Abstract

Proccessible FePt3 alloy nanoparticles with sizes smaller than 50 nm open the avenue to novel magnetic sensor, catalytic and biomedical applications. Our research objective was to establish a highly scalable synthesis technique for production of single-crystalline FePt3 alloy nanoparticles. We have elaborated a one-pot thermal decomposition technique for the synthesis of superparamagnetic FePt3 nanoparticles (FePt3 NPs) with mean sizes of 10 nm. Subsequent tiron coating provided water solubility of the FePt3 NPs and further processibility as bidental ligands enable binding to catalyst surfaces, smart substrates or biosensors. The chemical composition, structure, morphology, magnetic, optical and crystallographic properties of the FePt3 NPs were examined using high resolution transmission electron microscopy, high-angle annular dark field-scanning transmission electron microscopy, scanning transmission electron microscopy-energy-dispersive X-ray spectroscopy mapping, Fourier transform infrared-attenuated total reflection, X-ray powder diffraction, X-ray photoelectron spectroscopy, vibrating sample magnetometry and UV–Vis absorption spectroscopy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, bimetallic nanocrystals have received significant attention for nanoengineering, nanoelectronics and nanomedicine because of their particularly physical and chemical properties. Iron platinum alloy nanostructures in the L10, L11 and L12 phases were engineered for applications as being magnetic sensors, catalysts, drug delivery tools, and biomedical imaging [6, 14, 21, 27, 32, 39]. Highly ordered FePt alloy nanocomposites exhibit an encouraging potential for ultrahigh density magnetic recording media and high-performance permanent magnets due to their uniaxial magnetocrystalline anisotropy, whereas chemically disordered FePt alloy nanoparticles promise applications in medical diagnostics (e.g. MPI, CT and MRI) [4, 14, 23]. FePt and FePt3 alloys may crystallize in three different crystal structures: FePt3 (L12, AuCu3- type cubic), FePt (L10, AuCu-type tetragonal) and Fe3Pt (L12, AuCu3-type cubic), the magnetic properties of which depend on the synthesis procedure [2, 8, 9, 14]. On the other hand, in the respective chemically disordered high-temperature FePt phase, the Fe and Pt atoms are randomly distributed over the lattice sites and thus, exhibit isotropic magnetic behavior [27, 35]. The most common synthesis routes for preparing FePt, Fe3Pt or FePt3 nanoparticles are the thermal decomposition technique and the polyol synthesis [21, 23]. The face centered cubic (fcc) FePt phase can be transformed into the face centered tetragonal (fct) phase by high temperature annealing. Unfortunately, thermal annealing gives rise to agglomeration of FePt alloy nanocrystals which is accompanied by the emergence of undesired shapes and broad size distributions [13, 21]. The formation of FePt alloy nanocrystals depend on the growth from two different metals (Fe and Pt) at distinct reaction temperatures [21]. Sun et al. synthesized FePt alloy nanocrystals by thermally decomposing Fe(CO)5 and Pt(acac)2 in the presence of the reducing agent oleyl amine and the surfactant oleic acid. Cytotoxic Fe(CO)5 can be substituted by iron(III) acetylacetonate or iron(III) oleate. Moreover high-boiling temperature solvents such as di-n-octyl ether or 1-octadecene are required for thermal decomposition synthesis routes. Polyol synthesis techniques are based on solvents such as tetraethylene glycol (TEG) and ethylene glycol (EG) which simultaneously serve as solvent and reducing agent for the metallic precursor [23, 33]. One major drawback of these demanding synthesis techniques is the impossibility to adjust the growth of FePt alloy nanoparticles within a uniform crystal phase (fcc or fct).

