Abstract

Electrochemical biosensors made of titanium dioxide have generated significant interest due to their high sensitivity and selectivity for the detection of a variety of diseases. This study focuses on the impact of thermal treatment in an oxygen environment on the electrical properties of titanium dioxide thin films deposited on silicon substrates using pulsed laser deposition; the films were subjected to temperatures of \(\varvec{100\,\,^{\circ }C}\), \(\varvec{400\,\,^{\circ }C}\), and \(\varvec{600\,\,^{\circ }C}\). The primary objective was to explore how thermal processing influences the electrical characteristics of the thin films, with the goal of enhancing their capacitance and thereby improving the performance of sensors developed by functionalizing these films; X-ray photoelectron spectroscopy revealed the presence of Ti\(^{4+}\), Ti\(^{3+}\) and TiO\(_x\) species in the untreated thin film and in the heat-treated films, with an increase in TiO\(_x\) species observed after oxygen heat treatment. Atomic force microscopy demonstrated a decrease in the surface homogeneity of the films at elevated treatment temperatures, which corresponded to a reduction in capacitive behavior; this was further corroborated by Nyquist plots derived from electrochemical capacitance spectroscopy (ECS). The study found that the electrochemical capacitance at lower frequencies decreased significantly from \(\varvec{1.02\,\, \mu Fcm^{-2}}\) to \(\varvec{0.25\,\, \mu Fcm^{-2}}\) when the treatment temperature was increased to \(\varvec{600\,\,^{\circ }C}\)

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Titanium dioxide (TiO\(_2\)) thin films can be produced at low costs through various methods, including magnetron sputtering [1,2,3,4], physical vapor deposition of electron beams [5, 6], cathodic arc [7,8,9,10], pulsed laser deposition (PLD) [11,12,13], atomic layer deposition [14], sol–gel [15, 16], spray pyrolysis [17], hybrid processes (ionic implantation+cathodic arc) [18,19,20,21,22], and chemical vapor deposition [23]. TiO\(_2\) thin films exhibit excellent electrical and semiconducting properties, high substrate adhesion, photo corrosion resistance, strong ultraviolet absorption, good photocatalytic activity, biocompatibility, nontoxicity, and quantum confinement; these characteristics make them suitable for potential applications in biosensors, supercapacitors, electrochromic coatings, photocatalysts for degrading organic pollutants (self-cleaning), and antifog coatings [11, 24,25,26,27,28].

TiO\(_2\) exists in three crystalline phases: anatase, rutile, and brookite [29, 30]. Anatase and rutile have a tetragonal crystal structure, while brookite has an orthorhombic crystal structure [30, 31]. In bulk material, rutile is the stable phase; however, anatase is generally preferred for the preparation of solution phases [30, 32]; furthermore, anatase and brookite are metastable phases that can easily transform into rutile with increasing temperature [30, 33, 34].

PLD is a coating technique that allows for precise control of the film thickness, ensuring good homogeneity and reproducibility. The characteristics of PLD-fabricated films depend on various experimental conditions, such as substrate type, the distance between the substrate surface and the target, the deposition time and temperature, laser frequency and fluence, gas type and pressure of the deposition chamber [12, 13, 35].

In this research work, we report the results obtained from the analysis of the chemical composition of the surface by X-ray photoelectron spectroscopy (XPS), the characterization of the surface morphology by atomic force microscopy (AFM), Raman spectroscopy (RS), and the evaluation of the electrical properties by electrochemical impedance of TiO\(_2\) thin films deposited on silicon substrates by the PLD technique as a function of the annealing temperature.

2 Methodology

The experimental methodology in this research work was sequentially developed as follows: preparation and deposition of the substrate surface, thermal treatment of the coated substrates, and subsequent morphological, structural, and electrochemical surface characterization.

2.1 Titanium dioxide thin-film deposition

TiO\(_2\) thin films on Si surfaces were fabricated using the PLD technique, as shown in Fig. 1; a turbomolecular pump system ensures a residual pressure of \(1 \times 10^{-5} \,\, Pa\) in the deposition chamber. The Ti target was a \(5\,\,cm\) diameter, \(1\,\,cm\) thick disk, rotating at \(28\,\,rpm\) during the process; it was ablated by a neodymium-doped yttrium aluminum garnet (Nd:YAG) third harmonic \(355\,\,nm\) laser. The laser beam impinged at \(45\,\,^{\circ }\) on the Ti target surface at a repetition rate of \(10 \,\, Hz\), with a pulse width of \(8 \,\, ns\), and an energy per pulse of approximately \(88\,\,mJ\), provided by Quantel’s Q-Smart 850 equipment [13]. The TiO\(_2\) thin films were deposited at room temperature (RT) with an oxygen pressure of \(4.6 \,\, Pa\), a separation distance of approximately \(5 \,\, cm\) between the target and Si substrate surfaces, for \(7 \,\, min\).

