Abstract

A new type of modified bismuth silicate glass has been manufactured with vanadium and copper cations in a traditional rapid cooling method. FTIR spectra have been used to identify the different structural units of this glass. The spectral analysis showed the presence of BiO3 and BiO6 as basic structural units in all studied samples and the presence of bismuth as a former the glass network with silica. The radiation shielding properties were explored using a narrow beam transmission method in 0.662, 1.173 and 1.33 MeV. The effective atomic numbers for the sample containing the highest CuO ratio showed higher energy values than the other studied samples studied. The mean free path of the prepared glasses has been compared to other commercial radiation shielding. The comparison indicates that the glasses produced are more efficient in relation to radiotherapy compared to conventional commercial radiation protection glass. Microhardness measurements were made of the glass recorded at load at 300 g. The replacement of CuO by V2O5 has been found to increase the cross-link density in addition to the observed difference in the atomic mass of Cu and V, thus increasing the hardness.

Similar content being viewed by others

1 Introduction

Recently, radiation shielding has become a subject of interest among many applications in which radiation is being used, for instance, nuclear power plants, industry, academic and scientific applications, and radiotherapy. Since glass is a solid and transparent material, researchers try to develop a new type of glass system that can protect users against certain amounts of radiation without loss of transparency. This type of glass has been developed to accomplish double tasks possessing high transparency. The knowledge of gamma-ray interaction parameters like the mass attenuation coefficient and half value layer is extremely important in the field of radiation shielding materials [1,2,3,4,5]. Good thermal stability and high density of the bismuth-based silicate glass encourage many studies to be undertaken to understand their radiation shielding efficiencies. Interest in bismuth-silicate glasses has increased due to their unique optical features [6, 7].

Glasses containing transitional metal (TM) ions are interesting properties because of the many oxidation states of these ions in the glass matrix [8, 9]. Among TM the vanadium pentoxide is one of the most studied material since it is a former network glass [9] their presence in another glass matrix determines the modified network due to V4+Ions.

Glasses containing copper oxide received a lot of attention because of the presence of copper ions in both Cu+ and CuO2+ valence states [10]. The glasses that contain the TM ions were mainly studied because of their interest in optical applications, thermal and magnetic applications [8, 11]. Bismuth silicate glass contains mixed TM ions are Interesting since in these glasses there are mixed exchange pairs of Cu2+ and V4+ Pairs on different properties of that glass. Vanadium penta-oxide has attracted attention in recent years because of its potential use as cathode material in solid devices. Direct current (DC) conductivity of vanadium oxide glasses [10].

In recent works, the structure of the bismuth-silicate glasses has been studied by using IR spectroscopic methods. Since all the bismuth-silicate glasses we have identified, two structural units: pyramidal BiO3 and octahedral BiO6 units in different proportion [12, 13]. On the other hand, it is well known that SiO2 is one of the most common glasses former and is present in almost all important commercially glasses. The introduction of transition-metal oxide (V2O5 or CuO) in the glass matrix changes the structure of glasses, where the metal oxide is acting as a modifier and can define semi-conducting properties of the glasses [14]. In the literature, different investigators have studied SiO2 based glasses as a promising novel radiation shielding materials. For example, Rahimi et al. [15] reported the radiation attenuation properties for Ti and Zr containing lead silicate glasses. The authors have been reporting that the glass sample with SiO2 contents of 26.9 wt% has good radiation shielding properties. Singh et al. [16] used a narrow beam transmission method to measure the mass attenuation coefficients for PbO–SiO2 glass system at 0.662, 1.173 and 1.332 MeV. They compared the radiation shielding properties PbO–SiO2 glasses with some types of other concretes. Recently, Bagheria et al. [17] used the MCNP-4C code, XMuDat programs, and XCOM to study the radiation shielding performance of silicate glasses containing BaO, PbO and Bi2O3 within the photon energy range 10 keV to 10 MeV. The authors compared their theoretical results with the experimental data reported by other research groups. Besides, Kaur et al. [18] fabricated Bi2O3–B2O3–SiO2–Na2O glass system using a melt quenching technique and measured the mass attenuation coefficients for the prepared glasses at 662 keV. Also, Singh et al. [19] used the geometrical progression (G-P) fitting method to study the exposure build-up factor for bismuth boro-silicate glasses. The authors found that the values of the exposure buildup factor strongly depend on the bismuth concentration and the energy of the incident photons. Tekin et al. [20] used the Monte Carlo code MCNPX to investigate the photon shielding properties of the B2O3–Bi2O3–SiO2–TeO2 glass system. They used the MCNPX code to calculate the mass attenuation coefficient at 356, 662, 1173 and 1332 keV photon energies. They compared the obtained results with those calculated by XCOM and good agreement between MCNPX and XCOM results were reported. This work aims to study how both Cu2+ and V5+ cations affect the structural and the radiation shielding properties of some bismuth silicate glasses. The following chemical formula was chosen to achieve the purpose of this study; x wt% CuO–(30-x) wt% V2O5–50 wt% Bi2O3–10 wt% Na2O–10 wt% SiO2, where (0 ≤ x ≤ 30).

