Abstract

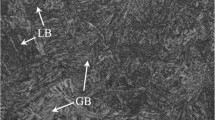

The effect of Zr addition (0.005, 0.013, and 0.054 wt.%) on the microstructure and toughness of simulated coarse-grained heat-affected zone in high-strength low-alloy steels was revealed using a Gleeble 2000 thermal simulator. It was observed that elongated MnS inclusions were formed in the lowest Zr-containing steel, while only pure equiaxed ZrO2 existed in the 0.054Zr steel (Zr content of 0.054 wt.%). Complex oxide–sulfide inclusions (ZrO2 + MnS) with size of (1.40 ± 0.25) μm were formed in 0.013Zr steel (Zr content of 0.013 wt.%). The complex inclusions refined the prior austenite grain, and the nucleation of acicular ferrite was promoted compared to those of 0.005Zr steel (Zr content of 0.005 wt.%) and 0.054Zr steel. Consequently, the 0.013Zr steel possessed superior low-temperature impact toughness in relation to 0.005Zr and 0.054Zr steels. Thus, moderate Zr addition can be considered as an effective method to refine the structure and improve the mechanical properties of the coarse-grained heat-affected zone.

Similar content being viewed by others

References

B. Hwang, Y.G. Kim, S. Lee, Y.M. Kim, N.J. Kim, J.Y. Yoo, Metall. Mater. Trans. A 36(2005) 2107–2114.

X.L. Wan, K.M. Wu, H.H. Wang, W.Y. Lu, L. Cheng, China Welding 23 (2014) No. 4, 56–62.

K.M. Wu, Z.G. Li, A.M. Guo, X.L. He, L.Q. Zhang, A.H. Fang, L. Cheng, ISIJ Int. 46 (2006) 161–165.

X.L. Wan, K.M. Wu, L. Cheng, R. Wei, ISIJ Int. 55 (2015) 679–685.

Z.M. Cui, L.G. Zhu, Y.L. Li, Q.J. Zhang, C.L. Yan, W.L. Mo, J. Iron Steel Res. Int. 23 (2016) 586–592.

A.S. Kumar, B.R. Kumar, G.L. Datta, V.R. Rangganath, Mater. Sci. Eng. A 527 (2010) 954–960.

Y. Liu, G.Q. Li, X.L. Wan, H.H. Wang, K.M. Wu, R.D.K. Misra, Mater. Sci. Technol. 33 (2017) 1750–1764.

M.H. Shi, P.Y. Zhang, F.X. Zhu, ISIJ Int. 54 (2014) 188–192.

Y. Ci, Z.Z. Zhang. J. Iron Steel Res. Int. 24 (2017) 966–972.

Y. Li, X.L. Wan, L. Cheng, K.M. Wu, Scripta Mater. 75 (2014) 78–81.

X.L. Wan, K.M. Wu, G. Huang, K.C. Nune, Y. Li, L. Cheng, Sci. Technol. Weld. Join. 21 (2016) 295–302.

M. Fattahi, N. Nabhani, M. Hosseini, N. Arabian, N. Rahimi, Micron 45 (2013) 107–114.

S. Shanmugan, R.D.K. Misra, J. Hartmann, S.G. Jansto, Mater. Sci. Eng. A 441 (2006) 215–229.

P. Cizek, B.P. Wynne, C.H.J. Davies, P.D. Hodgson, Metall. Mater. Trans. A 46 (2015) 407–425.

W.J. Hui, N. Xiao, X.L. Zhao, Y.J. Zhang, Y.F. Wu, J. Iron Steel Res. Int. 24 (2017) 641–648.

C. Wang, R.D.K. Misra, M.H. Shi, P.Y. Zhang, Z.D. Wang, F.X. Zhu, G.D. Wang, Mater. Sci. Eng. A 594 (2014) 218–228.

N.N. Rykalin, Calculation of heat transactions during welding, VEB Verlag Technik, Berlin, Germany, 1957.

A.F. Gourgues, H.M. Flower, T.C. Lindley, Mater. Sci. Technol. 16 (2000) 26–40.

J.L. Lee, Y.T. Pan, Mater. Sci. Eng. A 136 (1991) 109–119.

H. Goto, K.I. Miyazawa, T. Kazuaki, ISIJ Int. 35 (1995) 286–291.

Y. Li, X.L. Wan, W.Y. Lu, A.A. Shirzadi, O. Isayev, O. Hress, K.M. Wu, Mater. Sci. Eng. A 659 (2016) 179–187.

A.M. Guo, S.R. Li, J. Guo, P.H. Li, Q.F. Ding, K.M. Wu, X.L. He, Mater. Charact. 59 (2008) 134–139.

X.H. Huang, Principle of steel metallurgy, 4rd ed., Metallurgical Industry Press, Beijing, China, 2013.

O.I. Malyi, Z. Chen, G.G. Shu, P. Wu, J. Mater. Chem. 21 (2011) 12363–12368.

B. Beidokhti, A.H. Koukabi, A. Dolati, J. Mater. Process. Technol. 209 (2009) 4027–4036.

H. Mabuchi, R. Uemori, M. Fujioka, ISIJ Int. 36 (1996) 1406–1412.

T. Sawai, M. Wakoh, Y. Usehima, S. Mizoguchi, ISIJ Int. 32 (1992) 169–173.

Y. Li, X.L. Wan, L. Cheng, K.M. Wu, Mater. Sci. Technol. 32 (2016) 88–93.

D.S. Sarma, A.V. Karasev, P.G. Jönsson, ISIJ Int. 49 (2009) 1063–1074.

Ø. Grong, L. Kolbeinsen, C. van der Eijk, G. Tranell, ISIJ Int. 46 (2006) 824–831.

F.J. Barbaro, P. Kraukalis, K.E. Easterling, Mater. Sci. Technol. 5 (1989) 1057–1068.

K.Y. Park, S.W. Hwang, J.H. Ji, C.H. Lee, Met. Mater. Int. 17 (2010) 349–356.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51671149), Wuhan Science and Technology Program (Grant No. 2019010701011382), Major Technology Innovation of Hubei Province (2016AAA022) and 111 Project. R.D.K. Misra gratefully acknowledges continued collaboration with WUST as Guest Professor.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lei, Jw., Wu, Km., Li, Y. et al. Effects of Zr addition on microstructure and toughness of simulated CGHAZ in high-strength low-alloy steels. J. Iron Steel Res. Int. 26, 1117–1125 (2019). https://doi.org/10.1007/s42243-019-00319-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00319-6