Abstract

Synergic extraction of Eu(III) as representative of rare earth elements was conducted with 0.01 mol dm−3 of trifluoroacetyl-pyrazolin-5-one (HPMTFP) and then with synergic mixture of HPMTFP and crown ethers (benzo-15-crown-5, 18-crown-6, 15-crown-5) in dichloromethane (DCM) from aqueous solution having pH 1.0–3.5. Slope analysis method was used for determining the composition of the synergic adduct i.e. Eu(PMTFP)3 that came out to be Eu(PMTFP)3·2S, where S = neutral oxo-donor and -PMTFP = conjugate base of HPMTFP molecule. Selective extraction of Eu(III) was found in the presence of various masking agents like citrate, oxalate, bromide, thiosulphate, chromate ions and of some cations. The accuracy of the developed procedure was checked by analyzing real lake sample (IAEA-SL-3) as a reference material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Europium is one of the most costly metal among the rare earth elements because it is present in very small amount i.e. 0.05–0.10% w/w in its ores i.e. monazite and bastnaesite [1,2,3]. Its use is increasing day by day. Today europium is used in almost every field like electronics, ceramic industry, metallurgy industry, nuclear and medical fields [4,5,6]. With the ever-increasing use of europium and its compounds, attention is being turned to the extraction and separation of this metal with high efficiency and selectivity. Among various technologies which can be employed for the extraction and separation of the metals, solvent extraction is one of the most commonly employed technique. The solvent extraction comprises of two different immiscible liquids, organic and aqueous phases which are ultimately mixed on agitiation. The two phase system requires the use of an extractant that transfer the metal cations from aqueous medium into an organic phase [7, 8]. The extracting agents used should be capable of satisfying the solvation and coordination preferences of the cationic solute into the organic phase [9]. The extraction efficiency of extractant can be improved by using mixture of two extractants that is called synergistic extraction and is an important type of solvent extraction. It can not only improve the extraction efficiency but also enhance the stability of the extracted complexes in the organic phase [10, 11].

A number of researchers have focused on synergic extraction of rare earth elements by using mixture of different extracting agents such as hydrogen dicarboylcobaltate with dibutyl diethylcarbamoyl methylene phosphonate [12], picrolonic acid with methyl isobutyl ketone [13], nitric acid with 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester [14], thenoyltrifluoroacetone with trioctylphosphine oxide, diphenyl sulphonide and tributylphosphate [15], crown ethers and picrate ions [16], picrolonic acid with tributylphosphineoxide [17], picrolonic acid-trioctylphosphine oxide, triphenylphosphine oxide and and tributylphosphate, [18] picrolonic acid-B15C5 [19], di-n-butylsulfoxide-Cyanex-272 [20], 3-Methyl-1-phenyl-4-trifluoroacetyl-2-pyrazolin-5-one (HPMTFP) and tribenzylamine and 2-thenoyl-trifluoroacetone with tribenzylamine [21, 22]. However, due to some shortcomings, such as co-extraction, poor selectivity and third phase formation there is still a need of more specific extracting agents for the extraction of europium.

The β-diketone compounds has gained much attention for the extraction of metal ions due to their specific properties and structures (the presence of two carbonyl groups separated with one carbon atom). Among β-diketone, 1-phenyl-3-methyl-4 trifluoroacetyl-2-pyrazolin-5-one (HPMTFP) has strong electron with drawing effect of trifluoroacetyl group, and acidic character (pka = 3.12) that can be used as a reagent for the extraction of hydrolysable metals at low pH range [22]. Its behavior towards hard metal ions such as alkaline earth and rare earths is well-known in literature [23, 24].

Among the neutral donors, crown ethers are the best choice for increasing the extraction efficiency of the extracting agents. The binding ability of crown ethers with metals depend on size-matching effect which plays a primary role in complexation They enhance the extraction efficiency due to their cavity and chelating ring size, cycle rigidity and presence of donor atoms which facilitate coordination strength and high degree of metal ion selectivity. [25,26,27].

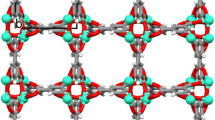

In continuation to our earlier work [10, 11, 13, 17,18,19,20,21,22, 27,28,29], another schematic study consisting of 1-phenyl-3-methyl-4-trifluoroacetyl-2-pyrazolin-5-one (HPMTFP) in dichloromethane (DCM) as single extractant and then with synergic mixture of HPMTFP and crown ethers (B-15C-5, 18-C-6 and 15-C-5) in DCM for the extraction of europium(III) is presented. The optimum conditions for the extraction of europium using synergic mixture of HPMTFP and crown ethers was also studied. The mechanism of extraction and the effect of cations and anions on the extraction of europium was also studied. The chemical structure of HPMTFP and crown ethers is shown in Fig. 1.

