Abstract

Background

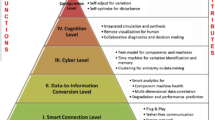

An intelligent predictive health management paradigm for industrial machinery is inevitable in Industry 4.0. The machinery health failure/degradation data acquired as time-series sensor signals are analyzed for fault detection, prediction, and maintenance decision-making. Deep learning is a promising computational tool for machinery health prognostics. However, the implementation of deep learning algorithms for machinery health prognostics has enormous challenges, which have a certain scope for discussion in the present era of Industry 4.0.

Purpose

To motivate industrial practitioners for developing a machine degradation data acquisition system and employ deep learning model training algorithms for machinery health management thus fit themselves into an Industry 4.0 era.

Methods

The review show-up the recent research works focused on the implementation of deep learning algorithms for developing an intelligent predictive maintenance model for future industries. First, to address the most popularly used deep learning architectures and their significance in machinery health prognostics. Then, outline the characteristics of a few benchmark time-series machinery failure datasets available in open repositories that are widely utilized in the literature for validating deep learning algorithms. Finally, the paper provides the state-of-art contribution of various researchers on implementing deep learning approaches and optimized hyper-parameter selection for accurate machinery health diagnostics and prognostics.

Results

The mandate to have large-size machinery failure data for training deep learning algorithm can be regarded as a major limitation. Hyper-parameter optimization, architecture design, and data training of deep learning algorithms are still challenging and unpredictable, which can pull back industrialists from implementing intelligent health management of industrial machinery.

Conclusions

Further research works are required to encourage industrial field failure data acquisition and to unveil the black-box nature of deep learning algorithms to make an intelligible prognostic platform with automated hyper-parameter selection to instigate industrialists to set about an autonomous machinery health management system.

Similar content being viewed by others

Availability of Data and Materials

All data and references are cited.

Code Availability

No software or codes were used.

References

Lecun Y, Bengio Y, Hinton G (2015) Deep learning. Nature 521:436–444. https://doi.org/10.1038/nature14539

Kumar M, Jindal MK, Sharma RK et al (2020) Performance evaluation of classifiers for the recognition of offline handwritten Gurmukhi characters and numerals: a study. Artif Intell Rev 53:2075–2097. https://doi.org/10.1007/s10462-019-09727-2

Gupta S, Thakur K, Kumar M (2020) 2D-human face recognition using SIFT and SURF descriptors of face’s feature regions. Vis Comput. https://doi.org/10.1007/s00371-020-01814-8

Arora M, Kumar M, Garg KN (2018) Facial emotion recognition system based on PCA and gradient features. Natl Acad Sci Lett 41:365–368. https://doi.org/10.1007/s40009-018-0694-2

Bansal M, Kumar M, Kumar M (2020) 2D Object recognition techniques: state-of-the-art work. Arch Computat Methods Eng. https://doi.org/10.1007/s11831-020-09409-1

Kaur P, Kumar R, Kumar M (2019) A healthcare monitoring system using random forest and internet of things (IoT). Multimed Tools Appl 78:19905–19916. https://doi.org/10.1007/s11042-019-7327-8

Dargan S, Kumar M, Rohit M, Gulshan A (2019) A survey of deep learning and its applications: a new paradigm to machine learning. Arch Comput Methods Eng 27:1071–1092. https://doi.org/10.1007/s11831-019-09344-w

Emmert-Streib F, Yang Z, Feng H, Tripathi S, Dehmer M (2020) An introductory review of deep learning for prediction models with Big Data. Front Artif Intell. 3:1–23. https://doi.org/10.3389/frai.2020.00004

Wang J, Ma Y, Zhang L, Gao RX, Wu D (2018) Deep learning for smart manufacturing: methods and applications. J Manuf Syst 48:144–156. https://doi.org/10.1016/j.jmsy.2018.01.003

Khan S, Yairi T (2018) A review on the application of deep learning in system health management. Mech Syst Signal Process 107:241–265. https://doi.org/10.1016/j.ymssp.2017.11.024

Lei Y, Li N, Guo L, Li N, Yan T, Lin J (2018) Machinery health prognostics: a systematic review from data acquisition to RUL prediction. Mech Syst Signal Process 104:799–834. https://doi.org/10.1016/j.ymssp.2017.11.016

Lee GY, Kim M, Quan YJ et al (2018) Machine health management in smart factory: a review. J Mech Sci Technol 32:987–1009. https://doi.org/10.1007/s12206-018-0201-1

Zhao R et al (2019) Deep learning and its applications to machine health monitoring. Mech Syst Signal Process 115:213–237. https://doi.org/10.1016/j.ymssp.2018.05.050

Baur M, Albertelli P, Monno M (2020) A review of prognostics and health management of machine tools. Int J Adv Manuf Technol 107:2843–2863. https://doi.org/10.1007/s00170-020-05202-3

Xia T, Dong Y, Xia L, Du S, Pan E, Xi L (2018) Recent advances in prognostics and health management for advanced manufacturing paradigms. Reliab Eng Syst Safety 178:255–268

Wang D, Tsui K, Miao Q (2018) Prognostics and health management: a review of vibration based bearing and gear health indicators. IEEE Access 6:665–676. https://doi.org/10.1109/ACCESS.2017.2774261

Gardner MW, Dorling SR (1998) Artificial neural networks (the multilayer perceptron) - a review of applications in the atmospheric sciences. Atmos Environ 32:2627–2636. https://doi.org/10.1016/S1352-2310(97)00447-0

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2:359–366. https://doi.org/10.1016/0893-6080(89)90020-8

Theodoridis S (2015) Machine learning: a Bayesian and optimization perspective. https://doi.org/https://doi.org/10.1016/B978-0-12-801522-3.00018-5

Kisi O, Uncuoğlu E (2005) Comparison of three back-propagation training algorithms for two case studies. Indian J Eng Materials Sci 12:434–442

Arthur CK, Temeng VA, Ziggah YY (2020) Performance Evaluation of Training Algorithms in Backpropagation Neural Network Approach to Blast-Induced Ground Vibration Prediction. Ghana Mining Journal 20:20–33. https://doi.org/10.4314/gm.v20i1.3

Rumelhart D, Hinton G, Williams R (1986) Learning representations by back-propagating errors. Nature 323:533–536. https://doi.org/10.1038/323533a0

Mutasem KSA, Khairuddin O, Shahrul AN (2009) Back propagation algorithm: the best algorithm among the multi-layer perceptron algorithm. Int J Comput Sci Netw Secur 9(4):378–383

