Abstract

Thin film epitaxy is essential for state-of-the-art semiconductor applications. The combination of different substrates and deposition methods leads to various crystallographic orientation relationships between thin films and substrates, which have a decisive impact on thin film performance. By utilizing pulsed laser deposition, we discovered a very high-index \((7 \overline{1 } 4)\)–oriented NiO thin film when deposited on r-plane \(\text{(10}\overline{1}\text{2)}\) sapphire substrates. The in-plane epitaxial relations are \({[13\overline{1 }]}_{\text{NiO}}\text{||[1}\overline {2}{\text{10]}}_{\text{Sapphire}}\) and \({[\overline{1 }12]}_{\text{NiO}}\text{||[10}\overline{11}{\text{]}}_{\text{Sapphire}}\), and the lattice mismatch is 3.2% and 0.4% along two directions, respectively. Exchange bias studies by the deposition of Co on NiO (111) and NiO \((7 \overline{1 } 4)\) show different behaviors, which may be associated with the spin density and alignment on the surface.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Wide-bandgap semiconductors (WBGSs) provide devices with much higher breakdown voltage, switching frequency, and operating temperature [1,2,3]. NiO is a promising WBGS material with p-type conductivity controlled by nickel vacancies or cation doping [4], which is essential in forming p-n heterojunctions with n-type semiconductors like ZnO and GaN [5, 6]. In addition, NiO displays antiferromagnetic behavior with AF2 ordering and a Néel temperature of 525 K. The outstanding electrical, magnetic, and optical properties of NiO have attracted wide attention in a variety of applications, such as light-emitting diodes, gas sensors, spin valve, and resistive random access memory devices [7,8,9,10,11,12]. The importance of the high-index NiO films could exhibit different spin structures and crystal symmetries compared with bulk NiO. It is therefore open various possibilities to study the crystal symmetry–induced spin splitting effect such as the anomalous Hall effect and the antiferromagnetic tunneling magnetoresistance effect [13, 14].

Extensive studies have been focused on the fabrication of various NiO nanostructures, including nanodots [15], nanotubes [16], nanowires [17], nanoflakes [18], and thin films [19]. NiO thin films have been mainly prepared by physical vapor deposition, such as sputtering [20], pulsed laser deposition (PLD) [21], and molecular beam epitaxy [22], while chemical approaches like chemical vapor deposition [23], sol–gel method [24], and others [25] can also be employed. For most thin films, the properties are highly dependent on the statistical distribution of grain orientations, also known as texture. Epitaxy refers to a particular texture when all the grains in a thin film are aligned by the crystallographic orientations of the single-crystal substrates, which is critical to produce high-quality semiconductor devices like p-n junctions. For instance, the crystallographic orientation relationships (CORs) between NiO thin films and yttria-stabilized zirconia (YSZ)–buffered Si substrates are (111)NiO||(100)YSZ and (100)NiO||(100)YSZ under low and high oxygen pressures, respectively [26]. Meanwhile, the epitaxial growth of NiO thin film on MgO (100) substrate favors (100) plane [24].

Sapphire (α-Al2O3) is frequently utilized as an interlayer between NiO-based p-n junctions to enhance device performance. The vast majority of previous studies concerning epitaxial NiO/Al2O3 heterojunction used Al2O3 (0001) substrates, and the CORs agreed to be (111)NiO||(0001)Sapphire with two domain structures [27,28,29,30,31]. Compared to c-plane (0001) sapphire, very little research has been conducted on the growth of NiO thin films on m-plane \(\text{(10}\overline{1}\text{0)}\), a-plane \(\text{(}\overline{1}\overline{1}\text{20)}\), and r-plane \(\text{(10}\overline{1}\text{2)}\) sapphire substrates. Becker et al. studied the growth of NiO films on sapphire substrates of four surface planes by ion beam sputtering and found NiO films deposited on a-plane and r-plane were (111) and (110) oriented, respectively [30]. In this work, we demonstrate new CORs between NiO thin film and r-plane sapphire can be achieved via PLD. The NiO thin film is \((7 \overline{1 } 4)\) oriented, and such high-index growth has never been reported in previous studies concerning oxide thin film epitaxy.

