Abstract

Present article reports on reduced graphene oxide (rGO) modified poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT: PSS) based transparent conducting electrodes for flexible optoelectronic applications. PEDOT: PSS samples embedded with different rGO concentrations i.e. 0, 1, 2, 3, 4, 5 wt% were prepared and later on, bar coated on polyethylene terephthalate substrate using a 30 μm wire size bar. Various parameters including sheet resistance, bending test (outside and inside bending), optical transmittance etc. were estimated. Our analysis indicates that the samples with 1 wt% rGO possess improved results i.e. low sheet resistance (315 ± 8 Ω/sq.) and high transmittance (~ 74%). Additionally, the sample shows low electrical resistance variation up to 12% (maximum increase) during outward bending and 9% (maximum decrease) during inward bending of the sample for bending curvature from 20 to 100 m−1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Transparent conducting electrode (TCE) is an essential part of various optoelectronic devices such as light-emitting diodes, photovoltaic cells, touch screens, solar cells, and flat-panel displays [1,2,3]. Among various TCEs, Indium tin oxide (ITO) is most preferred as it wealth with attracting characteristics like high transmittance (~ 90%) and low sheet resistance (~ 10 Ω/sq.) [4]. Still, the quest to develop improved materials for flexible TCE applications is on, as ITO possesses practical limitations of its brittle nature. Additionally, limited indium resources restrict the prolonged run use for future flexible optoelectronics devices. Hence, there is a requirement of alternate material for ITO as TCE. Several TCE materials like transparent conducting polymers (TCPs), metal nanowires, carbon nanotubes, and graphene have been explored for replacing ITO [4, 5]. Among these materials, both graphene and TCPs play a vital role due to their lightweight, low sheet resistance, high transparency, and flexibility [6,7,8]. Chemical vapor deposition (CVD) is the most preferred technique to deposit graphene. However, the CVD technique requires high temperatures (~ 1000 °C) operation under a high vacuum, making it infeasible to deposit graphene directly on flexible (polymer) substrates [9]. Some of the transfer processes have been explored to deposit graphene on polymer substrates using CVD [10], however challenges remain persists in discovering suitable mechanisms for graphene films transfer on flexible substrates without developing cracks during the transfer process, obtaining large-area graphene film with a clean surface and achieving a low-cost transfer process. To undertake CVD technique issues, several solutions have been proposed for the graphene deposition [11, 12]. Nevertheless, yet no process has been precise enough to deposit graphene on a flexible substrate. Among TCPs, Polyaniline (PANI), Polypyrrole (PPy), and PEDOT: PSS are well-known polymers [13,14,15,16], but PEDOT: PSS is most preferred materials because of its low sheet resistance and high transmittance [14, 16]. The conductivity of PEDOT: PSS can be enhanced by chemical treatment with some solvent including sulfuric acid, formic acid, Polyethylene Glycol, N,N-dimethyl formamide, xylitol, tetrahydrofuran, methoxyethanol, and dimethyl sulfoxide (DMSO) [17,18,19,20,21,22,23,24,25,26], [27]. Despite this, PEDOT:PSS has several problems such as inhomogeneous electrical properties and poor long‐term stability [28, 29].

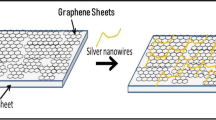

In the present work, for achieving a flexible TCE as an alternate of ITO, rGO modified PEDOT: PSS TCE was fabricated on a flexible PET sheet using a bar coating technique with high performance and stability. At first, graphene oxide (GO) was synthesized using modified Hummer’s method and then rGO was synthesized by reducing the GO using L-ascorbic acid. The different proportion of synthesized rGO was mixed in PEDOT: PSS solution and deposited on a PET sheet using bar coating technique as explained in Sect. 2. The deposited film was further exposed to the DMSO solution. Vibrational analysis including Raman spectra, FTIR absorption measurement; sheet resistance, flexibility, of the fabricated electrodes was estimated. The results and conclusion of the work is discussed in Sect. 3, 4 respectively.

2 Materials and methods

Materials: graphite powder, PEDOT: PSS (1.3 wt% dispersion in water) were obtained from Sigma Aldrich (USA); dimethyl sulfoxide (DMSO), and polyethylene terephthalate (PET) film were used for making transparent conducting films. In addition to this, soap solution, isopropyl alcohol (IPA), deionized (DI) water, and nitrogen gas were used to prepare the PET substrate for film deposition.

