Abstract

The performance of Fenton oxidation processes with simultaneous application of two oxidants including (H2O2) and sodium persulfate (Na2S2O8), in the presence of iron (Fe2+) as a catalyst to oxide dinitrotoluene (DNT) was investigated. For optimization of processes, the effect of operational parameters such as solution pH, oxidant dosages, reaction time and initial DNT concentrations on their performance was evaluated. All experiments were conducted at room temperature (25 ± 2 °C). For all studied processes, the efficiency of pollutant removal was enhanced by increasing the oxidant dosages, while it witnessed a reduction with increasing the initial DNT concentration. The results showed that Fe2+/H2O2/Na2S2O8 system was more efficient in alkaline conditions and the oxidizing of DNT followed pseudo-first-order kinetics. At optimum conditions, the mineralization degree was higher than 86%. Moreover, high potential of DNT removal in a petrochemical effluent sample was observed. Fenton process in the presence of simultaneous application of Na2S2O8 and H2O2 can be used as an effective and promising method for petrochemical wastewaters treatment, due to high efficiency in contaminants removal and also high potential of mineralization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, by an enhancement in legislation roles against water resources contamination, lots of studies have performed on improvement in water remediation approaches and development of cost-effective techniques for removal of organic pollutants from wastewater. DNT is an explosive nitroaromatic that can exist in the environment as six isomers containing approximately 80% of 2,4-DNT and 20% of 2,6-DNT and the other four forms including 2,3-DNT, 2,5-DNT, 3,4-DNT, and 3,5-DNT that make up only 5 percent of the technical grade [1].

DNT is widely used in munitions, polyurethane foams and as an intermediate in dyes, plastics, herbicides, and airbag of automobiles [2, 3]. It is obtained from nitration of toluene (or nitrotoluenes) and commonly found in surrounded environmental of petrochemical plants [4]. Bradley et al. [5] showed that the indigenous microorganisms collected from munitions-contaminated soil can transform 2,4- and 2,6-DNT to amino-nitrointermediates within 70 days. Due to the moderate solubility and lower volatility of DNT, it may uptake and accumulate by plants but may lead to transportation of DNT to the surface and ground waters until degradation by light, oxygen, or biota [6]. DNT is considered as a toxic chemical agent for many organisms, and the chronic exposures may have damaging effects on human health including blood, nervous system, liver, and kidney [7] DNT was introduced as a priority pollutant by the EPA. It was listed on the EPA’s Drinking Water Contaminant Candidate List 2 (probable human carcinogen) for possible regulation under the Safe Drinking Water Act [7]. Therefore, it is indicated that the DNT releases to the water are considered as the main source of human exposure and an important environmental issue that must be resolved.

Fenton oxidation, as an Advanced Oxidation Process (AOP), was used successfully in treatment of different artificial wastewaters with various contaminants, like phenols [8,9,10,11,12,13,14,15], nitrophenols [16, 17], chlorophenols [18,19,20], nitrotoluene [21, 22], and cresols [23]. Fenton’s oxidation with ferrous iron (Fe2+) can generate strong oxidant hydroxyl-1 that led to degradation of recalcitrant organics at acidic conditions [24]. It can promote the wastewater treatment efficiency by reducing the discharge of pollutants into the natural waters, minimizing the effluent toxicity and consequently, increasing the capability of post-biological treatments [25].

The most principal treatment techniques to DNT removal are included adsorption, advanced oxidation processes (AOPs), chemical reduction, and bioremediation [26]. The important benefits of AOPs are its non-selectivity property and quick kinetic reactions [27]. Fenton’s reagents (H2O2, Fe2+) have been known as the most applicable type of AOPs. Mohanty and Wei reported [22] the high degradation of 2,4-DNT, using Fenton’s reagent, by an optimum molar ratio of H2O2:Fe2+:2,4-DNT; 520:2.5:1. Li et al. applied UV/Fenton’s reagent to remove nitroaromatic substances, which found a direct relationship between the reaction rate and the number and position of the nitrogroups on the aromatic ring. Ho [28] investigated the photo-oxidation of 2,4-DNT in the presence of H2O2 and presented the reaction pathway which consists of dinitrobenzaldehyde and dinitrobenzene, corresponding to that reported by Larson et al. [29]. Chen et al. [30] proposed that oxidative degradation of DNT isomers leads to o-, m-, p-mononitrotoluene (MNT), and 1,3-dinitrobenzene, respectively.