2 Experiment procedures

NiO thin films were deposited on r-plane \(\text{(10}\overline{1}\text{2)}\) and c-plane (0001) sapphire substrates by pulsed laser deposition (PLD) equipped with a 248 nm KrF excimer laser. A commercial NiO target (purity 99.99%) was used as a single source and rotated continuously during the ablation for uniform deposition. The main chamber was evacuated to a base pressure of 10-8 torr. The deposition was carried out at 600 ℃ and the oxygen partial pressure was set to be 10-2 torr. We also varied the deposition temperature and oxygen partial pressure. It showed that the deposition temperature of 600 ℃ and 10-2 torr oxygen partial pressure resulted in the best quality of the samples. The laser fluence and deposition frequency were ~2 J/cm2 and 2 Hz, leading to a deposition rate of ~0.02 nm/s. The crystallographic orientations of the NiO thin film were evaluated by X-ray diffraction (XRD), as well as transmission electron microscopy (TEM). X-rays were generated from a Cu target with a wavelength of 1.5406 Å (Cu Kα line). The chemical states were analyzed by X-ray photoelectron spectroscopy (XPS) with monochromatic Al Ka source (1486.68 eV). Magnetic measurement was done by a physical property measurement system attached with a vibrating sample magnetometer (VSM). X-ray absorption spectroscopy (XAS) and X-ray magnetic circular dichroism (XMCD) were performed at Singapore Synchrotron Light Sources (SSLS).

3 Results and discussion

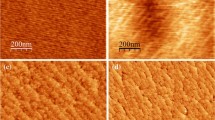

XRD was employed to examine the crystalline structure of the thin film grown on the r-plane sapphire. However, no peak can be observed via ω/2θ scan. In this case, the thin film is either amorphous or has an extremely small plane spacing d parallel to the substrate surface. XRD can be interpreted by Bragg’s law 2dsinθ = nλ, and only those planes with interplanar spacing d larger than λ/2 are possible to generate XRD peaks. The chemical states of Ni were investigated by XPS, as shown in Fig. 1a. The spectrum of Ni edge shows the distinguishable multiplet-split Ni2p3/2 (NiO) peak with the summit located at 854.5 eV, which is identical to the NiO thin film grown by sputtering [32]. In addition, the composition analysis from XPS indicates that the ratio of Ni and O is close to 1, suggesting little oxygen vacancies in NiO. Thus, the NiO thin film grown on r-plane sapphire might remain the crystallized rock salt structure without significant distortion, in which the lattice constant is a = 4.1684 Å (space group: Fm3m). Actually, atomic force microscopy (AFM) images also show the difference of NiO on c- and r-plane sapphire. A strip morphology with relatively smaller grain size surface is observed for NiO grown on c-plane, while relatively large grain size with knit-like shapes can be seen for NiO grown on r-plane, confirming the well-crystalline structure with little oxygen vacancies. As XRD ω/2θ scan failed to characterize the crystallographic orientations, the NiO thin film must have extremely high-index surface planes or have a disordered structure. We alternatively used selected area electron diffraction (SAED) attached with the TEM system to identify the crystalline structure since the wavelength of the electrons in SAED is very small compared to that of the X-ray and thus can detect the planes with much smaller interplanar distance.

