Abstract

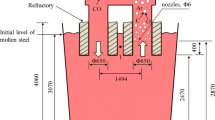

The two-fluid model coupled with population balance model was used for simulating the gas–liquid flow in the Ruhrstahl–Heraeus (RH) degasser. The predicted circulation flow rate was compared with that measured from a water model experiment to validate the mathematical model. Then, influence of snorkel immersion depth on liquid circulation flow rate was numerically investigated under an atmospheric pressure of 101 and 84 kPa, respectively. Predicted result indicates that the circulation flow rate of the RH degasser in the high-altitude area was severely reduced because of the decrease in atmospheric pressure. However, increasing the snorkel immersion depth from 0.5 to 0.7 m can compensate for the decrease in atmospheric pressure. Industrial test result indicates that decarburization rate is significantly enhanced by increasing the snorkel immersion depth. Through optimization, the percentage of heats with a final carbon content less than 0.002 wt.% is significantly increased from 22.0% to 96.4%.

Similar content being viewed by others

References

G. Chen, J. Yang, L. Li, M. Zhang, S. He, J. CO2 Util. 50 (2021) 101586.

Y. Huang, G.G. Cheng, Q. Wang, S.J. Li, W.X. Dai, Ironmak. Steelmak. 47 (2020) 655–664.

M.A. van Ende, Y.M. Kim, M.K. Cho, J. Choi, I.H. Jung, Metall. Mater. Trans. B 42 (2011) 477–489.

D.Q. Geng, H. Lei, J.C. He, Metall. Mater. Trans. B 41 (2010) 234–247.

S. Chen, H. Lei, M. Wang, Steel Res. Int. 92 (2021) 2100032.

S. Chen, H. Lei, H. Hou, C. Ding, H. Zhang, Y. Zhao, J. Mater. Res. Technol. 15 (2021) 5141–5150.

H. Ling, F. Li, L. Zhang, A.N. Conejo, Metall. Mater. Trans. B 47 (2016) 1950–1961.

G. Chen, S. He, Y. Li, Metall. Mater. Trans. B 48 (2017) 2176–2186.

Y. Luo, C. Liu, Y. Ren, L. Zhang, Steel Res. Int. 89 (2018) 1800048.

Q. Cao, D. Chu, J. Zhang, H. Bi, Y. Xuan, P. Li, JOM 73 (2021) 2660–2671.

J. Dong, C. Feng, R. Zhu, G. Wei, J. Jiang, S. Chen, Metall. Mater. Trans. B 52 (2021) 2127–2138.

C. Liu, L. Zhang, Y. Sun, W. Yang, Metall. Mater. Trans. B 53 (2022) 670–681.

K. Peng, C. Liu, L. Zhang, Y. Sun, Metall. Mater. Trans. B 53 (2022) 2004–2017.

K. Peng, J. Wang, Q. Li, C. Liu, L. Zhang, Metall. Mater. Trans. B 54 (2023) 928–943.

G. Chen, S. He, Y. Li, Y. Guo, Q. Wang, JOM 68 (2016) 2138–2148.

B. Zhu, Q. Liu, M. Kong, J. Yang, D. Li, K. Chattopadhyay, Metall. Mater. Trans. B 48 (2017) 2620–2630.

J.J.M. Peixoto, W.V. Gabriel, T.A. Santos Oliveira, C.A. Silva, I.A. Silva, V. Seshadri, Metall. Mater. Trans. B 49 (2018) 2421–2434.

S.F. Chen, H. Lei, M. Wang, B. Yang, L.J. Dai, Y. Zhao, Vacuum 167 (2019) 255–262.

G. Chen, S. He, Metall. Mater. Trans. B 53 (2022) 208–219.

B. Wang, B. Zhu, B. Zhang, JOM 73 (2021) 2920–2928.

G. Chen, Q. Wang, S. He, Metall. Res. Technol. 116 (2019) 617.

G. Chen, Q. Wang, S. He, Steel Res. Int. 94 (2023) 2200298.

T. Kuwabara, K. Umezawa, K. Mori, H. Watanabe, ISIJ Int. 28 (1988) 305–314.

M. Zhu, Y. Wu, C. Du, Z. Huang, J. Iron Steel Res. Int. 12 (2005) No. 2, 20–24.

J. Zhang, L. Liu, X. Zhao, S. Lei, Q. Dong, ISIJ Int. 54 (2014) 1560–1569.

H. Ling, L. Zhang, Metall. Mater. Trans. B 49 (2018) 2709–2721.

G. Chen, S. He, Ind. Eng. Chem. Res. 58 (2019) 18855–18865.

C.W. Li, G.G. Cheng, X.H. Wang, G.S. Zhu, A.M. Cui, J. Iron Steel Res. Int. 19 (2012) No. 5, 23–28.

Y.H. Li, Y.P. Bao, M. Wang, R. Wang, D.C. Tang, Ironmak. Steelmak. 42 (2015) 366–372.

V. Seshadri, C.A. da Silva, I.A. da Silva, G.A. Vargas, P.S.B. Lascosqui, Ironmak. Steelmak. 33 (2006) 34–38.

D.Q. Geng, J.X. Zheng, K. Wang, P. Wang, R.Q. Liang, H.T. Liu, H. Lei, J.C. He, Metall. Mater. Trans. B 46 (2015) 1484–1493.

G. Chen, S. He, Vacuum 130 (2016) 48–55.

S. He, G. Chen, C. Guo, Ironmak. Steelmak. 46 (2019) 771–776.

Y.G. Park, W.C. Doo, K.W. Yi, S.B. An, ISIJ Int. 40 (2000) 749–755.

Y.G. Park, K.W. Yi, S.B. Ahn, ISIJ Int. 41 (2001) 403–409.

L. Zhang, F. Li, JOM 66 (2014) 1227–1240.

G. Chen, S. He, Vacuum 153 (2018) 132–138.

L. Schiller, Z. Naumann, Zeitschrift des Vereins Deutscher Ingenieure 77 (1935) 318–320.

O. Simonin, P. Viollet, Modeling of turbulent two-phase jets loaded with discrete particles. Phenomena in multiphase flows, Hemisphere Publ. Corporation, London, UK, 1990.

M. Hounslow, R. Ryall, V. Marshall, AIChE. J. 34 (1988) 1821–1832.

H. Luo, Coalescence, breakup and liquid circulation in bubble column reactors, The Norwegian Institute of Technology, Trondheim, Norway, 1993.

H. Luo, H.F. Svendsen, AlChE. J. 42 (1996) 1225–1233.

M. Sano, K. Mori, Y. Fujita, Tetsu-to-Hagane 65 (1979) 1140–1148.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 52104321), the Natural Science Foundation of Chongqing, China (Grant No. CSTB2023NSCQ-MSX0871), and the Science and Technology Research Program of Chongqing Municipal Education Commission (Grant No. KJQN202101404).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Gj., He, Sp. Prediction of liquid circulation flow rate in RH degasser: improvement of decarburization at low atmospheric pressure. J. Iron Steel Res. Int. (2024). https://doi.org/10.1007/s42243-023-01166-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42243-023-01166-2