AOPs were used for the removal of DNT from wastewater [16,17,18, 22, 31], but none of them have discussed Na2S2O8/H2O2/Fe+2 system.

In this study, Fe2+/H2O2/Na2S2O8 process was applied for the removal of DNT and chemical oxygen demand (COD) from synthetic solution and real petrochemical wastewater sample. Petrochemical industries have a significant amount COD. Therefore, the experiments were carried out to find the optimal input variables. In order to achieve this goal, specific objectives were defined. Test was performed in a batch system to investigate the influence of experimental factors including pH, oxidant dosages, reaction time, and initial concentration of DNT and to find the optimum condition in simultaneous presence of H2O2 and Na2S2O8 in the presence of Fe2+ on removal of DNT from synthetic solution and original petrochemical wastewater sample. Also, the kinetic model of the DNT oxidation rate was determined.

2 Materials and methods

DNT (97%, Merck) was used as a pollutant. H2O2 (50%, Merck) and Na2S2O8 (99%, Merck) were applied as oxidants. FeSO4.7H2O (98%, Merck) was used as a catalyst. NaOH (98%, Merck) and HCl (98%, Merck) were applied to adjust solution pH. K2Cr2O7 (99%, Merck), (NH4)2 Fe (SO4)2·6H2O known as Mohr’s salt (99%, Merck) and C12H8N2.H2O (99%, Merck) were used for measuring COD.

Research was carried out on a different conditions such as varied DNT concentrations (40, 50, 100, 120 and 160 mg/l), solution pH (2, 3, 6, 7, 9 and 11), reaction times (20, 25, 30 and 60 min), oxidant dosages (0.1, 0.2, 0.3, 0.5 and 0.6 g), and fixed dosage of ferrous iron (0.3 g). All chemicals were in analytical grade, and aqueous solutions were prepared with analytical grade Milli-Q water (Millipore). A 100 mg/l DNT solution was prepared in distilled water to investigate the potential of used oxidants in DNT removal and find the optimum treatment conditions. An original sample of petrochemical wastewater was collected to examine the process efficiency of DNT removal. To assess the effects of the matrix, the blank samples were used. To identify the characteristics of original wastewater samples, several parameters were measured. Also, the GC/MS analysis was performed to measure DNT and its isomers concentrations in original samples (PerkinElmer, Norwalk, 7800, USA). The optimum flow rate of the carrier gas (He) was 25 ml/min, and the injection volume was 0.3 μl with thermal planning system: temperature = 80 °C, time = 6 S, speed = 30 °C/min 30).

The kinetic constants of Fenton oxidation to remove DNT were investigated and determined. Pseudo-first-order kinetic model was made to determine the kinetic constants and represented by the following reaction [32]:

where C was the DNT concentration, α was the order of the reaction, K was the reaction rate constant, and t was the time. For a first-order reaction, the equation changed to

where C0 and Ct were the initial and time t DNT concentrations, respectively. According to the equation, a plot of ln(C/C0) against t will yield to a straight line with a slope of k.

