Abstract

The present study is aimed to develop a high strength concrete by using mineral admixtures of wood ash (WA), metakaolin (MK), and chemical admixture. In order to check the compatibility, physical and chemical properties of the materials are studied. The specific gravity, bulk density and fineness of the ordinary Portland cement, wood ash and metakaolin have been studied. When compare to other materials, metakaolin has a more fineness and it implies the more reactivity than the wood ash. Similarly, the physical properties of the fine aggregate and coarse aggregates are also studies. And compressive strength, water absorption test, rapid chloride penetration test is also conducted. From the test report, it can be noted that the maximum compressive strength is achieved 83 N/mm2 in 10% WA + 20% MK blended concrete. The lowest water absorption and chloride permeability were obtained as 2.5% and 348 C respectively in 10% WA + 20% MK blended concrete. At the end of the experimental works, all obtained results were correlated with each other. The water absorption is well correlated with compressive strength (R2 = 84.9%) and charge passed (R2 = 91.5%). Finally, the cost analysis was carried out to understand the cost benefits of using the wood ash and metakaolin in high strength concrete.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the modern world, the construction industry is taking part in the country's development. And concrete is one of the most important construction materials from the past four decades due to its versatility and high durability than other construction materials. However, there was a need for the development of special concrete such as high strength concrete, high-performance concrete, etc. to faster and durable construction of various civil engineering structures [1, 2]. From the previous studies, it can be noted that concrete strength depends upon the water-cement ratio and the materials used that are used other than the conventional materials such as cement, fine aggregate, coarse aggregate, and water [3]. The manufacturing of high strength concrete is somewhat different from conventional concrete preparation by means of using additional materials such as mineral and chemical admixtures and using of techniques like re-vibration and seeding [4,5,6]. At the same time, the production cost for the manufacturing of HSC is higher than conventional concrete manufacturing [7, 8]. In order to reduce the cost of the HSC production without compromising the strength and durability of the concrete, some supplementary materials such as mineral admixtures or burnt ash or silica fume etc. are added. For maintaining such quality in the HSC, many pieces of research are carrying out throughout the world [9, 10]. In this paper, a new attempt is made to manufacture the HSC with the addition of metakaolin and wood ash in the binary and ternary systems.

Numerous researched are being carrying out on industrial by-products and other agricultural waste materials such as wood ash (WA) or rice husk ash (RHA) which can be used as cement replacement in concrete [11]. As the construction industry is second largest industry in the world, construction materials like cement and aggregates has increased which is the main ingredients in concrete. Also, the cement industry is one of the main sources which release large amounts of major consumer of natural resources like aggregate and has high power and emitting huge quantity of CO2 emission. So, using of such by product and agricultural wastes ashes solves a two kind of problems that the disposal as well providing a viable alternative for cement substitutes in concrete, and subsequent minimization of CO2 emission. Many scholars are put their time to study the behaviors of the concrete while using the wood ash and the suitably to replace cement partially in concrete production. Hence, incorporating the usage of wood ash as replacement for cement in blended cement is beneficial for the environmental point of view as well as producing low cost construction entity thus leading to a sustainable relationship [6, 12].

In other hands, the production cost for HSC is higher than the conventional/low grade concrete due to the addition of mineral or/and chemical admixtures. Many researches are carrying out to reduce the cost of the production HSC by studying on the usage of industrial by product as mineral admixtures [13,14,15]. In this study, it is proposed to use two types of mineral admixtures such as wood ash and metakaolin, and chemical admixture of superplasticizer (conplast SP430). The wood ash is prepared by collecting the wood waste from the wood sawmills, and waste is fired. After complete combustion of wood waste, ash is formed with high amorphous silica. Then the wood ash is ground well to increase the surface area of the ash particle. Before the application of wood ash, physical as well as chemical properties are checked through suitable testing procedures [16].

Metakaolin is an effective mineral admixture consisting of high alumina (Al) content usually obtained by thermal process on Kaolin clay. Since MK carries higher number of amorphous products such as alumina and silica, it helps to accelerate the setting time of the concrete [14, 17]. From the previous studies, it can be noted that MK blended concrete compressive strength, flexural strength, permeability characteristics and corrosion behavior is much improved than other mineral admixture blended concrete. Hence, MK is considered as a high reactive pozzolanic material for cement replacement. In this research work, wood ash and metakaolin are used as a cement replacement material to develop the high strength concrete and to enhance the structural properties. The WA and MK are replaced to the total quantity of the cement by means of binary and ternary system [18, 19].

