Abstract

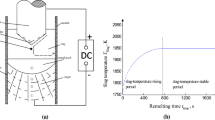

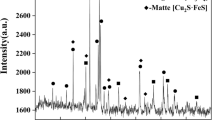

Slag is the heart of electroslag remelting (ESR) process. A new mathematical model to design the optimized slag for ESR was developed based on slag–metal equilibrium theory, ion and molecule coexistence theory and modified Butler’s equation. It was assumed that an overall thermodynamic equilibrium did exist at electrode tip–slag interface. With this model, the equilibrium slag and its surface tension could be obtained quantitatively when the initial compositions of consumable electrode were given. An industrial experiment with four types of slags was carried out in a special steel plant in China. The variation of Al, Si and Mn corresponded well with the deviation of corresponding oxide from equilibrium, reflecting the reasonability of the model. Besides that, the effects of Al in electrode as well as CaO, CaF2 and MgO in slag on the equilibrium slag, dissolved oxygen and surface tension were discussed in detail.

Similar content being viewed by others

References

A. Rückert, H. Pfeifer, Magnetohydrodynamics 45 (2009) 527–533.

V. Weber, A. Jardy, B. Dussoubs, D. Ablitzer, S. Rybéron, V. Schmitt, S. Hans, H. Poisson, Metall. Mater. Trans. B 40 (2009) 271–280.

S.K. Maity, N.B. Ballal, G. Goldhahn, R. Kawalla, ISIJ Int. 49 (2009) 902–910.

B. Hernandez-Morales, A. Mitchell, Ironmak. Steelmak. 26 (1999) 423–438.

G. Hoyle, Electroslag processes: principles and practice, Applied Science Publishers, London, UK, 1983.

T.R. Bandyopadhyay, P.K. Rao, N. Prabhu, Metall. Min. Ind. 4 (2012) 6–16.

S.F. Medina, A. Cores, ISIJ Int. 33 (1993) 1244–1251.

F. Reyes-Carmona, A. Mitchell, ISIJ Int. 32 (1992) 529–537.

A. Mitchell, F. Reyes-Carmona, E. Samuelsson, Trans. ISIJ 24 (1984) 547–556.

Z. Jiang, D. Hou, Y. Dong, Y. Cao, H. Cao, W. Gong, Metall. Mater. Trans. B 47 (2016) 1465–1474.

D. Hou, Z. Jiang, Y. Dong, Y. Cao, H. Cao, W. Gong, Ironmak. Steelmak. 43 (2016) 517–525.

M.E. Fraser, The loss of reactive elements during electroslag processing of iron-base alloys, The University of British Columbia, Vancouver, UK, 1974.

J. Zhang, Computational thermodynamics of metallurgical melts and solutions, Metallurgical Industry Press, Beijing, China, 2007.

Z. Li , Electroslag metallurgy theory and practice, Metallurgical Industry Press, Beijing, China, 2011.

B.M. Patchett, D.R. Milner, Welding J. 51 (1972) 491-s–505-s.

R.J. Hawkins, D.J. Swinden, D.N. Pocklington, Electroslag refining, The Iron and Steel Institute, London, UK, 1973.

J.A.V. Butler, Proc. R Soc. Lond. A 135 (1932) 348–375.

The Japan Society for the Promotion of Science, Steelmaking data sourcebook, in: The 19th Committee on Steelmaking, Gordon and Breach Science Publishers, New York, USA, 1988.

H. Suito, R. Inoue, ISIJ Int. 36 (1996) 528–536.

J. Wei, A. Mitchell, Acta Metall. Sin. 20 (1984) B271–B273.

C.R. Taylor, J. Chipman, Trans. AIME 154 (1943) 228–246.

J. Zhang, W.X. Yuan, J. Univ. Sci. Technol. Beijing 17 (1995) 418–423.

J.X. Li, J. Zhang, J. Univ. Sci. Technol. Beijing 22 (2000) 316–319.

X.M. Yang, J.P. Duan, C.B. Shi, M. Zhang, Y.L. Zhang, J.C. Wang, Metall. Mater. Trans. B 42 (2011) 738–770.

X.M. Yang, CB. Shi, M. Zhang, G.M. Chai, F. Wang, Metall. Mater. Trans. B 42 (2011) 1150–1180.

S.C. Duan, X.L. Guo, H.J. Guo, J. Guo, Ironmak. Steelmak. 44 (2017) 168–184.

S.C. Duan, C. Li, X.L. Guo, H.J. Guo, J. Guo, W.S. Yang, Ironmak. Steelmak. 45 (2018) 655–664.

V.D. Eisenhüttenleute, M. Allibert, Slag atlas, Woodhead Publishing Ltd., Düsseldorf, Germany, 1995.

M. Hanao, T. Tanaka, M. Kawamoto, K. Takatani, ISIJ Int. 47 (2007) 935–939.

T. Tanaka, T. Kitamura, I.A. Back, ISIJ Int. 46 (2006) 400–406.

J.Y. Choi, H.G. Lee, ISIJ Int. 42 (2002) 221–228.

S. Li, G. Cheng, Z. Miao, L. Chen, C. Li, X. Jiang, ISIJ Int. 57 (2017) 2148–2156.

M.E. Fraser, A. Mitchell, Ironmak. Steelmak. 3 (1976) 279–287.

S. Li, G. Cheng, L. Yang, L. Chen, Q. Yan, C. Li, AIST, Nashville, USA, 2017, pp. 1449–1457.

C.B. Shi, J. Li, J.W. Cho, F. Jiang, I.H. Jung, Metall. Mater. Trans. B 46 (2015) 2110–2120.

J. Strandh, K. Nakajima, R. Eriksson, P. Jönsson, ISIJ Int. 45 (2005) 1597–1606.

J. Strandh, K. Nakajima, R. Eriksson, P. Jönsson, ISIJ Int. 45 (2005) 1838–1847.

J.Y. Choi, H.G. Lee, ISIJ Int. 43 (2003) 1348–1355.

H. Abdeyazdan, B.J. Monaghan, R.J. Longbottom, M.A. Rhamdhani, N. Dogan, M.W. Chapman, Metall. Mater. Trans. B 48 (2017) 1970–1980.

M. Sasabe, Y. Kinoshita, Tetsu-to-Hagané 65 (1979) 1727–1736.

Acknowledgements

The authors wish to express their gratitude to Xining Special Steel Plant, China, as well as to the National Natural Science Foundation of China (Grant Nos. 51874034 and 51674024) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Sj., Cheng, Gg., Huang, Y. et al. Mathematical model for design of optimized multi-component slag for electroslag remelting. J. Iron Steel Res. Int. 27, 380–391 (2020). https://doi.org/10.1007/s42243-020-00373-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00373-5