Theoretical oxygen demand that is defined as a required dosage of oxygen for oxidation of compound to end products including CO2, NH3, H2PO4 −, SO42−, and H2O was obtained using standard method in the literature [33]. Removal efficiency of aromatic compounds was monitored by COD measurements. It was determined by closed reflux-titrimetric method according to the standard methods [34]. The COD removal efficiency of DNT compounds in wastewater (η) was obtained using the following equation:

The DNT removal efficiency (β) from wastewater and synthetic solutions was calculated using the following equation:

3 Results

3.1 Choice of optimal pH conditions

Figure 2 shows the effect of pH variation (pH 2, 3,6,7, 9 and 11) in initial DNT concentration of 100 mg/L, 0.2 g H2O2 and 0.5 g Na2S2O, 0.3 g/Fe+ 2 over 60 min) on the removal efficiency of DNT by Fenton process of Na2S2O8/H2O2/Fe+ 2. Results showed the significant effect of pH on process efficiency. Maximum (100%) and minimum (63.7%) removal efficiencies of DNT were obtained at pH values of 11 and 3, respectively. In pH above 6, the removal efficiency increases significantly and complete elimination was obtained in pH 11. Therefore, this point was selected as an optimum pH value. A similar trend was also observed in COD removal efficiency. Based on the results presented in Fig. 1, it can be stated that the efficiency of COD removal in both acidic and alkaline conditions was higher than neutral conditions.

3.2 Influence of initial DNT concentration

Figure 2 shows the results of experiments to assess the effect of the initial concentration on the removal of DNT. The DNT concentration varied between 40 and 160 mg/l. According to Fig. 2, increasing in the DNT initial concentration led to a reduction in their removal efficiency. At an initial concentration of 100 mg/l, there is a dramatical reduction in removal efficiency. So, it was selected as an optimal initial concentration of DNT. The same trend was observed for COD removal efficiency.

3.3 Influence of Na2S2O8 dose on DNT oxidation

The effect of different dosages of Na2S2O8 (0.1–0.6 g) was investigated on the removal efficiency of DNT and COD mineralization. The results are shown in Fig. 3. It is observed that by increasing the concentration of oxidant, the process efficiency increased significantly. Results indicated that with an increase in the amount of oxidant from 0.1 to 0.3 g, the DNT removal efficiency and COD mineralization increased to 66.8 and 57.2%, respectively. Findings also showed that under the experimental conditions, (initial concentration of 100 mg/L DNT and 0.5 g of Na2S2O8), complete DNT elimination was observed. So, the 0.5 g/l was selected as the optimal dosage of Na2S2O8. This amount of oxidant can reduce 86% of solution COD (Fig. 3).

In the Na2S2O8/H2O2/Fe+2 system, persulfate is a strong chemical oxidant (Eo = 2.01 V) which can be activated by transition metal ions such as Fe2+ under acidic pH to form a sulfate radical (SO −24 ), which in comparison with persulfate, is a stronger oxidizing agent (Eo = 2.60 V) [2, 22]. It is demonstrated that the persulfate ions have high reaction ability in 3 < pH > 10 [35]. Persulfate ions as an oxidant agent have an important role in the decomposition of organic compounds; (1) production of sulfate radicals that have high oxidation and reduction potential, (2) in alkaline conditions, sulfate radicals interacted with water molecules and hydroxyl ions (Eq. 1) and transformed into radical hydroxyl, which itself play a significant role in the decomposition of organic compounds.

The production of free hydroxyl and sulfate radicals is presented in Eqs. 2–13.

3.4 Influence of H2O2 dose on DNT oxidation

The effect of different amounts of H2O2 (0.1–0.6 g) on the efficiency of DNT removal at optimal conditions (pH = 11, 0.5 g Na2S2O8) is shown in Fig. 4. Results revealed that the removal efficiency of DNT was increased with increasing H2O2 dosage, but it was reduced when the oxidant dosage exceeded 0.2 g. Complete elimination of DNT and COD mineralization was obtained by application of 0.2 g H2O2. Therefore, the amount of 0.2 g of this oxidant was considered as an optimum amount for the subsequent experiments.

