Abstract

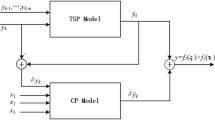

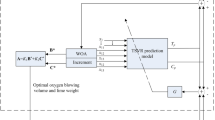

In order to improve the end-point hit rate of basic oxygen furnace steelmaking, a novel dynamic control model was proposed based on an improved twin support vector regression algorithm. The controlled objects were the end-point carbon content and temperature. The proposed control model was established by using the low carbon steel samples collected from a steel plant, which consists of two prediction models, a preprocess model, two regulation units, a controller and a basic oxygen furnace. The test results of 100 heats show that the prediction models can achieve a double hit rate of 90% within the error bound of 0.005 wt.% C and 15 °C. The preprocess model was used to predict an initial end-blow oxygen volume. However, the double hit rate of the carbon content and temperature only achieves 65%. Then, the oxygen volume and coolant additions were adjusted by the regulation units to improve the hit rate. Finally, the double hit rate after the regulation is reached up to 90%. The results indicate that the proposed dynamic control model is efficient to guide the real production for low carbon steel, and the modeling method is also suitable for the applications of other steel grades.

Similar content being viewed by others

References

M. Brämming, B. Björkman, C. Samuelsson, Steel Res. Int. 87 (2016) 301–310.

Z. Wang, F.M. Xie, B. Wang, Q. Liu, X. Lu, L. Hu, F. Cai, Steel Res. Int. 85 (2014) 599–606.

M. Han, C. Liu, Appl. Soft Comput. 19 (2014) 430–437.

X.Z. Wang, M. Han, J. Wang, Eng. Appl. Artif. Intell. 23 (2010) 1012–1018.

M. Han, Z.J. Cao, Neurocomputing 149 (2015) 1245–1252.

L.X. Kong, P.D. Hodgson, D.C. Collinson, ISIJ Int. 38 (1998) 1121–1129.

A.M.F. Fileti, T.A. Pacianotto, A.P. Cunha, Eng. Appl. Artif. Intell. 19 (2006) 9–17.

J. Jiménez, J. Mochón, J.S. de Ayala, F. Obeso, ISIJ Int. 44 (2004) 573–580.

C. Cortes, V. Vapnik, Mach. Learn. 20 (1995) 273–297.

Jayadeva, R. Khemchandani, S. Chandra, IEEE Trans. Pattern Anal. Machine Intell. 29 (2007) 905–910.

X. Peng, Neural Netw. 23 (2010) 365–372.

D. Gupta, Appl. Intell. 47 (2017) 962–991.

R. Rastogi, P. Anand, S. Chandra, Appl. Intell. 46 (2017) 670–683.

M. Tanveer, K. Shubham, M. Aldhaifallah, K.S. Nisar, Appl. Intell. 44 (2016) 831–848.

Y. Xu, L. Wang, Appl. Intell. 41 (2014) 299–309.

Y. Xu, X. Li, X. Pan, Z. Yang, Neural Comput. Appl. 30 (2018) 3799–3814.

N. Parastalooi, A. Amiri, P. Aliheydari, Neurocomputing 211 (2016) 84–97.

Y.F. Ye, L. Bai, X.Y. Hua, Y.H. Shao, Z. Wang, N.Y. Deng, Neurocomputing 197 (2016) 53–68.

M.A. Kumar, M. Gopal, Pattern Recognit. Lett. 29 (2008) 1842–1848.

Y.H. Shao, C.H. Zhang, Z.M. Yang, L. Jing, N.Y. Deng, Neural Comput. Appl. 23 (2013) 175–185.

H. Huang, S. Ding, Z. Shi, J. Comput. Res. Dev. 52 (2015) 561–568.

C. Gao, M.G. Shen, Metalurgija 58 (2019) 29–32.

J. Shen, G. Strang, Appl. Comput. Harm. Anal. 5 (1998) 312–331.

Acknowledgements

This work was supported by Liaoning Province PhD Start-up Fund (No. 201601291) and Liaoning Province Ministry of Education Scientific Study Project (No. 2017LNQN11).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, C., Shen, Mg., Liu, Xp. et al. End-point dynamic control of basic oxygen furnace steelmaking based on improved unconstrained twin support vector regression. J. Iron Steel Res. Int. 27, 42–54 (2020). https://doi.org/10.1007/s42243-019-00348-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00348-1