Abstract

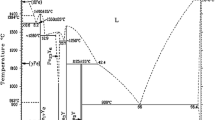

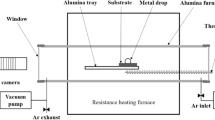

To reveal the mechanism of ferrite nucleation induced by Y2O2S inclusion in steel, the work of adhesion, interfacial energy, structure stability and electronic properties of Fe(111)/Y2O2S(001) interfaces with various terminations were first investigated using the first-principles calculations. Secondly, the steels with and without yttrium were prepared, while the rare earth yttrium-based inclusions in low carbon steel were characterized using an electron probe micro-analyzer, and the grain size of steel was analyzed using a scanning electron microscope with electron backscattered diffraction. The results show that the bonding strength of Fe/Y2O2S interfaces with S- and Y-terminations is stronger than that of the interface with O-terminations. The Fe–hcp–S interfaces with S-termination have the highest work of adhesion (4.01 J/m2) and the lowest interface distance (1.323 Å). The Fe–hcp–S interface exhibits the highest stability, and its interfacial bonding force is mainly attributed to the strong hybridization of Fe-3d and S-2p orbitals in the energy range of − 7.5–0 eV. Moreover, the interfacial energy of Fe–hcp–S is substantially lower than those of the ferrite(s)/Fe(L) interface and the ferrite–austenite interface, suggesting that Y2O2S inclusions in steel can efficiently promote ferrite nucleation. The experimental observations demonstrate that the ferrite grain size of steel containing 0.03 wt.% Y is much more refined than that of the steel without yttrium, and the average grain size of steel with and without Y is 102 and 258 μm, respectively. This indicates that the results of our calculations match with experimental findings.

Similar content being viewed by others

References

Z. Zhang, W. Wang, H. Fu, J. Xie, Mater. Sci. Eng. A 530 (2011) 519–524.

H.Z. Li, H.T. Liu, Y. Liu, Z.Y. Liu, G.M. Cao, Z.H. Luo, F.Q. Zhang, S.L. Chen, L. Lyu, G.D. Wang, J. Magn. Magn. Mater. 370 (2014) 6–12.

H.Z. Li, H.T. Liu, X.L. Wang, G.M. Cao, C.G. Li, Z.Y. Liu, G.D. Wang, Mater. Lett. 165 (2016) 5–8.

Y. Liu, C. Zhu, L. Huang, X. Chen, G. Li, JOM 74 (2022) 2645–2655.

A. Basso, I. Toda-Caraballo, D. San-Martín, F.G. Caballero, J. Mater. Res. Technol. 9 (2020) 3013–3025.

S. Fukumoto, A Mitchell, in: Proceedings of the 1991 Vacuum Metallurgy Conference on the Melting and Processing of Specialty Materials, I&SS, Inc., Pittsburgh, USA, 1991, pp. 3–7.

Z.H. Song, H.Y. Song, H.T. Liu, Mater. Sci. Eng. A 800 (2021) 140282.

H. Wang, Y.P. Bao, J.G. Zhi, C.Y. Duan, S. Gao, M. Wang, ISIJ Int. 61 (2021) 657–666.

W.C. Jiao, H.B. Li, H. Feng, Z.H. Jiang, L.F. Xia, S.C. Zhang, H.C. Zhu, W. Wu, Metall. Mater. Trans. B 51 (2020) 2240–2251.

R. Geng, J. Li, C. Shi, Ironmak. Steelmak. 48 (2021) 796–802.

R. Geng, J. Li, C. Shi, J. Zhi, B. Lu, Mater. Sci. Eng. A 840 (2022) 142919.

Y. Xie, M. Song, B. Wang, H. Zhu, Z. Xue, A. Mayerhofer, S.K. Michelic, C. Bernhard, J.L. Schenk, Metall. Mater. Trans. B 52 (2021) 2101–2110.

M. Song, B. Song, S. Zhang, Z. Xue, Z. Yang, R. Xu, ISIJ Int. 57 (2017) 1261–1267.

M. Song, B. Song, Z. Yang, S. Zhang, C. Hu, High Temp. Mater. Process. 36 (2017) 683–691.

Z. Adabavazeh, W.S. Hwang, Y.H. Su, Sci. Rep. 7 (2017) 46503.

J.S. Park, C. Lee, J.H. Park, Metall. Mater. Trans. B 43 (2012) 1550–1564.

Y.C. Yu, H. Li, S.B. Wang, Metall. Res. Technol. 114 (2017) 410.

