Abstract

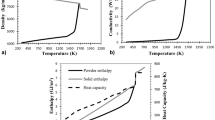

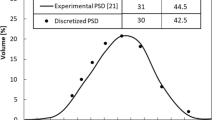

The Laser-Based Powder Bed Fusion (LPBF) process is an additive manufacturing (AM) technique used to fabricate intricate 3D metallic components from fine powder particles. This study presents a 2D semi-analytical model, an algorithm developed by incorporating multiple physical phenomena of the process, i.e., heat transfer, fluid flow, and Marangoni effect for computing temperature and velocity distribution, to estimate the melt-pool characteristics for the single-track melting. The laser input energy has been modelled as a moving Gaussian volumetric heat source, and the fluid flow phenomenon has been formulated by ‘Semi-Implicit Method for Pressure Linked Equations’ (SIMPLE) method. A set of two-dimensional transient conservation of mass, momentum, and energy equations are discretized as co-located mesh by Finite Volume Method (FVM) and iteratively solved by Alternating Direction Implicit (ADI) scheme to obtain temperature and velocity field. The Pressure Weighted Interpolation Method (PWIM) is incorporated to avoid pressure oscillation and allow the use of co-located mesh for fluid flow, making the model computationally efficient. The model is validated for Ti6Al4V and Inconel 718 alloy with the experimental findings from the literature. The obtained results are in good agreement with an average deviation of 5.78% and 20.07% for Ti6Al4V , whereas for Inconel 718, 7.87 and 19.53% for melt-pool depth and width, respectively, were observed. Subsequently, the melt-pool growth and characteristics influenced by various process parameters are also studied.

Graphical abstract

Similar content being viewed by others

Data availability

All data supporting this study's findings are included in this article.

Abbreviations

- A :

-

Fractional energy absorption

- A P ,A E ,A W ,A N ,A S :

-

Advection diffusion coefficients

- C :

-

Specific heat capacity

- D :

-

Hatch distance

- G :

-

Permeability

- K :

-

Thermal conductivity

- K p :

-

Thermal conductivity of powder

- K s :

-

Thermal conductivity of solid phase

- P :

-

Laser power

- Q :

-

Internal heat generation

- δQ conv :

-

Convective heat loss

- Q eff :

-

Heat density

- T :

-

Temperature

- \(\Delta T\) :

-

Increment in temperature

- T f :

-

Base-plate temperature

- T L :

-

Liquidus temperature

- T S :

-

Solidus temperature

- T 0 :

-

Initial temperature

- T ∞ :

-

Ambient temperature

- V :

-

Scan velocity

- \(a,b,c\) :

-

Laser parameters of semi-ellipsoid volumetric heat source

- \(d\) :

-

Computational constant

- h :

-

Heat transfer coefficient

- \(l\) :

-

Layer thickness

- \(p\) :

-

Pressure

- t :

-

Time instant

- t f :

-

Time counter for computation of front view

- t s :

-

Time counter for computation of side view

- \(\Delta t\) :

-

Time interval

- u :

-

X-direction molten material velocity component

- v :

-

Y-direction molten material velocity component

- w :

-

Z-direction molten material velocity component

- \(\Delta x\) :

-

Grid spacing

- \(x,y,z\) :

-

Global co-ordinates

- \({x}{\prime},{y}{\prime},z{\prime}\) :

-

Moving co-ordinates

- α :

-

Thermal diffusivity

- ε:

-

Liquid fraction

- \(\mu \) :

-

Viscosity

- \(\varphi \) :

-

Fractional porosity

- ρ :

-

Mass density

- ρ p :

-

Local mass density of powder phase

- ρ s :

-

Local mass density of solid phase

- \(\sigma \) :

-

Surface tension

- \(\tau \) :

-

Time steps to achieve quasi steady state

- \({\tau }_{x}\) :

-

Marangoni shear stress along x-direction

- \({\tau }_{y}\) :