In the present work, we have elaborated a straightforward synthesis route for chemically disordered fcc FePt3 nanocrystals. This one-pot synthesis is highly scalable for the preparation of superparamagnetic FePt3 nanoparticles (FePt3 NPs) for future electronic and biomedical applications. The one-pot synthesis technique comprises the preparation of a Pt(II) precursor solution and subsequent formation of FePt3 NPs. Subsequent ligand exchange with tiron provided dispersion stability and water solubility of the FePt3 NPs and moreover, facilitates their processing to thin magnetic films and their application as MRT/CT contrast agents in biomedical imaging. The tiron-coated FePt3 NPs were characterized by determining the average size, size distribution, morphology, crystallographic properties, colloidal stability, magnetic and optical properties. high resolution transmission electron microscopy (HRTEM), high-angle annular dark field-scanning transmission electron microscopy (HAADF-STEM), scanning transmission electron microscopy-energy-dispersive X-ray spectroscopy (STEM-EDX) mapping, Fourier transform infrared-attenuated total reflection (FTIR-ATR), X-ray powder diffraction (XRD), X-ray photoelectron spectroscopy (XPS), UV–Vis absorption spectroscopies were employed as microscopy and spectroscopy characterization techniques. The magnetic properties were examined using vibrating sample magnetometry.

2 Experimental

2.1 Materials

Dihydrogenhexachloroplatinate hexahydrate (H2Cl6Pt × 6H2O, ≥ 99,9%, Alfa Aesar), ethanol (≥ 99.8%, Carl-Roth), oleic acid (90%, Sigma-Aldrich), 1-octadecene (90%, Sigma-Aldrich), tert-butylamine borane (TBAB, 97%, Sigma-Aldrich), chloroform (≥ 99.9%, Sigma-Aldrich), isopropanol (≥ 98%, Sigma-Aldrich), tiron (97%, Sigma-Aldrich), oleylamine (80–90%, Acros Organics), n-hexane (95%, VWR), iron(III) acetylacetonate (Fe(acac)3, 97%, Fluka) were used for the synthesis of the FePt3 NPs. All chemicals are commercially available and were used without further purification. In all syntheses, ultrapure milli-Q water (18 MΩ) was used.

2.2 Preparation of the Pt(II) precursor solution

40.0 mg H2Cl6Pt × 6 H2O (0.077 mmol) were dissolved in 4.00 mL chloroform and 4.00 mL oleylamine (12.2 mmol) were added. The precursor solution was stirred for 10 min under ambient conditions. 70.0 mg TBAB (0.804 mmol) and 1000 μL oleylamine (1.22 mmol) in 1000 μL chloroform were mixed by sonication and added to the precursor solution. The mixture was stirred for 1 h at room temperature.

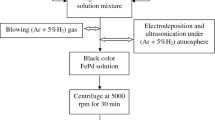

2.3 Synthesis of FePt3 NPs

Under argon atmosphere, the Pt(II) precursor solution in chloroform was added to a solution containing 15.0 mL 1-octadecene, 1.00 mL oleic acid (3.15 mmol) and 1.00 mL oleylamine (3.04 mmol). The reaction mixture was stirred for 30 min at 120 °C. Then 90.0 mg Fe(acac)3 (0.255 mmol) dissolved in 5.00 mL 1-octadecene were injected into the hot solution. The reaction mixture was heated to 320 °C and boiled under reflux over 2 h. After cooling down to room temperature the reaction mixture was exposed to air for 1 h. The FePt3 NPs were precipitated by the addition of 60 mL isopropanol and collected by centrifugation (11,000 rpm, 10 min). Afterwards the FePt3 NPs were washed with ethanol and centrifugation and redispersed in 10 mL n-hexane for storage.

2.4 Tiron-coating of the FePt3 NPs

100 mg tiron (0.302 mmol) in 1.50 mL milli-Q water were added to a dispersion of 10 mg FePt3 NPs in 2.50 mL n-hexane. This biphasic n-hexane/water NP mixture was sonicated for 1 h. Then n-hexane was removed using a rotary evaporator. The tiron-coated FePt3 NP dispersion formed a stable aqueous solution.