2 Material and method

2.1 Reagents and apparatus

HPMTFP was purchased from Tokyo chemical industry, Australia while Crown ethers (Benzo-15-Crown-5, 18-Crown-6 and 15-Crown-5) and dichloromethane (DCM) were procured from E. Merck Germany. Aqueous solutions of different pH, ranging from 1.0 to 3.0 were prepared by mixing required quantities of 0.1 mol dm−3 solutions of NaClO4 and HClO4 and from pH 3 to 5 were prepared by mixing required quantities of 0.1 mol dm−3 solutions of sodium acetate and acetic acid. By using pH meter, the pH of aqueous solutions was checked using model 605, from METROHOM Ltd, Switzerland whenever required. Perchloric acid (HClO4), sodium perchlorate (NaClO4), acetic acid (CH3COOH), and sodium acetate (CH3COONa) of analytical reagent grade were used. Eu2O3 of nuclear grade was procured from Johnson Mathey Chemical Ltd., England, and used as a target material to irradiate in the nuclear reactor to make the radiotracer 154/152Eu (III) [20]. The radiotracer purity was checked by using Canberra multichannel analyzer (4 K series 85) 25 cm3 (Ge) Li detector assembly. NaI (TI) scintillation detector connected with a scintillation counter assembly (Tennelec Inc.) were used to check the radioactivity of different radiotracers of metals. Wrist action electrical shaker from George and Griffin was used for well mixing of solutions.

2.2 Preparation of radiotracers

Known amounts of pure europium oxide of Johnson Mathew Chemical Ltd., England were subjected to thermal neutron irradiation in the research reactor PARR-1 of Pakistan Institute of Nuclear Science and Technology, Islamabad at a thermal neutron flux of 5 × 1013 n cm−2 s−1 for a proper time depending upon the half-life of the required radionuclide. Irradiated material was given enough cooling time to get rid of short lived radioisotopes formed (if any) during the irradiation process. Concentrated nitric acid (5 mL) was used to dissolve the irradiated material. The content was heated to near dryness, and the solution of each radiotracer was prepared by adding known volume of deionized water. The isotopic purity of the radiotracer was checked by a 25 cm3 Ge (Li) detector coupled with a 4 K series 85 Canberra multichannel analyzer. The count rate of the radiotracer was adjusted by proper dilution with the help of a well type NaI (Tl) gamma scintillation detector coupled with counting assembly (Tennelec, Inc., USA).

2.3 Pre-treatment of lake sediments

Standard reference material IAEA-SL-3, Lake sediment sample (1.0 g) was transferred into Teflon beaker, moist with water and added 10 mL of conc. HNO3 and 1–2 mL of hydrofluoric acid. The mixture was evaporated to near dryness and added water. It was again evaporated and sample was subjected to thermal neutron irradiation for proper time depending on the half-life of Eu(III). The europium in the sample was changed to radiotracer. Concentrated nitric acid (5 mL) was used to dissolve the irradiated material. The content was heated to near dryness, and the solution of radiotracer (Europium) was prepared by adding known volume of deionized water. NaI (Tl) gamma scintillation detector was used to determine the count rate of radiotracer.

2.4 Extraction procedure

The experiments were performed by using equal volume of 2 ml of 0.01 mol dm−3 of organic (in case of non-synergic extractant HMTFP in dichloromethane and in case of synergic extractant mixture of HPMTFP and crown ethers in dichloromethane) and aqueous phase adjusted to suitable pH in glass culture vials (16 mm × 120 mm) fitted with screw cap. 50 µl of radiotracer of 152,154Eu was added in each tube. Both phases were mixed by using electrical shaker for five minutes. After that phase separation was carried out by using centrifuge for 3 min. 1 ml of each phase was taken in counting glass vials. The concentration of metal in each phase were detected by Gamma counter. Then distribution coefficient (D) was calculated by dividing net organic phase activity with aqueous phase activity.

At least average of three background reading were taken as background count rate. Distribution ratio ‘D’ was calculated by using the following relation [22].

Then % extraction (% E) is given by following formula

All analysis was performed in triplicate (triplicate) and results are based on average of triplicate measurements.