-

Marangoni shear stress along y-direction

References

Chua, C.K., Leong, K.F.: 3D Printing and Additive Manufacturing. World Scientific (2017)

Gibson, I., Rosen, D., Stucker, B.: Additive Manufacturing Technologies 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer, New York (2015)

Foroozmehr, A., Badrossamay, M., Foroozmehr, E., Golabi, S.: Finite element simulation of selective laser melting process considering optical penetration depth of laser in powder bed. Mater. Des. 89, 255–263 (2016). https://doi.org/10.1016/j.matdes.2015.10.002

King, W.E., Barth, H.D., Castillo, V.M., Gallegos, G.F., Gibbs, J.W., Hahn, D.E., Kamath, C., Rubenchik, A.M.: Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 214, 2915–2925 (2014). https://doi.org/10.1016/j.jmatprotec.2014.06.005

Chakrabarty, A., Chakraborty, P., Jain, R., Sahu, V.K., Gurao, N.P., Bar, H.N., Khutia, N.: Influence of scanning and building strategies on the deformation behavior of additively manufactured AlSi10Mg: CPFEM and finite element studies. Met. Mater. Int. (2023). https://doi.org/10.1007/s12540-023-01418-6

Ransenigo, C., Tocci, M., Palo, F., Ginestra, P., Ceretti, E., Gelfi, M., Pola, A.: Evolution of melt pool and porosity during laser powder bed fusion of Ti6Al4V alloy: numerical modelling and experimental validation. Lasers Manuf. Mater. Process. 9, 481–502 (2022). https://doi.org/10.1007/s40516-022-00185-3

Zhang, T., Li, H., Liu, S., Shen, S., Xie, H., Shi, W., Zhang, G., Shen, B., Chen, L., Xiao, B., Wei, M.: Evolution of molten pool during selective laser melting of Ti-6Al-4V. J. Phys. D. Appl. Phys. (2019). https://doi.org/10.1088/1361-6463/aaee04

Eagar, T.W., Tsai, N.S.: Temperature fields produced by travelling distributed heat sources. In: Weld. Res. Suppl.; (United States). pp. 154–155 (1983)

Nguyen, N.T., Ohta, A., Matsuoka, K., Suzuki, N., Maeda, Y.: Analytical Solutions for Transient Temperature of Semi-Infinite Body Subjected to 3-D Moving Heat Sources. Weld. J. (Miami, Fla). 78, (1999)

Nguyen, N.T., Mai, Y.W., Simpson, S., Ohta, A.: Analytical Approximate Solution for Double Ellipsoidal Heat Source in Finite Thick Plate. Weld. J. (Miami, Fla). 83, (2004)

Roberts, I.A., Wang, C.J., Esterlein, R., Stanford, M., Mynors, D.J.: A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf 49, 916–923 (2009). https://doi.org/10.1016/J.IJMACHTOOLS.2009.07.004

Ross, A.J., Bitharas, I., Perkins, K.G., Moore, A.J.: Volumetric heat source calibration for laser powder bed fusion. Addit. Manuf. 60, 103267 (2022). https://doi.org/10.1016/J.ADDMA.2022.103267

Li, Z.-J., Dai, H., Xu, J., Huang, Z.-W.: A semi-analytical approach for analysis of thermal behaviors coupling heat loss in powder bed fusion. Int. J. Heat Mass Transf. 201, 123621 (2023). https://doi.org/10.1016/j.ijheatmasstransfer.2022.123621

Yadav, A.: Fundamentals of thermo-fluid-mechanical modeling in additive manufacturing processes. Adv Addit Manuf. Artif. Intell. (2023). https://doi.org/10.1016/B978-0-323-91834-3.00023-5

Pandey, A., Choudhary, S., Gaur, V.: A numerical study on microstructural features evolved across the melt pool in additively manufactured IN718 alloy. Mater. Sci. Eng. A 868, 144763 (2023). https://doi.org/10.1016/J.MSEA.2023.144763