2.5 Microscopic and spectroscopic characterization

HRTEM images were obtained using a Titan3 Themis 300 (FEI Company, Netherlands) equipped with a high-brightness field-emission gun (X-FEG), a monochromator system and two Cs-correctors (probe and image side) (CEOS GmbH, Germany). The microscope operates at an acceleration voltage of 200 kV. The morphology and elemental composition of the FePt3 NPs were examined by means HAADF-STEM using the Z-contrast. The STEM-EDX mappings were obtained using a Super-X detector for EDX spectroscopy. The HRTEM images were recorded using a FEI Ceta 16 M 4 K CMOS (complementary metal-oxide semiconductor) camera. HRTEM samples were prepared by dropping the FePt3 NP dispersions on Cu grids coated with an ultrathin carbon film layer.

XRD patterns of FePt3 NPs powder samples were measured at room temperature using a Philips/Panalytical X-Pert Pro equipped with a copper radiation, (Kα1 = 0.154056 nm and Kα2 = 0.154439 nm). The XRD measurements were repeated 10 times. In addition, the Rietveld profile fitting of the XRD pattern of the FePt3 NP sample was recorded by mounting in a silicon wafer to the XRD instrument at room temperature. Rietveld fitting was obtained by means of MAUD (Materials Analysis Using Diffraction) [15,16,17,18].

FTIR transmission spectra of the FePt3 NPs were recorded on an IR Prestige-21 spectrometer (Shimadzu, Japan) equipped with an attenuated ATR setup with a diamond/ZnSe crystal plate (Miracle ATR, Pike Technologies, U.S.A.).

XPS was conducted on a Quantera II microprobe (Physical Electronics Inc., Chanhassen, MN, USA) under ultrahigh vacuum conditions. The powder samples were mounted on a double-sided sticky tape to the sample holder. Monochromated Al Kα x-rays (1486.6 eV, source at 15 kV and 50 W) were focused on 200 × 200 µm2 homogeneously covered spots of the powder samples. The mostly non-conducting samples were neutralized by Ar+ ions and electrons. The pure Pt and pure Fe reference samples were presputtered to clean the surface. Photoelectrons were detected at an analyzer pass energy of 280 eV and 140 eV and the number of sweeps for signal averaging were 3 and 25 for survey and high-resolution spectra, respectively. A peak at 284.8 eV associated with C 1s core-level was taken as a reference for the binding energy scale of the FePt3 NP samples.

The magnetic properties of the FePt3 NPs were analyzed using a Quantum Design VSM-MPMS SQUID magnetometer at room temperature under an external magnetic field varied between − 5T and + 5T.

3 Results and discussions

3.1 HRTEM/HAADF-STEM/STEM-EDX analysis

According to the HRTEM image in Fig. 1a the FePt3 NPs are single crystalline and flower-like nanostructures with a mean size of 10 nm. Furthermore, the HRTEM image (Fig. 1a, insert) exhibits lattice fringe spacings with 0.194 nm which identifies the (200) lattice plane of the face centered cubic (fcc) phase. Figure 1b shows the HAADF-STEM image of the FePt3 NPs. The STEM-EDX mapping images visualize the homogeneous elemental distribution of Pt (green) and Fe (red) in the FePt3 NPs, and thereupon revealing their quasi-alloy FePt3 composition (Fig. 1c–e).

a HRTEM image of the FePt3 NPs, b HAADF-STEM image of FePt3 NPs, c STEM-EDX elemental mapping images showing the distribution of Pt (green) (Pt K-edge), d STEM-EDX elemental mapping images showing the distribution of Fe (red) (Fe K-edge), e merged image of the FePt3 NPs of the elemental distribution of Fe (red) and Pt (green)

3.2 XRD analysis

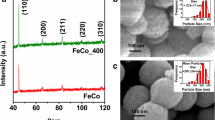

The crystal structure of the FePt3 NPs was elucidated by performing a powder XRD analysis. The XRD pattern in Fig. 2 displays prominent reflection peaks at 40.25, 46.75, 68.41, and 82.34 which are assigned to the (111), (200), (220), (311) planes of the disordered fcc FePt3 phase with the space group \({\text{Fm}}\bar{3}{\text{m}}\) (ICDD Ref: 001-089-2050) [29]. The Rietvield fit of the XRD data (Fig. 3) was obtained for the fcc phase of FePt3 and yielded the lattice constant a = 0.3852 nm [15,16,17,18]. The superlattice reflections (001) and (110) indicate a partially L12-ordered phase of FePt3. The average NP diameter was calculated to be 10 nm using the Debye–Scherrer equation [11], which agrees with the HRTEM analysis.