2.2 Thermal treatment

The heat treatment of the surfaces was performed in a high-pressure cell (HPC) coupled to the XPS analysis chamber. This setup allowed analysis of the samples without contact with the environment. The samples were cut in dimensions of \(1 \times 1\, cm\) and placed on a metal support equipped with a thermocouple to control the process and measure the sample temperature. The samples were then placed in the loading chamber until a pressure of \(1 \times 10^{-8}\, mbar\) was obtained; then they were transported through the transfer line of the equipment to the HPC. Oxygen (grade 5.0 UAP) was introduced into the HPC at a flow rate of \(50 \,\, ml/min\). The samples were subjected to annealing temperatures of \(100\,\,^{\circ }C\), \(400\,\,^{\circ }C\), and \(600\,\,^{\circ }C\) at a heating rate of \(5\,\,^{\circ }C/min\). They were then exposed to the oxidizing atmosphere for \(1 \,\, h\). After the procedure, the HPC pressure was set at \(1 \times 10^{-6}\, mbar\) to transport the samples to the XPS chamber for spectral analysis.

2.3 Surface chemical composition analysis

The structural properties of Si surfaces coated with TiO\(_2\) thin films were analyzed by XPS. Measurements were made on a SPECS (Germany) XPS/ISS/UPS surface characterization platform equipped with a PHOIBOS 150 2D-DLD energy analyzer package. A monochromatic Al K\(\alpha\) X-ray source (FOCUS 500) operated at \(100\,\,W\). The pass energy of the hemispherical analyzer was set at \(100\,\,eV\) for general spectra and \(20\,\,eV\) for high-resolution spectra [13]. The pressure in the analysis chamber was approximately \(1 \times 10^{-7}\,\,Pa\).

The samples were placed on metal supports with carbon conductive tape; surface charge compensation was controlled with a Flood Gun (FG 15/40-PS FG500) operated at \(58 \,\, \mu A\) and \(-3.2 \,\, eV\). General spectra were recorded first, followed by high-resolution spectra of C 1s, O 1s, Ti 2p, Ca 2p, N 1s, and F 1s. The stability of surface charge compensation was verified by recording the C 1s peak at the end of the analyses; data analysis was performed with the CasaXPS program (Casa Software Ltd), using the binding energy of photoelectron level C 1s (\(284.6\,\,eV\)) as the internal calibration standard. Shirley’s background was used in the peak decomposition. The relative sensitivity factors (RSF) values used were 1, 2.93, and 7.81 for C 1s, O 1s, and Ti 2p, respectively.

2.4 Surface morphology analysis

The morphology, roughness, and thickness of the TiO\(_2\) thin films deposited on Si substrates were analyzed by AFM; images were obtained using a Hitachi AFM5100N multifunction scanning probe microscope (SPM) unit, operating in noncontact mode with commercial probes (Nanoprobe FIB2-100 S). The thickness of the TiO\(_2\) thin film was obtained by measuring a step in an AFM image.

2.5 Crystal structure analysis

RS measurements were performed to analyze the crystal structure of all samples; RS spectra were acquired using a Horiba scientific LabRam HR evolution (Yobim Yvon, USA). A frequency-stabilized single diode laser was operated at \(532\,\,nm\); each spectrum was collected using a 100X long working distance objective and the acquisition time was \(2\,\,s\) for 20 averaged accumulations.

2.6 Electrical measurements

Electrical impedance spectroscopy (EIS) measurements were performed using a Metrohm PGSTAT-204 potentiostat equipped with an FRA-32 M module [36]; a three-electrode cell configuration was used, with the TiO\(_2\) thin film as the working electrode and the gold wire and Ag/AgCl (\(3\,\,mol L^{-1}\)) as the counter and reference electrodes, respectively. The electrochemical cell was isolated from external fields by placing it inside a Faraday box; EIS measurements were recorded in a phosphate buffered saline solution (PBS) (pH 7.4) at the open circuit potential (\(V_{OCP}\)) of the film (about \(0\,\,V\)) over a frequency range of \(1 \times 10^{6}\) to \(0.1\,\,Hz\), with a voltage peak to peak of \(10 \,\, mV\) [36]. Measurements were always made in triplicate and with the mean value of the measures, an inverse modeling was applied to the experimental data to interpret them.