In this work the physical and chemical properties of the materials such as ordinary Portland cement, wood ash, metakaolin, fine aggregate and coarse aggregate are planned to conduct. In order to check the fresh state properties, the compaction factor test is performed. The compressive strength, water absorption test and rapid chloride permeability test are also planned to perform to measure the strength and permeability properties of high strength concrete. It is also planned to know the interdependence between the obtained results.

2 Materials and methods

2.1 Materials

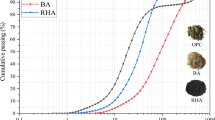

Ordinary Portland cement (OPC) confirming to IS 8112: 1989 for 43 Grade was used. Well graded ordinary river sand and locally available crushed rocks were used as fine aggregate and coarse aggregate confirming to the IS: 383-1970. From the sieve analysis the fineness modulus and other gradation properties were identified for fine and coarse aggregate. The fine aggregate is fall under Zone II category. The physical properties of the fine and coarse aggregate are shown in Table 1. The WA is prepared using the combustion of wood scrap obtained from sawmills. After combustion the ash is finely ground to increase the reactivity during the hydration process. Commercially available MK was used confirming to IS456:2000. The physical and chemical properties of OPC, WA and MK are shown in Table 2. From the results, the loss on ignition value for OPC, WA and MK are 3.12, 6.99 and 0.5 respectively. When compare to the OPC and Mk, WA LoI value is higher and slightly exceed the limit prescribed by IS code. However, the Loss on ignition value for MK is lower than other binding materials. It may be the responsible for higher reactivity during the hydration process and lead the earlier setting time. Portable water was used for entire work.

2.2 Mix proportioning

The mix proportioning for high strength concrete is carried out as per the guidelines given by IS456:2000 and IS10262:2009. For selecting the reference concrete (100% OPC concrete), seven trial mixes were developed with the variables of superplasticizer (SP) dosage, ratio of fine and coarse aggregate, water cement ratio and cement content. After 28 days of water curing, all the trial mixes were tested for compressive strength. The higher compressive strength is observed in a concrete with 390 kg/m3 as cement content, 0.35 W/C ratios, 2% of SP, 872 kg/m3 Fine aggregate, 1082 kg/m3 coarse aggregate. And this concrete is called as Normal Concrete (NC). The WA and MK are used as cement replacement materials to enhance the structural properties of the HSC. The Table 3 shows the mix proportioning details. Mixing of ingredients is an important part in the concrete manufacturing. The entire ingredients are batched (weighted) separately and to get uniform blending, binders (cement, WA and MK) are mixed separately in dry state. And then binder and fine aggregate are mixed thoroughly in dry state followed to coarse aggregate in the concrete mixture machine. The mixing process is continued up to 5 min, and then the water along with SP is added to the mixture. Finally, the mixing process is continued for 10 min to get the homogeneity. Nine cube of size 150 mm were prepared to conduct compressive strength test at 7 and 28 days and water absorption test. Three cylindrical specimens of size 100 mm diameter and 50 mm height were cast to conduct Rapid Chloride Penetration Test (RCPT).

2.3 Testing methods

The fresh state properties and harden properties of HSC is measured by means of conducting various tests such as compaction factor test (density ratio test), compressive strength test, fluid/water absorption test, rapid chloride penetration test (RCPT). The compaction factor test is mainly designed for the use in the laboratory but it can be used in the construction site. This test is more accurate and sensitive than the slump cone test. However, this test is particularly useful where the workability of concrete is lesser than the normal concrete workability. This test was conducted as per Indian standard code (IS1199). The concrete develops its strength with the hydration process due to the composition of the cementitious material blended in the concrete mix. The compressive strength for HSC at 28 days of water curing is conducted as per the Indian standard code (IS516).

Water permeability of the HSC was conducted for all the mixes at 28 days of water curing as per the procedure given by ASTM C642-81 [20,21,22,23,24]. Before conducting the water permeability test, the specimens were cleaned and then the specimens were dried in a hot air oven at 100—105 °C for one day. The dried specimens were cooled to normal temperature (25 °C), and measured the weight (W2). The dry specimens are submerged in a water tank and allow them to penetrate up to 48 h. This process is continued to get the constant value. Then the saturated weight of the specimens is noted (W1).