3.5 Influence of reaction time on DNT oxidation

Figure 5 shows the effect of reaction time on the removal efficiency of DNT by Na2S2O8/H2O2/Fe+ 2 in optimum pH and oxidants dosage. Results showed that the process efficiency for removing pollutants was increased with increase in reaction time. So, by increasing the reaction time to 20 min, the removal rates of DNT and COD were increased to 65.4 and 49.8%, respectively. Findings also revealed that under 25 min TIME, degradation of DNT and COD can reach to 100 and 86.9%, respectively, representing complete elimination of DNT from solution. It is also clear that the removal efficiency was almost constant after 25 min and no significant changes were made. So, 25 min was chosen as an optimal time for process. At the end of experiments, the optimal conditions are summarized in Table 1.

3.6 Fenton oxidation kinetics

In this study, the reaction rate constants and the correlation coefficients indicated that the degradation of DNT followed first-order kinetics. The values of first-order kinetics parameters for the removal of DNT by processes Na2S2O8/H2O2/Fe+2 are presented in Table 2. The constant coefficients of the reaction rate for the process were 8.4 × 10−3. The correlation coefficient value of model was 0.974.

3.7 Treatment of original petrochemical wastewater samples

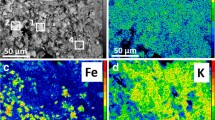

The performance of Na2S2O8/H2O2/Fe+ 2 was evaluated under optimal conditions to remove DNT from original petrochemical wastewater samples. The characteristics of sample wastewater are summarized in Table 3.

According to the results, the sample contains 1800 and 3285 mg/l DNT and COD, respectively. Also, the GC–MS analysis was performed to measure DNT and its isomers concentrations in original samples. Based on the results, the presence of some DNT isomers such as 2,4-DNT, 2,6-DNT, and MNT was confirmed. The results showed that removal efficiency of DNT and COD mineralization was 66.5 and 55.4%, respectively.

4 Discussion

Results of study revealed that the obtained best removal efficiencies (Table 1) were in the order of alkaline and acidic and neutral conditions. Complete removal of 100 mg/l DNT and 89.1% mineralization of COD were obtained in alkaline conditions after 25 min reaction time.

pH is one of the most important factors that affected the rate of chemical reactions. It influences the oxidation of chemicals directly or indirectly and different methods of treatment process.

High removal efficiency in alkaline conditions may due to the simultaneous presence of oxidizing agents including sulfate and hydroxyl radicals [35, 36]. Zhao et al. [37] studied the characteristics of activated sulfate ions in removing PAHs from soil. The results showed that the pH values above 10 (especially 12) were effective in removing PAHs from soil [37]. Also, Asgari et al. [38] studied the effect of pH on removal of pentachlorophenol from synthetic sewage by the microwave waves and sulfate ions. The results indicated that a higher eliminating efficiency of the contaminant was observed in alkaline pH [38]. Also, Furman et al. [39] showed the similar results in the study of anisole, nitrobenzene, and hexachloroethane oxidizing by sulfate ions. Lin et al. [40], studying the oxidation of phenol with UV-activated persulfates, found that the process is more effective in alkaline conditions. These findings were concurred with other studies [35, 36, 39, 41, 42].

In acidic conditions, hydroxyl radicals are dominant, and very small amounts of sulfate radicals can be present. The main role of organic matter oxidation is hydroxyl radicals, which in comparison with sulfate radicals has lower oxidation power. Therefore, the process efficiency in acidic conditions is less than alkaline conditions. Moreover, in neutral conditions, the production rate of both radicals is very low which leads to decreasing mineralization. Furthermore, COD is consistently lower than the removal efficiency of DNT, indicating that together with mineralization to CO2, some intermediates were also generated. These findings were concurred with the study of Ai et al. [43].

Results of study showed that by increasing Na2S2O8 dosages, the decomposition rate of DNT and the mineralization of the organic matter will increase. It may be related to higher content of oxidizing sulfate radicals, which resulted in higher pollutant decomposition. Other studies have reported similar results in using Fenton’s advanced oxidation process to decompose different types of organic materials [35, 36, 44].