3 Results and discussion

As a preliminary step, the Eu(III) (5 × 10−5 mol dm−3) extraction was studied from aqueous solution of pH 1.0–4.0 with HPMTFP in dichloromethane (0.01 mol dm−3). Initially extraction started from pH 2.0, which increased with the increase of pH and became quantitative at pH 3.5. After pH 3.5 it remained constant up to pH 4.0. Therefore, pH 3.5 where the extraction was quantitative was selected for further studies, for the extraction of Eu(III) with HPMTFP in dichloromethane.

The equilibration time for the extraction of Eu(III) (5 × 10−5 mol dm−3) with 0.01 mol dm−3 of HPMTFP in dichloromethane was studied from 1.0 to 10 min, so the optimum equilibration time used for extraction of metal ion was 5 min which was used for further study.

The composition of the extracted complex was investigated by slope analysis method. Two kinds of experiments were carried out for this study. First, the effect of variation in the pH of the aqueous phase on the distribution ratio (D) of Eu(III) was studied. This study was used to find out the number of HPMTFP participating as anion (-PMTFP) to satisfy the primary valency of Eu(III). In second experiment, the effect of variation in the amount of HPMTFP on the distribution ratio (D) of Eu(III) at constant pH (3.0) was studied. This experiment was conducted to find out the total number of HPMTFP attached to Eu(III) ions. The detail of these experiments is given below.

In order to find out the total number of HPMTFP molecules that are participating as anions (-PMTFP), the pH of aqueous solution was varied from 2.2 to 3.4 for the extraction of 5 × 10−5 mol dm−3 Eu(III) using 0.01 mol dm−3 of HPMTFP in dichloromethane. Figure 2 represent the plot of log of the distribution ratio (D) versus the pH of the aqueous phase. The slope of the plot of log D vs. pH obtained is 2.86 ± 0.03 (correlation co-efficient R2 = 0.995), which indicates that three conjugate ions of HPMTFP are present in the europium complex to satisfy its primary valency.

To find out the total number of HPMTFP molecules that are attached per extracted adduct, the concentration of HPMTFP in DCM was varied from 0.001 to 0.01 mol dm−3 at pH 3.5 for the extraction of 5 × 10−5 mol dm−3 Eu(III) and the result is shown in Fig. 3. The slope of the plot of log D vs. log [HPMTFP] is found to be 2.91 ± 0.04 (correlation co-efficient R2 = 0.995) indicating that total three molecules of HPMTFP are involved in adduct formation with Eu(III) and none of these is present as neutral donor.

The data from these experiments was used to derive extraction mechanism of Eu(III) with HPMTFP alone as follows,

For which the equilibrium constant Keq is

The distribution ratio “D” is given as,

Here [Eu(PMTFP)3(org) is the concentration of metal ion in organic phase and [Eu]+3 is concentration of europium ion in aqueous phase. By putting the value of “D” from Eq. 5 into 4 we get,

Taking log of above equation,

The value of LogKeq for HPMTFP was calculated using Eq. 7 and found to be − 2.45 as given in Table 2.

In order to check the synergic effect, crown ethers (B15C5, 18C6 and 15C5) were used as neutral donor with HPMTFP for the extraction of Eu(III) ions (5 × 10−5 mol dm−3). In order to know the individual role of crown ethers for the extraction of Eu(III), the extraction of Eu(III) with 0.01 mol dm−3 of B15C5, 18C6 and 15C5 has been studied from aqueous solutions of pH 1.0–3.5. The results showed negligible extraction (< 1%) in this pH range with crown ethers alone. Then synergic extraction of Eu(III) (5 × 10−5 mol dm−3) with equimolar mixture of HPMTFP and different crown ethers (B15C5, 18C6 and 15C5) in dichloromethane (0.01 mol dm−3) was studied from pH 1.0–3.5. The results are shown in Fig. 4. The synergic extraction of Eu(III) with the mixture of HPMTFP and crown ethers (B15C5, 18C6 and 15C5) started from pH 1.5, become quantitative at pH 2.5 (98%), after this pH it remained constant up to pH 3.0.

Synergic coefficient (Dsyn) of HPMTFP with different crown ethers (B15C5, 18C6 and 15C5) was calculated using the following relation as shown in Table 1

where Dmix., DHPMTFP and DCE is the distribution ratios of synergic mixture, HPMTFP and crown ethers respectively.