At first, PET substrates (2.5 cm × 2.5 cm) were cut and cleaned by sonication in soap solution then rinsed in DI water, after that the substrate was sonicated in isopropyl alcohol, and then rinsed in DI water. The substrates were dried with nitrogen and treated with oxygen plasma for 5 min each to enhance the wettability and adhesive strength of the substrate. Graphene oxide (GO) was synthesised using a modified Hummer’s method. In brief, 3 g graphite was dissolved in 60 ml of concentrated H2SO4 using stirring at room temperature for 24 h. Thereafter, the solution was placed in an ice bath to maintain the solution temperature up to 10 °C. Then 3 g of NaNO3 was added to the solution and stirred for 30 min by sustaining the temperature 10 °C in an ice bath, and took out the solution from the ice bath, and stirred it again for 1 h at room temperature. After that, the solution was diluted with 240 ml of DI and stirred it for 30 min and again diluted the solution with 1L of DI, after that 45 ml of H2O2 slowly added drop by drop for 30 min. The resulted solution was washed with HCl (5%wt): 65.2 ml of HCl in 84.8 ml of DI and filtered with a paper filter and washed to achieve neutral pH. The resulted product was dried at 80 0C in the oven for 48 h to receive GO powder. Thereafter, reduced graphene oxide (rGO) was synthesised by reducing the GO using L-ascorbic acid. Aqueous suspension of GO was prepared by ultra-sonicating 500 mg of GO in 1 L DI for 2 h. Thereafter, 500 mg of ascorbic acid was added and the solution was sonicated for the next 24 h. The resulting suspension was filtered and washed with DI water multiple times and dried at 60 °C in a vacuum oven.

Different concentrations 0%, 1%, 2%, 3%, 4%, and 5% (wt%) of rGO was mixed in PEDOT: PSS and sonicated for 4 h each. The prepared solution was deposited on a PET sheet using a bar coating and treated with DMSO. DMSO is a high boiling solvent and strongly enhanced the conductivity of PEDOT:PSS layer [30]. Respective change in sheet resistance and transmittance of the deposited layers were observed. A schematic diagram of the experiment is given in Fig. 1.

2.1 Characterization techniques

The deposited films of rGO modified PEDOT: PSS on PET substrates were characterized by different methods. The sheet resistance of the deposited samples was estimated by the four-probe (Vijayanta Electronics, India) technique. The analysis of surface roughness of the layer was carried out by Atomic Force Microscopy (AFM) using a machine of model Pro 47, provided by NT-MDT spectrum instruments Russia. The optical transmittance measurements were carried out on UV–Vis Spectrophotometer (Rescholar, India). The optical images were taken by optical microscope (Olympus BX53M) and the molecular vibrations of synthesised GO and rGO were characterised by Raman spectroscopy via Raman Spectrometer setup (WI Tec Alpha300 RAS) and FTIR absorption via FTIR spectrometer (PerkinElmer Spectrum Two) available in BML Munjal University, Gurugram. The bending test of the deposited samples was performed by taking the relative variation of electrical resistance using Keithley 2450 as a function of bending curvature for both sides including outer bending and inner bending.

3 Results and discussion

In this work, rGO/PEDOT: PSS based transparent conducting electrodes were prepared. In rGO synthesis process, first of all GO was synthesised using modified Hummer’s method and then it was reduced in rGO form using L-ascorbic acid. The resulted GO and rGO were characterised and analysed by Raman and FTIR spectroscopy shown in Fig. 2. Raman spectra of GO and rGO present a D-band at 1310 cm−1 and a G-band at 1609 cm−1. The D peak shows the presence of defects and amorphous structure and the G peak shows the ordered sp2 bond as reported by Pimenta et al. [31]. Due to the double resonance, D' peak at 1730 cm−1 is presents in Raman spectra of both GO and rGO [32]. From the Fig. 2a, it was observed that the intensity ratios (ID band/IG band) for GO were 0.6 while 0.64 for rGO which is slightly high than GO, and showed the number of defects increases during reduction due to the restoration of numerous graphitic domains from the amorphous regions of graphite oxide as also reported in accordance with [31, 32].

The FTIR spectrum of synthesised GO is shown in Fig. 2b and indicates the presence of C-O (alkoxy) vibration stretch at 1048 cm−1 and 1110 cm−1; C = C vibration at 1620 cm−1; C = O vibration at 1713 cm−1 and O–H stretch at 3397 cm−1. In the case of rGO sample the FTIR spectrum comprising minor peaks ay 1056 cm−1, 3333 cm−1 while slightly strengthened peak at 1647 cm−1 as reported by Aboulkas et al. [33]. These observations confirmed the formation of rGO.