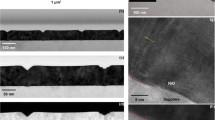

Two cross-sectional TEM sample foils (S1, S2) were prepared by a Zeiss Auriga scanning electron microscopy (SEM)/focused ion beam (FIB) along the orientations as shown in Fig. 1b, in which the two samples are perpendicular to \(\text{[1}\overline{2}\text{10]}\) and \({\text{[10}\overline {11}\text{]}}\) of the sapphire substrate, respectively. The high-resolution TEM (HRTEM) image of the S1 sample and the corresponding SAED pattern are shown in Fig. 2a and b. The thickness of the film is around 45 nm, and HRTEM (Fig. 2b) shows lattice spacing of 0.29 nm, corresponding to NiO (101) plane. Figure 2c shows the diffraction patterns of the sample including these from substrates and film. It is obvious that in addition to the diffraction pattern of the sapphire substrate, there is another set of diffraction pattern belonging to NiO, suggesting the single-crystalline nature of the NiO thin film. The pattern indexing of sapphire and NiO is marked in blue and red colors, respectively. The calculated diffraction zone axis of NiO in the S1 sample is indexed \([13\overline{1 }]\), perpendicular to \([2\overline{2 }\overline{4 }]\) that extends along the interface. Since the diffraction zones of NiO and sapphire substrate are parallel, one in-plane COR between the NiO thin film and sapphire substrate is \({[13\overline{1}]}_{\text{NiO}}\text{||[1}\overline{2}{\text{10]}}_{\text{Sapphire}}\). Obtained by calculating \([2\overline{2 }\overline{4 }]\times [13\overline{1 }]=[14 \overline{2 } 4]\), the surface plane of the NiO thin film is therefore \((7 \overline{1 } 4)\). To confirm the result, HRTEM and SAED were also conducted on the S2 sample, as shown in Fig. 2d–f. The thickness is also approximately 45 nm, consistent with sample 1. In addition, HRTEM indicates a d-spacing of the lattice around 0.24 nm, corresponding to NiO \(\left(1, \overline{1, }\; 1\right)\) plane. The SAED pattern indexing is a bit complicated as some points of NiO and sapphire crystal are overlapped, for example, NiO \((0.5 1.5 \overline{0.5})\) and sapphire \((1 \overline{2 } 1 0)\) shown in Fig. 2f. Compared to Fig. 2c, it is much easier to interpret Fig. 2f because both NiO \((13\overline{1})\) and sapphire \(\text{(}\overline{1}{\text{2}}\overline{1}\text{0)}\) lay along the interface, suggesting the in-plane COR of \({[13\overline{1 }]}_{\text{NiO}}\text{||[1}\overline{2}{\text{10]}}_{\text{Sapphire}}\) is consistent with the result obtained by S1 sample. The calculation of two diffraction zones indicates that the other in-plane COR is \({[\overline{1}12]}_{\text{NiO}}\text{||[10}\overline{1}\overline{1}{\text{]}}_{\text{Sapphire}}\). Therefore, the CORs between the NiO thin film and sapphire substrate are \({(7\overline{1 }4)}_{\text{NiO}}\text{||(10}\overline{1}{\text{2)}}_{\text{Sapphire}}\) (out-of-plane) and \({[13\overline{1 }]}_{\text{NiO}}\text{||[1}\overline{2}{\text{10]}}_{\text{Sapphire}}\) and \({[\overline{1 }12]}_{\text{NiO}}\text{||[10}\overline{1}\overline{1}{\text{]}}_{\text{Sapphire}}\) (in-plane), as illustrated in Fig. 3a.

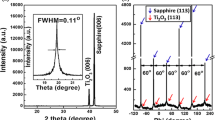

The interplanar distance of NiO \((7 \overline{1 } 4)\) plane is 0.5131 Å, indeed smaller than half the wavelength of Cu Kα radiation λ/2 = 0.7703 Å. Although the surface plane cannot be directly characterized by XRD ω/2θ scan, we can still use XRD phi (Φ) scan to explore the in-plane epitaxial relation. NiO (202) plane, which appears in the SAED (Fig. 2b), was chosen, and the corresponding scan parameters are ψ = 16.78°, 2θ = 63.08°, and ω = 31.54°. A single sharp peak is clearly noted in the phi scan (Fig. 3b), confirming the orientation of surface plane is \((7 \overline{1 } 4)\). In addition, the diffraction of sapphire (0006) plane was also measured, and the substrate and thin film peaks are separated by ~ 180°. Thus, the observed phi scan results agree with the CORs obtained from the TEM diffraction.