Wang L, Zeng Yi, Chen T (2015) Backpropagation neural network with adaptive differential evolution algorithm for time series forecasting. Expert Syst Appl 42(2):855–863. https://doi.org/10.1016/j.eswa.2014.08.018

Lera G, Pinzolas M (2002) Neighborhood-based Levenberg-Marquardt Algorithm for Neural Network Training. IEEE Trans Neural Netw 13(5):1200–1203. https://doi.org/10.1109/TNN.2002.1031951

Eom K, Jung K, Sirisena H (2003) Performance improvement of backpropagation algorithm by automatic activation function gain tuning using fuzzy logic. Neurocomputing 50:439–460. https://doi.org/10.1016/S0925-2312(02)00576-3

LeCun Y, Boser B, Denker JS, Henderson D, Howard RE, Hubbard W et al (1989) Backpropagation applied to handwritten zip code recognition. Neural Comput 1:541–551. https://doi.org/10.1162/neco.1989.1.4.541

Dhillon A, Verma G (2020) Convolutional neural network: a review of models, methodologies, and applications to object detection. Prog Artif Intell 9:85–112. https://doi.org/10.1007/s13748-019-00203-0

Aloysius N, Geeth M (2017) A review on deep convolutional neural networks. Proc. 2017 IEEE Int Conf Commun Signal Process ICCSP 588–59. Doi:https://doi.org/10.1109/ICCSP.2017.8286426

Lipton ZC, Berkowitz J, Elkan C (2015) A Critical Review of Recurrent Neural Networks for Sequence Learning 1–38. http://arxiv.org/abs/1506.00019.

Sherstinsky A (2020) Fundamentals of Recurrent Neural Network (RNN) and Long Short-Term Memory (LSTM) network. Phys D Nonlinear Phenom 404:1–43. https://doi.org/10.1016/j.physd.2019.132306

Shrestha A, Mahmood A (2019) Review of Deep Learning Algorithms and Architectures. IEEE Access 7:53040–53065. https://doi.org/10.1109/ACCESS.2019.2912200

Hochreiter S, Schmidhuber J (1997) Long Short-Term Memory. Neural Comput 9:1735–1780. https://doi.org/10.1162/neco.1997.9.8.1735

Zhao S, Zhang Y, Wang S, Zho B, Cheng C (2019) A recurrent neural network approach for remaining useful life prediction utilizing a novel trend features construction method. Meas J Int Meas Confed 146:279–288. https://doi.org/10.1016/j.measurement.2019.06.004

Houdt GV, Mosquera C, Nápoles G (2020) A review on the long short-term memory model. Artif Intell Rev 53:5929–5955. https://doi.org/10.1007/s10462-020-09838-1

Gers F, Schmidhuber J, Cummins F (2000) Learning to forget: continual prediction with LSTM. Neural Comput 12:2451–2471. https://doi.org/10.1162/089976600300015015

Zhang J, Wang P, Yan R, Gao RX (2018) Long short-term memory for machine remaining life prediction. J Manuf Syst 48:78–86. https://doi.org/10.1016/j.jmsy.2018.05.011

P. Smolensky (1986) Information processing in dynamical systems: foundations of Harmony Theory. In: D. E. Rumelhart and J. L. McClelland, eds. Parallel Distributed Processing. Cambridge: MIT Press. 194–281. https://ieeexplore.ieee.org/document/6302931?arnumber=6302931

Hinton, Geoffrey E (2012) A practical guide to training restricted Boltzmann machines. Neural networks: Tricks of the trade. Springer, Berlin, Heidelberg, 599–619. https://doi.org/https://doi.org/10.1007/978-3-642-35289-8_32

Liao L, Jin W, Pavel R (2016) Enhanced restricted boltzmann machine with prognosability regularization for prognostics and health assessment. IEEE Trans Ind Electron 63:7076–7083. https://doi.org/10.1109/TIE.2016.2586442

Liu R, Yang B, Zio E, Chen X (2018) Artificial intelligence for fault diagnosis of rotating machinery: a review. Mech Syst Signal Process 108:33–47. https://doi.org/10.1016/j.ymssp.2018.02.016

Benuwa B, Zhan Y, Ghansah B (2016) A Review of Deep Machine Learning. Int J Eng Res Africa 24:124–136. https://doi.org/10.4028/www.scientific.net/JERA.24.124

Bengio Y, Lamblin P, Popovici D, Larochelle H (2007) Greedy layerwise training of deep networks. Proceedings of the 20th International Conference on Neural Information Processing Systems (NIPS’07) 153–160.

Gm H, Gourisaria MK, Pandey M, Rautaray SS (2020) A comprehensive survey and analysis of generative models in machine learning. Comput Sci Rev 38:100285. https://doi.org/10.1016/j.cosrev.2020.100285

Zhao G, Zhang G, Ge Q, Liu X (2016) Research advances in fault diagnosis and prognostic based on deep learning. Prognostics and System Health Management Conference (PHM-Chengdu), Chengdu. doi: https://doi.org/10.1109/PHM.2016.7819786.

Goodfellow IJ, Pouget-Abadie J, Mirza M, Bing X, Warde-Farley D, Ozair S, et al. (2014) Generative Adversarial Nets. In: International Conference on Neural Information Processing Systems Montréal, QC https://arxiv.org/abs/1406.2661.

Feng J, Feng X, Chen J, Cao X, Zhang X (2020) Generative adversarial networks based on collaborative learning and attention mechanism for hyperspectral image classification. Remote Sens Artic 12:1–24. https://doi.org/10.3390/rs12071149

Hinton GE, Salakhutdinov RR (2006) Reducing the dimensionality of data with neural networks. Science 313:504–507. https://doi.org/10.1126/science.1127647

Janak L, Stetina J, Fiala Z, Hadas Z (2016) Quantities and Sensors for Machine Tool Spindle Condition Monitoring. MM Sci J. https://doi.org/10.17973/MMSJ.2016_12_2016204

Lee J, Qiu H, Yu G, Lin J, Rexnord Technical Services (2007) IMS, University of Cincinnati. Bearing Data Set, NASA Ames Prognostics Data Repository (http://ti.arc.nasa.gov/project/prognostic-data-repository), NASA Ames Research Center, Moffett Field, CA

FEMTO Bearing Data Set, NASA Ames Prognostics Data Repository (http://ti.arc.nasa.gov/project/prognostic-data-repository), NASA Ames Research Center, Moffett Field, CA

Nectoux P, Gouriveau R, Medjaher K, Ramasso E, Morello B, Zerhouni N, Varnier C (2012) PRONOSTIA: An Experimental Platform for Bearings Accelerated Degradation Test. IEEE International Conference on Prognostics and Health Management, Denver, CO, USA