3.3 FTIR-ATR spectra

Oleic acid and oleylamine were used as stabilizing agents for the high-temperature synthesis of the FePt3 NPs. In the FTIR-ATR spectrum of the FePt3 NPs (Fig. 4, black solid line) the peaks at 2853 cm−1 and 2925 cm−1 were assigned to the symmetric and asymmetric CH2 stretching modes of oleic acid and oleylamine [5]. Water solubility and further processability of the FePt3 NPs were achieved by tiron coating through ligand exchange. The binding modus of tiron was elucidated by analyzing the FTIR-ATR spectrum of tiron-coated FePt3 NPs (Fig. 4, red solid line). This FTIR-ATR spectrum exhibits the characteristic vibrational bands of tiron being bound via the catechol group at the FePt3 NP surface (Fig. 5). The broad band in the region of 3100–3600 cm−1 arose from the symmetric O–H stretching vibrations of water. The vibrational peak at 1250 cm−1 and 1190 cm−1 are assigned to the asymmetric S=O stretching vibration, and the band at 1031 cm−1 is ascribed to the symmetric O=S=O stretch of tiron [28]. The peak at 630 cm−1 identifies the C–S stretching vibration. The peaks at 1596 cm−1, 1459 cm−1 and 1426 cm−1 refer to the carbon–carbon stretching vibrations in the aromatic ring of the tiron [28].

3.4 XPS analysis

Figure 6 exhibits the Fe 2p spectral region, namely the Fe 2p3/2 and Fe 2p1/2 multiplet for the FePt3 NPs and a pure metal Fe. The Fe 2p spectral region consists of two peaks at approximately 712.8 eV and 726.8 eV. The higher binding energy of the multiplet as compared to the metal reference (707.0 eV and 720.0 eV) and relatively high full width at half maximum of approximately 7 eV for the peak at lower binding energy is often assigned to the presence of a multitude of different iron species in positive oxidation states such as iron oxides [19, 22, 25, 26, 36, 37]. Qualitatively, the low binding energy tail of the NPs Fe 2p3/2 component overlaps with the respective signal of the pure metal Fe at 707.0 eV. This effect is assigned to the presence of iron species that show only slightly higher binding energy as compared to metal Fe like for example Fe–Pt alloys [20, 30].

Figure 7 shows the Pt 4f region comprising the Pt 4f 7/2 and Pt 4f 5/2 multiplet. The Pt 4f 7/2 peak for the NPs is evidenced at 0.2 eV towards lower binding energies as compared to the pure metal Pt at 71.2 eV. The effect, which is just of the order of the uncertainty from the peak referencing of the spectrum, points to the formation of an interfacial Fe–Pt alloy and electron transfer at the interface towards the more electronegative Pt [20, 30]. The peak at higher binding energies (75–78 eV) is assigned to the presence of precursor ions in the spectrum of the FePt3 NPs.

3.5 UV–Vis absorption spectroscopy

Figure 8 depicts the UV–Vis absorption spectrum of tiron-coated FePt3 NPs in water.

The UV–Vis absorption spectrum of tiron-coated FePt3 NPs displays a broad absorption band around 650 nm (Fig. 8) which is due to electron transfer from Pt to the antibonding π-molecular orbitals of tiron [3, 10, 31, 38]. Valence tautomerization of tiron (OH to =O) of tiron may also contribute to the emergence of these broad absorption band (Fig. 9) [1, 3, 7, 10, 12, 24, 31, 34, 38].

