Abstract

The gum exudate from Terminalia Mentaly (GETM) was investigated for corrosion inhibition of N80 carbon steel in 1 M HCl solution using electrochemical and gravimetric measurements. GETM was found to be a good inhibitor for N80 steel corrosion in the 1 M HCl stimulated acidizing solution, affecting both cathodic and anodic reactions. The inhibition efficiency of GETM increased as the concentration increases but decreased with rise in temperature. Maximum inhibition efficiencies of 92.4%, 95.5% and 92.5% were obtained from electrochemical ımpedance spectroscopy (EIS), gravimetric and potentiodynamic polarization studies respectively, at 2.0 g/L GETM in 1 M HCl. Adsorption of GETM at the studied temperatures was found to follow Langmuir and Temkin isotherms and the action of inhibition suggests both physical and chemical adsorption on the metal surface. It was found from polarization study that GETM is a mixed type inhibitor but slightly acted more like an anodic inhibitor. EIS studies revealed that GETM increased the charge transfer resistance while diminishing the double layer capacitance with increasing concentration due to the formation of protective film on the steel. Surface morphological study performed using scanning electron microscopy (SEM) confirmed the formation of protective film of GETM on the N80 steel surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Hydrochloric acid stimulated acidizing solution is mainly used in the oil and gas industries during acid treatment to improve the productivity of oil wells. Acidizing have been in existence for over 100 years and predates every other technique of well stimulation including hydraulic fracturing. However, lack of efficient acid corrosion inhibitors to ensure the protection of pipeline steels in the wells limited the use of acidizing up until the early 1930′s.[1]. Having developed effective inhibitors for acid corrosion, acidizing of oil wells proliferated, leading to establishment of the well stimulation service industry. It is widely known today, that acidizing also known as acid treatment is one of the most effective means for improving stimulation (productivity) of wells in the oil and gas industry [2].

Several researches have been carried out on the application of various inorganic and organic compounds as corrosion inhibitors for metals in acidic medium. Most of the effective inhibitors have been those containing heteroatoms and multiple bonds in their molecular structure by which they get adsorbed on the metallic surface to prevent the dissolution of metals in the corrosive medium [3,4,5,6]. Though most synthesized compounds possesses good anti-corrosive potentials, majority of them are not safe in the environment and to human beings. Some of the known eco-friendly corrosion inhibitors include plant-based natural products [7, 8] and some nontoxic synthesized compounds such as, Schiff bases [9, 10], medicines [11, 12] and dyes [13, 14], which have been classified as green inhibitors. There has been increased interest on the use of natural substances as inhibitors of metal corrosion because apart from being ecologically friendly, they are readily available and cheap. Moreover, they are organic in nature with constituents including alkaloids, pigments, organic and amino acids and tannins which are known to exhibit inhibitive properties. Recent reports have shown that gum exudates from different plant such as Moringa Oleifera [15], Acacia Senegal [16], Acacia drepanolobium [16], Gum Arabic [17] Azadirachta indica [18], Raphia hookeri [19] Albizia ferruginea [20], Khaya senegalensis [20], Dorema ammoniacum [21] Ferula asafoetida [21], Guar Gum [22] etc. are efficient corrosion inhibitors being eco-friendly, green and less toxic.

The present work aims to contribute to the search for eco-friendly and affordable corrosion inhibitors as a replacement for the toxic and expensive inorganic and some organic inhibitors. This study on the corrosion inhibition of N80 carbon steel in 1 M HCl stimulated acidizing solution using gum exudate from Terminalia Mentaly, which has not been previously investigated, was carried out using different techniques like Electrochemical ımpedance spectroscopy (EIS), gravimetric and potentiodynamic polarization (PDP). Scanning Electron Microscopy (SEM) measurements were used to study the surface morphologies.

2 Experimental

2.1 Material preparation

The N80 steel plates utilized for all tests were sourced from an oil field in Nigeria. The plates with thickness 2 mm and composition as described previously [23] were cut into coupons of dimensions 30 × 20 mm for gravimetric and surface morphological studies, and 25 × 10 mm for electrochemical tests. Prior to the measurements, the N80 steel samples were polished using various grades (# 400–1000) of silicon carbide paper, washed with double distilled water, rinsed and degreased in ethyl alcohol and acetone respectively then finally air-dried and stored in a desiccator. The N80 steel samples used for electrochemical studies were encapsulated in epoxy resin with an exposed surface area of 1 cm2. 1 M HCl solution prepared with AR grade 37% HCl in double distilled water was used as the corrosive medium.