Huang H, Baddour N (2019) Bearing Vibration Data under Time-varying Rotational Speed Conditions. Mendeley Data. https://doi.org/10.17632/v43hmbwxpm.2

Saxena A, Goebel K (2008) Turbofan Engine Degradation Simulation Data Set. NASA Ames Prognostics Data Repository (http://ti.arc.nasa.gov/project/prognostic-data-repository), NASA Ames Research Center, Moffett Field, CA

Saxena A, Goebel K, Simon D, Eklund N, (2008) Damage Propagation Modeling for Aircraft Engine Run-to-Failure Simulation. Proceedings of the 1st International Conference on Prognostics and Health Management (PHM08), Denver CO. doi: https://doi.org/10.1109/PHM.2008.4711414

Saxena A, Goebel K (2008) PHM08 Challenge Data Set. NASA Ames Prognostics Data Repository (http://ti.arc.nasa.gov/project/prognostic-data-repository), NASA Ames Research Center, Moffett Field, CA

Case Western Reserve University Bearing Data Center. Available: https://csegroups.case.edu/bearingdatacenter/pages/download-data-file

Agogino A, Goebel K (2007) BEST lab, UC Berkeley. Milling Data Set. NASA Ames Prognostics Data Repository (http://ti.arc.nasa.gov/project/prognostic-data-repository), NASA Ames Research Center, Moffett Field, CA

Lei Y et al (2018) Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech Syst Signal Process 104:799–834. https://doi.org/10.1016/j.ymssp.2017.11.016

Kang R, Gong W, CHEN Y, (2020) Model-driven degradation modeling approaches: Investigation and review. Chin J Aeronaut 33:1137–1153. https://doi.org/10.1016/j.cja.2019.12.006

Kan MS, Tan ACC, Mathew J (2015) A review on prognostic techniques for non-stationary and non-linear rotating systems. Mech Syst Signal Process 62–63:1–20. https://doi.org/10.1016/j.ymssp.2015.02.016

Gebraeel NZ, Lawley MA, Liu R, Parmeshwaran V (2004) Residual life predictions from vibration-based degradation signals: a neural network approach. IEEE Trans Industr Electron 51:694–700. https://doi.org/10.1109/TIE.2004.824875

Gebraeel NZ, Lawley MA (2008) A neural network degradation model for computing and updating residual life distributions. IEEE Trans Autom Sci Eng 5:154–163. https://doi.org/10.1109/TASE.2007.910302

Mahamad AK, Saon S, Hiyama T (2010) Predicting remaining useful life of rotating machinery based artificial neural network. Comput Math Appl 60:1078–1087

Elforjani M (2016) Estimation of remaining useful life of slow speed bearings using acoustic emission signals. J Nondestr Eval 35:32–62. https://doi.org/10.1007/s10921-016-0378-0

Lu C, Tao L, Fan H (2014) An intelligent approach to machine component health prognostics by utilizing only truncated histories. Mech Syst Signal Process 42:300–313. https://doi.org/10.1016/j.ymssp.2013.08.025

Vamsi I, Sabareesh GR, Penumakala PK (2019) Comparison of condition monitoring techniques in assessing fault severity for a wind turbine gearbox under non-stationary loading. Mech Syst Signal Process 124:1–20. https://doi.org/10.1016/j.ymssp.2019.01.038

Salameh JP, Cauet S, Etien E, Sakout A, Rambault L (2018) Gearbox condition monitoring in wind turbines: a review. Mech Syst Sig Process 111:251–264. https://doi.org/10.1016/j.ymssp.2018.03.052

Sun J, Zuo H, Yang H, Michael P (2010) Study of ensemble learning-based fusion prognostics. Prognostics and System Health Management Conference, Macao. https://doi.org/10.1109/PHM.2010.5414582

Yang F, Habibullah MS, Zhang T, Xu Z, Lim P, Nadarajan S (2016) Health index-based prognostics for remaining useful life predictions in electrical machines. IEEE Trans Industr Electron 63:2633–2644. https://doi.org/10.1109/TIE.2016.2515054

Tian Z (2012) An artificial neural network method for remaining useful life prediction of equipment subject to condition monitoring. J Intell Manuf 23:227–237. https://doi.org/10.1109/ICRMS.2009.5270220

Liu D, Xie W, Liao H, Peng Y (2014) An integrated probabilistic approach to lithium-ion battery remaining useful life estimation. IEEE Trans Instrum Meas 64:660–670. https://doi.org/10.1109/TIM.2014.2348613

Liao LX, Kottig F (2014) Review of hybrid prognostics approaches for remaining useful life prediction of engineered systems, and an application to battery life prediction. IEEE Trans Reliab 63:191–207. https://doi.org/10.1109/TR.2014.2299152

Sbarufatti C, Corbetta M, Manes A, Giglio M (2016) Sequential Monte-Carlo sampling based on a committee of artificial neural networks for posterior state estimation and residual lifetime prediction. Int J Fatigue 83:10–23. https://doi.org/10.1016/j.ijfatigue.2015.05.017

Li D, Wang W, Ismail F (2013) Fuzzy neural network technique for system state forecasting. IEEE Trans Cybern 43:1484–1494. https://doi.org/10.1109/TCYB.2013.2259229

Pan Y, Er MJ, Li X, Yu H, Gouriveau R (2014) Machine health condition prediction via online dynamic fuzzy neural networks. Eng Appl Artif Intell 35:105–113. https://doi.org/10.1016/j.engappai.2014.05.015

Lei Y, He Z, Zi Y, Hu Q (2007) Fault diagnosis of rotating machinery based on multiple ANFIS combination with Gas. Mech Syst Signal Process 21:2280–2294. https://doi.org/10.1016/j.ymssp.2006.11.003

Wang W, Golnaraghi MF, Ismail F (2004) Prognosis of machine health condition using neuro-fuzzy systems. Mech Syst Signal Process 18:813–831. https://doi.org/10.1016/S0888-3270(03)00079-7

Wang W, Vrbanek J (2008) An evolving fuzzy predictor for industrial applications. IEEE Trans Fuzzy Syst 16:1439–1449. https://doi.org/10.1109/TFUZZ.2008.925918

Fagang Z, Jin C, Lei G, Xinglin L (2009) Neuro-fuzzy based condition prediction of bearing health. J Vib Control 15:1079–1091. https://doi.org/https://doi.org/10.1177/1077546309102665

Tran VT, Yang BS, Tan ACC (2009) Multi-step ahead direct prediction for the machine condition prognosis using regression trees and neuro-fuzzy systems. Expert Syst Appl 36:9378–9387. https://doi.org/10.1016/j.eswa.2009.01.007