3 Results and discussion

Four TiO\(_2\) thin films were obtained by PLD under identical experimental conditions. Three of these samples were thermally treated at temperatures of \(100\,\,^{\circ }C\), \(200\,\,^{\circ }C\), and \(400\,\,^{\circ }C\), respectively; experimental analyzes, including surface morphology, crystal structure, and electrical characterization, were conducted on all four samples, as described in the following sections.

3.1 Surface chemical composition analysis

The XPS spectra of the TiO\(_2\) thin film, as shown in Fig. 2a, reveal the presence of peaks corresponding to Ti 2s, O 1s, Ti 2p, C 1s, Ti 3s, Ti 3p, and O 2s; consequently, the analysis of the XPS peaks confirms the presence of oxygen and titanium in the TiO\(_2\) thin film. In particular, carbon was also detected, likely due to organic contamination from exposure to ambient conditions. The elemental compositions of the thin film of untreated TiO\(_2\) and those subjected to thermal treatment with oxygen are presented in Table 1.

The O 1s spectra of the TiO\(_2\) thin film, depicted in Fig. 2b, exhibit four distinct peaks; the peak at \(529.8\,\,eV\) is attributed to oxygen bond with titanium (titanium oxides) [13, 37,38,39]. The presence of Ti-OH species is evidenced by the signal obtained at \(530.6\,\,eV\) [13, 38, 39]; the peaks at \(531.5\,\,eV\) and \(532.4\,\,eV\) are attributed to the carboxyl group, (C = O) -OH [39], of contaminating organic compounds. The presence of hydroxyl groups on the film’s surface is likely due to interaction with the environment after fabrication, as the oxide surface rapidly reacts with atmospheric water vapor, leading to hydroxylation [13, 38]; furthermore, the high-resolution XPS spectrum of Ti 2p for the thin film, shown in Fig. 2c, displays peaks at \(458.3\,\,eV\) and \(464.1\,\,eV\), corresponding to \(2p_{3/2}\) and Ti \(2p_{1/2}\), respectively, which are indicative of Ti\(^{4+}\) from the TiO\(_2\) lattice [39, 40]. Signals at \(457.1\,\,eV\) and \(462.8\,\,eV\) are associated to Ti\(^{3+}\) in the TiO\(_2\) lattice [39, 40], while the contributions at \(459.4\,\,eV\) and \(465.3\,\,eV\) are related to the existence of non-stoichiometric titanium oxide, TiO\(_x\) [39]. As indicated in Table 1, there is a trend of decreasing carbon content on the thin film surface with increasing temperatures of thermal treatment in oxygen.

The high-resolution XPS spectra of O 1 s for thin films with thermal treatment with oxygen, as shown in Fig. 3a, b, and c, reveal peaks corresponding to the lattice oxygen of TiO\(_2\), surface hydroxyl groups (Ti-OH) and carboxyl group, (C=O)-OH; similarly, the Ti spectrum 2p, depicted in Fig. 3d, e, and f, displays peaks corresponding to Ti\(^{4+}\), Ti\(^{3+}\) and TiO\(_x\) species, consistent with findings in the untreated thin film. The thin film post \(100\,\,^{\circ }C\) treatment exhibits high-resolution XPS spectra of O 1s and Ti 2p very similar to those of the starting material (see Fig. 2b and c, Fig. 3a and d); however, the spectra for films treated at \(400\,\,^{\circ }C\) and \(600\,\,^{\circ }C\) show a decrease in the percentage contribution of the peak related to oxygen in the carboxyl group of organic contaminants, and consequently a slight increase in the percentage of peaks attributed to Ti-O and Ti-OH (in the O 1s spectrum), as indicated in Table 2. Furthermore, high-resolution XPS of Ti 2p analyses indicate an increase in the amount of TiO\(_x\) species formed at higher treatment temperatures (see Table 3); it was also observed that two peaks of Ti (doublets Ti \(2p_{1/2}\) and Ti \(2p_{3/2}\)) experienced a shift to higher binding energies as the treatment temperature was higher. This shift can be related to the crystalline phase transitions of TiO\(_2\) [37,38,39,40,41].

