Abstract

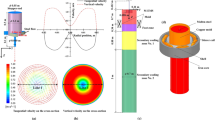

Optimization of mathematical model of flow field in slab continuous casting mold was performed by means of industrial measurement and mathematical modeling. The rod deflection method was used to quantitatively measure the velocities near the mold surface at high temperature. The measurement results were compared with the simulation results of three mathematical models at different argon gas flow rates of 6, 10 and 14 L min−1. The model 1 neglects the mold powder layer, thermal effect and solidified shell. The model 2 only considers the influence of mold powder layer. The model 3 considers the influence of mold powder layer, thermal effect and solidified shell on the flow field. In all three models, the diameter of argon bubbles obeys Rosin–Rammler distribution fitted according to the experimental data of others’ previous work. With increasing the argon gas flow rate, the velocity of liquid steel near the mold surface decreases. The model 1 seriously underestimates the shear stress of liquid steel near the mold surface, and its calculation results show higher velocity near the mold surface, lower turbulent kinetic energy and wider distribution of argon gas bubbles in the mold. The simulation results of model 2 only considering the viscous resistance of the mold powder layer to liquid steel makes the velocity near the surface lower than the measurement results obviously. The calculated velocities near the mold surface with model 3 are in best agreement with the measured results, showing the reasonable spatial distribution range of argon bubbles in the mold and the moderate turbulent kinetic energy. In the present conditions, the best argon gas flow rate is 10 L min−1 due to the moderate velocity near the mold surface, the appropriate distribution of argon gas bubbles in the mold and the smallest fluctuation amplitude on the mold surface.

Similar content being viewed by others

Abbreviations

- A mush :

-

Mushy zone constant

- c W :

-

Specific heat capacity of cooling water, J kg−1 K−1

- D :

-

Width or thickness of mold, mm

- d :

-

Distance to meniscus, m

- d b :

-

Bubble diameter, m

- d m :

-

Effective length of mold, m

- F mom :

-

Momentum exchange caused by interphase force traction, N m−3

- F D :

-

Drag force, N

- F f :

-

Buoyancy, N

- F g :

-

Gravity force, N

- F i :

-

Flow rate of cooling water on a certain face of mold, L min−1

- F L :

-

Lift force, N

- F P :

-

Pressure gradient force, N

- F V :

-

Virtual mass force, N

- F vol :

-

Interface tension volume force, N m−3

- g(g i, g j, g k):

-

Gravity acceleration vector, m s−2

- h :

-

Equivalent heat transfer coefficient between solidified shell and cooling water, kJ m−2 h−1 °C−1

- k :

-

Interface curvature, m−2

- m :

-

Cooling water flow rate of mold, kg s−1

- m b :

-

Bubble mass, kg

- M eff :

-

Effective cooling area of mold, m2

- n :

-

Normal vector of interface, m−1

- \(\hat{\varvec{n}}\) :

-

Unit normal vector of interface, m−1

- p :

-

Pressure, Pa

- p 1, p 2 :

-

Pressure on both sides of two-phase interface, Pa

- \(\stackrel{\mathrm{-}}{\text{\it q}}\) :

-

Average heat flux in mold area, W m−2

- q s :

-

Heat flux between solidified shell and cooling water, W m−2

- R 1, R 2 :

-

Principal radii of curvature at two-phase interface in orthogonal directions, m

- S :

-

Additional momentum source caused by solidification, N m−3

- t :

-

Time, s

- ∆T :

-

Temperature rise of cooling water flowing through mold, K

- T :

-

Temperature, K

- T liquidus :

-

Liquidus temperature, K

- T solidus :

-

Solidus temperature, K

- T w :

-

Cooling water temperature, °C

- u(u i, u j, u k):

-

Velocity of continuous phase, m s−1

- u b :

-

Bubble velocity, m s−1

- u i , j :

-

Velocity perpendicular to i, j plane, m s−1

- u p :

-

Casting speed, m s−1

- W :

-

Cooling intensity, L m−2 s−1

- X :

-

Distance from meniscus to bottom of mold, cm

- x(x i, x j, x k):

-

Location vector, m

- α slag :

-

Volume fraction of liquid mold powder

- α steel :

-

Volume fraction of liquid steel

- β :

-

Liquid fraction of steel

- ε :

-

Turbulent energy dissipation rate, m2 s−3

- κ :

-

Turbulent kinetic energy, m2 s−2

- λ 2 :

-

Secondary dendrite spacing, m

- μ l :

-

Liquid viscosity, Pa s

- μ slag :

-

Viscosity of liquid mold powder, Pa s

- μ steel :

-

Viscosity of liquid steel, Pa s

- μ t :

-

Turbulent viscosity, Pa s

- ξ :

-

Small constant to avoid a zero denominator

- ρ :

-

Density of continuous phase, kg m−3

- ρ b :

-

Bubble density, kg m−3

- ρ slag :

-

Density of liquid mold powder, kg m−3

- ρ steel :

-

Density of liquid steel, kg m−3

- σ :

-

Interface tension coefficient, N m−1

- i, j, k :

-

Indices for different spatial coordinate directions

References

Z.H. Zhang, H.L. Wu, L. Feng, S.F. Liu, Y. Zhang, J. Iron Steel Res. 28 (2016) No. 5, 1–6.

X.P. Yang, G.Q. Li, J.P. Rao, Z.Z. Yang, J. Wuhan Univ. Sci. Technol. 39 (2016) 12–18.

C.N. Wang, L.Y. Wen, D.F. Chen, Z. Peng, J. Zhang, X. Jin, D.J. Zhang, Chin. J. Process Eng. 9 (2009) 325–328.