Chen C, Zhang B, Vachtsevanos G, Orchard M (2011) Machine condition prediction based on adaptive neuro–fuzzy and high-order particle filtering. IEEE Trans Industr Electron 58:4353–4364. https://doi.org/10.1109/TIE.2010.2098369

Chen C, Vachtsevanos G, Orchard ME (2012) Machine remaining useful life prediction: an integrated adaptive neuro-fuzzy and high-order particle filtering approach. Mech Syst Signal Process 28:597–607. https://doi.org/10.1016/j.ymssp.2011.10.009

Hussain S, Gabbar HA (2013) Vibration analysis and time series prediction for wind turbine gearbox prognostics. IJPHM Spec Issue Wind Turbine PHM 1:69–80. http://www.phmsociety.org/sites/phmsociety.org/files/phm_submission/2013/ijphm_13_014.pdf

Zurita D, Carino JA, Delgado M, Ortega JA (2014) Distributed neuro-fuzzy feature forecasting approach for condition monitoring. In: IEEE Conference on Emerging Technology and Factory Automation, IEEE, Barcelona 1–8. doi: https://doi.org/10.1109/ETFA.2014.7005180

Liu J, Wang W, Golnaraghi F (2009) A multi-step predictor with a variable input pattern for system state forecasting. Mech Syst Signal Process 23:1586–1599. https://doi.org/10.1016/j.ymssp.2008.09.006

Vapnik VN (1999) An overview of statistical learning theory. IEEE Trans Neural Networks 10:988–999. https://doi.org/10.1109/72.788640

Dong S, Luo T (2013) Bearing degradation process prediction based on the PCA and optimized LS-SVM model. Measurement 46:3143–3152. https://doi.org/10.1016/j.measurement.2013.06.038

Omoregbee HO, Heyns PS (2019) Fault classification of low-speed bearings based on support vector machine for regression and genetic algorithms using acoustic emission. J Vib Eng Technol 7:455–464. https://doi.org/10.1007/s42417-019-00143-y

Niu G, Yang BS (2010) Intelligent condition monitoring and prognostics system based on data-fusion strategy. Expert Syst Appl 37:8831–8840. https://doi.org/10.1016/j.eswa.2010.06.014

Carino JA, Zurita D, Delgado M, Ortega JA, Romero-Troncoso RJ (2015) Remaining useful life estimation of ball bearings by means of monotonic score calibration. IEEE International Conference on Industrial Technology, IEEE, Seville 1752–1758. doi: https://doi.org/10.1109/ICIT.2015.7125351

Kimotho JK, Sondermann-Woelke C, Meyer T, Sextro W (2013) Machinery prognostic method based on multi-class support vector machines and hybrid differential evolution–particle swarm optimization. Chem Eng Trans 33:619–624. https://doi.org/10.3303/CET1333104

Sloukia F, Aroussi ME, Medromi H, Wahbi M (2013) Bearings prognostic using mixture of Gaussians hidden Markov model and support vector machine. ACS International Conference on Computer Systems and Applications, IEEE, Ifrane. 1–4. doi: https://doi.org/10.1109/AICCSA.2013.6616438

Lobato THG, da Silva RR, da Costa ES et al (2020) An Integrated approach to rotating machinery fault diagnosis using, EEMD, SVM, and Augmented Data. J Vib Eng Technol 8:403–408. https://doi.org/10.1007/s42417-019-00167-4

Benkedjouh T, Medjaher K, Zerhouni N, Rechak S (2013) Remaining useful life estimation based on nonlinear feature reduction and support vector regression. Eng Appl Artif Intell 26:1751–1760. https://doi.org/10.1016/j.engappai.2013.02.006

Benkedjouh T, Medjaher K, Zerhouni N, Rechak S (2015) Health assessment and life prediction of cutting tools based on support vector regression. J Intell Manuf 26:213–223. https://doi.org/10.1007/s10845-013-0774-6

Liu J, Vitelli V, Zio E, Seraoui R (2015) A novel dynamic-weighted probabilistic support vector regression-based ensemble for prognostics of time series data. IEEE Trans Reliab 64:1203–1213. https://doi.org/10.1109/TR.2015.2427156

Liu J, Zio E (2016) An adaptive online learning approach for support vector regression: Online-SVR-FID. Mech Syst Signal Process 76–77:796–809. https://doi.org/10.1016/j.ymssp.2016.02.056

Fumeo E, Oneto L, Anguita D (2015) Condition based maintenance in railway transportation systems based on big data streaming analysis. Procedia Comput Sci 53:437–446. https://doi.org/10.1016/j.procs.2015.07.321

Loutas TH, Roulias D, Georgoulas G (2013) Remaining useful life estimation in rolling bearings utilizing data-driven probabilistic E-support vectors regression. IEEE Trans Reliab 62:821–832. https://doi.org/10.1109/TR.2013.2285318

Khelif R, Chebel-Morello B, Malinowski S, Laajili E, Fnaiech F, Zerhouni N (2017) Direct remaining useful life estimation based on support vector regression. IEEE Trans Industr Electron 64:2276–2285. https://doi.org/10.1109/TIE.2016.2623260

Soualhi A, Medjaher K, Zerhouni N (2015) Bearing health monitoring based on Hilbert-Huang transform, support vector machine, and regression. IEEE Trans Instrum Meas 64:52–62. https://doi.org/10.1109/TIM.2014.2330494

Widodo A, Yang BS (2011) Application of relevance vector machine and survival probability to machine degradation assessment. Expert Syst Appl 38:2592–2599. https://doi.org/10.1016/j.eswa.2010.08.049

Wang PF, Youn BD, Hu C (2012) A generic probabilistic framework for structural health prognostics and uncertainty management. Mech Syst Signal Process 28:622–637. https://doi.org/10.1016/j.ymssp.2011.10.019

Goebel K, Saha B, Saxena A, Mct N, Riacs N (2008) A comparison of three data-driven techniques for prognostics. 62nd Meeting of the Society for Machinery Failure Prevention Technology. 119–131. https://ti.arc.nasa.gov/m/pub-archive/1442h/1442%20(Goebel).pdf

Saha S, Saha B, Saxena A, Goebel K (2010) Distributed prognostic health management with Gaussian process regression. IEEE Aerospace Conference, IEEE. https://doi.org/10.1109/AERO.2010.5446841

Aye SA, Heyns PS (2017) An integrated Gaussian process regression for prediction of remaining useful life of slow speed bearings based on acoustic emission. Mech Syst Signal Process 84:485–498. https://doi.org/10.1016/j.ymssp.2016.07.039