Yang, Y., Knol, M.F., van Keulen, F., Ayas, C.: A semi-analytical thermal modelling approach for selective laser melting. Addit. Manuf. 21, 284–297 (2018). https://doi.org/10.1016/j.addma.2018.03.002

Liu, B., Fang, G., Lei, L.: An analytical model for rapid predicting molten pool geometry of selective laser melting (SLM). Appl. Math. Model. 92, 505–524 (2021). https://doi.org/10.1016/j.apm.2020.11.027

Khorasani, M., Ghasemi, A.H., Leary, M., Cordova, L., Sharabian, E., Farabi, E., Gibson, I., Brandt, M., Rolfe, B.: A comprehensive study on meltpool depth in laser-based powder bed fusion of Inconel 718. Int. J. Adv. Manuf. Technol. 120, 2345–2362 (2022). https://doi.org/10.1007/s00170-021-08618-7

Ullah, R., Lian, J., Akmal, J., Wu, J., Niemi, E.: Prediction and validation of melt pool dimensions and geometric distortions of additively manufactured AlSi10Mg. Int. J. Adv. Manuf. Technol. 126, 3593–3613 (2023). https://doi.org/10.1007/s00170-023-11264-w

Le, T.N., Lo, Y.L.: Effects of sulfur concentration and Marangoni convection on melt-pool formation in transition mode of selective laser melting process. Mater. Des. 179, 107866 (2019). https://doi.org/10.1016/j.matdes.2019.107866

Karimipour, A., Abedini, E., Ajam, H., Sarvari, S.M.H.: Modeling of fluid flow and heat transfer in laser welding with a moving heat source. Adv. Mater. Res. 622, 618–622 (2013). https://doi.org/10.4028/www.scientific.net/AMR.622-623.618

Ye, X.-H., Chen, X.: Three-dimensional modelling of heat transfer and fluid flow in laser full-penetration welding. J. Phys. D Appl. Phys. 35, 1049 (2002). https://doi.org/10.1088/0022-3727/35/10/313

Cook, P.S., Murphy, A.B.: Simulation of melt pool behaviour during additive manufacturing: Underlying physics and progress, (2020)

Wang, Z., Yan, W., Liu, W.K., Liu, M.: Powder-scale multi-physics modeling of multi-layer multi-track selective laser melting with sharp interface capturing method. Comput. Mech. 63, 649–661 (2019). https://doi.org/10.1007/s00466-018-1614-5

Wu, Y.-C., San, C.-H., Chang, C.-H., Lin, H.-J., Marwan, R., Baba, S., Hwang, W.-S.: Numerical modeling of melt-pool behavior in selective laser melting with random powder distribution and experimental validation. J. Mater. Process. Technol. 254, 72–78 (2018). https://doi.org/10.1016/J.JMATPROTEC.2017.11.032

Zhang, D., Zhang, P., Liu, Z., Feng, Z., Wang, C., Guo, Y.: Thermofluid field of molten pool and its effects during selective laser melting (SLM) of Inconel 718 alloy. Addit. Manuf. 21, 567–578 (2018). https://doi.org/10.1016/j.addma.2018.03.031

He, Q., Xia, H., Liu, J., Ao, X., Lin, S.: Modeling and numerical studies of selective laser melting: Multiphase flow, solidification and heat transfer. Mater. Des. 196, 109115 (2020). https://doi.org/10.1016/J.MATDES.2020.109115

Wang, Y., Ji, X., Liang, S.Y.: Analytical modeling of temperature distribution in laser powder bed fusion with different scan strategies. Opt. Laser Technol. 157, 108708 (2023). https://doi.org/10.1016/j.optlastec.2022.108708

Zagade, P., Gautham, B.P., De, A., DebRoy, T.: Analytical estimation of fusion zone dimensions and cooling rates in part scale laser powder bed fusion. Addit. Manuf. 46, 102222 (2021). https://doi.org/10.1016/j.addma.2021.102222