3.2 Surface morphology analysis

AFM images of TiO\(_2\) thin films, untreated and thermally treated, are presented in Fig. 4; the surface of the untreated TiO\(_2\) thin film, which exhibits a homogeneous topography with a root mean square (RMS) roughness of \(0.2\,\,nm\) and a thickness of \(18\,\,nm\), is presented in Fig. 4a. The AFM analysis indicates that the roughness increases with the temperature of the thermal treatment, as detailed in Table 4; these roughness values were determined for the entire area of the corresponding AFM image for each thin film. Thermally treated thin films, as shown in Fig. 4c and d, show inhomogeneous surfaces with the formation of large dots on the TiO\(_2\) surface at elevated temperatures of \(400\,\,^{\circ }C\) and \(600\,\,^{\circ }C\), resulting in increased RMS roughness values of \(0.5\,\,nm\) and \(0.7\,\,nm\), respectively.

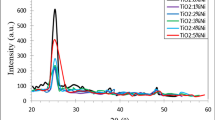

3.3 Crystal structure analysis

The Raman spectrum of the untreated TiO\(_2\) thin film, as shown in Fig. 5, reveals the characteristic peaks of the rutile phase at \(233 \,\, cm^{-1}\), \(433\,\, cm^{-1}\), \(620\,\, cm^{-1}\), and \(822 \,\ cm^{-1}\), corresponding to the two-phonon scattering [42], \(E_g\) [42, 43], \(A_{1\,g}\) [42, 43], and \(B_{2\,g}\) [43] modes, respectively; however, after thermal treatment, the peak of the anatase phase in \(147\,\,cm^{-1}\), attributed to the mode \(E_g\) and close to the reported value of \(143\,\,cm^{-1}\) [42], becomes more pronounced at higher temperatures (\(400\,\,^{\circ }C\) and \(600\,\,^{\circ }C\)) indicating a possible crystalline phase transition (from amorphous to anatase) that correlates well with the results of the XPS analyzes of the shift of the Ti 2p peaks for TiO\(_2\). Furthermore, the peaks associated with the rutile phase, observed in the Raman spectrum of the untreated TiO\(_2\) thin film, are also present in the spectra of the thermally treated films. The signals at \(300\,\,cm^{-1}\) and \(520\,\,cm^{-1}\) in all Raman spectra are attributed to Si-Si in the Si substrate [43]. Likewise, the band centered at approximately \(950\,\,cm^{-1}\) is indicative of the Si-O-Ti bond formed between the TiO\(_2\) thin film and the substrate [44]; these findings suggest the coexistence of anatase and rutile phases in TiO\(_2\) thin films thermally treated at \(400\,\,^{\circ }C\), and \(600\,\,^{\circ }C\).

3.4 Electrical properties

The electrical properties of the TiO\(_2\) thin film, as shown in Fig. 6, are accurately represented by a multi-Cole capacitive model given by Eq. 1; in the capacitive model, the values of \(\chi ^2\) for the samples treated at different temperatures are below the critical value (79), indicating that the models accurately describe the experimental data. However, the \(\chi ^2\) value for the non-thermally treated sample (2650) exceeds this critical threshold, suggesting that the standard deviation of the experimental data is smaller than the deviation of the fitting curve from the experimental data’s mean value; despite this, the graphical representation of the data suggests that the model describes the electrical properties of the surface. The parameters of this model are described in Table 5 and visually illustrated in the circuit diagram in Fig. 7. In the Nyquist plot (see Fig. 6a), the first two components of Eq. 1 appear as Cole-Cole semicircles, while the third component, evident only at a higher temperature of \(600\,\,^{\circ }C\), manifests itself as a constant phase element at lower frequencies; the first Cole-Cole corresponds to the lower frequency behavior, and the second corresponds to the higher frequency. The circuit diagram (see Fig. 7) reveals three parallel electrical paths: two predominantly capacitive, modeled by the Cole-Cole equations, and a third path characterized by a constant phase element.