Fawaz HI, Forestier G, Weber J, Idoumghar L, Muller PA (2019) Deep learning for time series classification: a review. Data Min Knowl Discov 33:917–963. https://doi.org/10.1007/s10618-019-00619-1

Subrahmanyam M, Sujatha C (1997) Using neural networks for the diagnosis of localized defects in ball bearings. J Tribol Int 30(10):739–752. https://doi.org/10.1016/S0301-679X(97)00056-X

Samanta B, Al-Balushi K (2003) Artificial neural network-based fault diagnostics of rolling element bearings using time-domain features. Mech Syst Signal Process 17(2):317–328. https://doi.org/10.1006/mssp.2001.1462

Gunerkar RS, Belgamwar JAK, SU, (2019) Fault diagnosis of rolling element bearing based on artificial neural network. J Mech Sci Technol 33:505–511. https://doi.org/10.1007/s12206-019-0103-x

de Almeida LF, Bizarria JW, Bizarria FC, Mathias MH (2015) Condition-based monitoring system for rolling element bearing using a generic multi-layer perceptron. J Vib Control 21(16):3456–3464. https://doi.org/10.1177/1077546314524260

Rafiee J, Arvani F, Harifi A, Sadeghi M (2007) Intelligent condition monitoring of a gearbox using artificial neural network. Mech Syst Sign Process 21(4):1746–1754

Peel L (2008) Data driven prognostics using a Kalman filter ensemble of neural network models. In: International Conference on Prognostics and Health Management, Denver, CO 1-6. doi: https://doi.org/10.1109/PHM.2008.4711423

Huang R, Xi L, Li X, Richard Liu C, Qiu H, Lee J (2007) Residual life predictions for ball bearings based on self-organizing map and back propagation neural network methods. Mech Syst Signal Process 21:193–207. https://doi.org/10.1016/j.ymssp.2005.11.008

Babu GS, Zhao P, Li XL (2016) Deep Convolutional Neural Network Based Regression Approach for Estimation of Remaining Useful Life. In: Navathe S, Wu W, Shekhar S, Du X, Wang X, Xiong H, eds. Database Systems for Advanced Applications. DASFAA 2016. Lecture Notes in Computer Science, Springer, Cham. 9642:214–228. https://doi.org/https://doi.org/10.1007/978-3-319-32025-0_14

Singh S, Howard CQ, Hansen C (2016) Convolutional neural network based fault detection for rotating machinery. J Sound Vib 377:331–345. https://doi.org/10.1016/j.jsv.2016.05.027

Liu R, Meng G, Yang B, Sun C, Chen X (2017) Dislocated time series convolutional neural architecture: an intelligent fault diagnosis approach for electric machine. IEEE Trans Industr Inf 13(2):1310–1320. https://doi.org/10.1109/TII.2016.2645238

Ding X, He Q (2017) Energy-fluctuated multiscale feature learning with deep convnet for intelligent spindle bearing fault diagnosis. IEEE Trans Instrum Meas 66(8):1926–1935. https://doi.org/10.1109/TIM.2017.2674738

Janssens O, Slavkovikj V, Vervisch B, Stockman K, Loccufier M, Verstockt S, Van de Walle R, Van Hoecke S (2016) Convolutional neural network based fault detection for rotating machinery. J Sound Vib 377:331–345. https://doi.org/10.1016/j.jsv.2016.05.027

Lu C, Wang Z, Zhou B (2017) Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification. Adv Eng Inform 32:139–151. https://doi.org/10.1016/j.aei.2017.02.005

Guo X, Chen L, Shen C (2016) Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 93:490–502. https://doi.org/10.1016/j.measurement.2016.07.054

Wang P, Ananya YR, Gao RX (2017) Virtualization and deep recognition for System Fault Classification. J Manuf Syst 44:310–316. https://doi.org/10.1016/j.jmsy.2017.04.012

You W, Shen C, Guo X, Jiang X, Shi J, Zhu Z (2017) A hybrid technique based on convolutional neural network and support vector regression for intelligent diagnosis of rotating machinery. Adv Mech Eng 9(6):1–17

Zhang W, Peng G, Li C, Chen Y, Zhang Z (2017) A new deep learn- ing model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals. Sensors 17(425):1–21.

Fuan W, Hongkai J, Haidong S, Wenjing D, Shuaipeng W (2017) An adaptive deep convolutional neural network for rolling bearing fault diagnosis. Meas Sci Technol 28(9):1–25. https://doi.org/10.1088/1361-6501/aa6e22

Li S, Liu G, Tang X, Lu J, Hu J (2017) An ensemble deep convolutional neural network model with improved D-S evidence fusion for bearing fault diagnosis. Sensors 17(8): 1729. https://dx.doi.org/https://doi.org/10.3390/s17081729

Xie Y, Zhang T (2017) Fault diagnosis for rotating machinery based on convolutional neural network and empirical mode decomposition. Shock Vib. https://doi.org/10.1155/2017/3084197

Lu C, Wang Z, Zhou B (2017) Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification. Adv Eng Inf 32:139–151. https://doi.org/10.1016/j.aei.2017.02.005

Li X, Ding Q, Sun J (2018) Remaining useful life estimation in prognostics using deep convolution neural networks. Reliab Eng Syst Saf 172:1–11. https://doi.org/10.1016/j.ress.2017.11.021

Guo L, Lei Y, Li N, Yan T, Li N (2018) Machinery health indicator construction based on convolutional neural networks considering trend burr. Neurocomputing 292:142–150. https://doi.org/10.1016/j.neucom.2018.02.083

Wang B, Le Y, Li N, Yan T (2019) Deep separable convolutional network for remaining useful life prediction of machinery. Mech Syst Signal Process 134:106330. https://doi.org/10.1016/j.ymssp.2019.106330

Xu X, Wu Q, Li X, Huang B (2020) Dilated Convolution Neural Network for Remaining Useful Life Prediction. ASME J Comput Inf Sc Eng 20(2):021004. https://doi.org/10.1115/1.4045293

Heimes FO (2008) Recurrent neural networks for remaining useful life estimation,” in Prognostics and Health Management. PHM 2008 International Conference on IEEE 1–6. doi: https://doi.org/10.1109/PHM.2008.4711422.