By comparing the results given in Table 1, it was found that a significant synergism (114.5) was obtained by the mixture of HPMTFP + B15C5 for Eu(III) (5 × 10−5 mol dm−3) extraction from aqueous medium of pH 2.5 compared with the synergic effect of other crown ethers like 18C6 and 15C5. Here the cavity size of the crown ethers with respect to the cation radius is very important. The maximum synergism of B15C5 is due to its cavity size i.e., 0.17–0.22 nm [29] that match with the ionic radius of Eu(III) (0.116 nm) [30] as compared to 15C5 (0.08–0.22) and 18C6 (0.26 nm) [31, 32].

Slope analysis method was used for the determination of the composition of the synergic adduct which is considered to be responsible for Eu(III) (5 × 10−5 mol dm−3) extraction. To evaluate the number of conjugate base of HPMTFP attached with metal ion, the extraction of Eu(III) (5 × 10−5 mol dm−3) was carried out with equimolar mixture (0.01 mol dm−3) of HPMTFP + B15C5, HPMTFP + 18C6 and HPMTFP + 15C5 in DCM separately from aqueous phase having pH 1.0–2.4 and the results are shown in Fig. 5. This plot gives the slopes of 2.83 for HPMTFP + B15C5, 2.89 for HPMTFP + 18C6 and 2.81 for HPMTFP + 15C5 systems. The slope values indicate that three molecules of conjugate base are participating per adduct to neutralize the Eu(III) ion.

In synergic extraction of Eu(III) (5 × 10−5 mol dm−3), concentration of one of parameter either acidic (HPMTFP) or neutral ligand (crown ether) was varied by keeping other parameter constant to see the nature and composition of adduct. For this purpose, the extraction of Eu(III) (5 × 10−5 mol dm−3) was carried out by varying concentration of HPMTFP (0.001–0.01 mol dm−3) with constant concentration of crown ethers (0.01 mol dm−3) at pH 2.5. The graph of log (D) vs. log [HPMTFP] was plotted and the result are shown in Fig. 6 . The slope of plot of log (D) vs. log [HPMTFP] obtained is 2.8 for B15C5 (0.01 mol dm−3), 3.06 for 18C6 (0.01 mol dm−3) and 2.91 for 15C5 (0.01 mol dm−3) with correlation coefficient of 0.996, 0.995 and 0.997 respectively. Slope value showed that three molecules of HPMTFP were attached with metal ion per extracted adduct and no one is coordinated as neutral donor.

The effect of crown ethers concentration on the extraction of Eu(III) (5 × 10−5 mol dm−3) was evaluated by varying the concentration of crown ethers from 0.001 to 0.01 mol dm−3 at pH 2.5 and keeping the concentration of HPMTFP (0.01 mol dm−3) constant. (figure 7). The linear lines with the values of 2.13 for B15C5, 1.83 for 18C6 and 2.02 for 15C5 with the correlation coefficient of 0.995 and 0.996 and 0.994 respectively were obtained. The slope value indicated that two molecules of B15C5, 18C6 and 15C5 are present per synergic adduct, responsible for the extraction of Eu(III) ions into organic phase.

The mechanism of synergic extraction of Eu(lll) by using synergic mixtures of HPMTFP and CE can be written as:

The equilibrium constant for the synergic mixture is given by;

The distribution ratio ‘D’ for the above reaction mixture is given by

Putting the value of ‘D’ from Eq. 10 in Eq. 9

Taking log on both sides, we get

By using equation ‘12’ the values of ‘Log Kmix’ for Eu(PMTFP)3·2 B15C5, Eu(PMTFP)3·2 18C6 and Eu(PMTFP)3·2 15C5 were calculated and given in Table 2.

The formation constant (Kf) of the mixture is given by;

Taking log on both sides,

The formation constant (log Kf) can be calculated for different synergic mixtures which is found to be 7.06 for mixture of HPMTFP + B15C5, 6.62 for HPMTFP + 18C6 and 6.44 for HPMTFP + 15C5 as shown in Table 2.

