Abstract

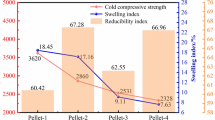

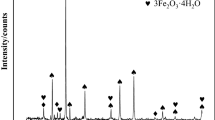

Magnesium fluxed pellets are the focus of blast furnace burden research for reducing environmental load. The pelletizing, roasting and metallurgical properties of a Chinese fine magnetite ore with the addition of magnesium flux were experimentally tested, and the effects of basicity on the consolidation behavior, compressive strength, and reducibility of magnesium fluxed pellets were systematically clarified. Then, the mechanisms were analyzed by means of thermodynamics calculation and scanning electron microscopy–energy-dispersive spectrometry analysis methods. The results show that the consolidation behavior of magnesium fluxed pellets during roasting process was obviously promoted with increasing the basicity of the magnesium fluxed pellets. The compressive strength increased firstly and then decreased, reaching the maximum value of 2352 N/pellet with the basicity of 1.0. The reduction degree increased gradually with enhancing the basicity owing to the fact that the decomposition of the added CaCO3 could increase the porosity of pellets, thereby increasing the CO diffusion in pellet during reduction. Simultaneously, the reduction swelling index was improved with increasing the basicity because the generated calcium ferrite could effectively suppress the growth of iron whiskers.

Similar content being viewed by others

References

J. Wang, W.Q. Zhong, Chin. J. Chem. Eng. 24 (2016) 1104–1111.

H. Zhou, M.X. Zhou, Z.H. Liu, M. Cheng, J.Z. Chen, Fuel 179 (2016) 322–331.

H.F. Wang, Y.D. Pei, C.X. Zhang, Z.X. Zhao, Iron and Steel 51 (2016) No. 1, 1–7.

X.H. Fan, M. Gan, T. Jiang, L.S. Yuan, X.L. Chen, J. Cent. South Univ. Technol. 17 (2010) 732–737.

J. Pal, C. Arunkumar, Y. Rajshekhar, G. Das, M.C. Goswami, T. Venugopalan, ISIJ Int. 54 (2014) 2169–2178.

S. Dwarapudi, T.K. Ghosh, V. Tathavadkar, M.B. Denys, D. Bhattacharjee, R. Venugopal, Int. J. Miner. Process. 112–113 (2012) 55–62.

S. Dwarapudi, T.K. Ghosh, A. Shankar, V. Tathavadkar, D. Bhattacharjee, R. Venugopal, Int. J. Miner. Process. 99 (2011) 43–53.

A.A. El-Geassy, M.I. Nasr, M.H. Khedr, K.S. Abdel-Halim, ISIJ Int. 44 (2004) 462–469.

B. Xu, T. Hou, X.L. Chen, Q. Li, T. Jiang, P. Li, J. Cent. South Univ. 20 (2013) 2806–2810.

N.A. El-Hussiny, I.A. Nafeaa, M.G. Khalifa, S.S. Abdel-Rahim, M.E.H. Shalabi, Int. J. Sci. Eng. Res. 7 (2016) 66–74.

Y.P. Zhang, J.Y. Fu, T. Jiang, Y.B. Yang, Sintering and Pelletizing 27 (2002) No. 4, 11–14.

D.Q. Zhu, T.J. Chun, J. Pan, J.L. Zhang, Int. J. Miner. Process. 125 (2013) 51–60.

S.H. Li, T.J. Chen, Y.M. Zhang, J. Zhao, Sintering and Pelletizing 36 (2011) No. 1, 33–37.

S. Gunther, ISIJ Int. 38 (1998) 457–462.

J.V. Khaki, Y. Kashiwa, K. Ishii, Ironmak. Steelmak. 21 (1994) 56–63.

F.M. Shen, Q.J. Gao, X. Jiang, G. Wei, H.Y. Zheng, Int. J. Miner. Metall. Mater. 21 (2014) 431–437.

Q.J. Gao, F.M. Shen, G. Wei, X. Jiang, H.Y. Zheng, J. Iron Steel Res. Int. 20 (2013) No. 7, 25–28.

G.F. Zhou, F. Yang, Research on Iron and Steel 37 (2009) No. 2, 10–12.

Q.J. Gao, G. Wei, Y.B. He, F.M. Shen, J. Northeast. Univ. Nat. Sci. 34 (2013) 103–106.

W. Zhao, H.T. Wang, Z.G. Liu, M.S. Chu, Z.W. Ying, J. Tang, JOM 69 (2017) 1737–1744.

J. Tang, M.S. Chu, F. Li, Y.T. Tang, Z.G. Liu, X.X. Xue, Int. J. Miner. Metall. Mater. 22 (2015) 562–572.

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51974131), Science and Technology Project of Hebei Education Department (No. BJ2017021), NCST Natural Science Funds for Distinguished Young Scholars (No. JQ201711), and Hebei Province Natural Science Fund for Excellent Young Scholars (No. E2018209248).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., An, Hf., Liu, Wx. et al. Effect of basicity on metallurgical properties of magnesium fluxed pellets. J. Iron Steel Res. Int. 27, 239–247 (2020). https://doi.org/10.1007/s42243-019-00307-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00307-w