The synthesised rGO was mixed in PEDOT: PSS solution using different concentrations 0%, 1%, 2%, 3%, 4%, and 5% referred as S0, S1, S2, S3, S4, and S5 respectively. These solutions are sonicated for 4 h before deposition. The prepared solution was deposited on a PET sheet using a bar coating with a bar of wire size 30 μm. The sheet resistance of the deposited layer was measured. The alteration in sheet resistance with the rGO concentration in PEDOT: PSS is reported in Fig. 3a. The sheet resistance at rGO concentration 1% (wt%) in PEDOT: PSS showed a sheet resistance of 315 ± 8 Ω/sq. which is the lowest among other samples.

The transmittance of all the samples S0, S1, S2, S3, S4, and S5 were measured using an absorption spectrophotometer as shown in Fig. 3b, and found that the optical transmittance of the S1 in the visible region is higher in comparison to S2, S3, S4, and S5 samples. When the rGO concentration increases, the optical transmittance appears to be reduced. From Fig. 3, it is observed that the sample S1 has low sheet resistance (315 ± 8 Ω/sq.) and high transmittance (~ 74%) in comparison to the rest of the rGO modified PEDOT: PSS samples shows a good combination for using as TCE. The combination of sheet resistance (315 ± 8 Ω/sq.) and transmittance (~ 74%) of S1 sample is much better than that was reported by Liu. et al. (sheet resistance 600 Ω/sq. and transmittance ~ 80% for Graphene/PEDOTP:SS) and Kiyoung et al. (sheet resistance 2.3 kΩ/sq. and transmittance ~ 80% for rGO/PEDOT:PSS) in their individual work [34,35,36].

To analyse the uniformity or surface roughness of the deposited layer, AFM characterisation using Atomic Force Microscopy (AFM) using a machine of model Pro 47, provided by NT-MDT spectrum instruments Russia and optical images of the samples were recorded with an optical microscope (Olympus BX53M) as shown in Figs. 4, 5. The surface images reveal that the surface roughness increases with increasing the concentration of rGO in PEDOT: PSS. Sample S1 shows better quality in comparison to other samples including S2, S3, S4, and S5.

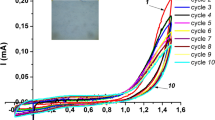

The flexibility and reliability of the deposited samples were tested by bending test using beakers of different diameters including 10, 8, 6, 4, 3 and 2 cm with bending curvature 20, 25, 33, 50, 67, and 100 m−1. Both inner bending and outer bending of the samples were performed by the equation given below that defined the relative variation of electrical resistance [37]:

where R0 is the resistance of the unbent sample [bending curvatures (ρ) = 0] and R is the resistance of the bent sample at different bending curvatures (ρ) values.

In this measurement, the variation in electrical resistance of the fabricated flexible transparent conducting samples was measured and shown in Fig. 6. Sample S1 indicate the least variation in electrical resistance (12% max. increases), in comparison to the other samples. Sample S2 indicate variation ~ 15% (increases); sample S3 showed variation ~ 16.5% (increases); sample S4 showed variation ~ 17.4% (increases) and sample S5 showed variation ~ 20% (increases) in electrical resistance for bending outer curvatures from 20 to 100 m−1 shown in Fig. 6a. The increase in resistance on outward bending is due to tensile stresses that tend to separate the layer particles from each other [38].

In a similar way, electrical resistance variation as a function of inward bending curvatures of rGO/PEDOT: PSS hybrid layer was measured and shown in Fig. 6b. Sample S1 shows minimum electrical resistance variation (~ 9% decreases), in comparison to the other prepared samples including sample S2 showed variation ~ 12.5%, sample S3 showed a variation ~ 14% (decreases), sample S4 showed a variation ~ 16% (decreases) and sample S5 showed a variation ~ 17% (decreases) in electrical resistance for inward bending curvatures from 20 to 100 m−1. The inward bending may create an overlap of the crumpled graphene films that results in a decrease in resistance [39].

Henceforth, the sample S1 is reported having the least sheet resistance (315 ± 8 Ω/sq.), high transmittance (~ 74%), better smooth surface, and lowest variation in electrical resistance during the inward (9% max. decreases) and outward bending (12% max. increases) in comparison to rest of the samples (S2, S3, S4, and S5). Hence, the sample S1 looked reliable and better for flexible TCE applications.