The formation of synergic adduct formed by metal and –PMTFP is in the form of Eu(PMTFP)3·2CE where-PMTFP act as acidic ligand and CE = crown ethers act as neutral donor. Similar type of synergic adducts by using various lanthanides and actinides were already reported in the literature [29]. The acidic ligand HPMTFP form aquo complex with Eu(III), so the extraction coefficient is very low and the lowering of this extraction coefficient is due to the presence of water molecules the complex showed great solubility in water than in non- polar solvent. The formation of such kind of aqua complexes for the rare earth metals is also cited in the literature [18]. Addition of crown ethers replace water molecules from aquo complex in a stepwise manner that increase the extraction of adduct in the organic phase. So synergism increases due to the replacement of water molecule by crown ethers. One more possibility is that expansion of coordination number of europium takes place in synergic adduct. The coordination number of europium is 6 in + 3 oxidation state, as strong ligand approaches the metal ions, the unpaired electron paired which in turn increase the coordination number of europium from 6 to 8. The synergic adduct Eu(PMTFP)3. 2CE justifies the 8 co-ordination number of europium where each –PMTFP act as bidentate ligand and CE = crown ethers act as monodentate ligand. The expansion of the co-ordination number of rare earth elements on the addition of neutral donors is already reported in the literature [29]. The proposed structure of the complex is shown in Fig. 8.

The equilibrium constant or formation constant (log Kf) was calculated for HPMTFP and crown ethers is in the order B15C5 > 18C6 > 15C5 i.e., 7.06 > 6.62 > 6.44 (Table 2) for Eu(III). The equilibrium constants obtained is actually the concentration quotients calculated assuming that the activity coefficients of the species involved does not show any significant variations under the experimental conditions. By comparing with some of previously developed method we have seen that the extraction effieciency of Eu(III) by using HPMTFP and crown ethers especially with B15C5 is quite higher (Table 3).

The loading capacity of extractant systems (0.01 mol dm−3 of synergic systems i.e. HPMTFP + B15C5, HPMTFP + 18C6 and HPMTFP + 15C5 in DCM) was studied by changing the concentration of Eu(III) from 10 to 300 mgL−1 at pH 2.5. It is clear from the result that % extraction f Eu(III) decreased with increase in metal concentration for all the extractant systems studied here. The decrease in extraction at high metal concentration might be due to saturation of extractant systems with metal ions. This indicates that at high concentration the extraction of metal ion can be improved by increasing the concentration of extractant systems.

The effect of various cations (added as nitrate and chloride salt) and anions (added ad sodium or potassium salt) on the extractability of Eu(III) ions (5 × 10−5 mol dm−3) was studied by adding many fold higher concentration of cations and anions than Eu(III). A given species was considered to interfere if it resulted in a ± 5% variation in the absorbance signal [33]. In this case the constant concentration of 0.01 mol dm−3 of HPMTFP and synergic mixtures i.e. HPMTFP + B15C5, HPMTFP + 15C5 and HPMTFP + 18C6 mixture in DCM was used. The results are shown in Tables 4 and 5. Among the cations, Mn2+ interfered in the extraction of Eu(III) by using HPMTFP alone and its extraction was improved by using all the three synergic mixtures i.e., HPMTFP-B15C5, HPMTFP-18C6 and HPMTFP-15C5. Cd2+ has reduced the extraction of Eu(III) to 82.5%, 83.6% and 89% by using HPMTFP, HPMTFP-15C5 and HPMTFP-18C6 mixture respectively. Fe2+ reduced the extraction of of Eu(III) to 83% by using HPMTPF and its interference was reduced by extracting Eu+2 using a mixture of HPMTFP and 15C5. Fe3+ also interfered in the extraction of Eu(III) and its extraction is improved by using synergic mixture of HPMTFP-B15C5. The other studied cations did not show any significant effect on the extraction of Eu(III). The data showed that the interference of many of the interfering cations can be minimized by using synergic mixture of HPMTPF + B15C5. This might be due to higher formation constant of Eu(III) with HMPTPF-B15C5.

The results for the extraction behavior of Eu(III) (5 × 10−5 mol dm−3) from aqueous phase containing added anions indicated that fluoride has reduced the extraction of Eu(III) to 89.7% and ascorbate to 88.3% by using HPMTFP alone while HPMTFP-B15C5 mixture increased the extraction of Eu(III) to 88.5% and ascorbate to 89.3%. There is the possibility that these anions might form the chelates with the metal ion under investigation and interfered in its extraction in organic phase. The rest of the anions have no worse effect on the extraction of the Eu(III).