2 Materials and methods

2.1 Preparation of glass

The chemical formula, x wt% CuO–(30-x) wt% V2O5–50 wt% Bi2O3–10 wt% Na2O–10 wt% SiO2, where (0 ≤ x ≤ 30) was considered to prepare some oxide glasses. For each sample, all components were mixed together and then introduced directly into an electric furnace at 1100 °C for 2 h.

2.2 Density and molar volume

The density of these glasses was measure at room temperature using Archimedes principle. The density of glass samples (ρ) was calculated using the formula

where W1 is the weight of empty specific gravity bottle, W2 is the weight of specific gravity bottle with saWmple, W3 is the weight of specific gravity bottle with sample and distill water, and W4 is the weight of specific gravity bottle with distill water.

Molar volume was calculated using the following relation:

where Mi is the molecular weight of the ith component and Xi is the molar fraction of the ith component [21].

2.3 FTIR measurements

The FTIR spectra were measured, for all samples, at ambient temperature in the spectral range 4000–400 cm−1 by a Fourier Transform infrared spectrometer with 1 cm−1 spectral resolution.

2.4 Attenuation measurements

The mass attenuation coefficients have been measured using the γ-ray spectrometer (NUCLEONIX, GR611 M) which includes a detector and multichannel analyzer (NUCLEONIX, MC 1000U). The scintillation detector was a good type (2 × 2 in.) NaI (Tl) crystal with 0.656″ diameter and 1.546″ depth. The NaI (Tl) detector has an energy resolution equal to about 12% at 662 keV. Radioactive point sources 60Co and 137Cs each 5 mCi strength. The online analysis of γ-ray spectrum was performed using Aspect computer software. The source was confined in lead cylinder collimator having 0.52 cm aperture. Collimator was placed in front of source collimator to produce 0.42 cm beam. The distance between source and detector was kept fixed at 40 cm. The glasses of thickness 0.5–1.5 mm were selected and irradiated by 0.662 MeV photons emitted from 137Cs and 1.173 and 1.33 MeV photons emitted from 60Co. The incident and attenuated intensities of γ-rays were measured by recording optimum count (104) for fix preset of time. The linear attenuation coefficient (µ) values for the prepared glasses (CuV1–CuV7) were determined using the next relation [22]:

where I0 and I are the intensities of the initial and attenuated gamma radiation energies respectively, ρ is the density, and t is the glass sample thickness. The mass attenuation coefficient values were then obtained by dividing the µ values by the density of the glass samples. From the mass attenuation coefficients (µ/ρ) we have calculated other shielding parameters such as effective atomic number, half value layers etc. [23]. Additionally, the theoretical values of µ/ρ were calculated using XCOM software for possible comparison with the experimental obtained values [25]. The effective atomic number is another important parameter that characterize the radiation shielding properties of the certain material. In his work, Hine [26] reported that a single number cannot uniquely describe the atomic number in the several energy regions for any composite materials. This number is known as effective atomic number (Zeff) and it is varied with the photon energy. The next relation was used to evaluate the Zeff for the glass samples under study [27]:

where fi represents the fraction by the mole of each constituent element, Ai is the atomic weight and Zj is the atomic number. Besides, the electron density represents the number of electrons per unit mass of the interacting materials. From the calculated Zeff values, we can calculate this quantity using the following relation:

where NA is Avogadro constant and \(A\) is the mean atomic mass.