One of the causes of corrosion in concrete is chloride penetration. The chloride penetration in concrete is mainly happened due to the fact of the permeability of the concrete. So, in order to check the chloride permeability of concrete, rapid chloride penetration test is conducted as per the procedure described by ASTM C 1202 (1991) or AASHTO T 277 (1989). In this RCPT test the amount of charge passed through the concrete specimen of 100 mm diameter 50 mm height. The test setup for conducting the chloride permeability is shown in Fig. 1. It consisting of two reservoir, one reservoir contains sodium chloride solution and other contains sodium hydroxide solution in a suitable proportion. In sodium hydrochloride reservoir anode terminal is connected whereas cathode terminal is connected. Before using the specimens, the specimens were cleaned well and suitably cut from the core sample. The samples were placed in the holder with the help of nut bold and to avoid the leakage of chemicals epoxy resin was applied tin the edge of the specimen. Bothe anode and cathode terminals are connected to the power supply unit. The power of 60 V is applied to the reservoir. Due to the attraction between NaOH and NaCl, the chloride ion is penetrating the surface and the reading is noted. The higher reading indicating the high vulnerability of the corrosion. The time is noted, as an electrical indication of chloride permeability, is being monitored during 6 h test duration as per test procedure of. Depending upon the charge passed (in coulombs) in the concrete medium, it is categorized in to High (greater than 4000 coulombs), Moderate (2000–4000 coulombs), Low (1000–2000 coulombs), Very low (100–1000 coulombs) and Negligible (less than 100 coulombs) of chloride ion permeability [24,25,26].

3 Results

3.1 Compaction factor test

Compaction factor test is used to check the fresh state properties of the concrete. The test results for all mixes are shown in Fig. 2. As per the IS guidelines (IS1199:1959) the workability can be classified in to five groups depending upon the compaction factor value as shown in Table 4.

3.2 Compressive strength

The compressive strength for WA and MK blended HSC at 7 days and 28 days is shown in Fig. 3. The compressive strength for normal concrete at 28 days is noted as 61.06 N/mm2. The maximum compressive strength at 28 days water curing for wood ash blended HSC is observed in 20% replacement level and it is decreased up to 40% replacement. The gradual decreasing of compressive strength of WA blended concrete may be due to the fact of water demand to react the WA. It is confirmed by the fresh properties of the WA blended concrete. Due to reduced workability, voids may be introduced and subsequent reduction of the compressive strength [27, 28].

3.3 Water absorption

Water absorption is another important property, mainly used to assess the fluid permeability in the concrete structures. If the water absorption is low, the vulnerability of any chemicals, sulphate or corrosion attack will be low and increase the durability of the structures. The 100%OPC blended HSC water absorption is 3.9% of the mass of the concrete.

3.4 Rapid chloride penetration test

RCPT is an indirect method to assess the probability of corrosion in the reinforced cement concrete structures due to external agencies. In this work, all the mixes were tested to get the charge passed in coulombs. The charge passed through the specimens for wood ash and metakaolin blended high strength concrete is shown in Fig. 4.

4 Discussion

From the compaction factor test results, it can be observed that the normal concrete (M0) compaction factor value is 0.94. And this compaction factor value is higher than all other wood ash and metakaolin blended mixes. By considering the wood ash blended concrete, the compaction factor value is gradually decreased in the range between 0.92 and 0.81, when the replacement level is increased. It may be due to the fineness and reactivity of the WA than OPC. The MK blended concrete shown the very lowest degree of workability than OPC and WA blended concrete (0.91 to 0.75). The main reasons behind the lower workability may be due to the fact of high reactivity and more fineness of the material than other binding materials. Similarly, WA and MK blended HSC degree of workability were lower than OPC and WA blended concrete [13].

The maximum compressive strength (28 days) for MK blended HSC is observed as 69.88 N/mm2 at 20% replacement level, then the strength is decreased up to 40%. However, 30% MK blended HSC compressive strength is higher than the normal HSC (100%OPC). It is also may be due to the fact of higher water demand for the hydration process. When look on the WA and MK (ternary system) blended HSC, 15%WA + 25%MK blended HSC showed higher compressive strength than all other mixes. But 25%WA + 15%MK blended HSC compressive strength was lower than the reference mix. From these results, it may be concluded that the cement can be replaced by wood ash and metakaolin in ternary system with suitable proportions.

The water absorption for WA blended HSC, gradually decreased up to 20% replacement and then increased. The same trend for compressive strength is observed in MK blended HSC and WA + MK blended HSC. The lowest water absorption is noted in the 15%WA + 25%MK blended HSC.