The Terminalia Mentaly (TM) gum exudate was collected from its parent tree at the University of Port Harcourt Nigeria and authenticated by Plant Science Department of same University. Weighed amount of the dry gum was thoroughly washed with distilled water to remove dust and sand impurities, and soaked for two days in 100 mL of 1 M HCl solution. The GETM which was soluble in the acid solution (solubility = 53% v/v) was used for the corrosion studies after preparation at concentration range from 0.1 g/L to 2.0 g/L.

2.2 Electrochemical measurements

The EIS and PDP tests were performed by employing a CHI model of electrochemical workstation (CHI-760) utilizing electrochemical cell assembly consisting of three electrodes. In the cell, N80 steel was the working electrode, the reference electrode was saturated calomel electrode (SCE) and Platinum foil was the counter electrode. Gamry E-Chem software was used to analyze the data. The electrochemical measurements were conducted in aerated, non-stirred 1 M HCl solutions containing different concentrations of GETM. Each experiment was run in triplicate to check reproducibility and average values of the electrochemical data recorded. All tests were performed in a solution temperature of 303 K. Before performing each test, the N80 steel was submerged in the corrosive medium for 30 min to attain steady open circuit potential (OCP). EIS measurements employed an AC signal with 10 mV peak to peak amplitude within the frequency range 100–0.01 Hz. PDP curves were obtained at a scan rate of 1 mV/s, at − 250 to + 250 mV against SCE with respect to EOCP.

2.3 Gravimetric measurement

The N80 steel samples previously weighed and recorded were immersed in 250 mL of 1 M HCl without and with various concentrations of GETM at 303 K. Each specimen was removed from the various test solution after an exposure period of 5 h, scrubbed with bristle brush under running water, rinsed in acetone, dried and reweighed [24]. The difference in weight of the N80 steel before and after immersion in the test solutions was recorded as the weight loss. The same test as described above which was carried out three times was also performed at 313, 323 and 333 K. The weight loss data measured in mg was utilized to evaluate the corrosion rate (CR), deploying the following equation:

where W is weight loss in mg, A is the area of N80 steel specimen in cm2 and t is exposure time in h. The surface coverage (θ) and inhibition efficiency (IWL %) of GETM were determined using the corrosion rate values as follows:

where \(C_{R}^{o}\) and \(C_{R}^{i}\) are corrosion rates in blank and inhibited acid solutions.

2.4 SEM analyses

The surface morphologies of the N80 steel without and with 2.0 g L−1 GETM was assessed utilizing a JEOL 5300 model of scanning electron microscope while applying a voltage of about 15 kV and 1000 × magnification. The pre-treated steel specimens were immersed in the various test solutions for 4 h and thereafter retrieved at the expiration of the stipulated time, cleaned and subsequently scanned.

3 Results and discussion

3.1 Electrochemical impedance spectroscopy (EIS)

EIS spectra help in the proof of protective film formation on metal surfaces. Figure 1 presents the Nyquist plots obtained at OCP for N80 steel without and with GETM inhibitor in 1 M HCl solution at 303 K. The Nyquist plots have a single depressed semi-circular loop over the entire frequency range, which indicates that N80 steel electrode dissolution in the aggressive acid is controlled by charge-transfer process which functions on the magnitude of change of the double layer capacitance [4, 25, 26]. The size of the semicircle increases with increase in GETM concentration. However, the impedance spectra are not perfect semicircles, which could be attributed to frequency dispersion effect resulting from inhomogeneity of the electrode surface [27, 28]. The impedance data were analyzed by utilizing the equivalent circuit shown in Fig. 2. The circuit consists of the electrolyte or solution resistance \((R_{s} )\), charge transfer resistance \((R_{ct} )\) in parallel combination with constant phase element (CPE) standing in for the capacitor. The validity of the equivalent circuit was ascertained from the χ2 values presented in Table 1. The magnitude of CPE \(\mathop Y\limits^{\prime }_{o}\) is related to the impedance (ZCPE) by the equation:

where ω is the angular frequency \((\omega=2\pi {f_{max}})\), at which the imaginary part of the impedance \(( - Z_{im} )\) is maximum, \(f_{max}\) is maximum AC frequency, \(j^{2} = \sqrt {( - 1)}\) is the imaginary unit and n is the exponent (phase shift), associated with the heterogeneity or roughness of the metal surface [29]. With \(n = - 1, 0\) or close to 1, the CPE represents an inductance, a resistance or a capacitor respectively. Still, for a Warburg impedance, n = 0.5. In this study, the values of n are close to 1 for both uninhibited and inhibited environment suggesting that the CPE represents a capacitor [30, 31]. These values of n indicate that the molecules of GETM adsorbed as pseudo-capacitive protective films on the N80 steel surface [3]. Double layer capacitance \(\left( {C_{dl} } \right)\) values were evaluated utilizing the following equation [32]:

The inhibition efficiency (IEIS %) calculated from Rct values is expressed by the relation [33]:

where, \(R_{ct}^{i}\) and \(R_{ct}^{o}\) stand for charge transfer resistance with and without inhibitors. The derived and calculated EIS parameters are presented in Table 1.

