Abstract

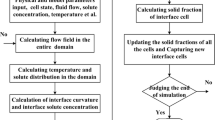

Based on the principles of metal solidification and cellular automaton (CA), as well as AlN precipitation thermodynamics and kinetics, a CA model of interdendritic AlN precipitation was established by coupling a large-size mesh describing the dendrite growth of Fe–C–Al–N alloys and a small-size mesh representing AlN precipitation based on transient chemical equilibrium. The results of single dendrite growth stimulated by this model were compared with the Lipton–Glicksman–Kurz solution to verify the correctness of the matrix dendrite growth simulation. The AlN morphology and dimensions obtained from the CA model simulations are following the experimental results. The presence of equiaxed dendrite in the computational domain results in a significant coarsening of the columnar dendrite and a uniform solute distribution around them, and the AlN solid phase fraction decreases. Simulations of AlN precipitation at different wetting angles were also performed, and it was found that the solid phase fraction of AlN decreased with the increase in wetting angle. Thus, it is confirmed that the established model is an effective method to simulate interdendritic AlN precipitation.

Similar content being viewed by others

References

T. Zhang, X. Zhang, Z. Guo, Y. Wang, C. Li, L. Lan, Acta Metall. Sin. (Engl. Lett.) 26 (2013) 483–488.

P. Presoly, R. Pierer, C. Bernhard, Metall. Mater. Trans. A 44 (2013) 5377–5388.

J.I. Jang, S. Lee, Y. Kang, Metall. Mater. Trans. B 52 (2021) 1582–1589.

M. Sennour, C. Esnouf, Acta Mater. 51 (2003) 943–957.

A. Tuling, B. Mintz, Mater. Sci. Technol. 32 (2015) 568–575.

M.N. Wahab, M.J. Ghazali, A.R. Daud, Key Eng. Mater. 462–463 (2011) 307–312.

J. Chen, C. Bao, Y. Wang, C. Suryanarayana, Acta Metall. Sin. (Engl. Lett.) 28 (2015) 1354–1363.

X. Li, M. Wang, Y. Bao, J. Gong, W. Pang, JOM 71 (2019) 3135–3141.

M. Rappaz, Acta Metall. Mater. 34 (1993) 93–124.

C.A. Gandin, M. Rappaz, Acta Metall. Mater. 42 (1994) 2233–2246.

R. Chen, Q. Xu, B. Liu, J. Mater. Sci. Technol. 30 (2014) 1311–1320.

C. Yang, Q. Xu, B. Liu, Rare Met. 39 (2019) 147–155.

R. Chen, Q. Xu, B. Liu, Comput. Mater. Sci. 105 (2015) 90–100.

X. Gao, X. Meng, L. Cui, K. Zhang, M. Zhu, Mater. Res. Express 7 (2020) 056505.

X. Gao, X. Meng, L. Cui, M. Zhu, Mater. Res. Express 6 (2019) 096583.

X. Meng, X. Gao, S. Huang, M. Zhu, Metals 8 (2018) 529–532.

X. Meng, L. Cui, Y. Shi, M. Zhu, J. Iron Steel Res. Int. 28 (2021) 997–1008.

J. Wang, H. Meng, J. Yang, Z. Xie, J. Comput. Sci. 48 (2021) 101265.

S. Luo, W. Wang, M. Zhu, Int. J. Heat Mass Transfer 116 (2018) 940–950.

W. Wang, S. Yin, S. Luo, M. Zhu, Metall. Mater. Trans. B 50 (2019) 1531–1541.

K. Liu, J. Wang, Y. Yang, Y. Zhou, C. Cao, Comput. Mater. Sci. 188 (2021) 110172.

A. Pineau, G. Guillemot, G. Reinhart, N. Manglinck-Noël, C. Gandin, Acta Mater. 191 (2020) 230–244.

A. Choudhury, K. Reuther, E. Wesner, A. August, B. Nestler, M. Rettenmayr, Comput. Mater. Sci. 55 (2012) 263–268.

C.H. Chen, A.M. Tabrizi, P.A. Geslin, A. Karma, Acta Mater. 202 (2021) 463–477.

S. Liu, K. Hong, Y.C. Shin, Comput. Mater. Sci. 192 (2021) 110405.

S. Pan, M. Zhu, Acta Mater. 58 (2010) 340–352.

D. Sun, M. Zhu, S. Pan, D. Raabe, Acta Mater. 57 (2009) 1755–1767.

M. Zhu, D. Sun, S. Pan, Q. Zhang, D. Raabe, Modell. Simul. Mater. Sci. Eng. 2 (2014) 034006.

M. Zhu, S. Pan, D. Sun, H. Zhao, ISIJ Int. 50 (2010) 1851–1858.

M. Hu, C. Sun, H. Fang, M. Zhu, Eur. Phys. J. E 43 (2020) 16.

Q. Zhang, D. Sun, S. Pan, M. Zhu, Int. J. Heat Mass Trans. 146 (2020) 118838.

N. Ren, J. Li, N. Bogdan, Comput. Mater. Sci. 180 (2020) 109714.

S. Meng, A. Zhang, Z. Guo, Q. Wang, Comput. Mater. Sci. 184 (2020) 109784.

J. Chen, Common use chart and thermodynamic data for steelmaking, 2nd ed., Metallurgical Industry Press, Beijing, China, 2011.

H. Suito, R. Inoue, ISIJ Int. 36 (1996) 528–536.

W. Wang, S. Luo, M. Zhu, Crystals 6 (2016) 147–158.

L. Beltran-sanchez, D.M. Stefanescu, Metall. Mater. Trans. A 35 (2004) 2471–2485.

Q. Yong, Second phases in structural steels, Metallurgical Industry Press, Beijing, China, 2006.

S. Luo, M. Zhu, S. Louhenkilpi, ISIJ Int. 52 (2012) 823–830.

J. Lipton, M.E. Glicksman, W. Kurz, Mater. Sci. Eng. 65 (1984) 57–63.

Z. Deng, Y. He, J. Liu, B. Yan B, A. Mclean, Metals 9 (2019) 1091.

M. Nabeel, M. Alba, N. Dpgan, Crystals 10 (2020) 1054.

Acknowledgements

This research was funded by the National Natural Science Foundation of China (Grant No. 52074071).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, L., Shi, Yh. & Meng, Xn. AlN precipitation during steel solidification using CA model. J. Iron Steel Res. Int. 29, 1789–1799 (2022). https://doi.org/10.1007/s42243-022-00766-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00766-8