Also, the results of study showed that increasing the amount of H2O2 was effective, up to a certain value and at higher values no significant changes were observed in the process efficiency. The produced radicals in high concentrations of H2O2 can be used in H2O2 scavenging and hybrid open (combined) mechanisms. Subsequently, only a small amount of these chemically active components is reacted with the pollutant to be decomposed that was concurred with findings of other results [14, 45]. Other studies found that H2O2 would be effective up to a certain amount and in higher levels is either ineffective or has negative effects, due to the recombination of hydroxyl radicals [14, 46, 47]. Wu et al. [48] showed that increase in the H2O2 up to a critical concentration led to enhance the removal efficiency of humic substances. Murray and Parsons [49] studied the removal of natural organic matter from drinking water by the Fenton and Photo-Fenton process and showed that at the constant concentration of ferrous iron (Fe2+), increasing of hydrogen peroxide concentration, led to higher removal efficiency, but decreased dramatically after critical concentration.

The reaction time has a significant impact on the AOPs process. It is observed that high reaction time led to increase in the efficiency of DNT removal by the system. More reaction time may allow to make more reactions between pollutant and the oxidizing agent and increase the final efficiency. In this study, the high and rapid decomposition rate was observed due to the presence of both sulfate oxidation and hydroxyl radicals in the solution, both of which reacted simultaneously with organic matter and decomposed them. Sun et al. [50] showed that more oxidizing of dimethyl phthalate by Ag+/Na2S2O8/UV process can be achieved at higher reaction time. The same results obtained by studies including Asgari et al. [38], on the removal of pentachlorophenol using a combination of microwave/Na2S2O8, and Sun et al. to remove azo dye Acid Orange 7 by the interaction of heat, UV, and anions with common oxidants: persulfate, peroxymonosulfate, and hydrogen peroxide [51].

Based on the GC analysis, the presence of some DNT isomers such as 2,4-DNT, 2,6-DNT, and MNT was confirmed. He et al. [2] investigated the performance and kinetic parameters of Fenton oxidation of 2,4- and 2,6-DNT (DNT) in water–acetone mixtures and explosive contaminated soil washing-out solutions at a laboratory scale. Results demonstrated the following reaction pathway for 2,4-DNT primary degradation: 2,4-DNT → 2,4-dinitrobenzaldehyde → 2,4-dinitrobenzoic Acid → 1,3-dinitrobenzene → 3-nitrophenol and a series of radical propagation and termination reactions. Results of kinetics model reactions were concurred by Celin [52] revealed the high ability of first-order kinetic model for describing DNT Fenton’s degradation.

5 Conclusion

Fenton oxidation was a feasible method that was used to degrade DNT in aqueous solution. In the present research, removal of DNT and COD from a petrochemical wastewater by Na2S2O8/H2O2/Fe+ 2 could reach 100 and 89.1%, respectively, under the following optimal condition: the H2O2 and Na2S2O8 oxidant dosages of 0.2 and 0.5 g, respectively, the pH = 11.0 and the reaction time of 25 min. The oxidizing of DNT followed pseudo-first-order kinetics. The removal efficiency increased with H2O2 dosage but became reduced when H2O2 was in excess of 0.2 g. Moreover, higher concentration of Na2S2O8 up to critical concentration of 0.5 g led to higher degradation, since higher amounts reduced the removal efficiency.

The results showed that removal efficiency of DNT and COD mineralization was 66.5 and 55.4%, respectively. However, it could be suggested that these processes have a good potential for polluted or industrial wastewaters.