Peng Y, Wang H, Wang J, Liu D, Peng X (2012) A modified echo state network based remaining useful life estimation approach. 2012 IEEE Conference on Prognostics and Health Management, Denver, CO, 1–7. doi: https://doi.org/10.1109/ICPHM.2012.6299524

Yuan M, Wu Y, Lin L (2016) Fault diagnosis and remaining useful life estimation of aero engine using LSTM neural network. IEEE Int Conf Aircraft Utility Syst 2016:135–140. https://doi.org/10.1109/AUS.2016.7748035

Zhao R, Wang J, Yan R, Mao K (2016) Machine health monitoring with LSTM networks. IEEE Int Conf Sens Technol. https://doi.org/10.1109/ICSensT.2016.7796266

He M, Zhou Y, Li Y, Wu G, Tang G (2020) Long short-term memory network with multi-resolution singular value decomposition for prediction of bearing performance degradation. Meas J Int Meas Confed 156:107582. https://doi.org/10.1016/j.measurement.2020.107582

ElSaid AER, El Jamiy F, Higgins J, Wild B, Desell T (2018) Optimizing long short-term memory recurrent neural networks using ant colony optimization to predict turbine engine vibration. Appl Soft Comput J 73:969–991. https://doi.org/10.1016/j.asoc.2018.09.013

Zhao R, Yan R, Wang J, Mao K (2017) Learning to monitor machine health with convolutional bi-directional LSTM networks. Sensors 17(2):273. https://doi.org/10.3390/s17020273

Zhao R, Wang D, Yan R, Mao K, Shen F, Wang J (2017) Machine health monitoring using local feature-based gated recurrent unit networks. IEEE Trans Industr Electron 65(2):1539–1548. https://doi.org/10.1109/TIE.2017.2733438

Elsheikh A, Ouali YS, MS, (2019) Bidirectional handshaking LSTM for remaining useful life prediction. Neurocomputing 323:148–156. https://doi.org/10.1016/j.neucom.2018.09.076

Lee K, Kim J, Kim J, Hur K, Kim H (2018) CNN and GRU combination scheme for Bearing Anomaly Detection in Rotating Machinery Health Monitoring. 2018 1st IEEE International Conference on Knowledge Innovation and Invention (ICKII), Jeju 102–105. doi: https://doi.org/10.1109/ICKII.2018.8569155.

Malhotra P, TV V, Ramakrishnan A, Anand G, Vig L, Agarwal P, Shroff G (2016) Multi-sensor prognostics using an unsupervised health index based on LSTM encoder-decoder. arXiv:1608.06154 [cs.LG]

Xia T, Song Y, Zheng Y, Xi PE (2020) An ensemble framework based on convolutional bi-directional LSTM with multiple time windows for remaining useful life estimation. Comput Ind 115:103182. https://doi.org/10.1016/j.compind.2019.103182

Zhang B, Zhang S, Li W (2019) Bearing performance degradation assessment using long short-term memory recurrent network. Comput Ind 106:14–29. https://doi.org/10.1016/j.compind.2018.12.016

Chen Y, Peng G, Zhu Z, Li S (2020) A novel deep learning method based on attention mechanism for bearing remaining useful life prediction. Appl Soft Comput J 86:105919. https://doi.org/10.1016/j.asoc.2019.105919

Wu Y, Yuan M, Dong S, Lin L, Liu Y (2018) Remaining useful life estimation of engineered systems using vanilla LSTM neural networks. Neurocomputing 275:167–179. https://doi.org/10.1016/j.neucom.2017.05.063

Wang F et al (2019) Remaining Life Prediction Method for Rolling Bearing Based on the Long Short-Term Memory Network. Neural Process Lett 50:2437–2454. https://doi.org/10.1007/s11063-019-10016-w

Liao L, Jin W, Pavel R (2016) Enhanced restricted Boltzmann machine with prognosability regularization for prognostics and health assessment. IEEE Trans Industr Electron 63(11):7076–7083. https://doi.org/10.1109/TIE.2016.2586442

Deutsch J, He D (2016) Using deep learning based approaches for bearing remaining useful life prediction. Annual Conference of the Prognostics and Health Management Society, PHM Society 1–7. https://www.phmsociety.org/sites/phmsociety.org/files/phm_submission/2016/phmc_16_040.pdf

Deutsch J, He D (2018) Using deep learning-based approach to predict remaining useful life of rotating components. IEEE Trans Syst, Man, Cybern: Syst 48(1):11–20. https://doi.org/10.1109/TSMC.2017.2697842

Li C, Sanchez RV, Zurita G, Cerrada M, Cabrera D, Vásquez RE (2016) Gearbox fault diagnosis based on deep random forest fusion of acoustic and vibratory signals. Mech Syst Signal Processing 76:283–293. https://doi.org/10.1016/j.ymssp.2016.02.007

Shao S, Sun W, Wang P, Gao RX, Yan R (2016) Learning features from vibration signals for induction motor fault diagnosis. In: 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH 71-76. doi: https://doi.org/10.1109/ISFA.2016.7790138

Shao SY, Sun WJ, Yan RQ, Wang P, Gao RX (2017) A deep learning approach for fault diagnosis of induction motors in manufacturing. Chinese J Mech Eng 30(6):1347–1356. https://doi.org/10.1007/s10033-017-0189-y

Zhang L, Gao H, Wen J, Li S, Liu Q (2017) A deep learning-based recognition method for degradation monitoring of ball screw with multi-sensor data fusion. Microelectron Reliab 75:215–222. https://doi.org/10.1016/j.microrel.2017.03.038

Wang X, Huang J, Ren G, Wang D (2017) A hydraulic fault diagnosis method based on sliding-window spectrum feature and deep belief network. J Vibroeng 19(6):4272–4284. https://doi.org/https://doi.org/10.21595/jve.2017.18549

Han D, Zhao N, Shi P (2017) A new fault diagnosis method based on deep belief network and support vector machine with Teager-Kaiser energy operator for bearings. Adv Mech Eng 9(12):1–11. https://doi.org/10.1177/1687814017743113

Chen Z, Deng S, Chen X, Li C, Sanchez RV, Qin H (2017) Deep neural networks-based rolling bearing fault diagnosis. Microelectron Reliab 75:327–333. https://doi.org/10.1016/j.microrel.2017.03.006

Oh H, Jung JH, Jeon BC, Youn BD (2018) Scalable and unsupervised feature engineering using vibration-imaging and deep learning for rotor system diagnosis. IEEE Trans Industr Electron 65(4):3539–3549. https://doi.org/10.1109/TIE.2017.2752151

Ma M, Chen X, Wang S, Liu Y, Li W (2016) Bearing degradation assessment based on weibull distribution and deep belief network. 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH 382-385. doi: https://doi.org/10.1109/ISFA.2016.7790193

Chen Z, Li C, Sánchez RV (2015) Multi-layer neural network with deep belief network for gearbox fault diagnosis. J Vibroeng 17(5):2379–2392. https://www.jvejournals.com/article/16039