The obtained results showed increased \(R_{ct}\) values and a decrease in \(C_{dl}\) values for N80 steel in 1 M HCl solution with GETM compared to the bare electrolyte (1 M HCl) without GETM. The \(R_{ct}\) and \(C_{dl}\) continually increased and decreases respectively as the inhibitor concentration increases, which eventually leads to an increase in IEIS %. The observed increase in \(R_{ct}\) values with inhibitor addition indicates protective thin layer formation on the N80 steel surface as a result of adsorption of GETM molecules. Again, decrease in the values of \(C_{dl}\) could be due the lowering of the local dielectric constant, or maybe increased electrical double layer thickness, indicating that GETM molecules function by adsorption at the metal/solution interface [34, 35].

3.2 Potentiodynamic polarization

The kinetics of the reactions taking place at the cathodic and anodic sites of the corrosion cell is understood by carrying out polarization experiments. Figure 3 presents the Tafel polarization curves for N80 steel in 1 M HCl solution with and without various concentrations of GETM at 303 K. The current–potential curves in Fig. 3 show that the anodic and cathodic segments were shifted towards lower region of the corrosion current density upon adding GETM inhibitor as compared to the bare 1 M HCl. The kinetic parameters derived from the curves by extrapolation of the Tafel lines, including corrosion current density \(i_{corr}\), cathodic and anodic Tafel slops (βc, βa), corrosion potential \(E_{corr}\) and inhibition efficiency (IPDP %) are listed in Table 2. The IPDP % values were calculated using Eq. 6 [33]:

where, \(i_{corr}\) and \(i^{o}_{corr}\) refers to the corrosion current density with and without inhibitors.

It is seen from Fig. 3 that the introduction of GETM affected both the anodic and cathodic arms of the Tafel plot suggesting that it acted as a mixed type inhibitor. However the anodic partial reaction is more affected than the cathodic as also observed from the higher values of βa compared to βc, indicating that GETM slightly acted more like an anodic inhibitor. The \(i_{corr}\) values are observed to have decreased with increase in the inhibitor concentration with the least value obtained at the optimum concentration (2.0 g L−1), because of protective film formation on the N80 steel surface by adsorption [36]. Table 2 also reveals that the \(E_{corr}\) shifted to a more noble positive value upon addition of GETM compared to the blank. Nevertheless, the maximum shift in \(E_{corr}\) value between the uninhibited and inhibited system is less than 85 mV, supporting that GETM acted as a mixed-type inhibitor [37, 38]. The IPDP % values increased with increase in GETM concentration in agreement with EIS result.

3.3 Gravimetric measurement

Figure 4a-b shows the variation of corrosion rate (CR) and corrosion inhibition efficiency (IWL %) of GETM with its concentrations. Figure 4a shows that the introduction of GETM diminished the corrosion rate at different temperatures and the CR continually decreased as the inhibitor concentration increases. The IWL % on the other hand, increased with increase in inhibitor concentration (Fig. 4b), indicating that the adsorption and surface protective ability of GETM is strengthened with its concentration thus separating the N80 steel surface from the aggressive solution by thin layer formation on the metal surface [39, 40]. In addition, the corrosion inhibition performance of GETM has been compared with those of gum exudates from different plants reported in literature as shown in Table 3.