Figure 10 presents the magnetization curve of a powder sample of tiron-coated FePt3 NPs at room temperature under an external magnetic field varied between − 5T and + 5T. The lack of any hysteresis loop verifies superparamagnetism of the FePt3 NPs [29]. The Ms value of the FePt3 NPs is 35.90 emu/g. The observed superparamagnetism reflects the chemical disorder of the FePt3 NPs.

3.6 Formation of FePt3 alloy nanoparticles

The FePt3 alloy nanoparticles were synthesized via the thermal decomposition route at 320 °C using Fe(acac)3 and oleylamine stabilized Pt2+ cations as Pt source. The formation of the chemically disordered FePt3 nanoparticles requires the co-reduction of Fe3+ and Pt2+ cations. Since Pt is a noble metal and Fe is a transition metal, the Pt2+ cations are faster reduced to Pt0 which sparks Pt nucleation. The Pt nuclei presumably catalyze the oleylamine-induced reduction of Fe3+ to Fe0 [2]. Subsequent nanoparticle growth occurs via the incorporation of Fe atoms into the Pt rich nuclei. The final size and stabilization are adjusted by the precursor/oleyl acid (oleylamine) ratio. The final stoichiometric composition and structure of the FePt3 alloy nanoparticles follow from the reaction temperature as well as from the Fe and Pt precursor concentrations.

4 Conclusions

Our objective was to develop a highly scalable wet-chemistry technique for the synthesis of processible, superparamagnetic FePt3 NPs for versatile applications in electronics, catalysis and medicine. We elaborated a facile one-pot thermal decomposition procedure for the preparation of 10 nm-sized FePt3 nanocrystals which exhibit superparamagnetism. A straightforward subsequent ligand exchange procedure yielded watersoluble tiron-coated FePt3 NPs suited for processing to thin magnetic films or for application as CT/MRI contrast agents.

The stoichiometry and structural properties of the FePt3 NPs were elucidated using HRTEM, HAADF, STEM-EDX, XPS and XRD. We could unambiguously show that FePt3 NPs with a mean size of 10 nm crystallize in the chemically disordered fcc phase with the space group \({\text{Fm}}\bar{3}{\text{m}}\). The chemical disorder substantiated the superparamagnetism of the FePt3 NPs as being evident from the hysteresis-less magnetization curve. The optical properties and ligand binding modi of tiron-coated FePt3 NPs were examined using UV–Vis absorption and FTIR transmission spectroscopy. The aqueous FePt3 NPs solution exhibits a broad absorption band around 650 nm, which is ascribed to an electron transfer from the Pt atoms to antibonding π-molecular orbitals of tiron which binds through its catechol moiety to the FePt3 surface. This particular optical property of tiron-coated FePt3 NPs demonstrates the high catalytic potential of FePt3.

References

Angelomé PC, Soler-Illia GJDA (2005) Organically modified transition-metal oxide mesoporous thin films and xerogels. Chem Mater 17:322–331

Chen S, Andre P (2012) Colloidal syntheses of FePt nanoparticles. Int J Nanotechnol 9:39–68

Chen Y, Zhang H (2013) Complexation facilitated reduction of aromatic N-oxides by aqueous FeII–tiron com plex: reaction kinetics and mechanisms. Environ Sci Technol 47:11023–11031

Chou S-W, Yu-Hong Shau Y-H, Wu P-C, Yang Y-S, Shieh D-B, Chen C-C (2010) In vitro and in vivo studies of FePt nanoparticles for dualmodal CT/MRI molecular imaging. J Am Chem Soc 132:13271

De Berti IP, Cagnoli MV, Pecchi G, Alessandrini JL, Stewart SJ, Bengoa JF, Marchetti SG (2013) Alternative low-cost approach to the synthesis of magnetic iron oxide nanoparticles by thermal decomposition of organic precursors. Nanotechnology 24:175601

Fukuda K, Fujieda S, Shinoda K, Suzuki S, Jeyadevan B (2012) Low temperature synthesis of FePt alloy nano-particles by polyol process. J Phys: Conf Ser 352:012020

Gardner RR, Gerdes AL, Seeley JA (2013) Tiron-containing detergents having acceptable color, U.S. Patent No. 8, 399, 396. U.S. Patent and Trademark Office, Washington, DC

