi G (2018) Linear and nonlinear optical efficiency of novel neodymium nanoparticles doped tellurite glass for advanced laser glass. Educ JSMT 5(2):47–66

Annapoorani K, Maheshvaran K, Arunkumar S, Suriya Murthy N, Marimuthu K (2015) Structural and luminescence behavior of Er3+ ions doped Barium tellurofluoroborate glasses. Spectrochim Acta Part A Mol Biomol Spectrosc 135:1090–1098. https://doi.org/10.1016/j.saa.2014.08.003

Lakshminarayana G et al (2017) Physical, structural, thermal, and optical spectroscopy studies of TeO2–B2O3–MoO3–ZnO–R2O (R = Li, Na, and K)/MO (M = Mg, Ca, and Pb) glasses. J Alloys Compd 690:799–816. https://doi.org/10.1016/j.jallcom.2016.08.180

Kaur A, Khanna A, Aleksandrov LI (2017) Structural, thermal, optical and photo-luminescent properties of barium tellurite glasses doped with rare-earth ions. J Non Cryst Solids 476:67–74. https://doi.org/10.1016/j.jnoncrysol.2017.09.025

Kassab LRP, Courrol LC, Seragioli R, Wetter NU, Tatumi SH, Gomes L (2004) Er3+ laser transition in PbO–PbF2–B2O3 glasses. J Non Cryst Solids 348:94–97. https://doi.org/10.1016/j.jnoncrysol.2004.08.132

Basavapoornima C et al (2017) Spectroscopic and pump power dependent upconversion studies of Er3+-doped lead phosphate glasses for photonic applications. J Alloys Compd 699:959–968. https://doi.org/10.1016/j.jallcom.2016.12.199

Mostafa AG et al (2015) Studying the elastic properties of glasses based on Ckd using ultrasonic technique. Dig J Nanomater Biostruct 10(3):935–940

Abdulbaset AAA et al (2017) Effect of neodymium nanoparticles on elastic properties of zinc tellurite glass system. Adv Mater Sci Eng 2017:1–7

Yousef ES (2013) Er3+ ions doped tellurite glasses with high thermal stability, elasticity, absorption intensity, emission cross section and their optical application. J Alloy Compd J 561:234–240. https://doi.org/10.1016/j.jallcom.2013.01.199

Umar SA, Halimah MK, Chan KT, Latif AA (2017) Polarizability, optical basicity and electric susceptibility of Er3+ doped silicate borotellurite glasses. J Non Cryst Solids 471:101–109. https://doi.org/10.1016/j.jnoncrysol.2017.05.018

Saddeek YB (2004) Ultrasonic study and physical properties of some borate glasses. Mater Chem Phys 83:222–228. https://doi.org/10.1016/j.matchemphys.2003.09.051

Mustafa IS, Ain N, Razali N, Ibrahim AR, Yahaya Z, Kamari HM (2015) From rice husk to transparent radiation protection material. J Intelekt 9(2):1–6

Ahmad AF, Zulkifly A, Abdul Halim S, Suzan JO, Umar SA (2018) Synthesis, thermal, dielectric, and microwave reflection loss properties of nickel oxide filler with natural fiber-reinforced polymer composite. J Appl Polym Sci 135:1–10. https://doi.org/10.1002/app.46998

Raju CN, Babu R, Babu AM (2019) Investigation on physical, structural and optical properties of Er3+—doped bismuth borate glasses for optical fiber amplifier applications. J Emerg Technol Innov Res 6:1. https://doi.org/10.1729/journal.19547

Azlan MN, Halimah MK, Suriani AB, Azlina Y, Umar SA, El-mallawany R (2019) Upconversion properties of erbium nanoparticles doped tellurite glasses for high efficient laser glass. Opt Commun 448:82–88. https://doi.org/10.1016/j.optcom.2019.05.022

Rodriguez O et al (2016) Characterization of silica-based and borate-based, titanium-containing bioactive glasses for coating metallic implants. J Non Cryst Solids 433:95–102. https://doi.org/10.1016/j.jnoncrysol.2015.09.026

Ali AA, Rammah YS, Shaaban MH (2019) The influence of TiO2 on structural, physical and optical properties of B2O3–TeO2–Na2O–CaO glasses. J Non Cryst Solids 514:52–59. https://doi.org/10.1016/j.jnoncrysol.2019.03.030

Rammah YS, Ali AA, Abdelghany AM (2018) Optical properties of bismuth borotellurite glasses doped with NdCl3. J Mol Struct. https://doi.org/10.1016/j.molstruc.2018.07.071

Azlan MN, Halimah MK, Hajer SS, Suraini AB, Azlina Y, Umar SA (2019) Enhanced optical performance of tellurite glass doped with samarium nanoparticles for fiber optics application. Chalcogenide Lett 5:215–229