Half-value layer (HVL) and mean free path (MFP) are other two important quantities that describe the effectiveness of radiation shielding. HVL represents the thickness of a glass sample that reduces the initial intensity of the gamma photon to half. Furthermore, MFP is the average distance between two successive gamma photon interactions [27]. The lower is the value of HVL or MFP, more is the interactions of gamma photon with the glass sample, thus the better is the shielding performance of the sample. The next two equations were used to evaluate the HVL and MFP for the prepared glass samples [28]:

where µ is the linear attenuation coefficient.

2.5 Microhardness measurements

For all the samples, Vickers hardness Hv = 1.8p/d2 was measured using a micro hardness tester (Leco AMH 100, USA), where p is the indentation load and d is the diagonal length impression.

3 Results and discussion

3.1 FTIR spectra

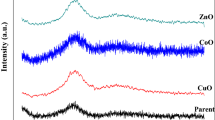

To understand the effect of addition of CuO in the bismuth silicate glass matrix, by analyzing the infrared. Fourier transform infrared FTIR is one of the most popular tools that is used in the characterization processes for such kind of glasses. FTIR spectroscopic analysis of a certain material gives useful information about the building blocks, the chemical bonds in addition to the nature of the internal structure. Figures 1 and 2 show the FTIR spectra of the all prepared samples. Each spectrum consists of more than one broadband the thing which characterizes amorphous structures. So, it can state that the prepared glasses have short range ordered structures. As it is seen, the FTIR charts show the absorbance as a function of the wave number, where each absorption process has a peak due to the vibration of certain molecular group or chemical bond. Therefore, for all the samples, the multi absorption peaks refer to variables of the structural groups and chemical bonds. Each spectrum was de-convoluted to some of the individual peaks Provided that the sum of areas under these peaks is equal to the total area under the original spectrum, as in Fig. 2 for x = 0 mol%. The spectra for all the samples were de-convoluted by the same way, such that the deconvolution results were recorded in Table 1. Looking carefully at the data in this table one can conclude that Bi cations have two different coordination states BiO3 and BiO6, it means that some of Bi3+ occupied the interstitial vacancies in the glass network as a glass modifier, while some other share in the glass network as a glass former with Si4+ cations. A sub band at around 1000–1050 cm−1 (clearly shown in Fig. 1 was observed in 1st four samples, this is assigned to V = O stretching mode. The position of sub-band remained unchanged by changing the composition of CuO. Another sub-band appears at around 900–950 cm−1, which becomes less broad with increase in CuO content and is attributed to the vibrations of VO2− groups of the VO4 polyhedra, while the intense band at 1020 cm−1 is related to the vibrations of the VO2− groups of the VO5 group [3]. The absorption band at 600–620 cm−1 (Fig. 1) starting from 15% CuO content that can be due to the Cu–O bonds [8, 9]. However, the relative area of this band decreases with increasing of CuO content. The increasing of CuO content on expense of V2O5 results in an increase of the electron cloud density around the oxygen in the BiO3 and SiO2 unit, leading to an increase in the Bi–O–Si band and consequently contributing to the shift towards higher wavenumbers. This process forms new Si–O–Cu bridging bonds due to the induced electrostatic field causing a weakening of the silicate network [29]. The absence of V5+ groups and bonds may be due to two factors: the first is its low relative concentration and the second is it sharing to BiO6 and Si–O–Si in the vibration are equal to about 480 cm−1 [29, 30].

3.2 Density and molar volume

Any change in the internal structure of the solid material causes a significant change in the value of its density. Therefore, density measurement is one of the crucial tools used to indicate the occurrence of any change in the internal structure of the material. The density values of all prepared glasses were measured and recorded in Table 2. The density increases gradually with increasing of copper oxide content in the glass compositions. This one confirms that the glass structure becomes more tightly packed with increasing CuO content. This behavior also may be due to the replacement of CuO (density is 6.3 g/cm3 with V2O5 (density is 3.4 gm/cm3) [31]. The density values were used to calculate the molar volumes for the prepared glasses. These volumes may be useful for comparison between the stability of the prepared glasses. As seen in Table 2, the value of the molar volume decreases as CuO is increased. Such behavior may be attributed to two factors: the first is a decrease of the number of oxygen atoms and the second one is the replacement of high ionic radius cation V5+ by short ionic radius cation Cu2+. The decrease of the molar volume values with CuO content may be an indication to increase of the thermal stability of study glasses in addition to a decrease of their refractive index magnitudes. The density and molar volume results indicate that CuO has a strong effect on the glass network construction. Both density and molar volume ware used in the following relations to calculate some principle parameters such as the refractive index n and molar refractivity Rm [32, 33]:

where χi refers to Pauling electronegativity, ni is the number of atoms of ith elements while N is the total atoms in the chemical compound, rj is molar fraction of the oxide j th in the glass matrix. In Eq. 7 ngomaaa represents the glass refractive index, A and B are the numbers of cations and all atoms in the glass chemical formula, respectively. Following the Table 3 it can be observed that each sample has ratio Rm/Vm < 1 which means non-metal nature [34] random network structure. The values of the electronegativity were observed to decrease with increasing x values. The important thing which may cause the decrease in the number of the oxygen atoms, may be a result of replacement V2O5 by CuO. Also, it can be observed that the calculated refractive index shows slightly decrease with increasing CuO content This result may mean that the increase of Cu2+ content favor a decrease of the optical band gap for the studied glasses, Since the refractive index depend on the electronegativity value which has direct dependence on the optical band gap according to the following relation 7 [34]. In other word the increase of Cu2+ content is expected to improve the nonlinear optical properties of the studied glasses.

3.3 Photon interaction parameters

Gamma-ray linear attenuation coefficient (µ) determines the absorption of gamma-rays in unit length of an absorbent material. µ strongly depends on the energy of the incident energy gamma-ray and the density of the absorptive material. Photon penetration in matter is governed statistically by the probability per unit distance µ propagated that a photon interacts by one physical process or another. Gamma-ray attenuation graph for the absorbers of CuV2 glass sample (as an example) from the spectrometer are shown in Fig. 3. The slope of the absorption graph gives the experimental gamma-ray linear attenuation coefficient µ for CuV2 glass sample. From the measured µ and the density of the glass samples, we calculate the experimental mass attenuation coefficient values, and we can denote it by (µ/ρ)Exp.. To test the validity of the experimental results, the values of the µ/ρ for the prepared glasses were calculated by the XCOM program. The (µ/ρ)Exp and (µ/ρ)XCOM at 662, 1173 and 1332 keV are plotted and presented in Fig. 4.

It can be seen that the µ/ρ)Exp. and (µ/ρ)XCOM coincides with each other at the given photon energies. Also, the difference between (µ/ρ)Exp and (µ/ρ)XCOM values were evaluated using the next relation:

The differences between both the experimentally determined and theoretically calculated µ/ρ values are found in the content range of 0.87–8.30%, 1.58–7.74%, 0.76–8.87%, 0.75–8.89%, 0.65–8.56% 0.54–8.76% and 0.55–8.80% for CuV1–CuV7 glasses, respectively. The differences between the experimental and theoretical (XCOM) results are small and this validates the narrow beam transmission method used in this work. Also, it is evident from Fig. 4, that the µ/ρ values for the CuV1–CuV7 glasses decrease with the increase of the energy of the photon. The Zeff values for the prepared glasses are shown in Fig. 5, where the present Zeff results have the same trends as Yasaka et al. [35] who measured the Zeff of zinc bismuth borate glasses within the energy range 0.223–0.662 keV. The range of Zeff as depicted in Fig. 4 are 18.16–20.77, 18.60–21.25, 19.07–21.77, 19.56–22.30, 20.07–22.86, 20.61–23.46 and 21.18–24.08 for CuV1–CuV7 glasses, respectively. Besides, the Zeff values are found to increase with increasing CuO content.