To study the recovery, the Eu(III) from organic phase back stripping process was done to make organic phase reusable. NH4OH (0.1 mol dm−3), deionized water and HNO3 (0.1 mol dm−3) solution was used as strippants for back stripping of Eu(III) from the organic phases (HPMTFP + B15C5, HPMTFP + 18C6 and HPMTFP + 15C5) loaded with Eu(III). By using equal portions of fresh strippants and mixing well with organic phase loaded with Eu(III), the back stripping process was done thrice. During shaking, Eu(III) migrate from organic phase to the stripping agent. After three successive cycles loaded strippant were collected together and amount of Eu(III) was detected radiometrically. Among tested strippant ammonium hydroxide give 97% recovery of Eu(III) from HPMTFP-B15C5, 92% from HPMTFP-18C6 and 93% from HPMTFP-15C5 in three successive steps. Although ammonium hydroxide solution gave best results but it was not selected because of hydrolysis of metal ion in ammonium hydroxide solution. The recovery of Eu(III) with distilled water was found to be 96.0% from HPMTFP-B15C5, 91.0% from HPMTFP-18C6 and 94.0% from HPMTFP-15C5 in three successive steps. HNO3 (0.1 mol dm−3) was found to be poor strippant as it gave less than 80% removal of Eu(III) from all synergic extractants. Due to economical suitability, deionized water was finally selected as stripping agent.

The ability of synergic mixtures (HPMTFP + B15C5, HPMTFP + 18C6 and HPMTFP + 15C5) in dichloromethane to be recycled for the extraction of Eu(III) was studied (Table 6). The process was repeated four times. The extraction efficiency of the extractants has been checked and found to be almost same after four cycles without any significant deterioration.

Method precision was evaluated by the repeatability and reproducibility assays and expressed by the % relative standard deviation (% RSDs). The repeatability of method was studied at consecutive seven days interval while the reproducibility of the method was tested between three analysts for three different concentration levels of Eu(III) i.e., 5, 10 and 15 mg L−1. The precision of the method was found to be < 7% and varied between 1.5 and 6.7%.

In order to check the accuracy of the method it was applied on real lake sample (IAEA-SL-3) and concentration of Eu(III) was determined using the proposed method using mixture of HPMTFP and crown ethers (B15C5) as extractants. The result for the europium content in the IAEA SL-3 is in good agreement with the reported value. These results showed that the developed method can be applied to samples having complex matrix for the accurate determination of Eu(III) (Table 7).

4 Conclusions

The present experimental investigations were developed for the extraction of Eu(III) by using HPMTFP as single extractant and synergic mixture of HPMTFP and Crown ethers (B15C5, 15C5, 18C6). From experimental data it was revealed that by using HPMTFP alone, the maximum extraction of Eu(III) was found at pH 3.5 and composition of the adduct was found to be [Eu(PMTFP)3]. While maximum extraction of Eu(III) were found by using synergic mixture of HPMTFP and crown ethers (B15C5, 15C5, 18C6) at pH 2.5 with the composition of synergic adduct Eu(PMTFP)3·2CE. Among crown ethers maximum synergism was shown by HPMTFP + B15C5 mixture due to matching of its cavity size with the ionic radii of Eu(III) ion. The value of K of synergic mixture (logKmix) was found much higher as compared to single extractant (logKPMTFP) Selective extraction of Eu(III) was found in the presence of various masking agents like citrate, oxalate, bromide, thiosulphate, chromate ions and of some cations. Among strippants, H2O was found excellent solvent for back extraction of Eu(III) from synergic mixtures. The results also indicated that synergic mixtures can be recycled many time without any deterioration. Method precision was also evaluated and found to be < 7%. The method was applied successfully for the extraction of Eu(III) from standard reference material IAEA SL-3.

References

Shahida S, Ali A (2014) Determination of europium (III) in environmental samples using a flow injection analysis system with on-line preconcentration and spectrophotometric detection. J Radioanal Nucl Chem 300(1):423–429. https://doi.org/10.1007/s10967-014-2959-7

Jelinek L, Wei Y, Arai T, Kumagai M (2007) Selective Eu(III) electro-reduction and subsequent separation of Eu(II) from rare earths(III) via HDEHP impregnated resin. Solvent Extr Ion Exch 25:503–513. https://doi.org/10.1080/07366290701415911

Rabie KA, Sayed SA, Lasheen TA, Salama IE (2007) Europium separation from a middle rare earth concentrate derived from Egyptian black sand monazite. Hydrometallurgy 86:121–130. https://doi.org/10.1016/j.hydromet.2006.10.007

Morais CA, Ciminelli VST (1998) Recovery of europium from a rare earth chloride solution. Hydrometallurgy 49:167–177. https://doi.org/10.1016/S0304-386X(98)00022-X