In epitaxy, it is expected that the deposited material forms a crystalline overlayer that has one well-defined orientation with respect to the substrate crystal structure. In order to explain the observed epitaxial relationship, we analyze the crystal structures of sapphire \((10\overline{1 }2)\) and NiO \((7 \overline{1 } 4)\) planes. The sapphire \((10\overline{1 }2)\) plane consists of rectangular cells with side lengths aSapphire = 4.76 Å in \(\text{[1}\overline{2}\text{10]}\) direction and bSapphire = 15.39 Å in \(\text{[10}\overline {11}\text{]}\) direction, while the cell parameters of NiO \((7 \overline{1 } 4)\) plane are aNiO = 13.83 Å in \([1 3 \overline{1 }]\) direction and bNiO = 5.11 Å in \([\overline{1 } 1 2]\) directions. It is effortless to notice that 3aSapphire ≈ aNiO and bSapphire ≈ 3bNiO. The lattice mismatch can be calculated as \({m}_{a}=\frac{3{a}_{Sapphire}-{a}_{NiO}}{3{a}_{Sapphire}}=3.2\%\) and \({m}_{b}=\frac{{b}_{Sapphire}-3{b}_{NiO}}{{b}_{Sapphire}}=0.4\%\). By comparison, the lattice mismatch of epitaxial (111) NiO thin film grown on c-plane (0001) sapphire is 24.15%, which can be reduced to 7.52% by introducing domain matching epitaxy [27]. Therefore, NiO \((7 \overline{1 } 4)\) plane and sapphire \((10\overline{1 }2)\) plane have much smaller mismatch, especially in b direction, as illustrated in Fig. 4a.

a A schematic diagram of lattice matching of NiO \((7 \overline{1 } 4)\) plane and sapphire \((10\overline{1 }2)\) plane. b, c A schematic diagram of spin structure in NiO thin film in (111) and \((7 \overline{1 } 4)\) planes. d, and (e) The spin structures in the interface of Co (2 nm)/NiO (111) and Co (2 nm)/NiO \((7 \overline{1 } 4)\), respectively

Different epitaxial relationships to the substrate often generate divergent crystal properties. Below the Néel temperature, NiO is antiferromagnetic with the magnetic moments of Ni oriented in \(\langle 1 1 \overline{2 }\rangle\) direction within {111} planes, while the adjacent {111} planes are antiparallelly coupled. For the NiO thin film grown on c-plane sapphire, the Ni spins align ferromagnetically on the epitaxial (111) plane. In contrast, in \((7 \overline{1 } 4)\)-oriented NiO, the Ni spins can align in \([\overline{1 } 1 2]\) direction within \((1 \overline{1 } 1)\) plane. The angle between \((7 \overline{1 } 4)\) plane and \((1 \overline{1 } 1)\) plane is 31.48°, and the spins are aligned antiferromagnetically within the \((7 \overline{1 } 4)\) plane, as illustrated in Fig. 4c, while the spin structure of (111)-oriented NiO is shown in Fig. 4b, which is ferromagnetically aligned in the plane. This spin structure of \((7 \overline{1 } 4)\)-oriented NiO may lead to different electronic and magnetic properties, especially when NiO thin films serve as potential antiferromagnetic pinning layers.