3.4 Adsorption studies

The mechanism of interaction between the N80 steel (adsorbent) and the adsorbate (GETM inhibitor) can be better explained using the adsorption isotherms. Surface coverage (\(\theta\)) values at various GETM concentrations in 1 M HCl in the temperature range (303–333 K) was fitted with different adsorption isotherms such as, Temkin, Langmuir, Freundlich, El-Awady, Frumkin and Flory–Huggins [41]. The Langmuir adsorption isotherm was the best fit, expressed as:

where \(C_{inh}\) represent inhibitor concentration and \({K}_{ads}\) the equilibrium constant of adsorption–desorption process. Figure 5 presents linear plots of \(C_{inh} /{\uptheta }\) against \(C_{inh}\) at all studied temperatures, by which the \(K_{ads}\) values were deduced from the intercept of the plots. The obtained results reveal that all the linear regression coefficients (R2) and the slope are close to unity (Table 4), indicating that GETM adsorption on N80 steel surface follows Langmuir adsorption isotherm [42]. The slope values as seen in Table 4 show that the deviation from ideal Langmuir isotherm is not very pronounced. The slope of an ideal Langmuir isotherm should be equal to unity, which means absence of interaction between the adsorbed species. When the slope values are less or greater than unity, it indicates that there is interaction among the adsorbed species on the surface of the metal [43]. Temkin isotherm was therefore considered because the model considers lateral interaction. The Temkin model can be expressed as follows:

Figure 6 presents linear plots of \({\uptheta }\) against \(\log C_{inh}\) with slope equal to \(- 2.303/2{\text{a}}\) and intercept equal to \(\left( { - \frac{2.303}{{2{\text{a}}}}} \right)\log K_{ads}\). The Temkin adsorption parameters are also presented in Table 4. The observed relatively high linear regression coefficients (R2) confirm the applicability of the Temkin model to the adsorption of GETM on N80 carbon steel surface. The negative values of the interaction parameter (a) indicate that repulsion exists in the adsorption layer [44]. The fit of the experimental data to the Langmuir and Temkin isotherms indicates that GETM inhibit N80 steel corrosion by adsorption on the metal surface. The additives could be adsorbed by the interaction between the free electron of the heteroatoms on the GETM moiety and steel surface (chemisorption). The adsorption standard Gibb’s free energy \(\Delta G_{ads}^{o}\) was deduced from its relationship with \(K_{ads}\) expressed as [45]:

where \(1 \times {10}^{3}\) is the concentration of water molecules expressed in g L−1, R and T represents gas constant and absolute temperature, respectively. It is well known that high \(K_{ads}\) value and a low \(\Delta G_{ads}^{o}\) value automatically results to a high metal-inhibitor interaction. \(K_{ads}\) values as presented in Table 4 are fairly high enough which is the reason for a strong interactions between the inhibitor and the N80 steel [46]. The values of \(\Delta G_{ads}^{o}\) listed in Table 4 are seen to be negative in all the cases, indicating the spontaneity of GETM adsorption on the steel surface and the stability of the protective layer on the N80 steel. The free energy of adsorption \(\left( {\Delta G_{ads}^{o} } \right)\) values obtained using the Langmuir isotherm ranged from − 21.87 to − 22.84 kJ/mol and for Temkin isotherm, from − 35.10 to − 36.03 kJ/mol. These values of \(\neg \Delta G_{ads}^{o}\) indicate complex mode of interactions, which involve both chemisorption and physisorption mechanisms between N80 steel and the gum exudate [47].

3.5 Effect of temperature

The influence of temperature on the stability of protective film of GETM on N80 steel surface likewise temperature effect on the CR and IWL % was evaluated by gravimetric measurements at temperature range 303–333 K without and with various concentrations of GETM in 1 M HCl. Figure 4a and b clearly show that increase in temperature augments the CR but diminished the inhibition efficiency [48]. The values of CR were used to deduce the apparent activation energy \({E}_{a}\) according to the Arrhenius equation [31]:

where Å, T and R represent the pre-exponential factor, absolute temperature and gas constant, respectively. Figure 7a presents linear regression between log CR and 1/T, through which \({E}_{a}\) was calculated from the slope \(( - E_{a} /2.303R)\) of the graph and listed in Table 5. Other thermodynamic parameters such as enthalpy of activation (ΔH*) and entropy of activation (ΔS*) were evaluated by utilizing the transition state equation given as:

where N and h are Avogadro's number and Planck constant, respectively. Linear plots of log (CR/T) vs. 1/T obtained is depicted in Fig. 7b, through which ΔH* values were calculated from the slope \(( - \Delta H^{*} /2.303R)\) and ΔS* from the intercept \([{\log}(R/Nh) + \Delta S^{*} /2.303R]\) and also presented in Table 5. The result in Table 5 shows that \(E_{a}\) values for the solution with GETM are higher than that without the inhibitor, which suggests that more energy barrier is needed for the corrosion reaction to take place [49]. Generally, values of \(E_{a}\) between 20 and 40 kJ mol−1 suggest physisorption mechanism while \({E}_{a}\) values between 80–240 kJ mol−1 suggest chemisorption. In this study, the value ranges between 48.29 and 64.54 kJ mol−1 which suggests that the adsorption of GETM involves both physical and chemical adsorption. The positive values of ΔH* in both systems, show the endothermic nature of N80 steel dissolution. The negative high values of ΔS* suggests that the activated complex in the rate ascertaining step representing dissociation with a more ordered platform on going from reactants to the activated complex [50].

