Abstract

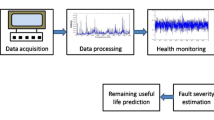

Various direct and indirect sensing methods for machine condition monitoring have been reported in the literature. Among these methods, acoustic emission technique is one of the effective means of monitoring rolling element bearings during industrial processes. Today, many machines use computerized classification in a wide range of applications. Further, recent developments indicate the drive towards integration of diagnosis and prognosis algorithms in future integrated machine health management systems. With this in mind, this paper concentrates on the estimation of the remaining useful life for bearings whilst in operation. To implement this, a linear regression classifier and multilayer artificial neural network model have been proposed to correlate the selected AE features with corresponding bearing wear throughout laboratory experiments. Results showed that the proposed models exhibit good prediction performance. This paper also presents the use of a new representative fault indicator, signal intensity estimator, employed for AE signals originating from natural degradation of slow speed rolling element bearings. It is concluded that the obtained results were promising and selecting this appropriate signal processing technique can significantly affect the defect identification.

Similar content being viewed by others

References

Jammu, N.S., Kankar, P.K.: A review on prognosis of rolling element bearings. Int. J. Eng. Sci. Technol. (IJEST) 3(10), 7497–7503 (2011)

Zhigang, T.: An artificial neural network method for remaining useful life prediction of equipment subject to condition monitoring. J. Intell. Manuf. ISSN 23(2), 0956–5515 (2012)

Medjaher, K., Tobon-Mejia, D.A., Zerhouni, N.: Remaining useful life estimation of critical components with application to bearings. IEEE Trans. Reliab. Inst. Electr. Electron. Eng. (2012) doi:10.1109/TR.2012.2194175

Nathan, B., Hai, Q., Neil, E., Ed, H., Taylor, R.: Physics-based remaining useful life prediction for aircraft engine bearing prognosis. In: Annual Conference of the Prognostics and Health Management Society (2009)

Shao, Y., Nezu, K.: Prognosis of remaining bearing life using neural networks. Proc. Inst. Mech. Eng. Part I 214(3), 217–230 (2000)

Gebraeel, N., Lawley, M., Liu, R., Parmeshwaran, V.: Residual life predictions from vibration-based degradation signals: a neural network approach. IEEE Trans. Ind. Electron. 51(3), 694–700 (2004)

Ghafari, S.H.: A fault diagnosis system for rotary machinery supported by rolling element bearings. PhD Thesis, University of Waterloo, Ontario (2007)

Sutrisno, E., Oh, H., Vasan, A.S.S., Pecht, M.: Estimation of remaining useful life of ball bearings using data driven methodologies. In: IEEE Conference on Prognostics and Health Management (PHM) (2012) doi:10.1109/ICPHM.2012.6299548

Goebel, K., Saha, B., Saxena, A.: A comparison of three data-driven techniques for prognostics. In: 62nd Meeting of the Society for Machinery Failure Prevention Technology (2008)

Kim, H.E., Tan, A.C., Mathew, J., Kim, E.Y., Choi, B.K.: Machine prognostics based on health state estimation using SVM. In: Proceedings of 3rd World Congress on Engineering Asset Management and Intelligent Maintenance Systems Conference, Vol. 199 (2008)

Tian, Z.: An artificial neural network method for remaining useful life prediction of equipment subject to condition monitoring. J. Intell. Manuf. 23(2), 227–237 (2009)

Ali, J.B., Chebel-Morello, B., Saidi, L., Malinowski, S., Fnaiech, F.: Accurate bearing remaining useful life prediction based on weibull distribution and artificial neural network. Mech. Syst. Signal Process. 56—-57, 150–172 (2015)

Tobon-Mejia, D.A., Medjaher, K., Zerhouni, N.: Tripot, G., Estimation of the remaining useful life by using Wavelet Packet Decomposition and HMMs. In: IEEE, Aerospace Conference. (2011) doi:10.1109/AERO.2011.5747561

Loutas, T.H., Roulias, D., Georgoulas, G.: Remaining useful life estimation in rolling bearings utilizing data-driven probabilistic e-support vectors regression. IEEE Trans. Reliab. 62(4), 821–832 (2013)

Elforjani, M., Mba, D.: Monitoring the onset and propagation of natural degradation process in a slow speed rolling element bearing with acoustic emission. J. Vib. Acoust. (2008) doi:10.1115/1.2948413

Elforjani, M., Mba, D.: Detecting the onset, propagation and location of non-artificial defects in a slow rotating thrust bearing with acoustic emission. Insight Non-Destruct. Test. Cond. Monit. (2008). doi:10.1784/insi.2008.50.5.264

Elforjani, M., Mba, D.: Condition monitoring of slow speed shafts and bearings with acoustic emission. Strain (2011) doi:10.1111/j.1475-1305.2010.00776.x

Price, E.D., Lees, A.W., Friswell, M.I.: Detection of severe sliding and pitting fatigue wear regimes through the use of broadband acoustic emission. IMechE J. Eng. Tribol. (2005) doi:10.1243/135065005X9817

Yoshioka, T.: Detection of rolling contact subsurface fatigue cracks using acoustic emission technique. J. Soc. Tribol. Lubr. Eng. 49(4), 303–308 (1993)

Elforjani, M., Mba, D.: Accelerated natural fault diagnosis in slow speed bearings with acoustic emission. Eng. Fract. Mech. 77(1), 112–127 (2010)

Norton, M.P., Karczub, D.G.: Fundamentals of Noise and Vibration Analysis for Engineers, 2nd edn. Cambridge University Press, Cambridge (2003)

Liu, Z., Zuo, M.J., Zhang, L.: Remaining useful life prediction of rolling element bearings based on health state assessment. In: Annual Conference of the Prognostics and Health Management Society, Vol. 5 (2014)

Murphy P.K.: Machine Learning A Probabilistic Perspective. MIT Press, Cambridge (2012)

Seber, G.E., Lee, A.: Linear Regression Analysis, 2nd edn. Wiley, Hoboken (2003)

Hocking, R.R.: Methods and Applications of Linear Models: Regression and the Analysis of Variance, 3rd edn. Wiley, New York (2013)

Chatterjee, S., Simonoff, S.J.: Handbook of Regression Analysis, 1st edn. Wiley, New York (2012)

Wikipedia https://en.wikipedia.org/wiki/Confusion_matrix, Accessed Date (2016)

Kubat, M.: An Introduction to Machine Learning. Springer, New York (2015)

Livingstone, J.D.: Artificial Neural Networks: Methods and Applications, 2009 Edition. Humana Press, Heidelberg (2008)

Hopgood, A.A.: Intelligent Systems for Engineers and Scientists, 2nd edn. CRC Press, Boca Raton (2001)

Heaton, J.: Artificial Intelligence for Humans, Volume 3: Deep Learning and Neural Networks. CreateSpace Independent Publishing Platform (2015)

Apolloni, B., Bassis, S., Marinaro, M., Apolloni, B.: New Directions in Neural Networks. In: 18th Italian Workshop on Neural Networks, WIRN, Frontiers in Artificial Intelligence and Applications, Vol. 193 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elforjani, M. Estimation of Remaining Useful Life of Slow Speed Bearings Using Acoustic Emission Signals. J Nondestruct Eval 35, 62 (2016). https://doi.org/10.1007/s10921-016-0378-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-016-0378-0