In order to study the exchange coupling effect, 2-nm Co films were deposited on NiO/sapphire (0001) and \((10\overline{1 }2)\). Then the composite films were annealed at 600 K under argon atmosphere with an in-plane magnetic field of 0.5 T due to the Néel temperature of NiO at 525 K [33]. Due to the different surface spin structures of the two substrates, it is expected to observe the different behaviors of exchange coupling. From Fig. 4b and c, the spin structure of (111) plane is ferromagnetically aligned, while the spins of \((7 \overline{1 } 4)\) plane are antiferromagnetically aligned. Therefore, the exchange coupling of Co and NiO spin structures in the interface is shown in Fig. 4d and e, respectively. Figure 5a and b are XAS and XMCD spectra of the samples deposited on the two substrates, which were carried out at the Singapore Synchrotron Light Source [34]. The valence state of Co is close to metallic Co, evidenced by the single peak at around 779 eV [35]. XMCD curves can be clearly seen from the polarized light measurement. It is to note during XAS measurement, no magnetic field was applied. Based on the sum rule calculations [34,35,36,37], the spin moment of Co on NiO/sapphire \((10\overline{1 }2)\) is 1.33 µB, and the orbital moment is 0.19 µB. The total moment is 1.33 + 0.19 = 1.52 µB, while the spin moment of Co on sapphire (0001) is 1.09 µB and the orbital moment is 0.15 µB. The total moment is 1.09 + 0.15 = 1.24 µB. The Co theoretical magnetic moment is around 1.71 µB. The moment value of Co on NiO/sapphire \((10\overline{1 }2)\) is very close to the theoretical value, indicating that there is little spin flopping after field cooling, while Co film on NiO/sapphire (0001) substrate has a large amount of spin flopping after field cooling, resulting in lower magnetic moment measured by XMCD. To further investigate the magnetic properties of Co exchange coupling with NiO substrates, XMCD hysteresis loops were taken, as shown in Fig. 5c and d. It is obvious to see that Co/NiO \((7 \overline{1 } 4)\) shows more out-of-plane anisotropy than that on NiO (111), which may be due to the antiferromagnetically aligned spins in the interface, leading to less spin flopping. From Fig. 5c, there is a small exchange bias EB = 0.0118 T, while an exchange bias of Co on NiO (111), EB = 0.0352 T. The larger exchange bias endorses the high-energy density of spins of Co on NiO (111). Since the field cooling is made from in-plane, we also measure the out-of-plane XAS and XMCD without applied any magnetic field, as shown in Fig. 5e and f. There is no XMCD signal from both samples. Hence, the out-of-plane exchange coupling can be neglected. Figure 5g and h are hysteresis loops of the two samples measured by a VSM attached in a PPMS system. From the curves, the exchange bias of Co on NiO (111) is around 0.0280 T, while the exchange bias of Co on NiO \((7 \overline{1 } 4)\) is approximately 0.0140 T, which is consistent with that measured by XAS.

a In-plane XAS and XMCD of Co on NiO/sapphire \((10\overline{1 }2)\) after field cooling; b in-plane XAS and XMCD of Co on NiO/sapphire (0001) after field cooling; c XMCD hysteresis loop of (a); d XMCD hysteresis loop of (b); e out-of-plane XAS and XMCD of Co on sapphire \((10\overline{1 }2)\); f out-of-plane XAS and XMCD of Co on sapphire (0001). g Hysteresis loop of Co on NiO/sapphire \((10\overline{1 }2)\) in-plane; h hysteresis loop of Co on NiO/sapphire (0001) in-plane

4 Conclusion

In this work, we have successfully fabricated high-index NiO on \((10\overline{1 }2)\) sapphire substrate with a small lattice mismatch. XRD and TEM analyses confirm the high-index \((7 \overline{1 } 4)\)–orientated NiO thin film. Comparing with normal (111) NiO thin film, the surface spin density is less but exhibits strong out-of-plane anisotropy which is exchange-coupled with Co (2 nm), due to the antiferromagnetically aligned spins of NiO in the interface. The new-discovered high-index–orientated NiO thin film may be useful for studying the basic physics and spin valve devices.

Data availability

The data is available upon request with reasonable reason.