3.6 SEM studies

SEM micrographs of N80 steel prior and after immersion in 1 M HCl without and with optimum concentration (2.0 g L−1) of GETM at 303 K for 4 h are shown in Fig. 8 (a-c). The SEM micrograph before immersion in corrosive solution (Fig. 7a) displays a clear and sleek surface of N80 steel due to corrosion free surface. Figure 8b depicts the SEM micrograph of N80 steel surface without the inhibitor, which is clearly seen to be badly damaged with cracks due to the metal dissolution in the acidic corrosive medium. However, in presence of GETM (Fig. 8c), the surface damage diminished and it looks smoother than without GETM. These observations suggest the adsorption of GETM molecules unto the N80 steel surface which in turn forms a deterrent film that inhibits the corrosion process.

3.7 Mechanism of inhibition

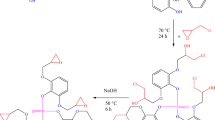

It is necessary to know the chemical composition of GETM to better explain its inhibition mechanism. Tizhe and co-workers [51] reported that GETM have a variety of phytochemicals like alkaloids, saponins, flavonoids, tannins and terpenes among others. These compounds are rich in conjugated aromatic structures and contain heteroatoms with free electron pairs that are available to form bonds with the metal surface [52]. It is therefore, pertinent to say that the adsorption of these compounds onto mild steel surface is responsible for the corrosion inhibition effect. Similar to most organic corrosion inhibitors, GETM also inhibit the corrosion of metals by blocking both anodic and cathodic reaction sites. Based on the results of the present study and several literature reports, anodic and cathodic reactions mechanism and their inhibition can be shown as follows [53,54,55]:

Anodic reactions:

The anodic dissolution of N80 steel proceeds according to the Eqs. (10) and (11). Nevertheless, with GETM, the anodic dissolution reactions rate slows down due to protective film formation by [GTEM] as represented in Eqs. (12) and (13) which separate the aggressive acidic solution from the metal surface.

Cathodic reactions:

Cathodic reactions majorly involve hydrogen gas evolution according to Eq. (14). Nevertheless, in the presence of GETM, the positively charged GETM moiety gets adsorbed at the cathodic site and inhibits cathodic reactions as shown in Eqs. (15) and (16). Generally, steel surfaces are known to carry positive charge in acidic medium, which attracts the electrolyte’s (e.g. HCl) negative ion. The adsorbed layer then assumes a negative charge and attracts the cations of the inhibitor. This means that the anion is seen as a junction between the two positive dipoles (GETM and steel) that forms a protective film of the molecules of GETM and prevents higher amount of corrosive solution passing to the steel surface.

4 Conclusion

The investigation of the surface protective ability of Terminalia Mentaly gum exudate for carbon steel corrosion in HCl stimulated acidizing solution carried out utilizing electrochemical ımpedance spectroscopy (EIS), gravimetric, potentiodynamic polarization (PDP) and scanning electron microscopy (SEM) measurements draw the following conclusions:

-

1.

The gum exudate from Terminalia Mentaly (GETM) has shown to be an effective inhibitor for N80 steel corrosion 1 M HCl and its protective ability enhances with increment in the inhibitor concentration.

-

2.

Results from PDP measurements show that GETM behave as a mixed inhibitor for N80 steel dissolution in 1 M HCl and to an extent retarded both anodic and cathodic corrosion with greater anodic effect.

-

3.

The mode of GETM adsorption on the steel surface obeyed Langmuir adsorption isotherm and proceeds by physical adsorption.

-

4.

EIS measurements show that GETM adsorb on N80 steel surface with diminishing the double-layer capacitance and increasing charge transfer resistance.

-

5.

The SEM results confirmed that the corrosion inhibition mechanism proceeds through adsorption process.

-

6.

The inhibition efficiencies obtained utilizing different techniques had fantabulous agreement.

