Abstract

Aluminum oxide inclusions in SWRS82B steel seriously affect the drawing performance of steel strands. The effects of different addition amounts of yttrium (within the range of 0%–0.026%) on the composition, morphology, size and spacing of aluminum oxide inclusions were studied by scanning electron microscopy and energy spectrum analysis. Based on classical thermodynamics and FactSage software, the predominance diagram of inclusions in Fe–O–S–Y system and the effect of the addition of rare earth yttrium on the stability of alumina inclusions were calculated. The results showed that molten steel was modified by adding the rare earth element yttrium. It can be inferred that the approximate route of target inclusion modification was: Al2O3 → Y2S3 + YAlO3 + Al2O3 → Y2S3 + YAlO3 + Y2O2S + YAlO3 + Al2O3 → Y2S3 + Y2O2S. The experimental samples with 0.026% added yttrium had the best inclusion characteristics, in which the inclusion surface density distribution was uniform, and the interfacial distance between inclusions was mainly in the range of 100–500 μm. After modification, the average inclusion size in molten steel was reduced by 6.9–8.6 μm. The mechanism of yttrium modification was discussed based on actual calculation results and experimental results.

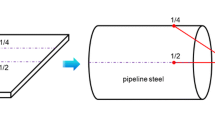

modified by adding different yttrium contents. a Sample S1; b sample S2; c sample S3; d sample S4

Similar content being viewed by others

References

N. Li, L. Wang, Z.L. Xue, C.Z. Li, A. Huang, F.F. Wang, Results Phys. 16 (2020) 102929.

C.F. Yu, Z.L. Xue, W.T. Jin, J. Iron Steel Res. Int. 23 (2016) 338–343.

C.P. Xin, F. Yue, C.X. Jiang, Q.F. Wu, High Temp. Mater. Proc. 35 (2016) 47–54.

D.W. Guo, Z.B. Hou, J.H. Cao, Z.A. Guo, Y. Chang, G.H. Wen, J. Iron Steel Res. Int. 27 (2020) 1163–1170.

L.P. Wu, J.S. Zhang, J.G. Zhi, Q. Liu, C. Su, S.B. Wang, L.L. Zou, Rare Met. Mater. Eng. 49 (2020) 2800–2806.

C.Y. Yang, Y.K. Luan, D.Z. Li, Y.Y. Li, J. Mater. Sci. Technol. 35 (2019) 1298–1308.

H.P. Wang, L. Xiong, L. Zhang, Y. Wang, Y.Y. Shu, Y.H. Zhou, Metall. Mater. Trans. B 48 (2017) 2849–2859.

Z. Adabavazeh, W.S. Hwang, Y.H. Su, Sci. Rep. 7 (2017) 46503.

X.D. Zou, D.P. Zhao, J.C. Sun, C. Wang, H. Matsuura, Metall. Mater. Trans. B 49 (2018) 481–490.

Y. Ren, Y.F. Wang, S.S. Li, L.F. Zhang, X.J. Zuo, S.N. Lekakh, K. Peaslee, Metall. Mater. Trans. B 45 (2014) 1291–1303.

H.T. Ling, L.F. Zhang, JOM 65 (2013) 1155–1163.

X.L. Zhang, S.F. Li, J.S. Yang, J.Q. Wu, Int. J. Miner. Metall. Mater. 27 (2020) 754–763.

Z.G. Wang, C.M. Song, Y.H. Zhang, H. Wang, L. Qi, B. Yang, Mater. Charact. 151 (2019) 112–118.

L. Li, D.Y. Li, J. Phys. Condes. Matter 31 (2019) 1361–1366.

G.X. Qiu, D.P. Zhan, C.S. Li, Y.K. Yang, Z.H. Jiang, H.S. Zhang, Nucl. Eng. Technol. 52 (2019) 811–818.

D.F. Liu, J. Qin, Y.H. Zhang, Z.G. Wang, J.C. Nie, Mater. Sci. Eng. A 797 (2020) 140238.

X.L. Kang, S.Y. Dong, H.B. Wang, S.X. Yan, X.T. Liu, B.S. Xu, Mater. Des. 188 (2020) 108434.

G.J. Cai, Y. Li, Y.R. Huang, R.D.K. Misra, ISIJ Int. 60 (2020) 2541–2548.

S. Gerasin, D. Kalisz, J. Iwanciw, J. Min. Metall. Sect. B Metall. 56 (2019) 11–25.

F. Pan, H.L. Chen, Y.H. Su, Y.H. Su, W.S. Hwang, Sci. Rep. 7 (2017) 2564–2571.

C. Pascal, M. Braccini, V. Parry, E. Fedorova, M. Mantel, D. Oquab, D. Monceau, Mater. Charact. 127 (2017) 161–170.

H.G. Fu, Q. Xiao, J.C. Kuang, Z.Q. Jiang, J.D. Xing, Mater. Sci. Eng. A 466 (2007) 160–165.

J. Yang, D.N. Zou, X.M. Li, Z.Z. Du, J. Iron Steel Res. Int. 14 (2007) 47–52.

H.J. Duan, Y. Zhang, Y. Ren, L.F. Zhang, J. Iron Steel Res. Int. 26 (2019) 962–972.

X.H. Huang, Principles of iron and steel metallurgy, 3rd ed., Metallurgical Industry Press, Beijing, China, 1981.

W.N. Shi, S.F. Yang, J.S. Li, Sci. Rep. 8 (2018) 4830–4839.

C.H. Wu, Study on behavior of inclusions in yttrium-based rare earth microalloyed E36 cast slab, University of Science and Technology Jiangxi, Ganzhou, China, 2016.

Y. Ren, L.F. Zhang, Y. Zhang, J. Iron Steel Res. Int. 25 (2018) 146–156.

Acknowledgements

No potential conflict of interest was reported by the author(s). This work was financially supported by the National Natural Science Foundation of China (Nos. 51864013 and 52074095). Also, this project supported by National Natural Science Foundation of Guizhou Province with grant No. [2019] 1086.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Li, Cr., Wang, Lz. et al. Effect of yttrium treatment on alumina inclusions in high carbon steel. J. Iron Steel Res. Int. 29, 655–664 (2022). https://doi.org/10.1007/s42243-021-00633-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00633-y