The capacitive Nyquist plots (see Fig. 6a) reveal that the thermal treatment with oxygen at \(100\,\,{^{\circ }}C\) maintains the capacitive behavior of the TiO\(_2\) thin films, but results in a reduction in the diameter of the low-frequency Cole-Cole semicircle (\(\Delta C_1\)). Specifically, the electrochemical capacitance \(\Delta C_1\) of the thin film decreases from \(1.02\,\, \mu Fcm{^{-2}}\) to \(0.65\,\, \mu Fcm {^{-2}}\) at \(100\,\,{^{\circ }}C\); at \(400\,\,{^{\circ }}C\), \(\Delta C_{1}\) increases to \(1.48\,\, \mu Fcm{^{-2}}\), but reaches its lowest value at \(600\,\,{^{\circ }}C\), which is \(0.25\,\ \mu Fcm{^{-2}}\). This decrease in electrochemical capacitance is probably related to the loss of the TiO\(_2\) coating in some regions, as suggested by the AFM images, which show that, at higher treatment temperatures, the RMS roughness increases and the homogeneity of the thin film is altered. The formation of pores that expose the silicon substrate is probable, given the nanometric dimension of the TiO\(_2\) thin film, which facilitates the quantum confinement that contributes to the electrochemical or quantum capacitance [45, 46]. The low thickness of the thin film, at \(18\,\,nm\), might lead to atomic rearrangement, resulting in the formation of pores and the exposure of the silicon substrate. Consequently, this could create a surface with two phases or different compositions, consisting of titanium oxides and silicon. Furthermore, XPS studies indicate that increasing the temperature during thermal treatment with oxygen leads to the formation of TiO\(_x\) species. Although non-stoichiometry TiO\(_2\) thin films lead to an elevated charge carrier concentration [47], which could lead to high electrochemical capacitance, this effect was not observed in this study, probably due to thermal treatment that alters the homogeneity of the thin film. XPS analyses also show that increasing the treatment temperature eliminates the content of organic species containing C and O, indicating that the thermal treatment of TiO\(_2\) thin films can serve as a surface cleaning strategy; However, there is a consequence of the change in the morphological and electrochemical properties.

The behavior of the Cole-Cole capacitance at higher frequencies contrasts with that observed at lower frequencies. However, the sum of \(\Delta C_1\) and \(\Delta C_2\) remains approximately close to \(2 \mu Fcm ^{-2}\) for the thin films, ranging from those that were not treated thermally to those treated at \(400^{\circ }C\). The thin film treated at \(600^{\circ }C\) exhibits a half value of \(\Delta C_{1} + \Delta C_{2} \approx 1 \mu Fcm^{-2}\); this indicates that exposure to 600\(^{\circ }C\) results in the most significant modification of electrical properties. This change is clearly evident in the Bode plot (see Fig. 6b), where the effect of the high-temperature treatment on the electrical characteristics of the thin film is clearly visible.

a Nyquist and (b) Bode graphs for the electrochemical capacitance spectra per electroactive geometric area (\(0.5 \,\ cm^{2}\)) of TiO\(_2\) thin films, both untreated and after treatments in oxygen at various temperatures; solid lines represent the fit to the model described by Eq. 1, with parameters detailed in Table 5. Measurements were made in a support electrolyte of PBS (pH = 7.4), around the open circuit potential (\(V_{OCP}\)), ranging from \(0.1\,\,Hz\) to \(100\,\,kHz\) with a peak to peak voltage of \(10\,\,mV\)

Circuit diagram representing the multi Cole-Cole model as described by Eq. 1

4 Conclusions

This study underscores the importance of maintaining a homogeneous coating on titanium dioxide thin films obtained from pulsed laser deposition to ensure capacitive behavior with high electrochemical capacitance values; the results of atomic force microscopy and X-ray photoelectron spectroscopy indicate that increasing the temperature during the thermal treatment of oxygen leads to less homogeneous surfaces with increased roughness and increased formation of TiO\(_{x}\) species, while organic compounds with carboxyl group are removed from the surface of the thin film proportionally to the increase in the treatment temperature. Furthermore, it was observed that the rise in temperature during the oxygen thermal treatment of the thin films, and consequently the decrease in the homogeneity of their coating, impact their electrical properties in such a way that the capacitive behavior is preserved only at high frequencies, with a decrease in the value of their electrochemical capacitance. The insights from this study are clearly extendable to nanostructured films applied as electrochemical capacitive sensors.

Data availability

Data will be available at the request of the interested parties.

References

B. Comert, N. Akin, M. Donmez, S. Saglam, S. Ozcelik, Titanium dioxide thin films as methane gas sensors. IEEE Sensors J. 16(24), 8890–8896 (2016)

S.M. Waita, B.O. Aduda, J.M. Mwabora, C.G. Granqvist, S.E. Lindquist, G.A. Niklasson, A. Hagfeldt, G. Boschloo, Electron transport and recombination in Dye sensitized solar cells fabricated from obliquely sputter deposited and thermally annealed TiO2 films. J. Electroan. Chem. 605(2), 151–156 (2007)

R. Gago, A. Redondo-Cubero, J.L. Endrino, I. Jiménez, N. Shevchenko, Aluminum incorporation in films studied by x-ray absorption near-edge structure. J. Appl. Phys. 105(11), 113521 1–6 (2009)