The increase in Zeff is referring to the replacement of V2O5 by CuO which has a higher effective atomic cross section than V2O5. Also, it should be noted that the Zeff decrease with increasing photon energy for all the prepared glasses (CuV1–CuV7), which means that there are more interactions of the glass sample with low energy photons. Moreover, the Zeff at 0.662 MeV are higher for all the titled glasses than for other photon energies due to the photoelectric absorption probability, which is very high at 0.662 MeV. This is since the increase in the energy of photon makes it be able of deeply penetrating in the glass sample [36]. From Fig. 5, it is obvious that CuV7 (contains a maximum CuO concentration) glass sample possesses the highest Zeff values among the prepared glass samples, which means that this sample show superior shielding properties. Thus, the radiation shielding properties of the glass system under study are enhanced with increasing CuO content.

The variation of HVL for the studied glasses is given in Fig. 6 versus photon energy. This figure shows an increasing trend of HVL for the prepared glass materials with the increasing of photon energies from 0.662 to 1.33 MeV. This one indicates that that the photons with higher energies have an ability to penetrate deeper to the glass sample in comparison with the lower photon energies. Also, it is clear from Fig. 6 that the increment of CuO for the glass samples leads to decrease in the HVL values. Following the Table 2, the density of the glass samples increases while the CuO content increases gradually, and it is well known that the HVL value is inversely proportional to the density, implying that the addition of CuO reduces the HVL hence improves the radiation shielding properties for the prepared glasses, as previously verified by Kurudirek et al. [1]. Besides, it is revealed that the CuV1 glass sample has the highest values of HVL (in the range of 1.14–2.07 cm), while CuV7 sample (which contains the highest amount of CuO) possesses the lowest values of HVL (in the range of 0.97–1.80 cm).

Figure 7 introduces the variety of MFP with photon energy for the CuV1–CuV7 glass samples. In this figure, there is observed decreasing order of MFP from CuV1 to CuV7. This trend of decrease in MFP shows that the increment in the weight percent of CuO enhances the radiation shielding feature of the prepared glasses. This means that CuV7 has the lowest MFP at all the 0.662, 1.173 and 1.33 MeV photon energies followed by others accordingly. The lower MFP of CuV7 glass sample could be understood from its high percentage fraction of CuO. This result emphasizes that CuV7 sample has superior radiation shielding performance. The MFP of the prepared glasses at 0.662 MeV are 1.65, 1.61, 1.56, 1.52, 1.48, 1.44 and 1.40 cm while the MFP of the three commercial radiation shielding glasses produced by SCHOTT (RS 323 G19, RS 360 and RS 520) are 3.57, 3.13 and 2 cm, respectively [37]. It is evident that the MFP values of all the fabricated glasses (CuV1–CuV7) are lower than RS 360, RS 323 G19 and RS 520 glasses. This result suggests that the prepared glasses have higher efficiency in terms of radiation shielding with respect to the selected commercial radiation shielding glass.

3.4 Hardness

Microhardness testing is a method of determining a material’s hardness or resistance to penetration. Microhardness measurements were performed for the prepared bismuth-silicate glasses within dentation loads at 300 g to identify the optimal experimental conditions. Figure 8 shows the test results for the present bismuth-silicate glasses. It is clearly seen that the hardness increases gradually with increasing CuO content. This may indicate that it is behaving like a former and leading to an increase bond rigidity. Consequently, it appears bond rigidity. Also, replacing CuO by V2O5 increases the cross-link density as well as the remarkable difference atomic mass of Cu and V and consequently the hardness increase. From density results, the increasing in density of glass means that the glass is more cohesive for the raptors forming the network and therefore the hardness makes the glass bear exposure to radiation and the resistance of breakage or scratching. This glass has a more solidity and the strength of its network, so it is a good resistance to radiation.

4 Conclusions

The bismuth-silicate glasses with the nominal composition of xCuO–(30-x) V2O5–50Bi2O3–10Na2O–10SiO2, where (0 ≤ x ≤ 30 wt%) were prepared successfully using conventional melt quenching method. FTIR spectroscopic analysis showed that the studied glasses contain BiO3 and BiO6 basic structural units. The results of the radiation shielding characteristics of the glasses prepared using the gamma ray spectrometer at different energies show that with the increase of CuO content, a slight increase, whereas HVL and MFP are gradually decreasing, which means that the thickness of the glass used for shielding is low. The effective atomic number value of CuV7 sample is high which contains the higher CuO concentration. So, the radiation shielding properties for the prepared glasses are being enhanced with increasing CuO content. Also, the density increases with the CuO content. Therefore, the glass is more cohesive in the network and there is an increase in the hardness that makes the glass bear exposure to radiation and the resistance of breakage or scratching. All the above results indicate that this glass containing copper oxide can be used as a good resistor of radiation.