References

M. Xu, D. Wang, K. Fu, D.H. Mudiyanselage, H. Fu, Y. Zhao, A review of ultrawide bandgap materials: properties, synthesis and devices. Oxford Open Mater. Sci. 2(1), itac004 (2022)

A. Waseem, Z. Ren, H.-C. Huang, K. Nguyen, X. Wu, X. Li, A review of recent progress in β-Ga2O3 epitaxial growth: effect of substrate orientation and precursors in metal–organic chemical vapor deposition. Phys. Status Solidi (A) 220(8), 2200616 (2023)

R.M.R. Pinto, V. Gund, C. Calaza, K.K. Nagaraja, K.B. Vinayakumar, Piezoelectric aluminum nitride thin-films: a review of wet and dry etching techniques. Microelectron. Eng. 257, 111753 (2022)

W. Ahmad, S. Chandra Bhatt, M. Verma, V. Kumar, H. Kim, A review on current trends in the green synthesis of nickel oxide nanoparticles, characterizations, and their applications. Environ. Nanotechnol., Monit. Manag. 18, 100674 (2022)

Z. Chen, T. Dedova, N. Spalatu, N. Maticiuc, M. Rusu, A. Katerski, I.O. Acik, T. Unold, M. Krunks, ZnO/NiO heterostructures with enhanced photocatalytic activity obtained by ultrasonic spraying of a NiO shell onto ZnO nanorods. Colloids Surf., A 648, 129366 (2022)

M. Meer, P. Pohekar, B. Parvez, S. Ganguly, D. Saha, Performance improvement in NiOx-based GaN MOS-HEMTs. Semicond. Sci. Technol. 37(8), 085007 (2022)

S. Zhuang, X. Ma, D. Hu, X. Dong, B. Zhang, Air-stable all inorganic green perovskite light emitting diodes based on ZnO/CsPbBr 3/NiO heterojunction structure. Ceram. Int. 44(5), 4685–4688 (2018)

X. Deng, L. Zhang, J. Guo, Q. Chen, J. Ma, ZnO enhanced NiO-based gas sensors towards ethanol. Mater. Res. Bull. 90, 170–174 (2017)

J. Ben Youssef, A. Layadi, Ferromagnetic resonance study of permalloy/Cu/Co/NiO spin valve system. J. Appl. Phys. 108(5), 053913 (2010)

J.Y. Son, Y.-H. Shin, H. Kim, H.M. Jang, NiO resistive random access memory nanocapacitor array on graphene. ACS Nano 4(5), 2655–2658 (2010)

J.B. Yi, J. Ding, Y.P. Feng, G.W. Peng, G.M. Chow, Y. Kawazoe, B.H. Liu, J.H. Yin, S. Thongmee, Size-dependent magnetism and spin-glass behavior of amorphous NiO bulk, clusters, and nanocrystals: experiments and first-principles calculations. Phys. Rev. B 76(22), 224402 (2007)

H.W. Shin, Y.-H. Shin, J.Y. Son, Resistive switching characteristics of epitaxial NiO thin films affected by lattice strains and external forces. Appl. Surf. Sci. 566, 150685 (2021)

P. Qin, H. Yan, X. Wang, H. Chen, Z. Meng, J. Dong, M. Zhu, J. Cai, Z. Feng, X. Zhou, L. Liu, T. Zhang, Z. Zeng, J. Zhang, C. Jiang, Z. Liu, Room-temperature magnetoresistance in an all-antiferromagnetic tunnel junction. Nature 613(7944), 485–489 (2023)

Z. Feng, X. Zhou, L. Šmejkal, L. Wu, Z. Zhu, H. Guo, R. González-Hernández, X. Wang, H. Yan, P. Qin, X. Zhang, H. Wu, H. Chen, Z. Meng, L. Liu, Z. Xia, J. Sinova, T. Jungwirth, Z. Liu, An anomalous Hall effect in altermagnetic ruthenium dioxide. Nat. Electron. 5(11), 735–743 (2022)

Y. Ahn, J.Y. Son, Thickness scaling effects of self-assembled NiO nanodots on resistive switching characteristics. J. Alloy. Compd. 872, 159666 (2021)