X. Jiao, W. Fu, Z. Shi, Z. Li, Y. Zhou, X. Xing, Z. Wang, Q. Yang, J. Alloy. Compd. 831 (2020) 154867.

J. Yang, J. Huang, D. Fan, S. Chen, X. Zhao, Appl. Surf. Sci. 384 (2016) 207–216.

Y. Hou, W. Zheng, Z. Wu, G. Li, N. Moelans, M. Guo, B.S. Khan, Acta Mater. 118 (2016) 8–16.

C. Zou, J. Li, L. Zhu, Y. Zhang, G. Yao, B. Tang, J. Wang, H. Kou, H. Song, W.Y. Wang, Intermetallics 133 (2021) 107173.

X. Zhang, S. Wang, Nanomaterials 11 (2021) 738.

S.D. Park, S.Y. Kim, D. Kim, Mater. Today Commun. 26 (2021) 102107.

H.H. Xiong, H.H. Zhang, H.N. Zhang, Y. Zhou, J. Iron Steel Res. Int. 24 (2017) 328–334.

X. Zhao, J. Zhang, S. Liu, C. Zhao, C. Wang, X. Ren, Q. Yang, Mater. Des. 110 (2016) 644–652.

S. Tang, L. Xu, B. Peng, F. Xiong, T. Chen, X. Luo, X. Huang, H. Li, J. Zeng, Z. Ma, L.L. Wang, Appl. Surf. Sci. 575 (2022) 151655.

L. Xu, J. Zeng, Q. Li, X. Luo, T. Chen, J. Liu, L.L. Wang, Chin. Chem. Lett. 33 (2022) 3947–3950.

G. Kresse, D. Joubert, Phys. Rev. B 59 (1999) 1758–1775.

J. Paier, R. Hirschl, M. Marsman, G. Kresse, J. Chem. Phys. 122 (2005) 234102.

J. Zeng, L. Xu, K. Dong, K. Yang, L.L. Wang, Adv. Theory Simul. 4 (2021) 2100169.

H.J. Monkhorst, J.D. Pack, Phys. Rev. B 13 (1976) 5188–5192.

M. Methfessel, A.T. Paxton, Phys. Rev. B 40 (1989) 3616–3621.

K. Momma, F. Izumi, J. Appl. Crystallogr. 44 (2011) 1272–1276.

D. Sun, J. Ding, Y. Yang, P. Zhang, J. Zhao, Int. J. Hydrog. Energy 44 (2019) 17105–17113.

D. Sun, R. Li, Y. Yang, J. Ding, P. Zhang, J. Zhao, Nucl. Mater. Energy 27 (2021) 100956.

M.E. Straumanis, D.C. Kim, Int. J. Mater. Res. 60 (1969) 272–277.

T.W. Chou, S. Mylswamy, R.S. Liu, S.Z. Chuang, Solid State Commun. 136 (2005) 205–209.

H. Xiong, C. Cao, G. Chen, B. Liu, Surf. Interfaces 27 (2021) 101467.

J. Yang, P. Zhang, Y. Zhou, J. Guo, X. Ren, Y. Yang, Q. Yang, J. Alloy. Compd. 556 (2013) 160–166.

Y. Wang, X. Liu, Q. Yang, Y. Liu, Z. Li, B. Guo, H. Mao, R.D.K. Misra, H. Xu, AIP Adv. 9 (2019) 125313.

B.L. Bramfitt, Metall. Trans. 1 (1970) 1987–1995.

L. Zhong, Z. Wang, R. Chen, J. He, Steel Res. Int. 92 (2021) 2100198.

X. He, J. Hu, Z. Zhang, W. Liu, K. Song, J. Meng, Surf. Interfaces 28 (2022) 101585.

X. Huang, L. Xu, H. Li, S. Tang, Z. Ma, J. Zeng, F. Xiong, Z. Li, L.L. Wang, Appl. Surf. Sci. 570 (2021) 151207.

H. Zhang, J. Wang, W. Huang, L. Wang, Z. Lu, Surf. Interfaces 30 (2022) 101833.

Z. Shi, S. Liu, Y. Zhou, X. Xing, X. Ren, Q. Yang, J. Alloy. Compd. 773 (2019) 264–276.

S. Niknafs, R. Dippenaar, ISIJ Int. 54 (2014) 526–532.

H. Jin, I. Elfimov, M. Militzer, J. Appl. Phys. 123 (2018) 085303.

S. Fukumoto, T. Okane, T. Umeda, W. Kurz, ISIJ Int. 40 (2000) 677–684.

Acknowledgements

This work was supported by NSFC (No. 52074135), Jiangxi Provincial Natural Science Foundation (No. 20224ACB214011), Youth Jinggang Scholars Program in Jiangxi Province (QNJG2020049) and Ganzhou Key Scientific and Technological Research and Development Plan.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Hh., Xiong, Hh., Qin, J. et al. Mechanism of ferrite nucleation induced by Y2O2S inclusion in low carbon steel. J. Iron Steel Res. Int. 30, 1291–1299 (2023). https://doi.org/10.1007/s42243-023-00986-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00986-6