References

Kurudirek M, Chutithanapanon N, Laopaiboon R, Yenchai C, Bootjomchai C (2018) Effect of Bi2O3 on gamma ray shielding and structural properties ofborosilicate glasses recycled from high pressure sodium lamp glass. J Alloys Compd 745:355–364

Obaid SS, Sayyed MI, Gaikwad DK, Pawar PP (2018) Attenuation coefficients and exposure build up factor of some rocks for gamma ray shielding applications. Radiat Phys Chem 148:86–94

Elbashir BO, Dong MG, Sayyed MI, Issa SAM, Matori KA, Zaid MHM (2018) Comparison of Monte Carlo simulation of gamma ray attenuation coefficients of amino acids with XCOM program and experimental data. Results Phys 9:6–11

Kurudirek M (2017) Heavy metal borate glasses: potential use for radiation shielding. J Alloys Compd 727:1227–1236

Kirdsiri K, Kaewkhao J, Pokaipisit A, Chewpraditkul W, Limsuwan P (2009) Gamma-rays shielding properties of xPbO:(100-x)B2O3 glasses system at662 keV. Ann Nucl Energy 36:1360–1365

Hall D, Newhause N, Borelli N, Dumbaugh W, Weidman D (1989) The study of CuO–B2O3–2Bi2O3 glasses by spectroscopic techniques. J Appl Phys Lett 54:1293

Komatsu T, Matusida K, Termochem S (1991) Thermal decomposition of Mg–Al hydroxides coprecipitated in the presence of oxalate ions. Acta 174:131

Mercier C, Palavit G, Montagne L, Follet C (2003) A survey of transition-metal-containing phosphate glasses. Sci Paris 5:693

Tricot G, Montagne L, Delevoye L, Palavit G, Kostoj V (2004) Redox and structure of sodium-vanadophosphate glasses. J Noncryst Solids 345:56–60

Vedeanu N, Cozar O, Ardelean I, Lendl B (2006) IR and Raman investigation of x(CuO∙V–2O5)(1 − x)[P2O5∙CaF2] glass system. J Optoelectron Adv Mater 8(1):78–81

Attallah M, Farouk M, El-Korashy A, ElOkr M (2018) Copper doped phosphate glass as an optical band pass filter. Silicon 10(2):547–554

Saudi HA, Mostafa AG, Sheta N, El Kameesy SU, Sallam HA (2011) The structural properties of CdO–Bi2O3 boro-phosphate glass system containing Fe2O3 and its role in attenuating neutrons and gamma rays. Phys B Phys Condens Matter 406:4001–4006

Saudi HA, El-Kameseey SU (2018) Investigation of modified zinc borate glasses doped with BaO as a nuclear radiation-shielding material. Radiat Detect Technol Methods 2:44. https://doi.org/10.1007/s41605-018-0075-x

Ardelean I (1978) Semiconduction in xFe2O3 (1 − x) [3B2O3∙PbO] glasses. Solid State Common 27:697–703

Singh N, Singh KJ, Singh K, Singh H (2006) Gamma-ray attenuation studies of PbO–BaO–B2O3 glass system. Radiat Meas 41:84

Singh KJ, Singh N, Kaundal RS, Singh K (2008) Gamma-ray shielding and structural properties of PbO–SiO2 glasses. Nuclear Instrum Methods Phys Res Sect B Beam Interact Mater Atoms 266:944–948

Bagheria R, Moghaddam AK, PezhmanShirmardi S, Azadbakhtd B, Salehi M (2018) Determination of gamma-ray shielding properties for silicate glasses containing Bi2O3, PbO, and BaO. J Noncryst Solids 479:62–71

KulwinderKaur KJ Singh, Anand V (2016) Structural properties of Bi2O3–B2O3–SiO2–Na2O glasses for gamma ray shielding applications. Radiat Phys Chem 120:63–72