Song X, Chang M, Pecht M (2013) Rare-earth elements in lighting and optical applications and their recycling. J Miner Met Mater Soc 65(10):1276–1282. https://doi.org/10.1007/s11837-013-0737-6

Bunzli JC (2010) Europium in the limelight. Nat Chem 2:696–697. https://doi.org/10.1038/nchem.760

Sorouraddin SM, Farajzadeh MA, Hassanyani A, Mogaddam MRA (2016) Combination of homogenous liquid–liquid extraction and dispersive liquid–liquid microextraction for extraction and preconcentration of amantadine from biological samples followed by its indirect determination by flame atomic absorption spectrometry. RSC Adv 6:108603–108610. https://doi.org/10.1039/c6ra16572a

Rydberg J, Cox M, Musikas C, Choppin G, Marcel D (2004) Solvent extraction principles and practice, revised and expanded. New York. https://doi.org/10.1201/9780203021460

Xie F, Zhamg T, Dreisinger D, Doyle F (2014) A critical review on solvent extraction of rare earths from aqueous solutions. Miner Eng 56:10–28. https://doi.org/10.1016/j.mineng.2013.10.021

Abbasi YA, Shahida S, Ali A, Khan MH, Khan MI (2019) Liquid–liquid extraction of neodymium (III) and europium (III) using synergic mixture of furosemide and tribenzylamine in benzyl alcohol. J Radioanal Nucl Chem 320:273–282. https://doi.org/10.1007/s10967-019-06467-z

Shahida S, Yasir AA, Imran M, Shah KH, Farooq U, Hafeez M, Ali A (2020) Synergistic extraction of Eu(III) and Nd(III) from aqueous medium using a mixture of sulfasalazine and 1,10-phenanthroline. J Radioanal Nucl Chem 324:1215–1223. https://doi.org/10.1007/s10967-020-07171-z

Makrlík E, Vaňura P, Selucký P (2008) Extraction of microamounts of europium and americium by using hydrogen dicarbollylcobaltate in the presence of dibutyl diethylcarbamoylmethylene phosphonate. J Radioanal Nucl Chem 275:309–312. https://doi.org/10.1007/s10967-007-7058-6

Ali A (2004) Extraction of Eu(III) and Tm(III) with picrolonic acid in methylisobutylketone. Radiochim Acta 92:101–104. https://doi.org/10.1524/ract.92.2.101.27462

Fu N, Tanaka M (2006) Modeling of the equilibria of yttrium(III) and europium(III) solvent extraction from nitric acid with PC-88A. Mater Trans 47:136–142. https://doi.org/10.2320/matertrans.47.136

Mathur JN, Pai SA, Khopkar PK (1977) Thermodynamics of synergistic extraction of europium (III) by mixtures of thenoyltrifluoroacetone and some neutral oxo-donors. J Inorg Nucl Chem 39:653–657. https://doi.org/10.1016/0022-1902(77)80582-4

Yuko H, Sakiko H (1984) Solvent Extraction of europium(III) with crown ethers and picrate ions. Solv Extr Ion Exch 2:451–458. https://doi.org/10.1080/07366298408918458

Ali A (2004) Synergistic extraction of Ce(III), Eu(III) and Tm(III) with a mixture of picrolonic acid and tributylphosphine oxide in chloroform. Radiochim Acta 92:925–929. https://doi.org/10.1524/ract.92.12.925.55102

Rehman H (2015) Synergistic extraction of Eu(III) with mixture of picrolonic acid and neutral organophosphorous extractants. J Radional Nucl Chem 303:139–145. https://doi.org/10.1007/s10967-014-3440-3

Ali A, Jamil Y Wasim (2006) Synergistic extraction of Ce(III), Eu(III) and Tm(III) with a mixture of picrolonic acid and benzo-15-crown-5 in chloroform. J Radional Nucl Chem 267:421–425. https://doi.org/10.1007/s10967-006-0065-1

Farzana A, Muhammad HK, Muhammad AM, Muhammad AC, Robert JB (2015) Synergic extraction of europium(III) with 1 M mixture of di-n-butylsulfoxide and bis(2,4,4-trimethylpentyl) phosphinic acid in chloroform and its subsequent determination by using arsenazo(III) as chromogenic reagent. Asian J Chem 27:3609–3615. https://doi.org/10.14233/ajchem.2015.18887