4 Conclusions

ITO is the most preferred TCE because of its high transmittance and low sheet resistance. However its brittle nature and limited indium resources restrict its use for future flexible optoelectronics devices. Hence, there is a requirement of alternate material for replacing ITO as TCE. Keeping this in view, the rGO modified PEDOT: PSS based TCE were deposited on a flexible PET sheet using a bar coating technique for achieving a flexible TCE as an alternate of ITO. The sheet resistance, optical transmittance, bending test (outside and inside bending) and surface roughness of the rGO modified PEDOT: PSS samples were measured. Our analysis reveals that the sample S1, having a concentration of rGO 1 wt% in PEDOT: PSS, showing better results i.e. low sheet resistance (315 ± 8 Ω/sq.) and high transmittance (~ 74%) with low electrical resistance variation 12% (max. increases) for outward bending and 9% (max. decreases) for inward bending of the sample for bending curvature from 20 to 100 m−1. Therefore, the sample with rGO 1 wt% in PEDOT: PSS is reported for its potential use as flexible TCE for optoelectronics applications.

References

Song T-B, Li N (2014) Emerging transparent conducting electrodes for organic light emitting diodes. Electronics 3(1):190–204

Chu H-C et al (2016) Spray-deposited large-area copper nanowire transparent conductive electrodes and their uses for touch screen applications. ACS Appl Mater Interf 8(20):13009–13017

Lee S et al (2020) Electrodeposited silver nanowire transparent conducting electrodes for thin film solar cells. ACS Appl Mater Interf 12:6169–6175

Sharma S, Shriwastava S, Kumar S, Bhatt K, Tripathi CC (2018) Alternative transparent conducting electrode materials for flexible optoelectronic devices. Opto-Electron Rev 26(3):223–235

López-Naranjo EJ, González-Ortiz LJ, Apátiga LM, Rivera-Muñoz EM, Manzano-Ramirez A (2016) Transparent electrodes: a review of the use of carbon-based nanomaterials. J Nanomater 2016:4928365. https://doi.org/10.1155/2016/4928365

Aronggaowa B, Kawasaki M, Shimomura T (2013) Thin, transparent conductive films fabricated from conducting polymer nanofibers. Polym J 45(8):819–823

Xia Y, Ouyang J (2015) Transparent conducting polymers. Organic Optoelectronic Materials. Springer, New York, pp 359–392

Gueye MN, Carella A, Faure-Vincent J, Demadrille R, Simonato J-P (2020) Progress in understanding structure and transport properties of PEDOT-based materials: a critical review. Prog Mater Sci 108:100616

Manawi Y, Samara A, Al-Ansari T, Atieh M et al (2018) A review of carbon nanomaterials’ synthesis via the chemical vapor deposition (CVD) method”. Materials (Basel) 11(5):822

Zaretski AV, Lipomi DJ (2015) Processes for non-destructive transfer of graphene: widening the bottleneck for industrial scale production. Nanoscale 7(22):9963–9969

Chandrashekar BN et al (2019) A universal stamping method of graphene transfer for conducting flexible and transparent polymers. Sci Rep 9(1):1–11

Chen M, Haddon RC, Yan R, Bekyarova E (2017) Advances in transferring chemical vapour deposition graphene: a review. Mater Horiz 4(6):1054–1063

Abad J, Padilla J (2018) Transparent conductive polymers . Trans Conduct Mater Mater Synth Charact Appl 29:193–244

Zhao P, Tang Q, Zhao X, Tong Y, Liu Y (2018) Highly stable and flexible transparent conductive polymer electrode patterns for large-scale organic transistors. J Colloid Interf Sci 520:58–63

Wang Y et al (2017) A highly stretchable, transparent, and conductive polymer. Sci Adv 3(3):e1602076

Lombardo V et al (2018) Transparent conductive polymer obtained by in-solution doping of PEDOT: PSS. Polymer (Guildf) 155:199–207

Mengistie DA, Ibrahem MA, Wang P-C, Chu C-W (2014) Highly conductive PEDOT: PSS treated with formic acid for ITO-free polymer solar cells. ACS Appl Mater Interf 6(4):2292–2299

Mengistie DA, Wang P-C, Chu C-W (2013) Highly conductive PEDOT: PSS electrode treated with polyethylene glycol for ITO-free polymer solar cells. ECS Trans 58(11):49–56

