Abstract

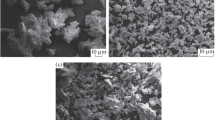

Copper alloy composite bit matrix was prepared by pressureless vacuum infiltration, using at least one of the three kinds of tungsten carbide particles, for example, irregular cast tungsten carbide, monocrystalline tungsten carbide and sintered reduced tungsten carbide particles. The effects of powder particle morphology, particle size and mass fraction of tungsten carbide on the microstructure and mechanical properties of copper alloy composite were investigated by means of scanning electron microscopy, X-ray diffraction and abrasive wear test in detail. The results show that tungsten carbide morphology and particle size have obvious effects on the mechanical properties of copper alloy composites. Cast tungsten carbide partially dissolved in the copper alloy binding phase, and layers of Cu0.3W0.5Ni0.1Mn0.1C phase with a thickness of around 8–15 μm were formed on the edge of the cast tungsten carbide. When 45% irregular crushed fine cast tungsten carbide and 15% monocrystalline cast tungsten carbide were used as the skeleton, satisfactory comprehensive performance of the reinforced copper alloy composite bit matrix was obtained, with the bending strength, impact toughness and hardness reaching 1048 MPa, 4.95 J/cm2 and 43.6 HRC, respectively. The main wear mechanism was that the tungsten carbide particles firstly protruded from the friction surface after the copper alloy matrix was worn, and then peeled off from the matrix when further wear occurred.

Similar content being viewed by others

References

G. Bruton, R. Crockett, M. Taylor, D. DenBoer, J. Lund, C. Fleming, A. White, Oilfield Review 26 (2014) 48–57.

P.K. Deshpande, R.Y. Lin, Mater. Sci. Eng. A 418 (2006) 137–145.

M.R. Taylor, A.D. Murdock, S.M. Evans, SPE Drill. Complet. 14 (1999) 34–41.

E. Hong, B. Kaplin, T. You, M.S. Suh, Y.S. Kim, H. Choe, Wear 270 (2011) 591–597.

G.Z. Jia, Research on key manufacturing process and mechanism of polycrystalline diamond tool, Dalian University of Technology, Dalian, China, 2015.

P.K. Deshpande, J.H. Li, R.Y. Lin, Mater. Sci. Eng. A 429 (2006) 58–65.

C. Liu, N. Lin, Y. He, C. Wu, Y. Jiang, J. Alloy. Compd. 594 (2014) 76–81.

Q. Yang, J. Yang, H. Yang, J. Ruan, Ceram. Int. 42 (2016) 18100–18107.

M.J. Sandstrom, The solid particle erosion of tungsten carbide in silicon carbide slurry, University of Utah, Utah, USA, 2003.

H.W. Xie, X. Liu, K. Hu, Y.X. Cai, Acta Mater. Compos. Sin. 36 (2019) 1235–1243.

Y.M. Zhao, L. Li, Superhard Material Engineering 28 (2016) No. 3, 1–6.

H.D. Ding, H.Q. Hao, Z.H. Jin, Journal of Xi’an Jiao Tong University 31 (1997) No. 4, 124–126.

M.Y. Gao, K. Zhang, Q. Zhou, H.F. Zhou, B.L. Liu, Drilling Engineering 45 (2018) No. 10, 185–189.

P. Šebo, Z. Moser, P. Švec, D. Janičkovič, E. Dobročka, W. Gasior, J. Pstruś, J. Alloy. Compd. 480 (2009) 409–415.

M. Akaishi, S. Yamaoka, Mater. Sci. Eng. A 209 (1996) 54–59.

M. Reyes, A. Neville, Wear 255 (2003) 1143–1156.

A. Sharif, Y.C. Chan, J. Alloy. Compd. 390 (2005) 67–73.

A. Onat, J. Alloy. Compd. 489 (2010) 119–124.

Z.F. Zhang, L.C. Zhang, Y.W. Mai, J. Mater. Sci. 30 (1995) 1961–1966.

B. Huang, Y. Gong, X. Xiang, W. Zhang, D. Dong, K. Shi, J. Gu, H. Xiong, L. Zhang, Vacuum 195 (2022) 110701.

K.H. Zheng, Y.M. Gao, L. Chen, Tribology 32 (2012) 176–182.

M.S. Suh, Y.H. Chae, S.S. Kim, Wear 264 (2008) 800–806.

K. Hu, H.W. Xie, X. Liu, Y.X. Cai, The Chinese Journal of Nonferrous Metals 30 (2020) 364–371.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 52074365). This work was also grateful to the Sichuan Science and Technology Program, China (Grant No. 2022YFG0289) and sponsored by the Funding Project of Key Laboratory of Sichuan Province for comprehensive Utilization of Vanadium and Titanium Resources, China (Grant No. 2018FTSZ26) and the Project Supported by the Opening Project of Material Corrosion and Protection Key Laboratory of Sichuan province, China (Grant Nos. 2021CL26, GK202104, and GK202106). This research was also supported by the Ph.D. Programs Foundation of Sichuan University of Science and Engineering, China (Grant No. 2021RC18).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have an influence on the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dong, Dq., He, Fy., Chen, Xh. et al. Effect of tungsten carbide particles on microstructure and mechanical properties of Cu alloy composite bit matrix. J. Iron Steel Res. Int. 31, 519–530 (2024). https://doi.org/10.1007/s42243-023-01076-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01076-3