Fu Y, Zhang Y, Qiao H, Li D, Zhou H, Leopold J (2015) Analysis of feature extracting ability for cutting state monitoring using deep belief networks. Procedia CIRP 31:29–34. https://doi.org/10.1016/j.procir.2015.03.016

Wang P, Gao RX, Yan R (2017) A deep learning-based approach to material removal rate prediction in polishing. CIRP Ann Manuf Technol 66(1):429–432. https://doi.org/10.1016/j.cirp.2017.04.013

Tamilselvan P, Wang P (2013) Failure diagnosis using deep belief learning based health state classification. Reliab Eng Syst Saf 115:124–135. https://doi.org/10.1016/j.ress.2013.02.022

Gao Z, Ma C, Song D, Liu Y (2017) Deep quantum inspired neural network with application to aircraft fuel system fault diagnosis. Neurocomputing 238:13–23. https://doi.org/10.1016/j.neucom.2017.01.032

Zhang C, Sun JH, Tan KC (2015) Deep belief networks ensemble with multi-objective optimization for failure diagnosis. 2015 IEEE International Conference on Systems, Man, and Cybernetics, Kowloon 32–37. doi: https://doi.org/10.1109/SMC.2015.19.

Zhang C, Lim P, Qin A, Tan KC (2017) Multiobjective deep belief networks ensemble for remaining useful life estimation in prognostics. IEEE Trans Neural Networks Learn Syst 28(10):2306–2318. https://doi.org/10.1109/TNNLS.2016.2582798

Lu W, Wang X, Yang C, Zhang T (2015) A novel feature extraction method using deep neural network for rolling bearing fault diagnosis. In: 27th Chinese Control and Decision Conference (IEEE, 2015) 2427–2431. doi: https://doi.org/10.1109/CCDC.2015.7162328.

Junbo T, Weining L, Juneng A, Xueqian (2015) Fault diagnosis method study in roller bearing based on wavelet transform and stacked autoencoder. In: 27th Chinese Control and Decision Conference (IEEE, 2015) 4608–4613. doi: https://doi.org/10.1109/CCDC.2015.7162738.

Zhao W, Lu C, Ma J, Wang Z (2015) A deep learning method using SDA combined with dropout for bearing fault diagnosis. Vibro- eng Proc 5:151–156. https://www.jvejournals.com/article/16220

Jia F, Lei Y, Lin J, Zhou X, Lu N (2016) Deep neural networks: a promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech Syst Signal Process 72:303–315. https://doi.org/10.1016/j.ymssp.2015.10.025

Liu H, Li L, Ma J (2016) Rolling bearing fault diagnosis based on STFT-deep learning and sound signals. Shock Vib. https://doi.org/10.1155/2016/6127479

Ahmed HOA, Dennis-Wong, d Nandi K (2016) Effects of deep neural network parameters on classification of bearing faults. IECON 2016–42nd Annual Conference of the IEEE Industrial Electronics Society 6329–6334. doi: https://doi.org/10.1109/IECON.2016.7793957.

Guo L, Gao H, Huang H, He X, Li S (2016) Multifeatures fusion and nonlinear dimension reduction for intelligent bearing condition monitoring. Shock Vib 216:10. https://doi.org/10.1155/2016/4632562

Tao S, Zhang T, Yang J, Wang X, Lu W (2015) Bearing fault diagnosis method based on stacked autoencoder and softmax regression. Control Conference (CCC), 34th Chinese. (IEEE, 2015) 6331–6335. doi: https://doi.org/10.1109/ChiCC.2015.7260634

Sun W, Shao S, Zhao R, Yan R, Zhang X, Chen X (2016) A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Measurement 1(89):171–178. https://doi.org/10.1016/j.measurement.2016.04.007

Chen Z, Li W (2017) Multi-sensor feature fusion for bearing fault diag- nosis using sparse auto encoder and deep belief network. IEEE Trans Instr Meas 66(7):1693–1702. https://doi.org/10.1109/TIM.2017.2669947

Lu C, Wang Z, Qin W, Ma J (2017) Fault diagnosis of rotary machinery components using a stacked denoising autoencoder-based health state identification. Signal Process 130:377–388. https://doi.org/10.1016/j.sigpro.2016.07.028

Hasani RM, Wang G, Grosu R (2017) An automated autoencoder correlation-based health-monitoring and prognostic method for machine bearings.

Sun J, Yan C, Wen J (2018) Intelligent bearing fault diagnosis method combining compressed data acquisition and deep learning. IEEE Trans Instr Meas 67(1):185–195. https://doi.org/10.1109/TIM.2017.2759418

Ahmed HOA, Wong MLD, Nandi AK (2018) Intelligent condition monitoring method for bearing faults from highly compressed measurements using sparse over-complete features. Mech Syst Signal Process 99:459–477. https://doi.org/10.1016/j.ymssp.2017.06.027

Khan SA, Prosvirin AE, Kim J (2018) Towards bearing health prognosis using generative adversarial networks: Modeling bearing degradation. IEEE 2018 International Conference on Advancements in Computational Sciences (ICACS) 1–6. doi: https://doi.org/10.1109/ICACS.2018.8333495

Zhang W, Li X, Jia X-D et al (2020) Machinery fault diagnosis with imbalanced data using deep generative adversarial networks. Measurement 152:107377. https://doi.org/10.1016/j.measurement.2019.107377

Huang Y, Tang Y, VanZwieten J, Liu J, Xiao X (2019) An Adversarial Learning Approach for Machine Prognostic Health Management. 2019 International Conference on High Performance Big Data and Intelligent Systems (HPBD IS), Shenzhen, China 163–168 doi: https://doi.org/10.1109/HPBDIS.2019.8735480.

Verstraete D, Droguett E, Modarres M (2020) A deep adversarial approach based on multi-sensor fusion for semi-supervised remaining useful life prognostics. Sensors 20:176. https://doi.org/10.3390/s20010176

Dai J, Wang J, Huang W, Shi J, Zhu Z (2020) Machinery health monitoring based on unsupervised feature learning via generative adversarial networks. IEEE/ASME Trans Mechatron. https://doi.org/10.1109/TMECH.2020.3012179

Wen W, Bai Y, Cheng W (2020) Generative adversarial learning enhanced fault diagnosis for planetary gearbox under varying working conditions. Sensors (Basel) 20(6):1685. https://doi.org/10.3390/s20061685

Gao S, Wang X, Miao X et al (2019) ASM1D-GAN: An Intelligent Fault Diagnosis Method Based on Assembled 1D Convolutional Neural Network and Generative Adversarial Networks. J Sign Process Syst 91:1237–1247. https://doi.org/10.1007/s11265-019-01463-8

Al-dulaimi A, Zabihi S, Asif A, Mohammadi A (2019) A multimodal and hybrid deep neural network model for Remaining Useful Life estimation. Comput Ind 108:186–196. https://doi.org/10.1016/j.compind.2019.02.004

Fink O et al (2020) Potential, challenges and future directions for deep learning in prognostics and health management applications. Eng Appl Artif Intell 92:103678. https://doi.org/10.1016/j.engappai.2020.103678

Yang L, Shami A (2020) On hyperparameter optimization of machine learning algorithms: Theory and practice. Neurocomputing 415:295–316. https://doi.org/10.1016/j.neucom.2020.07.061

Yu T, Zhu H (2020) Hyper-Parameter Optimization: A Review of Algorithms and Applications. arXiv preprint. arXiv:2003.05689.