The charge passed value for reference concrete is 1756 coulombs, this value is under the category of low probability of chloride penetration. When focus on the WA blended HSC, the lowest charge passing is 940 coulombs (very low probability category) in 20% replacement and then increased to 1850 C at 40% replacement. The lower charge passed value in MK blended high strength concrete is obtained 783 C in 20% MK blended HSC, and the charge passed values are increased. However, all charge passed values are under the category of low probability of corrosion intrusion. When considering the ternary blended systems, the lowest charge passed value is noted in 15%WA + 25%MK blended high strength concrete, but 25%WA + 15%MK blended HSC value is slightly higher than the reference concrete. From these results, it can be studied that the optimum cement replacement level is 20% in case of binary blended system, and 40% in case of ternary blended system.

4.1 Correlation between compressive strength, water absorption and charge passed

In order to know the interdependency between various properties of high strength concrete, the water absorption is correlated with compressive strength and charge passed. The correlation values between (a) water absorption and compressive strength and (b) water absorption and charge passed is shown in Fig. 5. For the correlation process, polynomial fit is used to explore the interdependencies. From the figure, the following equations are obtained (Fig. 5a and b). The R2 value for water absorption versus compressive strength and water absorption versus charge passed are 84.9% and 91.5% respectively. It is implying all the values of water absorption is well correlated with compressive strength and charge passed values and higher interdependency with each other (Table 5).

4.2 Cost analysis

In this work, cost analysis was conducted to determine the cost benefits of HSC containing the metakaolin and wood ash (See Table 6). As fine aggregate, coarse aggregate, water and SP are the constant quantity, their cost is not incorporated for this cost analysis. Instead, cement, wood ash, and metakaolin cost were analyzed. The OPC cement and Metakaolin were obtained from the local market, and the wood ash was prepared by using of wood scraps. The cost for OPC cement, Metakaolin and wood ash are 8.3, 7 and 1.5 rupees per kg. when considering the MK replacement, the cost of the product is nearer to the OPC. However, the wood ash production cost is much lower than the OPC and metakaolin. Therefore, the cost of the concrete production is reduced about 32.77% at the 40% replacement to the OPC. In the other hand, the cost of the production is lowed in the MK blended HSC, but it is very minimum than the WA blended HSC. From this cost analysis, it can be noted that the WA blended HSC has good structural properties and cost benefit.

5 Conclusion

From the experimental examinations on high strength concrete using wood ash and metakaolin, the following desired conclusion may be drawn,

-

1.

As this works mainly aimed to increase the replacement level in concrete manufacturing, the highest compressive strength was achieved at 20%WA, 20%MK and 15%WA + 25%MK blended HSC. The replacement level was increased up to 40% of the OPC in the high strength concrete. Hence, the overall cost of the production of HSC may minimized.

-

2.

The water absorption is a key indicator of the permeability of the concrete and the subsequent deterioration in concrete. In this experimental works was carried out to check the water absorption characteristics, and the water absorption was minimum at 20%WA, 20%MK and 15%WA + 25%MK blended HSC. It is also indicated the good performance of HSC

-

3.

Similarly, chloride penetration ability was checked through the rapid chloride penetration test. In the 15%WA + 25%MK blended HSC, the charge passed value was lower than all other blended HSC. And the category was very low for the probability of chloride intrusion.

-

4.

The prediction of the properties of concrete is essential to get overall idea of the interdependencies between various properties. In this work, correlations were made to understand the dependencies, as per the correlation results, the water absorption, compressive strength and RCPT values are well correlated (84.9% and 91.5% respectively).

-

5.

From this work, by the ternary blended system, the cement was replaced effectively by WA and MK up to 40%. The wood ash and metakaolin may be used as an effective cement replacement material to develop the high strength concrete.

-

6.

In future, this work may be expanded to study the corrosion behaviors of HSC containing wood ash and metakaolin. If the HSC passed all checks experimentally, it may be recommended for the real time future use in the construction field. And it will be enabled the concrete production with low cost (As discussed in Sect. 4.2), without compromising the structural properties and durability.

References

Habib A, Yildirim U, Eren O (2020) Mechanical and dynamic properties of high strength concrete with well graded coarse and fine tire rubber. Constr Build Mater 246:118502

Eisa AS, Elshazli MT, Nawar MT (2020) Experimental investigation on the effect of using crumb rubber and steel fibers on the structural behavior of reinforced concrete beams. Constr Build Mater 252:119078

Li Y, Zhang H, Liu G, Dawei Hu, Ma X (2020) Multi-scale study on mechanical property and strength prediction of aeolian sand concrete. Constr Build Mater 247:118538

Samimi K, Kamali-Bernard S, Maghsoudi AA, Maghsoudi M, Siad H (2017) Influence of pumice and zeolite on compressive strength, transport properties and resistance to chloride penetration of high strength self-compacting concretes. Constr Build Mater 151:292–311