R. Gago, F. Soldera, R. Hübner, J. Lehmann, F. Munnik, L. Vázquez, A. Redondo-Cubero, J.L. Endrino, X-ray absorption near-edge structure of hexagonal ternary phases in sputter-deposited TiAlN films. J. Alloys Comp. 561, 87–94 (2013)

M. Salado, M. Oliva-Ramirez, S. Kazim, A.R. González-Elipe, S. Ahmad, 1-dimensional TiO2 nano-forests as photoanodes for efficient and stable perovskite solar cells fabrication. Nano Energy 35, 215–222 (2017)

L. González-García, J. Parra-Barranco, J.R. Sánchez-Valencia, A. Barranco, A. Borrás, A.R. González-Elipe, M.C. García-Gutiérrez, J.J. Hernández, D.R. Rueda, T.A. Ezquerra, Correlation lengths, porosity and water adsorption in TiO2 thin films prepared by glancing angle deposition. Nanotechnol. 23(20), 205701:1–10 (2012)

B.D. Beake, G.S. Fox-Rabinovich, Y. Losset, K. Yamamoto, M.H. Agguire, S.C. Veldhuis, J.L. Endrino, A.I. Kovalev, Why can TiAlCrSiYN-based adaptive coatings deliver exceptional performance under extreme frictional conditions? Faraday Discuss. 156, 267–277 (2012)

J.L. Endrino, G.S. Fox-Rabinovich, R. Escobar Galindo, W. Kalss, S. Veldhuis, L. Soriano, J. Andersson, A. Gutiérrez, Oxidation post-treatment of hard AlTiN coating for machining of hardened steels. Surf. Coat. Technol. 204(3), 256–262 (2009)

V.D. Dugar-Zhabon, H.J. Dulcé-Moreno, H.A. Garnica-Villamizar, E.D. Valbuena-Niño, A new method for Surface modifications of carbon steels and alloys. Mater. Res. 15(6), 969–973 (2012)

P. Tsygankov, A. Plata, E.D V-Niño, C. Ochoa, F. Parada, C. Chacón, V. Dugar-Zhabon, Estudio de características voltio-ampéricas y peculiaridades de funcionamiento de un vaporizador de arco en vacío. Revista Colombiana de Física 43(2), 458–462 (2011)

B. Gao, S. Zhang, X. Ju, Y. Lin, X. Wang, Femtosecond pulsed laser deposition of nanostructured TiO2 films in atmosphere. AIP Adv. 7(9), 095206:1–7 (2017)

A. Ishii, Y. Nakamura, I. Oikawa, A. Kamegawa, H. Takamura, Low-temperature preparation of high-n TiO2 thin film on glass by pulsed laser deposition. Applied Surface Science 347, 528–534 (2015)

L. Bertel, R. Ospina, J.M. García-Martín, D.A. Miranda, Experimental analysis of folic acid adsorption on TiO2 thin-films. J. Vac. Sci. Technol. A 40(3), 033411:1–9 (2022)

L. Liu, R. Bhatia, T.J. Webster, Atomic layer deposition of nano-TiO2 thin films with enhanced biocompatibility and antimicrobial activity for orthopedic implants. Int. J. Nanomed. 12, 8711–8723 (2017)

X. Chen, Z. Yang, S. Si, Potentiometric urea biosensor based on immobilization of urease onto molecularly imprinted TiO2 film. J. Electroan. Chem. 635(1), 1–6 (2009)

N.D.S. Mohallem, M.M. Viana, M.A.M.L. de Jesus, G.H. de Magalhães Gomes, L.F. de Sousa Lima, E.D.L. Alves, Pure and nanocomposite thin films based on TiO2 prepared by sol-gel process: characterization and applications. In Titanium Dioxide - Material for a Sustainable Environment, ed. D. Yang (IntechOpen, United Kingdom, 2018)

H. Attouche, S. Rahmane, S. Hettal, N. Kouidri, Precursor nature and molarities effect on the optical, structural, morphological, and electrical properties of TiO2 thin films deposited by spray pyrolysis. Optik 203(163985), 1–7 (2020)

A.C. Pabón-Beltran, F. Sanabria-Martínez, C. Vásquez, J.J. Barba-Ortega, E.D. Valbuena-Niño, Study of concentration depth profiles of the titanium and nitrogen ions by SRIM/TRIM simulation. Ingeniería y Universidad 25(2), 1–16 (2021)

E.D. Valbuena-Niño, L. Gil, L. Hernández, F. Sanabria, Corrosion resistance of a carbon-steel surface modified by three-dimensional ion implantation and electric arc. Adv. Mater. Res. 9(1), 1–14 (2020)