Kaur S, Aggarwal H, Rani R (2020) Hyper-parameter optimization of deep learning model for prediction of Parkinson’s disease. Mach Vis Appl 31:32. https://doi.org/10.1007/s00138-020-01078-1

Bergstra J, Bengio Y (2012) Random search for hyper-parameter optimization. J Mach Learn Res 13(1):281–305. https://doi.org/10.5555/2188385.2188395

Hassan M, Sabar NR, Song A, (2018) Optimising Deep Learning by Hyper-heuristic Approach for Classifying Good Quality Images. ICCS, (2018) Lecture Notes in Computer Science, vol 10861. Springer, Cham. https://doi.org/10.1007/978-3-319-93701-4_41

Sabar NR, Turky A, Song A, Sattar A (2017) Optimising Deep Belief Networks by hyper-heuristic approach. IEEE Congress on Evolutionary Computation (CEC), San Sebastian 2738–2745 https://doi.org/https://doi.org/10.1109/CEC.2017.7969640

Wu J, Chen XY, Zhang H, Xiong LD, Lei H, Deng SH (2019) Hyperparameter optimization for machine learning models based on bayesian optimization. J Elect Sci Technol 17(1):26–40. https://doi.org/https://doi.org/10.11989/JEST.1674-862X.80904120

Xia Y, Liu C, Li Y, Liu N (2017) A boosted decision tree approach using Bayesian hyper-parameter optimization for credit scoring. Expert Syst Appl 78:225–241. https://doi.org/10.1016/j.eswa.2017.02.017

Bertrand H, Ardon R, Perrot M, Bloch I (2017) Hyperparameter optimization of deep neural networks: combining Hperband with Bayesian model selection. Conférence sur l’Apprentissage Automatique, 2017

Young SR, Rose DC, Karnowski T, Lim S, Patton RM (2015) Optimizing deep learning hyper-parameters through an evolutionary algorithm. Proc Workshop Mach Learn High-Perform Comput Environ. https://doi.org/10.1145/2834892.2834896

Xiao X, Yan M, Basodi S, Ji C, Pan Y (2020) Efficient Hyperparameter Optimization in Deep Learning Using a Variable Length Genetic Algorithm. ArXiv, abs/2006.12703

Itano F, de Abreu de Sousa MA, Del-Moral-Hernandez E (2018) Extending MLP ANN hyper-parameters Optimization by using Genetic Algorithm. International Joint Conference on Neural Networks (IJCNN), Rio de Janeiro 1–8 https://doi.org/https://doi.org/10.1109/IJCNN.2018.8489520

Sehgal A, La H, Louis S, Nguyen H (2019) Deep Reinforcement Learning Using Genetic Algorithm for Parameter Optimization. Third IEEE International Conference on Robotic Computing (IRC), Naples, Italy 596–601 https://doi.org/https://doi.org/10.1109/IRC.2019.00121

Suganuma M, Shirakawa S, Nagao T (2017) A genetic programming approach to designing convolutional neural network architectures. Proc Genetic Evol Comput Conf 10(1145/3071178):3071229

Pető L, Botzheim J, (2019) Parameter Optimization of Deep Learning Models by Evolutionary Algorithms. IEEE International Work Conference on Bioinspired Intelligence (IWOBI), Budapest, Hungary 27–32 https://doi.org/https://doi.org/10.1109/IWOBI47054.2019.9114508

Soo FC, Khaw HY, Chuah JH, Kanesan J (2018) Hyper-parameters optimisation of deep CNN architecture for vehicle logo recognition. IET Intelli Transport Sys 12(8):939–946. https://doi.org/10.1049/iet-its.2018.5127

Lorenzo PR, Nalepa J, Kawulok M, Ramos LS, Pastor JR (2017) Particle swarm optimization for hyper-parameter selection in deep neural networks. Proceedings of the Genetic and Evolutionary Computation Conference (GECCO '17). Association for Computing Machinery, New York, NY, USA 481–488 https://doi.org/https://doi.org/10.1145/3071178.3071208

Qolomany B, Maabreh M, Al-Fuqaha A, Gupta A, Benhaddou D (2017) Parameters optimization of deep learning models using Particle swarm optimization. 13th International Wireless Communications and Mobile Computing Conference (IWCMC), Valencia 1285–1290 https://doi.org/https://doi.org/10.1109/IWCMC.2017.7986470

Sun Y, Xue B, Zhang M, Yen GG (2018) An Experimental Study on Hyper-parameter Optimization for Stacked Auto-Encoders. IEEE Congress on Evolutionary Computation (CEC), Rio de Janeiro 1–8 https://doi.org/https://doi.org/10.1109/CEC.2018.8477921

Essien AE, Giannetti C (2020) A Deep Learning model for Smart Manufacturing using Convolutional LSTM Neural Network Autoencoders. IEEE Trans Ind Informatics. https://doi.org/10.1109/tii.2020.2967556

Wu Y, Yuan M, Dong S, Lin L, Liu Y (2018) Neurocomputing Remaining useful life estimation of engineered systems using vanilla LSTM neural networks. Neurocomputing 275:167–179. https://doi.org/10.1016/j.neucom.2017.05.063

Funding

Research fellowship and institute research fund provided by the Ministry of Human Resource Development (MHRD), the Government of India, and the National Institute of Technology Warangal.

Author information

Authors and Affiliations

Contributions

Authors have presented a literature survey to address the challenges of the implementation of deep learning and similar techniques for machinery health prognostics with a focus on the utilization of time-series machinery failure data.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declared no potential conflicts of interest concerning the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thoppil, N.M., Vasu, V. & Rao, C.S.P. Deep Learning Algorithms for Machinery Health Prognostics Using Time-Series Data: A Review. J. Vib. Eng. Technol. 9, 1123–1145 (2021). https://doi.org/10.1007/s42417-021-00286-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-021-00286-x