Abstract

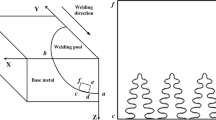

A two-dimensional cellular automaton–finite volume model was developed to simulate dendrite growth of Al-3 wt pct Cu alloy during solidification to investigate the effect of temperature and fluid flow on dendrite morphology, solute concentration distribution, and dendrite growth velocity. Different calculation conditions that may influence the results of the simulation, including temperature and flow, were considered. The model was also employed to study the effect of different undercoolings, applied temperature fields, and forced flow velocities on solute segregation and dendrite growth. The initial temperature and fluid flow have a significant impact on the dendrite morphologies and solute profiles during solidification. The release of energy is operated with solidification and results in the increase of temperature. A larger undercooling leads to larger solute concentration near the solid/liquid interface and solute concentration gradient at the same time-step. Solute concentration in the solid region tends to increase with the increase of undercooling. Four vortexes appear under the condition when natural flow exists: the two on the right of the dendrite rotate clockwise, and those on the left of the dendrite rotate counterclockwise. With the increase of forced flow velocity, the rejected solute in the upstream region becomes easier to be washed away and enriched in the downstream region, resulting in acceleration of the growth of the dendrite in the upstream and inhibiting the downstream dendrite growth. The dendrite perpendicular to fluid flow shows a coarser morphology in the upstream region than that of the downstream. Almost no secondary dendrite appears during the calculation process.

Similar content being viewed by others

References

M. Yang, S.M. Xiong, and Z. Guo: Acta Mater., 2016, vol. 112, pp. 261–72.

D. Szeliga, K. Kubiak, and J. Sieniawski: J. Mater. Process. Technol., 2016, vol. 234, pp. 18–26.

D.V. Alexandrov and P.K. Galenko: Phys.-Usp., 2014, vol. 57, pp. 771–86.

P.A. Molian and T.S. Srivatsan: J. Mater. Sci., 1990, vol. 25, pp. 3347–58.

G. Salloum-Abou-Jaoude, J. Wang, L. Abou-Khalil, G. Reinhart, Z. Ren, N. Mangelinck-Noel, X. Li, Y. Fautrelle, and H. Nguyen-Thi: J. Cryst. Growth, 2015, vol. 417, pp. 25–30.

N. Shevchenko, O. Roshchupkina, O. Sokolova, and S. Eckert: J. Cryst. Growth, 2015, vol. 417, pp. 1–8.

A.G. Murphy, W.U. Mirihanage, D.J. Browne, and R.H. Mathiesen: Acta Mater., 2015, vol. 95, pp. 83–89.

X. Zhan, Y. Wei, and Z. Dong: J. Mater. Process. Technol., 2008, vol. 208, pp. 1–8.

H.B. Dong and P.D. Lee: Acta Mater., 2005, vol. 53, pp. 659–68.

L. Nastac: Acta Mater., 1999, vol. 47, pp. 4253–62.

J.A. Spittle and S.G.R. Brown: J. Mater. Sci., 1995, vol. 30, pp. 3989–94.

M. Rappaz and C.A. Gandin: Acta Metall. Mater., 1993, vol. 41, pp. 345–60.

S. Pan and M. Zhu: Acta Mater., 2010, vol. 58, pp. 340–52.

W.J. Zheng, Z.B. Dong, Y.H. Wei, K.J. Song, J.L. Guo, and Y. Wang: Comp. Mater. Sci., 2014, vol. 82, pp. 525–30.

T. Takaki, S. Sakane, M. Ohno, Y. Shibuta, T. Shimokawabe, and T. Aoki: Acta Mater., 2016, vol. 118, pp. 230–43.

M.J.M. Krane, D.R. Johnson, and S. Raghavan: Appl. Math. Model., 2009, vol. 33, pp. 2234–47.

N. Al-Rawahi and G. Tryggvason: J. Comput. Phys., 2004, vol. 194, pp. 677–96.

N. Al-Rawahi and G. Tryggvason: J. Comput. Phys., 2002, vol. 180, pp. 471–96.

D. Li, R. Li and P. Zhang: Appl. Math. Model., 2007, vol. 31, pp. 971–82.

R. Siquieri, J. Rezende, J. Kundin, and H. Emmerich: Eur. Phys. J. Special Topics, 2009, vol. 177, pp. 193–205.

R. Xiao, Z. Wang, C. Zhu, L. Feng, and W. Li: J. Shanghai Jiaotong Univ. (Sci.), 2011, vol. 16, pp. 356–59.

R. Rojas, T. Takaki, and M. Ohno: J. Comput. Phys., 2015, vol. 298, pp. 29–40.

L. Yuan and P.D. Lee: Model. Simul. Mater. Sci., 2010, vol. 18, p. 055008.

D.K. Sun, M.F. Zhu, S.Y. Pan, C.R. Yang, and D. Raabe: Comput. Math. Appl., 2011, vol. 61, pp. 3585–92.

D. Sun, M. Zhu, S. Pan, and D. Raabe: Acta Mater., 2009, vol. 57, pp. 1755–67.

C. Gu, Y. Wei, X. Zhan, and Y. Li: Sci. Technol. Welding Joining, 2016, vol. 22, pp. 47–58.

K.J. Song, Y.H. Wei, Z.B. Dong, R. Ma, X.H. Zhan, W.J. Zheng, and K. Fang: Model. Simul. Mater. Sci., 2014, vol. 22, p. 015006.

K.J. Song, Y.H. Wei, Z.B. Dong, X.H. Zhan, W.J. Zheng, and K. Fang: Comp. Mater. Sci., 2013, vol. 72, pp. 93–100.

J.A. Warren and W.J. Boettinger: Acta Metall. Mater., 1995, vol. 43, pp. 689–703.

X.H. Wu, G. Wang, L.Z. Zhao, D.C. Zeng, and Z.W. Liu: Comp. Mater. Sci., 2016, vol. 117, pp. 286–93.

J.L. Murray: Int. Mater. Rev., 1985, vol. 30, pp. 211–34.

M. Zhu and D. Stefanescu: Acta Mater., 2007, vol. 55, pp. 1741–55.

M. Zhu, D. Sun, S. Pan, Q. Zhang, and D. Raabe: Model. Simul. Mater. Sci., 2014, vol. 22, p. 034006.

S. Luo and M.Y. Zhu: Comp. Mater. Sci., 2013, vol. 71, pp. 10–18.

L. Wei, X. Lin, M. Wang, and W. Huang: Comp. Mater. Sci., 2012, vol. 54, pp. 66–74.

J. Lipton, M.E. Glicksman, and W. Kurz: Metall. Trans. A, 1987, vol. 18A, pp. 341–45.

J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57–63.

L. Du and R. Zhang: Metall. Mater. Trans. B, 2014, vol. 45, pp. 2504–15.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51175253), the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), and the Fundamental Research Funds for the Central Universities (Grant No. NP2016204).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 22, 2017.

Rights and permissions

About this article

Cite this article

Gu, C., Wei, Y., Liu, R. et al. Effect of Temperature and Fluid Flow on Dendrite Growth During Solidification of Al-3 Wt Pct Cu Alloy by the Two-Dimensional Cellular Automaton Method. Metall Mater Trans B 48, 3388–3400 (2017). https://doi.org/10.1007/s11663-017-1060-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1060-3