F. Parada-Becerra, P. Tsygankov, V. Dugar-Zhabon, D.Y. Peña, J. Coronado, J. González, E.D. V-Niño, Morphologic evaluation of silicon surface modified with titanium and titanium+nitrogen. Acta Microscopica 28(2), 39–47 (2019)

F. Sanabria, L. Gil, C. Matos, E.D. V-Niño, Experimental evaluation on electrochemical corrosion of ion-implanted medium-carbon steel of titanium and titanium+nitrogen. Acta Microscopica 28(2), 72–86 (2019)

E.D. Valbuena-Niño, V. Dugar-Zhabon, H.J. Dulce Moreno, G. Peña Rodríguez, H.A. Garnica, P. Tsygankov, Aplicación de descargas simultáneas de alto voltaje y arco eléctrico para el tratamiento superficial avanzado de metales. Iteckne 9(1), 14–20 (2012)

W.B. Wang, A. Yanguas-Gil, Y. Yang, D.-Y. Kim, G.S. Girolami, J.R. Abelson, Superconformal chemical vapor deposition of thin films in deep features. J. Vac. Sci. Technol. A 32(5), 061502:1–10 (2014)

J. Bai, B. Zhou, Titanium dioxide nanomaterials for sensor applications. Chem. Rev. 114(19), 10131–10176 (2014)

L. Cardenas-Flechas, J.J. Barba-Ortega, M.R. Joya, Películas de óxido de cobre y hierro depositadas en Nanotubos de Titanio. Revista UIS Ingenierís 19(1), 171 (2020)

S. Nadzirah, S.C. Gopinath, N. Parmin, A.A. Hamzah, M.A. Mohamed, E.Y. Chang, C.F. Dee, State-of-the-art on functional titanium dioxide-integrated nano-hybrids in electrical biosensors. Crit. Rev. Anal. Chem. 52(3), 637–648 (2022)

L. Bertel, D.A. Miranda, J.M. García-Martín, Nanostructured titanium dioxide surfaces for electrochemical biosensing. Sensors 21(18), 6167:1–24 (2021)

T. Berger, D. Monllor-Satoca, M. Jankulovska, T. Lana-Villarreal, R. Gómez, The electrochemistry of nanostructured titanium dioxide electrodes. ChemPhysChem 13(12), 2824–2875 (2012)

A.M. Luís, M.C. Neves, M.H. Mendonça, O.C. Monteiro, Influence of calcination parameters on the TiO2 photocatalytic properties. Mater. Chem. Phys. 125(1–2), 20–25 (2011)

A.S Bakri, M.Z Sahdan, F Adriyanto, N.A. Raship, N.D.M Said, S.A Abdullah, M.S Rahim, Effect of annealing temperature of titanium dioxide thin films on structural and electrical properties. AIP Conference Proceedings 1788, 030030:1–8 (2017)

N. Barati, M.A. Faghihi Sani, H. Ghasemi, Z. Sadeghian, S.M.M. Mirhoseini, Preparation of uniform TiO2 nanostructure film on 316L stainless steel by sol-gel dip coating. App. Surf. Sci. 255(20), 8328–8333 (2009)

D. Reyes-Coronado, G. Rodríguez-Gattorno, M.E. Espinosa-Pesqueira, C. Cab, R. de Coss, G. Oskam, Phase-pure TiO2 nanoparticles: anatase, brookite and rutile. Nanotechnol. 19(14), 145605:1–10 (2008)

A. Di Paola, M. Bellardita, L. Palmisano, Brookite, the least known TiO2 photocatalyst. Catal. 3(1), 36–73 (2013)

R. Mechiakh, N. Ben Sedrine, R. Chtourou, and R. Bensaha, Correlation between microstructure and optical properties of nano-crystalline TiO2 thin films prepared by sol-gel dip coating. Appl. Surf. Sci. 257(3), 670–676 (2010)

S.N. Ogugua, O.M. Ntwaeaborwa, H.C. Swart, Latest development on pulsed laser deposited thin films for advanced luminescence applications. Coatings 10(11), 1078:1–22 (2020)

D.A. Miranda Mercado, E.V. Godoy Alarcón, E.D. V-Niño, Time evolution of electrical impedance spectra of Staphylococcus aureus and Escherichia coli bacteria. Bioelectrochem. 155, 108557:1–8 (2024)

L.D. Trino, E.S. Bronze-Uhle, A. George, M.T. Mathew, P.N. Lisboa-Filho, Surface physicochemical and structural analysis of functionalized titanium dioxide films. Colloids. Surf. A. Physicochem. Eng. Asp. 546, 168–178 (2018)