References

Kalfayan LJ (2008) Production Enhancement with Acid Stimulation, 2nd edn. PennWell, Tulsa

Economides MJ, Nolte KG (2000) Reservoir Stimulation, 3rd edn. John Wiley & Sons, Hoboken

Olasunkanmi LO, Ebenso EE (2020) Experimental and computational studies on propanone derivatives of quinoxalin-6-yl-4,5-dihydropyrazole as inhibitors of mild steel corrosion in hydrochloric acid. J Colloid Interface Sci. https://doi.org/10.1016/j.jcis.2019.11.097

Haque J, Ansari K, Srivastava V, Quraishi M, Obot I (2017) Pyrimidine derivatives as novel acidizing corrosion inhibitors for N80 steel useful for petroleum industry: a combined experimental and theoretical approach. J Ind Eng Chem. https://doi.org/10.1016/j.jiec.2017.01.025

Iroha NB, Nnanna LA (2019) Electrochemical and Adsorption Study of the anticorrosion behavior of Cefepime on Pipeline steel surface in acidic Solution. J Mater Environ Sci 10:898–908

El Defrawy AM, Abdallah M, Al-Fahemi MH (2019) Electrochemical and theoretical investigation for some pyrazolone derivatives as inhibitors for the corrosion of C-steel in 0.5 M hydrochloric acid. J Mol Liq. https://doi.org/10.1016/j.molliq.2019.110994

Iroha NB, Nnanna LA (2020) Leucas martinicensis as an inhibitor of carbon steel corrosion in acidic medium. Int J Res 7:19–26

Satapathy AK, Gunasekaran G, Sahoo SC et al (2009) Corrosion inhibition by Justicia gendarussa plant extract in hydrochloric acid solution. Corros Sci. https://doi.org/10.1016/j.corsci.2009.08.016

Zarrouk A, Hammouti B, Lakhlifi T et al (2015) New 1H-pyrrole-2,5-dione derivatives as efficient organic inhibitors of carbon steel corrosion in hydrochloric acid medium: Electrochemical, XPS and DFT studies. Corros Sci. https://doi.org/10.1016/j.corsci.2014.10.052

Onyeachu IB, Quraishi MA, Obot IB et al (2019) Newly synthesized pyrimidine compound as CO2 corrosion inhibitor for steel in highly aggressive simulated oilfield brine. J Adhes Sci Technol. https://doi.org/10.1080/01694243.2019.1585029

Abdallah M, Gad EAM, Sobhi M et al (2019) Performance of tramadol drug as a safe inhibitor for aluminum corrosion in 1.0 M HCl solution and understanding mechanism of inhibition using DFT. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2019.02.003

Matad PB, Mokshanatha PB, Hebbar N (2014) Ketosulfone drug as a green corrosion inhibitor for mild steel in acidic medium. Ind Eng Chem Res. https://doi.org/10.1021/ie500232g

Nagiub AM, Mahross M, Khalil HF et al (2013) Azo dye compounds as corrosion inhibitors for dissolution of mild steel in hydrochloric acid solution. Port Electrochimica Acta. https://doi.org/10.4152/pea.201302119

Sivakumar V, Velumani K, Rameshkumar S (2018) Colocid dye - a potential corrosion inhibitor for the corrosion of mild steel in acid media. Mat Res. https://doi.org/10.1590/1980-5373-mr-2017-0167

Jalajaa D, Jyothi S, Muruganantham VR et al (2019) Moringa Oleifera Gum Exudate As Corrosion inhibitor on Mild Steel in Acidic Medium. Rasayan J Chem. https://doi.org/10.31788/RJC.2019.1224096

Buchweishaija J (2009) Plants as a source of green corrosion inhibitors: the case of gum exudates from Acacia species (A. drepanolobium and A. senegal). Tanz J Sci 35:93–106

Bentrah H, Chala A, Djellab M (2017) The influence of temperature on the corrosion inhibition of API 5L X42 pipeline steel in HCl medium by gum Arabic. Anti-Corros Method M. https://doi.org/10.1108/ACMM-11-2016-1734

Malarvizhi M, Dheenadhayalan S, Brindha T et al (2016) Corrosion inhibition of mild steel in 1mol L−1 HCl using gum exudates of azadirachta indica. Adv Phys Chem. https://doi.org/10.1155/2016/5987528

Umoren SA, Obot IB, Ebenso EE et al (2009) The inhibition of aluminium corrosion in hydrochloric acid solution by exudate gum from Raphia hookeri. Desalination. https://doi.org/10.1016/j.desal.2008.09.005

Ameh PO (2015) A comparative study of the inhibitory effect of gum exudates from Khaya senegalensis and Albizia ferruginea on the corrosion of mild steel in hydrochloric acid medium. Int J Met. https://doi.org/10.1155/2015/824873