Saeed MM, Qayyum MA, Ali A (1997) Synergic extraction of Eu(III) with 3-Methyl-1-phenyl-4-trifluoroacetyl-2-pyrazolin-5-one (HPMTFP) and tribenzylamine (TBA) from perchlorate media. Radiochim Acta 76:205. https://doi.org/10.1524/ract.1997.76.4.205

Mufazzal SM, Ali A, Ahmed M, Cheema M, Qureshi I (1989) Synergic extraction of Eu(III) and Tb(III) by 2-thenoyltrifluoroacetone and tribenzylamine. J Radional Nucl Chem 131:149–159. https://doi.org/10.1007/BF02046619

Shigeo U, Freiser H (1987) Mixed-ligand chelate extraction of lanthanides with 1-phenyl-3-methyl-4- (trifluoroacetyl)-5-pyrazolone and some phosphine oxide compounds. Inorg Chem 26:3179–3181. https://doi.org/10.1021/ic00266a023

Mathur JN, Khopkar PK (1987) Liquid-liquid extraction of trivalent actinides and lanthanides with 1-phenyl-3-methyl-4- trifluoroacetyl pyrazolone-5. Polyhedron 6:2099–2102. https://doi.org/10.1016/S0277-5387(00)84271-0

De S, Boda A, Ali SM (2010) Preferential interaction of charged alkali metal ions (guest) within a narrow cavity of cyclic crown ethers (neutral host): a quantum chemical investigation. J Mol Struct Theochem 941:90–101. https://doi.org/10.1016/j.theochem.2009.11.009

Hamada T, Manabe K, Ishikawa S, Nagayama S, Shiro M, Kobayashi S (2003) Catalytic asymmetric aldol reactions in qqueous media using chiral bis-pyridino-18-crown-6-rare earth metal triflate complexes. J Am Chem Soc 125:2989–2996. https://doi.org/10.1021/ja028698z

Khan MH, Shahida S, Ali A (2008) Liquid-liquid extraction of uranium from nitric acid solution using di-n-butylsulfoxide in petroleum ether as extractant. Radiochim Acta 96:35–40. https://doi.org/10.1524/ract.2008.1458

Yasar AA, Shahida S, Ali A, Khan MH (2019) Liquid–liquid extraction of Hg(II) using furosemide in benzylalcohol. J Radioanal Nucl Chem 319:1029–1036. https://doi.org/10.1007/s10967-018-6400-5

Rahman H, Ali A, Anwar J, Yawar W (2006) Synergic extraction of rare earth elements using picrolonic and other neutral oxo-donors. J Radioanal Nucl Chem 267(1):421–425. https://doi.org/10.1007/s10967-006-0065-1

Maria A, Kurteva V (2016) Synergism as a phenomenon in solvent extraction of 4f-elements with calixarenes. RSC Adv 6(14):11303–11324. https://doi.org/10.1039/C5RA22306G

Sahu SK, Tumkur R (2000) The synergistic extraction of thorium(IV) and uranium(VI) with mixtures of 3phenyl-4-benzoyl-5-isoxazoloneand crown. Talanta 51:523–530. https://doi.org/10.1016/s0039-9140(99)00312-4

Hasegawa Y, Haruna S (2010) Solvent extraction of Eu(III) with crown ethers and picrate ion. Solv Extr Ion Exch 2(3):451–458. https://doi.org/10.1080/07366298408918458

Saeed MS, Farajzadeh MA, Saeed N, AfsharMogaddam MR (2017) Air-assisted liquid liquid microextraction combined with graphite furnace atomic absorption spectrometry for preconcentration and determination of trace amount of Co(II) and Ni(II) ions in water samples. Anal Bioanal Chem Res 4:227–238. https://doi.org/10.22036/abcr.2017.58497.1109

Acknowledgements

We are thankful to Director General PINSTECH for providing financial support for this research project. We are grateful to the Reactor Operation Group (ROG) of PINSTECH Islamabad, Pakistan for irradiating the target samples in the research reactor for the production of radionuclides used in this study. We are also grateful to chemistry division, PINSTECH for providing the lab facility to conduct the experimental work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghani, L., Shahida, S., Ali, A. et al. Liquid–liquid extraction of Eu(lll) using synergic mixture of 1-phenyl-3-methyl-4-trifluoroacetyl-2-pyrazolin-5-one and crown ethers. SN Appl. Sci. 2, 1541 (2020). https://doi.org/10.1007/s42452-020-03337-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03337-2