Zeyad AM, Tayeh BA, Yusuf MO (2019) Strength and transport characteristics of volcanic pumice powder based high strength concrete. Constr Build Mater 216:314–324

Abdullahi M (2006) Characteristics of wood ash/OPC concrete. Leonardo Electron J Pract Technol 8:9–16

Horaskulthai V, Phiuvanna S, Kaenbud W (2011) Investigation on the corrosion resistance of bagasse rice husk wood ash blended cement concrete by impressed voltage. Construct Build Mater 25(1):54–60

Eliche-Quesada D, Corpas-Iglesias FA, Perez Villarejo L, IglesiasGodino FJ (2012) Recycling of sawdust, spent earth oil from filtration, compost and marble residues for brick manufacturing. Constr Build Mater 34:275–284

Sanjaun MA, Zaragoza A, Agui JCL (2011) Standardization for an innovative world. Cem Concr Res 41:767–774

Ban CC, Mahyuddin R (2012) Mechanical strength, durability and drying shrinkage of structural mortar containing HCWA as partial replacement of cement. Constr Build Mater 30:320–329

Thomas BS (2018) Green concrete partially comprised of rice husk ash as a supplementary cementitious material—A comprehensive review. Renew Sustain Energy Rev 82:3913–3923

Zeyad AM, Tayeh BA, Saba AM, Johari M (2018) Workability, setting time and strength of high-strength concrete containing high volume of palm oil fuel ash. Open Civil Eng J 12:35–46

Chee BC, Mahyuddin R (2011) The implementation of wood waste ash as a partial replacement material in the production of structural grade concrete and mortar: an overview. Resour Conserv Recycl 55:669–685

Rejini R, Ball Richard J, Tarelho Luis AC, Allen Geoff C, Labrincha Joao A, Ferreira Victor M (2009) Characteristics and use of biomass fly ash in cement-based materials. J Hazard Mater 172:1049–1060

Ghafari E, Feys D, Khayat K (2016) Feasibility of using natural SCMs in concrete for infrastructure applications. Constr Build Mater 127:724–732

Mehta PK (1998) Role of pozzolanic and cementious material in sustainable development of the concrete industry. Spec Publ 178:1–20

Kupwade-Patil K, Palkovic SD, Bumajdad A, Soriano C, Büyüköztürk O (2018) Use of silica fume and natural volcanic ash as a replacement to Portland cement: micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr Build Mate 158:574–590

Megat Azmi MJ, Brooks J, Kabir S, Rivard P (2011) Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr Build Mater 25:2639–2648

Khan M, Alhozaimy A (2010) Properties of natural pozzolan and its potential utilization in environmental friendly concrete. Can J Civil Eng 38:71–78

Megat Azmi MJ, Zeyad A, Muhamad Bunnori N, Ariffin K (2012) Engineering and transport properties of high-strength green concrete containing high volume of ultrafine palm oil fuel ash. Constr Build Mater 30:281–288

Zeyad AM, Johari MAM, Tayeh BA, Yusuf MO (2017) Pozzolanic reactivity of ultrafine palm oil fuel ash waste on strength and durability performances of high strength concrete. J Clean Prod 144:511–522

Du H, Tan KH (2017) Properties of high-volume glass powder concrete. Cem Concr Compos 75:22–29

Islam GS, Rahman M, Kazi N (2017) Waste glass powder as partial replacement of cement for sustainable concrete practice. Int J Sustain Built Environ 6:37–44

ASTM C642 (2013) Standard test method for density, absorption, and voids in hardened concrete, American society for Testing and Materials, 2013 Edition, February 1, 2013

ASTM C1202 (1991) Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration, American society for Testing and Materials, 1991 Edition

AASHTO T 227 (2002) Standard method of test for density, relative density (specific gravity), or API gravity of crude petroleum and liquid petroleum products by hydrometer method, American Association of State Highway and Transportation Officials (AASHTO), 2002 Edition

IS 1199–1959 Methods of sampling and analysis of concrete, Bureau of Indian Standards, India, Eleventh Reprint NOVEMBER 1991, New Delhi

IS 516: Method of tests for strength of concrete, CED 2: Cement and Concrete by Bureau of Indian Standards, Eighteenth Reprint JuNE 2006, New Delhi

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Availability of data and material

Permission for getting the wood ash was obtained properly.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kannan, V., Raja Priya, P. Evaluation of the permeability of high strength concrete using metakaolin and wood ash as partial replacement for cement. SN Appl. Sci. 3, 90 (2021). https://doi.org/10.1007/s42452-020-04024-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-04024-y