T.-J. Wang, H. Huang, X.-R. Wu, H.-C. Yao, F.-M. Li, P. Chen, P.-J. Jin, Z.-W. Deng, Y. Chen, Self-template synthesis of defect-rich NiO nanotubes as efficient electrocatalysts for methanol oxidation reaction. Nanoscale 11(42), 19783–19790 (2019)

N. Kaur, M. Singh, A. Casotto, L. Sangaletti, E. Comini, Self-assembled monolayer functionalized NiO nanowires: strategy to enhance the sensing performance of p-type metal oxide. Chem. Commun. 59(10), 1329–1332 (2023)

R. Ahmad, M.A. Shah, Nickel oxide (NiO) nanoflakes prepared through hydrothermal method and integration into acetone gas sensing application. Chem. Pap. 77(1), 413–421 (2023)

M. Obaida, A.M. Fathi, I. Moussa, H.H. Afify, Characterization and electrochromic properties of NiO thin films prepared using a green aqueous solution by pulsed spray pyrolysis technique. J. Mater. Res. 37(14), 2282–2292 (2022)

M. Patel, H.-S. Kim, J. Kim, J.-H. Yun, S.J. Kim, E.H. Choi, H.-H. Park, Excitonic metal oxide heterojunction (NiO/ZnO) solar cells for all-transparent module integration. Sol. Energy Mater. Sol. Cells 170, 246–253 (2017)

S.K. Yadav, S. Dhar, Very thin (111) NiO epitaxial films grown on c-sapphire substrates by pulsed laser deposition technique. Semicond. Sci. Technol. 36(5), 055005 (2021)

J. Feldl, M. Budde, C. Tschammer, O. Bierwagen, M. Ramsteiner, Magnetic characteristics of epitaxial NiO films studied by Raman spectroscopy. J. Appl. Phys. 127(23), 235105 (2020)

T. Ikenoue, J. Inoue, M. Miyake, T. Hirato, Epitaxial growth of undoped and Li-doped NiO thin films on α-Al2O3 substrates by mist chemical vapor deposition. J. Cryst. Growth 507, 379–383 (2019)

Y. Kokubun, Y. Amano, Y. Meguro, S. Nakagomi, NiO films grown epitaxially on MgO substrates by sol-gel method. Thin Solid Films 601, 76–79 (2016)

J. Wang, L. Ma, X. Wang, X. Wang, J. Yao, Q. Yi, R. Tang, G. Zou, Sub-nanometer thick wafer-size NiO films with room-temperature ferromagnetic behavior. Angew. Chem. Int. Ed. 60(47), 25020–25027 (2021)

R. Molaei, R. Bayati, J. Narayan, Crystallographic characteristics and p-type to n-type transition in epitaxial NiO thin film. Cryst. Growth Des. 13(12), 5459–5465 (2013)

J.H. Lee, Y.H. Kwon, B.H. Kong, J.Y. Lee, H.K. Cho, Biepitaxial growth of high-quality semiconducting NiO thin films on (0001) Al2O3 substrates: microstructural characterization and electrical properties. Cryst. Growth Des. 12(5), 2495–2500 (2012)

R. Yamauchi, Y. Hamasaki, T. Shibuya, A. Saito, N. Tsuchimine, K. Koyama, A. Matsuda, M. Yoshimoto, Layer matching epitaxy of NiO thin films on atomically stepped sapphire (0001) substrates. Sci. Rep. 5, 14385 (2015)

S.D. Singh, M. Nand, A. Das, R.S. Ajimsha, A. Upadhyay, R. Kamparath, D.K. Shukla, C. Mukherjee, P. Misra, S.K. Rai, A.K. Sinha, S.N. Jha, D.M. Phase, T. Ganguli, Structural, electronic structure, and band alignment properties at epitaxial NiO/Al2O3 heterojunction evaluated from synchrotron based X-ray techniques. J. Appl. Phys. 119(16), 165302 (2016)