References

Lent EM, Crouse LCB, Quinn MJ Jr, Wallace SM (2012) Assessment of the in vivo genotoxicity of isomers of dinitrotoluene using the alkaline Comet and peripheral blood micronucleus assays. Mutat Res, Genet Toxicol Environ Mutagen 742(1–2):54–60. https://doi.org/10.1016/j.mrgentox.2011.11.013

He Y, Zhao B, Hughes JB, Han SS (2008) Fenton oxidation of 2,4- and 2,6-dinitrotoluene and acetone inhibition. Front Environ Sci Eng China 2(3):326–332. https://doi.org/10.1007/s11783-008-0038-4

Xu J, Jing N (2012) Effects of 2,4-dinitrotoluene exposure on enzyme activity, energy reserves and condition factors in common carp (Cyprinus carpio). J Hazard Mater 203:299–307

Darko-Kagya K, Khodadoust AP, Reddy KR (2010) Reactivity of lactate-modified nanoscale iron particles with 2,4-dinitrotoluene in soils. J Hazard Mater 182(1):177–183. https://doi.org/10.1016/j.jhazmat.2010.06.012

Bradley P, Chapelle F, Landmeyer J, Schumacher J (1994) Microbial transformation of nitroaromatics in surface soils and aquifer materials. Appl Environ Microbiol 60(6):2170–2175

Clausen JL, Scott C, Osgerby I (2011) Fate of nitroglycerin and dinitrotoluene in soil at small arms training ranges. Soil Sedim Contam Int J 20(6):649–671. https://doi.org/10.1080/15320383.2011.594108

(EPA) USEPA (2012) Dinitrotoluene (DNT) Technical Fact Sheet vol (9530566). EPA 505-F-12-001

Eisenhauer HR (1964) Oxidation of phenolic wastes. Journal (Water Pollution Control Federation) 36(9):1116–1128. Retrieved from http://www.jstor.org/stable/25035137

De Heredia JB, Torregrosa J, Dominguez JR, Peres JA (2001) Kinetic model for phenolic compound oxidation by Fenton’s reagent. Chemosphere 45(1):85–90

Esplugas S, Gimenez J, Contreras S, Pascual E, Rodrı́guez M (2002) Comparison of different advanced oxidation processes for phenol degradation. Water Res 36(4):1034–1042

Amiri H, Jaafarzadeh N, Ahmadi M, Martínez SS (2011) Application of LECA modified with Fenton in arsenite and arsenate removal as an adsorbent. Desalination 272(1):212–217. https://doi.org/10.1016/j.desal.2011.01.018

Jonidi Jafari A, Kakavandi B, Jaafarzadeh N, Rezaei Kalantary R, Ahmadi M, Akbar Babaei A (2017) Fenton-like catalytic oxidation of tetracycline by AC@Fe3O4 as a heterogeneous persulfate activator: adsorption and degradation studies. J Ind Eng Chem 45(Supplement C):323–333. https://doi.org/10.1016/j.jiec.2016.09.044

Kavitha V, Palanivelu K (2004) The role of ferrous ion in Fenton and photo-Fenton processes for the degradation of phenol. Chemosphere 55(9):1235–1243

Jaafarzadeh N, Kakavandi B, Takdastan A, Kalantary RR, Azizi M, Jorfi S (2015) Powder activated carbon/Fe3O4 hybrid composite as a highly efficient heterogeneous catalyst for Fenton oxidation of tetracycline: degradation mechanism and kinetic. RSC Adv 5(103):84718–84728

Farrokhi M, Kouti M, Mousavi GR, Takdastan A (2009) The study on biodegradability enhancement of landfill leachate by Fenton oxidation. Iran J Health Environ 2(2):114–123

Kang SF, Wang TH, Lin YH (1999) Decolorization and degradation of 2,4-dinitrophenol by fenton’s reagent. J Environ Sci Health, Part A 34(4):935–950

Ma Y-S, Huang S-T, Lin J-G (2000) Degradation of 4-nitrophenol using the Fenton process. Water Sci Technol 42(3–4):155–160

Ruppert G, Bauer R, Heisler G (1994) UV–O3, UV–H2O2, UV–TiO2 and the photo-Fenton reaction–comparison of advanced oxidation processes for wastewater treatment. Chemosphere 28(8):1447–1454