Behpour M, Ghoreishi SM, Khayatkashani M et al (2011) The effect of two oleo-gum resin exudate from Ferula asafoetida and Dorema ammoniacum on mild steel corrosion in acidic media. Corros Sci. https://doi.org/10.1016/j.corsci.2011.04.005

Abdallah M (2004) Guar gum as corrosion inhibitor for carbon steel in sulfuric acid solutions. Port Electrochimica Acta 22:161–175

Iroha NB, Maduelosi NJ (2020) Stem extract of Dissotis theifolia (Melastomataceae) as a green corrosion inhibitor for N80 steel in 1 M HCl solution. IOSR J Appl Chem. https://doi.org/10.9790/5736-1303013038

Hamilton-Amachree A, Iroha NB (2019) Corrosion inhibition of API 5L X80 pipeline steel in acidic environment using aqueous extract of Thevetia peruviana. Chem Int. https://doi.org/10.5281/zenodo.3516565

R Yıldız A Döner T Dogan I Dehri 2014 Experimental studies of 2- pyridinecarbonitrile as corrosion inhibitor for mild steel in hydrochloric acid solution Sci Corros 10.1016/j.corsci.2014.01.008

Iroha NB, Maduelosi NJ (2020) Pipeline steel protection in oil well acidizing fluids using expired pharmaceutical agent. Chem Int 6:267–276. https://doi.org/10.5281/zenodo.3735669

Doharea P, Ansaria KR, Quraishia MA, Obot IB (2017) Pyranpyrazole derivatives as novel corrosion inhibitors for mild steel useful for industrial pickling process: Experimental and Quantum Chemical study. J Ind Eng Chem. https://doi.org/10.1016/j.jiec.2017.03.044

Yousefi A, Javadian S, Dalir N, Kakemam J, Akbari J (2015) Imidazolium-based ionic liquids as modulators of corrosion inhibition of SDS on mild steel in hydrochloric acid solutions: experimental and theoretical studies. RSC Adv. https://doi.org/10.1039/C4RA10995C

Lgaz H, Chaouiki A, Albayati MR et al (2018) Synthesis and evaluation of some new hydrazones as corrosion inhibitors for mild steel in acidic media. Res Chem Intermediat. https://doi.org/10.1007/s11164-018-03730-y

Iroha NB, Hamilton-Amachree A (2019) Inhibition and adsorption of oil extract of Balanites aegyptiaca seeds on the corrosion of mild steel in hydrochloric acid environment. World Sci News 126:183–197

Verma C, Olasunkanmi LO, Bahadur I et al (2019) Experimental, density functional theory and molecular dynamics supported adsorption behavior of environmental benign imidazolium based ionic liquids on mild steel surface in acidic medium. J Mol Liq. https://doi.org/10.1016/j.molliq.2018.09.139

Nnanna LA, Iroha NB (2020) The protective effect of diphenoxylate drug on API X120 carbon steel corrosion in 15% hydrochloric acid environment. Adv Mater Lett. https://doi.org/10.5185/amlett.2020.051511

Iroha NB, James AO (2019) Adsorption behavior of pharmaceutically active dexketoprofen as sustainable corrosion Inhibitor for API X80 carbon steel in acidic medium. World News Nat Sci 27:22–37

El-Hajjaji F, Merimib I, El Ouasif L et al (2019) 1-Octyl-2-(octylthio)-1H-benzimidazole as a new and effective corrosion inhibitor for carbon steel in 1 M HCl. Port Electrochimica Acta. https://doi.org/10.4152/pea.201903131

Singh P, Chauhan DS, Srivastava K et al (2017) Expired atorvastatin drug as corrosion inhibitor for mild steel in hydrochloric acid solution. Int J Ind Chem. https://doi.org/10.1007/s40090-017-0120-5

Obot IB, Madhankumar A, Umoren SA et al (2015) Surface protection of mild steel using benzimidazole derivatives: experimental and theoretical approach. J Adhes Sci Technol. https://doi.org/10.1080/01694243.2015.1058544

Gerengi H, Ugras HI, Solomon MM et al (2016) Synergistic corrosion inhibition effect of 1-ethyl-1-methylpyrrolidinium tetrafluoroborate and iodide ions for low carbon steel in HCl solution. J Adhes Sci Technol. https://doi.org/10.1080/01694243.2016.1183407

Chidiebere MA, Simeon N, Njoku D et al (2017) Experimental study on the inhibitive effect of phytic acid as a corrosion inhibitor for Q235 mild steel in 1 M HCl environment. World News Nat Sci 15:1–19