B. Bharti, S. Kumar, H.N. Lee, R. Kumar, Formation of oxygen vacancies and Ti3+ state in TiO2 thin film and enhanced optical properties by air plasma treatment. Sci. Rep. 6(32355), 1–12 (2016)

H. Sopha, I. Mirza, H. Turčičova, D. Pavlinak, J. Michalicka, M. Krbal, J. Rodriguez-Pereira, L. Hromadko, O. Novák, J. Mužík, M. Smrž, E. Kolibalova, N. Goodfriend, N.M. Bulgakova, T. Mocek, J.M. Macak, Laser-induced crystallization of anodic TiO2nanotube layers. RSC Adv. 10, 22137–22145 (2020)

L.J. Hoyos, D.F. Rivera, A.F. Gualdrón-Reyes, R. Ospina, J. Rodríguez-Pereira, J.L. Ropero-Vega, M.E. Niño-Gómez, Influence of immersion cycles during n-\(\beta\)-Bi2O3 sensitization on the photoelectrochemical behaviour of N-F-codoped TiO2 nanotubes. Appl. Surf. Sci. 423, 917–926 (2017)

H. Navarro Pantaroto, J. Matozinho Cordeiro, L. Toniolo Pereira, A. Bandeira de Almeida, F.H. Nociti Junior, E. Cipriano Rangel, N.F. Azevedo Neto, J.H. Dias da Silva, V.A. Ricardo Barão, Sputtered crystalline TiO2 film drives improved surface properties of titanium-based biomedical implants. Mat. Sci. Eng. C. 119 (2021)

W. Su, J. Zhang, Z. Feng, T. Chen, P. Ying, C. Li, Surface phasesof TiO2 nanoparticles studied by UV Raman spectroscopy and FT-IR spectroscopy. J. Phys. Chem. C. 112, 7710–7716 (2008)

A. Mondal, J.C. Dhar, P. Chinnamuthu, N.K. Singh, K.K. Chattopadhyay, S.K. Das, S.C. Das, A. Bhattacharyya, Electrical properties of vertically oriented TiO2 nanowire arrays synthesized by glancing angle deposition technique. Electron. Mat. Letter. 9, 213–217 (2013)

M. Subramanian, S. Vijayalakshmi, S. Venkataraj, R. Jayavel, Effect of cobalt doping on the structural and optical properties of TiO2 films prepared by sol-gel process. Thin Solid Films 516, 3776–3782 (2008)

E.F. Pinzón, A. dos Santos, P.R. Bueno, Density of states of a nanoscale semiconductor interface as a transduction signal for sensing molecules. ACS Appl. Electron. Mater. 3(8), 3411–3417 (2021)

E.F Pinzón Nieto, E.V. Godoy Alarcón, Y.P. Sánchez, P.R. Bueno, Quantum rate dynamics and charge screening at the nanoscale level. Phys. Chem. Chem. Phys. 24, 16200–16206 (2022)

M. Radecka, A. Brudnik, K. Kulinowski, A. Kot, J. Leszczyński, J. Kanak, K. Zakrzewska, Titanium dioxide thin films with controlled stoichiometry for photoelectrochemical systems. J. Electron. Mater. 48, 5481–5490 (2019)

Acknowledgements

Authors acknowledge the teams of Laboratorio de Ciencia de Superficies and Laboratorio de Espectroscopia of Parque Tecnológico de Guatiguará at the Universidad Industrial de Santander for XPS and Raman analysis. E D V-Ninño expresses his gratitude to Universidad Industrial de Santander for the support through the postdoctoral position associated with the project VIE 2816.

Funding

Open Access funding provided by Colombia Consortium This work was partially financed by the postdoctoral position supplied by Universidad Industrial de Santander associated with grant number 2816.

Author information

Authors and Affiliations

Contributions

E.D.V.N. designed and performed the experiments, analyzed the data, and contributed to the discussion of the results; likewise, wrote and edited the paper; L.B. analyzed the data and contributed to the discussion of the results; D.A.M. managed and coordinated the overall research, wrote Python scripts for the inverse models presented in the paper, obtained the models parameters, contributed to the discussion of the results, the drafting, and editing paper. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

V-Niño, E.D., Bertel, L. & Miranda, D.A. Effects of thermal treatment on the electrical behavior of titanium dioxide thin-films. emergent mater. (2024). https://doi.org/10.1007/s42247-024-00694-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42247-024-00694-1