Pazoki M, Delarestaghi RM, Rezvanian MR, Ghasemzade R, Dalaei P (2015) Gas production potential in the landfill of Tehran by landfill methane outreach program. Jundishapur J Health Sci 7(4):20–25

Golbaz S, Jafari AJ, Kalantari RR (2013) The study of Fenton oxidation process efficiency in the simultaneous removal of phenol, cyanide, and chromium (VI) from synthetic wastewater. Desalin Water Treat 51(28–30):5761–5767

Li Z, Shea P, Comfort S (1997) Fenton oxidation of 2,4,6-trinitrotoluene in contaminated soil slurries. Environ Eng Sci 14(1):55–66

Mohanty NR, Wei IW (1993) Oxidation of 2,4-dinitrotoluene using Fenton’s reagent: reaction mechanisms and their practical applications. Hazard Waste Hazard Mater 10(2):171–183. https://doi.org/10.1089/hwm.1993.10.171

Kavitha V, Palanivelu K (2005) Destruction of cresols by Fenton oxidation process. Water Res 39(13):3062–3072

Palaniandy P, AHBA SF (2014) A review on the Fenton process for wastewater treatment. J Innov Eng 2(4):4–21

Barzegar G, Jorfi S, Soltani RDC, Ahmadi M, Saeedi R, Abtahi M, Ramavandi B, Baboli Z (2017) Enhanced Sono-Fenton-like oxidation of PAH-contaminated soil using nano-sized magnetite as catalyst: optimization with response surface methodology. Soil Sedim Contam Int J 26(5):538–557

Rodgers JD, Bunce NJ (2001) Treatment methods for the remediation of nitroaromatic explosives. Water Res 35(9):2101–2111

Venkatadri R, Peters RW (1993) Chemical oxidation technologies: ultraviolet light/hydrogen peroxide, Fenton’s reagent, and titanium dioxide-assisted photocatalysis. Hazard Waste Hazard Mater 10(2):107–149

Ho PC (1986) Photooxidation of 2,4-dinitrotoluene in aqueous solution in the presence of hydrogen peroxide. Environ Sci Technol 20(3):260–267

Larson RA, Jafvert CT, Boscá F, Marley KA, Miller PL (2000) Effects of surfactants on reduction and photolysis (> 290 nm) of nitroaromatic compounds. Environ Sci Technol 34(3):505–508

Chen W-S, Juan C-N, Wei K-M (2005) Mineralization of dinitrotoluenes and trinitrotoluene of spent acid in toluene nitration process by Fenton oxidation. Chemosphere 60(8):1072–1079

Liou MJ, Lu MC, Chen JN (2003) Oxidation of explosives by Fenton and photo-Fenton processes. Water Res 37(13):3172–3179. https://doi.org/10.1016/s0043-1354(03)00158-1

Cui K, Yi H, Zhou Z-j, Zhuo Q-f, Bing Y-x, Guo Q-w, Xu Z-c (2014) Fenton oxidation kinetics and intermediates of nonylphenol ethoxylates. Environ Eng Sci 31(5):217–224

(EPA) USEPA (2012) Drinking water standards and health advisories. Water Health 2012(4):644–649

American Public Health Association A (1995) Standard methods for the examination of water and wastewater, vol 21. American Public Health Association Washington, Washington

Block PA, Brown RA, Robinson D (2004) Novel activation technologies for sodium persulfate in situ chemical oxidation. In: Fourth international conference on the remediation of chlorinated and recalcitrant compounds. Battelle Memorial Institute, Monterey, CA

Xu X-R, Li X-Z (2010) Degradation of azo dye Orange G in aqueous solutions by persulfate with ferrous ion. Sep Purif Technol 72(1):105–111

Zhao D, Liao X, Yan X, Huling SG, Chai T, Tao H (2013) Effect and mechanism of persulfate activated by different methods for PAHs removal in soil. J Hazard Mater 254:228–235