M. Becker, A. Polity, P.J. Klar, NiO films on sapphire as potential antiferromagnetic pinning layers. J. Appl. Phys. 122(17), 175303 (2017)

Y. Wang, J. Ghanbaja, P. Boulet, D. Horwat, J. Pierson, Growth, interfacial microstructure and optical properties of NiO thin films with various types of texture. Acta Mater. 164, 648–653 (2019)

X. Luo, L.T. Tseng, S. Li, J.B. Yi, Room temperature ferromagnetic ordering of NiO films through exchange coupling. Mater. Sci. Semicond. Process. 30, 228–232 (2015)

J.B. Yi, J. Ding, Z.L. Zhao, B.H. Liu, High coercivity and exchange coupling of Ni∕NiO nanocomposite film. J. Appl. Phys. 97(10), 10K306 (2005)

H. Saadaoui, X. Luo, Z. Salman, X.Y. Cui, N.N. Bao, P. Bao, R.K. Zheng, L.T. Tseng, Y.H. Du, T. Prokscha, A. Suter, T. Liu, Y.R. Wang, S. Li, J. Ding, S.P. Ringer, E. Morenzoni, J.B. Yi, Intrinsic ferromagnetism in the diluted magnetic semiconductor Co:TiO2. Phys. Rev. Lett. 117(22), 227202 (2016)

X. Ding, X. Cui, C. Xiao, X. Luo, N. Bao, A. Rusydi, X. Yu, Z. Lu, Y. Du, X. Guan, L.-T. Tseng, W.T. Lee, S. Ahmed, R. Zheng, T. Liu, T. Wu, J. Ding, K. Suzuki, V. Lauter, A. Vinu, S.P. Ringer, J.B. Yi, Confinement-induced giant spin–orbit-coupled magnetic moment of Co nanoclusters in TiO2 films. ACS Appl. Mater. Interfaces 11(46), 43781–43788 (2019)

C.T. Chen, Y.U. Idzerda, H.J. Lin, N.V. Smith, G. Meigs, E. Chaban, G.H. Ho, E. Pellegrin, F. Sette, Experimental confirmation of the X-ray magnetic circular dichroism sum rules for iron and cobalt. Phys. Rev. Lett. 75(1), 152–155 (1995)

J.B. Yi, Y.Z. Zhou, J. Ding, G.M. Chow, Z.L. Dong, T. White, X. Gao, A.T.S. Wee, X.J. Yu, An investigation of structure, magnetic properties and magnetoresistance of Ni films prepared by sputtering. J. Magn. Magn. Mater. 284, 303–311 (2004)

Acknowledgements

J. Yi acknowledges the ARC Future Fellowship support (FT160100205). The authors would like to acknowledge the Singapore Synchrotron Light Source for providing the facility necessary for conducting the research. The Laboratory is a National Research Infrastructure under the National Research Foundation, Singapore. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not reflect the views of National Research Foundation, Singapore. The authors acknowledge the technical and scientific assistance of Sydney Microscopy & Microanalysis, the University of Sydney node of Microscopy Australia.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions Yi thanks the financial support from ARC Future Fellowship, FT160100205.

Author information

Authors and Affiliations

Contributions

Ding and Yi conceptualize the project. Ding fabricated the samples, did XRD and AFM analysis, and drafted the manuscript. Sathish measured the magnetic properties. Qu and Zheng did TEM analysis. Geng and Guan prepared the samples upon revision. Yu and Breeze did XAS and XMCD measurement/analysis. Qiao did XPS measurement and analysis. Suzuki did field annealing of the samples. Yi supervised the project.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ding, X., Sathish, C.I., Qu, J. et al. NiO thin film with an extremely high index \((7 \overline{1 } 4)\) on r-plane sapphire substrate. emergent mater. 6, 1623–1630 (2023). https://doi.org/10.1007/s42247-023-00543-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-023-00543-7