Green LA, Thuy TT, Mott DM, Maenosono S, Thanh NTK (2014) Multicore magnetic FePt nanoparticles: controlled formation and properties. RSC Adv 4:1039–1044

Heitsch AT, Lee DC, Korgel BA (2010) Antiferromagnetic single domain L12 FePt3 nanocrystals. J Phys Chem C 114:2512–2518

Hori M, Pagnoux C, Baumard JF, Nogami M (2007) Preparation of gold nanoparticles (GNP) aqueous suspensions by a new method involving tiron. J Mater Sci 42:80–86

Hossain AA, Rahman ML (2011) Enhancement of microstructure and initial permeability due to Cu substitution in Ni0.50-xCuxZn0.50Fe2O4 ferrites. J Magn Magn Mater 323:1954–1962

Koch S, Ackermann G, Scholze V (1981) Untersuchungen zur Anwendung ternärer Komplexe in der Photometrie-II Die Bestimmung des Titanium (IV) mit Tiron in Gegenwart von Iminodiessigsäure, Nitrilotriessigsäure bzw. Diethylentriaminpentaessigsäure Talanta 28:915–918

Lee Y, Garcia MA, Frey Huls NA, Sun S (2010) Synthetic tuning of the catalytic properties of Au-FePt3 nano-particles. Angew Chem 122:1293–1296

Liu Y, Jiang Y, Zhang X, Wang Y, Zhang Y, Liu H, Zhai H, Liu Y, Yang J, Yan Y (2014) Structural and magnetic properties of the ordered FePt3, FePt and Fe3Pt nanoparticles. J Solid State Chem 209:69–73

Lutterotti L (2010) Total pattern fitting for the combined size-strain-stress-texture determination in thin film diffraction. Nucl Instrum Methods Phys Res B Beam Interact Mater At 268:334–340. https://doi.org/10.1016/j.nimb.2009.09.053

Lutterotti L, Matthies S, Wenk HR, Schultz AJ, Richardson J (1997) Combined texture and structure analysis of deformed limestone from neutron diffraction spectra. J Appl Phys 81:594–600

Lutterotti L, Chateigner D, Ferrari S, Ricote J (2004) Texture, residual stress and structural analysis of thin films using a combined X-ray analysis. Thin Solid Films 450:34–41

Lutterotti L, Bortolotti M, Ischia G, Lonardelli I, Wenk HR (2007) Rietveld texture analysis from diffraction images. Z Kristallogr Suppl 26:125–130

McIntyre NS, Zetaruk DG (1977) X-ray photoelectron spectroscopic studies of iron oxides. Anal Chem 49:1521–1529

Medwal R, Sehdev N, Annapoorni S (2012) Electronic states of self-stabilized L10 FePt alloy nanoparticles. Appl Phys A 109:403–408

Meng Z, Li G, Ng SM, Wong HF, Yiu SC, Ho CL, Leung CW, Wong WY (2016) Nanopatterned L10-FePt nanoparticles from single-source metallopolymer precursors for potential application in ferromagnetic bit-patterned media magnetic recording. Polym Chem 7:4467–4475

Mills P, Sullivan JL (1983) A study of the core level electrons in iron and its three oxides by means of X-ray photoelectron spectroscopy. J Phys D Appl Phys 16:723

Nguyen HL, Howard LEM, Stinton GW, Giblin SR, Tanner BK, Terry I, Hughes AK, Ross IM, Serres A, Evans JSO (2006) Synthesis of size-controlled fcc and fct FePt nanoparticles. Chem Mater 18:6414–6424

Ozutsumi K, Uchima Y, Kawashima T (1990) Structure of iron(III)-Tiron complexes in aqueous solution. Anal Sci 6:573–577

Pana O, Leostean C, Soran ML, Stefan M, Macavei S, Gutoiu S, Pop V, Chauvet O (2013) Synthesis and characterization of Fe–Pt based multishell magnetic nanoparticles. J Alloys Compd 574:477–485