Asgari G, Seidmohammadi A, Chavoshani A (2014) Pentachlorophenol removal from aqueous solutions by microwave/persulfate and microwave/H2O2: a comparative kinetic study. J Environ Health Sci Eng 12(1):94

Furman OS, Teel AL, Ahmad M, Merker MC, Watts RJ (2010) Effect of basicity on persulfate reactivity. J Environ Eng 137(4):241–247

Lin Y-T, Liang C, Chen J-H (2011) Feasibility study of ultraviolet activated persulfate oxidation of phenol. Chemosphere 82(8):1168–1172

Movahedyan H, Mohammadi AS, Assadi A (2009) Comparison of different advanced oxidation processes degrading p-chlorophenol in aqueous solution. J Environ Health Sci Eng 6(3):153–160

Shiying Y, Ping W, Xin Y, Guang W, Zhang W, Liang S (2009) A novel advanced oxidation process to degrade organic pollutants in wastewater: microwave-activated persulfate oxidation. J Environ Sci 21(9):1175–1180

Ai Z, Yang P, Lu X (2005) Degradation of 4-chlorophenol by a microwave assisted photocatalysis method. J Hazard Mater 124(1–3):147–152

Jafari AJ, Kakavandi B, Jaafarzadeh N, Kalantary RR, Ahmadi M, Babaei AA (2017) Fenton-like catalytic oxidation of tetracycline by AC@Fe3O4 as a heterogeneous persulfate activator: adsorption and degradation studies. J Ind Eng Chem 45:323–333

Kakavandi B, Babaei AA (2016) Heterogeneous Fenton-like oxidation of petrochemical wastewater using a magnetically separable catalyst (MNPs@C): process optimization, reaction kinetics and degradation mechanisms. RSC Adv 6(88):84999–85011

Ahmadi M, Kakavandi B, Jorfi S, Azizi M (2017) Oxidative degradation of aniline and benzotriazole over PAC@FeIIFe2IIIO4: a recyclable catalyst in a heterogeneous photo-Fenton-like system. J Photochem Photobiol, A 336:42–53

Huang R, Fang Z, Yan X, Cheng W (2012) Heterogeneous sono-Fenton catalytic degradation of bisphenol A by Fe3O4 magnetic nanoparticles under neutral condition. Chem Eng J 197:242–249

Wu Y, Zhou S, Qin F, Peng H, Lai Y, Lin Y (2010) Removal of humic substances from landfill leachate by Fenton oxidation and coagulation. Process Saf Environ Prot 88(4):276–284

Murray CA, Parsons SA (2004) Removal of NOM from drinking water: Fenton’s and photo-Fenton’s processes. Chemosphere 54(7):1017–1023. https://doi.org/10.1016/j.chemosphere.2003.08.040

Sun DD, Yan XX, Xue WP (2013) Oxidative degradation of dimethyl phthalate (DMP) by persulfate catalyzed by Ag + combined with microwave irradiation. In: Xu Q, Ju Y, Ge H (eds) Advanced materials research, vol 610–613. Trans Tech Publications, pp 1209–1212

Yang S, Wang P, Yang X, Shan L, Zhang W, Shao X, Niu R (2010) Degradation efficiencies of azo dye Acid Orange 7 by the interaction of heat, UV and anions with common oxidants: persulfate, peroxymonosulfate and hydrogen peroxide. J Hazard Mater 179(1–3):552–558

Celin SM, Pandit M, Kapoor J, Sharma R (2003) Studies on photo-degradation of 2,4-dinitro toluene in aqueous phase. Chemosphere 53(1):63–69

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Takdastan, A., Ravanbakhsh, M., Hazrati, M. et al. Removal of dinitrotoluene from petrochemical wastewater by Fenton oxidation, kinetics and the optimum experiment conditions. SN Appl. Sci. 1, 794 (2019). https://doi.org/10.1007/s42452-019-0812-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0812-x