H.B. Lu, C.G. Cheng, Y. Li, M.L. Yang, Y. Jin, Iron and Steel 53 (2018) No. 4, 27–36.

S.M. Cho, B.G. Thomas, S.H. Kim, Metall. Mater. Trans. B 50 (2019) 52–76.

Y. Meng, B.G. Thomas, ISIJ Int. 46 (2006) 660–669.

A. Vakhrushev, M. Wu, A. Ludwig, G. Nitzl, Y. Tang, G. Hackl, Experimental Verification of a 3-Phase Continuous Casting Simulation Using a Water Model, in: Proceedings of 8th ECCC Conference, Graz, Austria, 2014.

P. Zhao, Q. Li, S.B. Kuang, Z.S. Zou, High Temp. Mater. Proc. 36 (2017) 551–565.

M. Saeedipour, S. Puttinger, S. Pirker, in: Proceedings of the 12th International Conference on Computational Fluid Dynamics in the Oil & Gas, Metallurgical and Process Industries, SINTEF Academic Press, Trondheim, Norway, 2017, pp. 507–513.

P. Sulasalmi, A. Kärnä, T. Fabritius, J. Savolainen, ISIJ Int. 49 (2009) 1661–1667.

M. Iguchi, J. Yoshida, T. Shimizu, Y. Mizuno, ISIJ Int. 40 (2000) 685–691.

Y.Z. Luo, L.J. Zhang, H.B. Li, Y. Cui, Y.J. Ni, X.W. Pei, China Metallurgy 26 (2016) No. 11, 34–40.

D.J. Zou, Z.S. Zou, Continuous Casting (2009) No. 6, 5–8+12.

Y. Meng, B.G. Thomas, Metall. Mater. Trans. B 34 (2003) 685–705.

B.G. Thomas, X. Huang, R.C. Sussman, Metall. Mater. Trans. B 25 (1994) 527–547.

J.M. Zhang, L.F. Wang, X.H. Wang, L. Zhang, H.B. Tang, Acta Metall. Sin. 39 (2003) 1281–1284.

C. Zhang, Y.Q. Wang, D.X. Cai, Z.M. Zhu, W.Z. Wang, J. Iron Steel Res. 12 (2000) No. 2, 21–24.

K. Sołek, M. Korolczuk-Hejnak, W. Ślęzak, Arch. Metall. Mater. 57 (2012) 333–338.

K. Sołek, M. Korolczuk-Hejnak, M. Karbowniczek, Arch. Metall. Mater. 56 (2011) 593–598.

X.B. Zhang, W. Chen, L.F. Zhang, China Foundry 14 (2017) 416–420.

S.D. Wang, X.B. Zhang, L.F. Zhang, Q.Q. Wang, Steel Res. Int. 89 (2018) 1800263.

L.F. Zhang, X.B. Zhang, Y. Ren, W. Yang, Metall. Res. Technol. 116 (2019) 215.

B. Rietow, B.G. Thomas, in: AISTech 2008 Steelmaking Conference Proceedings, AIST, Pittsburgh, PA, USA, 2008, pp. 1–11.

L. Ren, L.F. Zhang, Q.Q. Wang, Iron and Steel 51 (2016) No. 2, 49–54.

R. Chaudhary, B.T. Rietow, B.G. Thomas, in: Proceedings of the Materials Science and Technology Conference, Materials Science and Technology, Pennsylvania, USA, 2009, pp. 1090–1101.

T. Zhang, J. Yang, P. Jiang, Metals 9 (2019) 36.

P. Jiang, J. Yang, T. Zhang, G.J. Xu, H.J. Liu, J.J. Zhou, W. Qin, Metals 10 (2020) 9.

T. Zhang, J. Yang, G.J. Xu, H.J. Liu, J.J. Zhou, W. Qin, Int. J. Miner. Metall. Mater. 28 (2021) 238–248.

H.B. Lu, C.G. Cheng, Y. Li, M.L. Yang, Y. Jin, Iron and Steel 53 (2018) No. 4, 27–36+41.

N. Cao, M.Y. Zhu, J.X. Song, X.G. Leng, N.L. Cheng, in: Proceedings of the 8th National Conference on Continuous Casting, The Chinese Society for Metals, Haikou, China, 2007, pp. 248–252.

J.U. Brackbill, D.B. Kothe, C. Zemach, J. Comput. Phys. 100 (1992) 335–354.

L.B. Trindade, J.E.A. Nadalon, A.C. Contini, R.C. Barroso, Steel Res. Int. 88 (2017) 1600319.

Q.Q. Wang, Study on the multiphase flow, heat transfer and solidification, motion and entrapment of inclusions during continuous casting, University of Science and Technology Beijing, Beijing, China, 2017.

S.X. Li, X.M. Zhang, L. Li, P. Lan, H.Y. Tang, J.Q. Zhang, Chin. J. Eng. 41 (2019) 199–208.

P.C. Carman, Chem. Eng. Res. Des. 75 (1997) S32–S48.

J. Savage, W.H. Pritchard, J. Iron Steel Inst. 178 (1954) 269–277.

V. Seshadri, C.A. da Silva, I.A. da Silva, Iron and Steel Making 2 (2006) 499–510.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (U1960202) and HBIS Handan Iron and Steel Group Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Yb., Yang, J., Ma, C. et al. Mathematical modeling of flow field in slab continuous casting mold considering mold powder and solidified shell with high temperature quantitative measurement. J. Iron Steel Res. Int. 29, 445–461 (2022). https://doi.org/10.1007/s42243-021-00654-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00654-7