Mirkoohi, E., Ning, J., Bocchini, P., Fergani, O., Chiang, K.N., Liang, S.Y.: Thermal modeling of temperature distribution in metal additive manufacturing considering effects of build layers, latent heat, and temperature-sensitivity of material properties. J. Manuf. Mater. Process (2018). https://doi.org/10.3390/jmmp2030063

Mirkoohi, E., Sievers, D.E., Garmestani, H., Chiang, K., Liang, S.Y.: Three-dimensional semi-elliptical modeling of melt pool geometry considering hatch spacing and time spacing in metal additive manufacturing. J. Manuf. Process. 45, 532–543 (2019). https://doi.org/10.1016/J.JMAPRO.2019.07.028

Hagenlocher, C., O’Toole, P., Xu, W., Brandt, M., Easton, M., Molotnikov, A.: Analytical modelling of heat accumulation in laser based additive manufacturing processes of metals. Addit. Manuf. 60, 103263 (2022). https://doi.org/10.1016/j.addma.2022.103263

Ji, X., Wang, Y., Liang, S.Y.: Analytical modeling of temperature evolution in laser powder bed fusion considering the size and shape of the build part. J. Mater. Process. Technol. 301, 117452 (2022). https://doi.org/10.1016/j.jmatprotec.2021.117452

Mukherjee, T., Wei, H.L.L., De, A., DebRoy, T.: Heat and fluid flow in additive manufacturing—Part I: Modeling of powder bed fusion. Comput. Mater. Sci. 150, 304–313 (2018). https://doi.org/10.1016/j.commatsci.2018.04.022

Cao, Y., Faghri, A.: Thermal protection from intense localized moving heat fluxes using phase-change materials. Int. J. Heat Mass Transf. 33, 127–138 (1990). https://doi.org/10.1016/0017-9310(90)90147-M

Van, E.M., Baelmans, M., Mercelis, P., Kruth, J.P.: Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. Int. J. Heat Mass Transf. 50, 4872–4882 (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2007.02.044

Khan, K., Mohr, G., Hilgenberg, K., De, A.: Probing a novel heat source model and adaptive remeshing technique to simulate laser powder bed fusion with experimental validation. Comput. Mater. Sci. 181, 109752 (2020). https://doi.org/10.1016/j.commatsci.2020.109752

Gao, J., Wu, C., Hao, Y., Xu, X., Guo, L.: Numerical simulation and experimental investigation on three-dimensional modelling of single-track geometry and temperature evolution by laser cladding. Opt. Laser Technol. 129, 106287 (2020). https://doi.org/10.1016/j.optlastec.2020.106287

Nandi, S.K., Kumar, R., Anubhav, Agrawal, A.: Prediction of Melt-Pool Characteristics in SLM Process for Ti6Al4V Using a Semi-Analytical Model. In: Volume 1: Additive Manufacturing; Advanced Materials Manufacturing; Biomanufacturing; Life Cycle Engineering; Manufacturing Equipment and Automation. American Society of Mechanical Engineers (2021)

Nandi, S.K., Kumar, R., Agrawal, A.: Computationally inexpensive semi-analytical thermal model to predict melt-pool dimensions for a single-track in selective laser melting. J. Manuf. Process. 80, 469–479 (2022). https://doi.org/10.1016/j.jmapro.2022.06.025

Goldak, J.A., Akhlaghi., M.: Computational Welding Mechanics. In: Computational Welding Mechanics. pp. 1–15. Kluwer Academic Publishers (2006)

Voller, V.R., Cross, M., Markatos, N.C.: An enthalpy method for convection/diffusion phase change. Int. J. Numer. Methods Eng. 24, 271–284 (1987). https://doi.org/10.1002/nme.1620240119