Poulin S, Franca R, Moreau-Bélanger L, Sacher E (2010) Confirmation of X-ray photoelectron spectroscopy peak attributions of nanoparticulate iron oxides, using symmetric peak component line shapes. J Phys Chem C 114:10711–10718

Preller T, Knickmeier S, Menzel D, Temel B, Garnweitner G (2020) Exchange bias in FePt–FePt3 thin films by controlled phase transition of blended nanoparticle building blocks. Langmuir 36:2093–2101

Santos LRB, Chartier T, Pagnoux C, Baumard JF, Santillii CV, Pulcinelli SH, Larbot A (2004) Tin oxide nano particle formation using a surface modifying agent. J Eur Ceram Soc 24:3713–3721

Sarmphim P, Soontaranon S, Sirisathitkul C, Harding P, Kijamnajsuk S, Chayasombat B, Pinitsoontorn S, Chingunpitak J (2017) FePt3 nanosuspension synthesized from different precursors—a morphological comparison by SAXS, DLS and TEM. Bull Pol Acad Sci Tech 65:79–84

Sham TK, Yiu YM, Kuhn M, Tan KH (1990) Electronic structure of ordered and disordered Cu3Au: the behavior of the Au 5d bands. Phys Rev B 41:11881

Simaan AJ, Boillot ML, Carrasco R, Cano J, Girerd JJ, Mattioli TA, Ensling J, Spiering H, Gütlich P (2005) Electronic, vibrational, and structural properties of a spin-crossover catecholato-iron system in the solid state: theoretical study of the electronic nature of the doublet and sextet states. Chem Eur J 11:1779–1793

Suber L, Imperatori P, Bauer EM, Porwal R, Peddis D, Cannas C, Ardu A, Mezzi A, Kaciulis S, Notargiacomo A, Pilloni L (2016) Tuning hard and soft magnetic FePt nanocomposites. J Alloys Compd 663:601–609

Sun S, Murray CB, Weller D, Folks L, Moser A (2000) Monodisperse FePt nanoparticles and ferromagnetic FePt nanocrystal superlattices. Science 287:1989–1992

Taher MA, Asadollahzadeh H, Fazelirad H (2015) Determination of trace amounts of iron by a simple fluore- scence quenching method. Anal Methods 7:6726–6731

Vlaic P, Burzo E (2010) Magnetic behavior of iron-platinum alloys. J Optoelectron Adv Mater 12:1114–1124

Wilson D, Langell MA (2014) XPS analysis of oleylamine/oleic acid capped FePt3 nanoparticles as a function of temperature. Appl Surf Sci 303:6–13

Yamashita T, Hayes P (2008) Analysis of XPS spectra of Fe2+ and Fe3+ ions in oxide materials. Appl Surf Sci 254:2441–2449

Yao B, Peng C, Lu P, He Y, Zhang W, Zhang Q (2016) Fabrication of Tiron-TiO2 charge-transfer complex with excellent visible-light photocatalytic performance. Mater Chem Phys 184:298–305

Zheng Q, Zhang ZR, Du J, Lin LL, Xia WX, Zhang J, Bian BR, Liu JP (2019) A novel direct reduction method to synthesize ordered Fe-Pt alloy nanoparticles. J Mater Sci Technol 35:560–567

Acknowledgements

The authors thank Dr. Sebastian Bochmann (Chair of Chemistry of Thin Film Materials, Friedrich-Alexander University of Erlangen-Nürnberg) and M.Sc. Julian Hümmer (Inorganic and General Chemistry, Friedrich-Alexander University of Erlangen-Nürnberg) for supporting the VSM-SQUID measurement. C. H. and E. S. acknowledge financial support from the DFG through the Collaborative Research Center CRC953.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Akbulut, M.K., Harreiß, C., Löffler, M. et al. Facile one-pot synthesis of water-soluble fcc FePt3 alloy nanostructures. SN Appl. Sci. 2, 1744 (2020). https://doi.org/10.1007/s42452-020-03544-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03544-x