Chinnamat W, Laopaiboon R, Laopaiboon J, Pencharee S, Bootjomchai C (2017) Influence of ionic radius modifying oxides on the elastic properties of glasses using ultrasonic techniques and FTIR spectroscopy. Phys Chem Glass Eur J Glass Sci Technol Part B 58(5):207–216. https://doi.org/10.13036/17533562.58.5.101

Gouraud F, Chotard T, Karray R (2015) Structural, mechanical and optical investigations in the TeO2-rich part of the TeO2–GeO2–ZnO ternary glass system. Solid State Sci 40:20–30. https://doi.org/10.1016/j.solidstatesciences.2014.12.009

Marzouk SY, Gaafar MS (2007) Ultrasonic study on some borosilicate glasses doped with different transition metal oxides. Solid State Commun 144:478–483. https://doi.org/10.1016/j.ssc.2007.09.017

Halimah MKK et al (2019) Study of rice husk silicate effects on the elastic, physical and structural properties of borotellurite glasses. Mater Chem Phys 238:121891. https://doi.org/10.1016/j.matchemphys.2019.121891

Sidek HAA, Rosmawati S, Talib ZA, Halimah MK, Halim SA (2013) Effect of zinc on the elastic behaviour of (TeO2) 90 (AlF3) 10-x (ZnO) x glass system. Int J Basic Appl Sci 90(09):41–44

Poor HB, Aziz HA, Zamiri R (2013) Ultrasonic and optical properties and emission of Er3+/Yb3+ doped lead bismuth-germanate glass affected by Bi+/Bi2+ ions. J Lumin 143:526–533. https://doi.org/10.1016/j.jlumin.2013.05.053

Greaves GN, Greer AL, Lakes RS, Rouxel T (2011) Poisson’s ratio and modern materials. Nat Mater 10(11):823–837. https://doi.org/10.1038/nmat3134

Properties E (2007) Elastic properties and short-to medium-range order in glasses. J Am Ceram Soc 90(10):3019–3039. https://doi.org/10.1111/j.1551-2916.2007.01945.x

Rouxel T, Ji H, Hammouda T, Moréac A (2008) Poisson’s ratio and the densification of glass under high pressure. Phys Rev Lett 100(22):1–4. https://doi.org/10.1103/PhysRevLett.100.225501

Hasnimulyati L, Halimah MK, Zakaria A, Halim SA, Ishak M (2017) A comparative study of the experimental and the theoretical elastic data of Tm3+ doped zinc borotellurite glass. Mater Chem Phys 192:228–234. https://doi.org/10.1016/j.matchemphys.2017.01.086

Saddeek YB, Elsayed NZ (2015) Structural and mechanical features of some lanthanum tellurite glasses. Can J Phys 93(4):460–465. https://doi.org/10.1139/cjp-2014-0044

Saddeek YB, El Latif LA (2004) Effect of TeO2 on the elastic moduli of sodium borate glasses. Phys B Condens Matter 348(1–4):475–484. https://doi.org/10.1016/j.physb.2004.02.001

El-mallawany R (1999) Tellurite glasses Part 2. Anelastic, phase separation, Debye temperature and thermal properties. Mater Chem Phys 60:103–131

Zaid MHM, Matori KA, Abdul Aziz SH, Zakaria A, Ghazali MSM (2012) Effect of ZnO on the physical properties and optical band gap of soda lime silicate glass. Int J Mol Sci 13(6):7550–7558. https://doi.org/10.3390/ijms13067550

Rajesh S, Saravanan S, Palani R (2015) Structural and elastic properties of Li+ and W6+ metal ions doped with sodium borate glass using pulser—receiver technique. Int J Sci Res 2015:298–301

Saddeek YB (2005) Elastic properties of Gd 3 + -doped tellurovanadate glasses using pulse-echo technique. Mater Chem Phys 91:146–153. https://doi.org/10.1016/j.matchemphys.2004.11.005

Shelby JE (2005) Introduction to glass science and technology, 2nd edn. New York State College of Ceramics at Alfred University School of Engineering, Royal Society of Chemistry, Alfred, NY, USA

Laopaiboon R, Laopaiboon J, Pencharee S, Nontachat S, Bootjomchai C (2016) The effects of gamma irradiation on the elastic properties of soda lime glass doped with cerium oxide. J Alloys Compd 666:292–300. https://doi.org/10.1016/j.jallcom.2016.01.098

Acknowledgement

The authors appreciate the financial support for the work from the Minister of Higher Education of Malaysia and University Putra Malaysia through grant Putra Berimpak 9597200.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors wish to state that there is no conflict of interest whatsoever in this work and all authors who contributed to the development of this article have been listed and financial contributors duly acknowledged.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Umar, S.A., Halimah, M.K., Azlan, M.N. et al. Structural, elastic and thermo-physical properties of Er2O3 nanoparticles doped bio-silicate borotellurite glasses. SN Appl. Sci. 2, 291 (2020). https://doi.org/10.1007/s42452-020-2112-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-2112-x