Mobin M, Khan MA, Parveen M (2011) Inhibition of mild steel corrosion in acidic medium using starch and surfactants additives. J Appl Polym Sci 121:1558–1565

Anyiam CK, Ogbobe O, Oguzie EE et al (2020) Corrosion inhibition of galvanized steel in hydrochloric acid medium by a physically modified starch. SN Appl Sci. https://doi.org/10.1007/s42452-020-2322-2

Singh AK, Quraishi MA (2010) Effect of Cefazolin on the corrosion of mild steel in HCl solution. Corros Sci. https://doi.org/10.1016/j.corsci.2009.08.050

Iroha NB, Chidiebere MA (2017) Evaluation of the inhibitive effect of annona muricata.l leaves extract on low-carbon steel corrosion in acidic media. Int J Mater Chem. https://doi.org/10.5923/j.ijmc.20170703.01

Obot IB, Obi-Egbedi NO (2009) Ipomoea involcrata as an ecofriendly inhibitor for aluminium in alkaline medium. Port Electrochimica Acta. https://doi.org/10.4152/pea.200904517

Iroha NB, Ukpe RA (2020) Investigation of the inhibition of the corrosion of carbon steel in solution of HCl by Glimepiride. Commun Phys Sci 5:246–256

Cui M, Ren S, Zhao H et al (2018) Novel nitrogen doped carbon dots for corrosion inhibition of carbon steel in 1 M HCl solution. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2018.02.255

Iroha NB, Madueke NA (2018) Effect of triumfetta rhomboidea leaves extract on the corrosion resistance of carbon steel in acidic environment. Chem Sci Int J. https://doi.org/10.9734/CSJI/2018/45807

Dehghani A, Bahlakeh G, Ramezanzadeh B (2019) A detailed electrochemical/theoretical exploration of the aqueous Chinese gooseberry fruit shell extract as a green and cheap corrosion inhibitor for mild steel in acidic solution. J Mol Liq. https://doi.org/10.1016/j.molliq.2019.03.011

Ansari KR, Quraishi MA (2015) Experimental and quantum chemical evaluation of Schiff bases of isatin as a new and green corrosion inhibitors for mild steel in 20% H2SO4. J Taiwan Inst Chem E. https://doi.org/10.1016/j.jtice.2015.03.013

Ansari KR, Yadav DK, Ebenso EE et al (2012) Novel and effective pyridyl substituted 1,2,4-triazole as corrosion inhibitor for mild steel in acid solution. Int J Electrochem Sci 7:4780–4799

Deyab M, Ouarsal R, Lachkar M et al (2016) Phosphites compound: Novel corrosion inhibitor for radioactive waste container (carbon steel) in simulated Callovo-Oxfordian (COx) groundwater. J Mol Liq. https://doi.org/10.1016/j.molliq.2016.04.027

Tizhe T, Alonge S, Dakare M (2016) Comparative study of the quantitative phytochemical constituents and anti-bacterial activity of five tree species. Eur J Adv Res Biol life sci 4:29–38

Ameh PO (2018) Electrochemical and computational study of gum exudates from Canarium schweinfurthii as green corrosion inhibitor for mild steel in HCl solution. J Taibah Univ Sci. https://doi.org/10.1080/16583655.2018.1514147

Ma Y, Han F, Li Z et al (2016) Acidic-functionalized ionic liquid as corrosion inhibitor for 304 stainless steel in aqueous sulfuric acid. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.6b01492

Zhou X, Yang H, Wang F (2011) [BMIM]BF4 ionic liquids as effective inhibitor for carbon steel in alkaline chloride solution. Electrochim Acta. https://doi.org/10.1016/j.electacta.2011.01.081

Eddy NO, Odiongenyi AO, Ameh PO (2012) Corrosion inhibition potential of daniella oliverri gum exudate for mild steel in acidic medium. Int J Electrochem Sci 7:7425–7439

Acknowledgments

N. B Iroha, acknowledges the support received from Federal University Otuoke, Bayelsa, Nigeria. O. Akaranta, acknowledges the African centre of excellence in oilfield chemicals research, Institute of petroleum studies, University of Port Harcourt, Choba, Nigeria for providing financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Iroha, N.B., Akaranta, O. Experimental and surface morphological study of corrosion inhibition of N80 carbon steel in HCl stimulated acidizing solution using gum exudate from Terminalia Mentaly. SN Appl. Sci. 2, 1514 (2020). https://doi.org/10.1007/s42452-020-03296-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03296-8