Singh VP, Badiger NM, Chanthima N, Kaewkhao J (2014) Evaluation of gamma-ray exposure buildup factors and neutron shielding for bismuth borosilicate glasses. Radiat Phys Chem 98:14–21

HuseyinOzanTekin MI Sayyed, Manici T, EbruAltunsoy E (2018) Photon shielding characterizations of bismuth modified borate silicate tellurite glasses using MCNPX Monte Carlo code. Mater Chem Phys 211:9–16

Motke SG, Yawale SP, Yawale SS (2002) Infrared spectra of zincdoped leadborate glasses. Bull Mater Sci 25(1):75–78

Mostafa AMA, Issa Shams AM, Sayyed MI (2017) Gamma ray shielding properties of PbO–B2O3–P2O5 doped with WO3. J Alloys Compd 708:294–300

RajeshwariMirji BL (2017) Computation of the mass attenuation coefficient of polymeric materials at specific gamma photon energies. Radiat Phys Chem 135:32–44

Berger MJ, Coursey JS, Zucker MA, Chang J (1993) ESTAR, PSTAR, and ASTAR: computer programs for calculating stopping-power and range tables for electrons, protons, and helium ions (version 1.2.3). National Institute of Standards and Technology, Gaithersburg, MD, 2005. Originally published as: Berger, M.J., NISTIR 4999, National Institute of Standards and Technology, Gaithersburg, MD. http://physics.nist.gov/Star

Hine GJ (1952) The effective atomic numbers of materials for various gamma ray interactions. Phys Rev 85:725

Sayyed MI, Elhouichet H (2017) Variation of energy absorption and exposure buildup factors with incident photon energy and penetrationdepth for boro-tellurite (B2O3–TeO2) glasses. Radiat Phys Chem 130:335–342

Ersundu AE, Büyükyıldız M, Ersundu MÇ, Şakar E, Kurudirek M (2018) The heavy metal oxide glasses within the WO3–MoO3–TeO2 system to investigate the shielding properties of radiation applications. Prog Nuclear Energy 104:280–287

Sayyed MI, Lakshminarayana G (1018) Structural, thermal, optical features and shielding parameters investigations of optical glasses for gamma radiation shielding and defense applications. J Noncryst Solids 487:53–59

Colak SC (2017) Role of titanium ions on the optical and thermal properties of zinc borate glass doped with TiO2. Phys Chem Glass Eur J Glass Sci Technol B 58(1):41–48

Ramesh B, Shareefuddina MD, Sayanna R (2016) Synthesis of novel la 0.7 Ce 0.2 Sr 0.1 Fe 0.5 Mn 0.4 Co 0.1 O3 (LCSFMCO). J.Mater Today Proc 3:1914–1922

Karthikeyan B, Mohan S (2003) Effect of phosphorus oxide additives on the color and production conditions of Bi2O3–SiO2–P2O5 glass. Phys B 334:298

Davis EA, Mott N (1970) Conduction in non-crystalline systems V. Conductivity, optical absorption and photoconductivity in amorphous semiconductors. Philos Mag 22(179):0903–0922

Gomaa HM, Katlawy SM (2017) A new empirical method for estimating the refractive index of oxide glasses using internal structure information. Am J Mater Synth Process 2(6):94–96. https://doi.org/10.11648/j.ajmsp.20170206.14

El-Rabaie S, Taha T, Higazy A (2013) Non-linear optical and electrical properties of germanate glasses. J Phys B Condens Matter 429:1–5

Yasaka P, Pattanaboonmee N, Kim HJ, Limkitjaroenporn P, Kaewkhao J (2014) Gamma radiation shielding and optical properties measurements of zinc bismuth borate glasses. Ann Nuclear Energy 68:4–9

Tijani SA, Kamal SM, Al-Hadeethi Y, Arib M, Hussein MA, Wageh S, Dim LA (2018) Radiation shielding properties of transparent erbium zinc tellurite glass system determined at medical diagnostic energies. J Alloys Compd 741:293–299

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saudi, H.A., Gomaa, H.M., Sayyed, M.I. et al. Investigation of bismuth silicate glass system modified by vanadium and copper cations for structural and gamma-ray shielding properties. SN Appl. Sci. 1, 218 (2019). https://doi.org/10.1007/s42452-019-0197-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0197-x