Yildirim E et al (2018) A theoretical mechanistic study on electrical conductivity enhancement of DMSO treated PEDOT: PSS. J Mater Chem C 6(19):5122–5131

Rwei S-P, Lee Y-H, Shiu J-W, Sasikumar R, Shyr U-T (2019) Characterization of solvent-treated PEDOT: PSS thin films with enhanced conductivities. Polymers (Basel) 11(1):134

Nagata R, Yanagi Y, Fujii S, Kataura H, Nishioka Y (2014) Application of highly conductive DMSO-treated PEDOT: PSS electrodes to flexible organic solar cells, in 2014 21st international workshop on active-matrix flatpanel displays and devices (AM-FPD) 299–302

Yoon S-S, Khang D-Y (2016) Roles of nonionic surfactant additives in PEDOT: PSS thin films. J Phys Chem C 120(51):29525–29532

Shi H, Liu C, Jiang Q, Xu J (2015) Effective approaches to improve the electrical conductivity of PEDOT: PSS: a review. Adv Electron Mater 1(4):1500017

Nagata R, Yanagi Y, Fujii S, Kataura H, Nishioka Y (2015) Highly conductive DMSO-treated PEDOT: PSS electrodes applied to flexible organic solar cells. IEICE Trans Electron 98(5):411–421

Liu G et al (2020) Solvent treatment inducing ultralong cycle stability poly (3, 4-ethylenedioxythiophene): poly (styrenesulfonic acid) fibers as binding-free electrodes for supercapacitors. Int J Energy Res 44(7):5856–5865

Liu J et al (2018) Highly conductive hydrogel polymer fibers toward promising wearable thermoelectric energy harvesting. ACS Appl Mater Interf 10(50):44033–44040

Alshammari AS (2019) Effect of solvents treatment on the electrical stability and surface wetting properties of PEDOT: PSS thin films. Mater Lett 250:30–33

Jørgensen M, Norrman K, Krebs FC (2008) Stability/degradation of polymer solar cells. Sol energy Mater Sol cells 92(7):686–714

Schultheiss A et al (2020) Insight into the degradation mechanisms of highly conductive poly (3, 4-ethylenedioxythiophene) thin films. ACS Appl Polym Mater 2:2686–2695

Lingstedt LV et al (2019) Effect of DMSO solvent treatments on the performance of PEDOT: PSS based organic electrochemical transistors. Adv Electron Mater 5(3):1800804

Pimenta MA, Dresselhaus G, Dresselhaus MS, Cancado LG, Jorio A, Saito R (2007) Studying disorder in graphite-based systems by Raman spectroscopy. Phys Chem Chem Phys 9(11):1276–1290

Patel DK, Hong P-D, Rathore S (2019) Surface-enhanced Raman scattering of reduced graphene coated with silver nanoparticles. J Ceram Process Res 20(4):442–448

Aboulkas A, Hammani H, El Achaby M, Bilal E, Barakat A et al (2017) Valorization of algal waste via pyrolysis in a fixed-bed reactor: production and characterization of bio-oil and bio-char. Bioresour Technol 243:400–408

Woo Y (2019) Transparent conductive electrodes based on graphene-related materials. Micromachines 10(1):13

Liu Z, Parvez K, Li R, Dong R, Feng X, Müllen K (2015) Transparent conductive electrodes from graphene/PEDOT: PSS hybrid inks for ultrathin organic photodetectors. Adv Mater 27(4):669–675

Jo K et al (2011) Stable aqueous dispersion of reduced graphene nanosheets via non-covalent functionalization with conducting polymers and application in transparent electrodes. Langmuir 27(5):2014–2018

Sharma S et al (2020) Optical and electrical investigations of rubbing assisted few-layer graphene thin film for feasibility of flexible electrode. Optik (Stuttg) 203:163989

Luo S, Samad YA, Chan V, Liao K (2019) Cellular graphene: fabrication, mechanical properties, and strain-sensing applications. Matter 1(5):1148–1202

Chen H et al (2020) Enhanced stretchable and sensitive strain sensor via controlled strain distribution. Nanomaterials 10(2):218

Acknowledgements

TEQIP-III, MHRD Government of India funded this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sharma, S., Singh, K., Kumar, S. et al. Fabrication of reduced graphene oxide modified poly(3,4-ethylenedioxythiophene) polystyrene sulfonate based transparent conducting electrodes for flexible optoelectronic application. SN Appl. Sci. 3, 26 (2021). https://doi.org/10.1007/s42452-020-04034-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-04034-w