Brent, A.D., Voller, V.R., Reid, K.J.: Enthalpy-porosity technique for modeling convection-diffusion phase change: application to the melting of a pure metal. Numer. Heat Transf. 13, 297–318 (1988). https://doi.org/10.1080/10407788808913615

Voller, V.R., Swaminathan, C.R., Thomas, B.G.: Fixed grid techniques for phase change problems: a review. Int. J. Numer. Methods Eng. 30, 875–898 (1990). https://doi.org/10.1002/NME.1620300419

Patankar, S. V.: Numerical heat transfer and fluid flow. CRC Press (2018)

Ji, X., Zhang, S., Wang, Y., Liang, S.Y.: Effect of thermal-fluidic transport on the temperature distribution and the melt pool in laser powder bed fusion of Ti6Al4V. Opt. Laser Technol. 156, 108587 (2022). https://doi.org/10.1016/J.OPTLASTEC.2022.108587

Mishra, A.K., Kumar, A.: Govind: Deciphering the individual effects of the fluid flow and material evaporation physics on the melting characteristics and the re-solidification parameters during laser melting of solid Ti6Al4V substrate. Therm. Sci. Eng. Prog. 35, 101478 (2022). https://doi.org/10.1016/j.tsep.2022.101478

Patankar, S. V.: Calculation of the Flow Field, (2018)

Miller, T.F., Schmidt, F.W.: Use of a pressure-weighted interpolation method for the solution of the incompressible navier-stokes equations on a nonstaggered grid system. Numer. Heat Transf. 14, 213–233 (1988). https://doi.org/10.1080/10407788808913641

Date, A.W.: Complete pressure correction algorithm for solution of incompressible navier-stokes equations on a nonstaggered grid. Numer. Heat Transf. Part B Fundam. 29, 441–458 (1996). https://doi.org/10.1080/10407799608914991

Dong, L., Makradi, A., Ahzi, S., Remond, Y.: Three-dimensional transient finite element analysis of the selective laser sintering process. J. Mater. Process. Technol. 209, 700–706 (2009). https://doi.org/10.1016/j.jmatprotec.2008.02.040

Yin, J., Zhu, H., Ke, L., Lei, W., Dai, C., Zuo, D.: Simulation of temperature distribution in single metallic powder layer for laser micro-sintering. Comput. Mater. Sci. 53, 333–339 (2012). https://doi.org/10.1016/j.commatsci.2011.09.012

Hu, H., Argyropoulos, S.A.: Mathematical modelling of solidification and melting: A review, (1996)

Mills, K.C.: Recommended Values of Thermophysical Properties for Selected Commercial Alloys. Woodhead (2002)

Mills, K.C.: Thermophysical Properties of Selected Commercial Alloys. (2011)

Mukherjee, T., Wei, H.L.L., De, A., DebRoy, T.: Heat and fluid flow in additive manufacturing–Part II: Powder bed fusion of stainless steel, and titanium, nickel and aluminum base alloys. Comput. Mater. Sci. 150, 369–380 (2018). https://doi.org/10.1016/j.commatsci.2018.04.027

Dilip, J.J.S., Zhang, S., Teng, C., Zeng, K., Robinson, C., Pal, D., Stucker, B.: Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting. Prog. Addit. Manuf. 2, 157–167 (2017). https://doi.org/10.1007/s40964-017-0030-2

Romano, J., Ladani, L., Sadowski, M.: Laser additive melting and solidification of inconel 718: finite element simulation and experiment. JOM 68, 967–977 (2016). https://doi.org/10.1007/s11837-015-1765-1

Yan, W., Ge, W., Qian, Y., Lin, S., Zhou, B., Liu, W.K., Lin, F., Wagner, G.J.: Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater. 134, 324–333 (2017). https://doi.org/10.1016/j.actamat.2017.05.061

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bombe, D., Kumar, R., Nandi, S.K. et al. Semi-analytical formulation for single-track laser powder-bed fusion process to estimate melt-pool characteristics considering fluid-flow and marangoni effect. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01593-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01593-1