Abstract

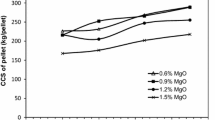

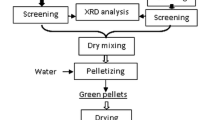

Six additives, i.e., limestone, lime, magnesite, magnesia, dolomite and light-burned-dolomite, were added for investigating their influences on the pellet quality. For green balls, adding lime and light-burned-dolomite makes the wet drop strength decrease firstly, and then increase with further increase of additive dosage. Ca(OH)2 affects the bentonite properties at the beginning, but the binding property of Ca(OH)2 will be main when the dosage is higher. The other four additives decrease the drop strength for their disadvantageous physical properties. For preheated pellets, no mater what kind of additive is added, the compressive strength will be decreased because of unmineralized additives. For roasted pellets, calcium additives can form binding phase of calcium-ferrite, and suitable liquid phase will improve recrystallization of hematite, but excessive liquid will destroy the structure of pellets, so the compressive strength of pellet increases firstly and then drops. When adding magnesium additives, the strength will be decreased because of the oxidation of magnetite retarded by MgO.

Similar content being viewed by others

References

ZHANG Yu-zhu, CENG Ming-shan, XIANG Li, TAO Wen. The influence of MgO and basicity on the viscosity of BF slag [J]. Journal of Materials and Metallurgy, 2005, 4(4): 253–256. (in Chinese)

EL-GEASSY A A, NASR M I, KHEDR M H, ABDEL-HALIM K S. Reduction behaviour of iron ore fluxed pellets under load at 1 023–1 273 K [J]. ISIJ International, 2004, 44(3): 462–469.

GUAN Xue-fang, HOU Hui-jun, OU Tao. The way of heightening MgO content of sintering and the effect of BF [J]. Sintering and Pelletizing, 2001, 26(2): 1–5. (in Chinese)

FU Ju-ying, JIANG Tao, ZHU De-qing. Sintering and pelletizing [M]. Changsha: Central South University Press, 1995: 296–298.

NUTTER S M, LI K. Effect of composition and structure on fluxed pellet reduction kinetics [J]. Transactions of the Iron and Steel Society of AIME, 1991, 12: 71–83.

JIANG Xin, WU Gang-sheng. Effect of MgO on sintering process and metallurgical properties of sinter [J]. Iron and Steel, 2006, 41(3): 8–12. (in Chinese)

SUN Jin-tuo. Investigation on rational basicity of sintering [J]. Iron and Steel, 2001, 36(8): 1–4. (in Chinese)

YANG Yong-bin, HUANG Gui-xiang, JIANG Tao, HUANG Zhu-chong. Application of organic binder as substitutes for bentonite in pellet preparation [J]. Journal of Central South University: Science and Technology, 2007, 38(5): 851–857. (in Chinese)

FENG Xiang-peng, ZHANG Yu-zhu, LI Zhen-guo. The effect of basicity on sintering strength in the condition of low-Si [J]. Sintering and Pelletizing, 2004, 29(2): 9–12. (in Chinese)

ADRIAN I P, BORJE B. Experiences with dolomite fluxed pellets by Lkab [C]// Proceedings of Ironmaking. New York: AIME, 1977, 366–383.

CHIZHIKOVA V M, VAINSHTEIN R M. Composition of iron-ore pellets with different types of additives [J]. Metallurgist, 2003, 47(9): 349–352.

BLEIFUSS R L, GOETZMAN H E, LOPEZ R D, BECKMAN C A. Development of Minnesota taconite fluxed pellets as an improved blast-furnace material [C]// Proceedings of AIME 47th Annual Mining Symposium. New York: AIME, 1986: 1–31.

OSAMU T, TAKESHI S, MAMORU O, ISAO F. Effect of MgO-component on various metallurgical properties of self-fluxed pellets [J]. Journal of the Iron and Steel Institute of Japan, 1980, 66(13): 1840–1849.

FRIEL J J, ERICKSON E S Jr. Chemistry microstructure and reduction characteristics of dolomite-fluxed magnetite pellets [J]. Metallurgical Transactions B: Process Metallurgy, 1980, 11(2): 233–243.

TAKESHI S, SHOJI S, OSAMU T, MAMORU O, ISAO F. High temperature reduction and softening properties of pellets with magnesite [J]. Transactions of the Iron and Steel Institute of Japan, 1983, 23(2): 153–160.

ZHANG Yong-ming. Characteristic and production practice of fluxed pellets contents MgO [J]. Sintering and Pelletizing, 1998, 23(2): 1–4. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2008BAB32B06) supported by the Key Projects in the National Science and Technology Pillar Program during the 11th Five-year Plan Period; Project(2009ybfz20) supported by the Program for Excellent Doctor’s Degree Paper in Central South University, China; Project(1343/74333001114) supported by the Postgraduate’s Paper Innovation Fund of Hunan Province, China

Rights and permissions

About this article

Cite this article

Fan, Xh., Gan, M., Jiang, T. et al. Influence of flux additives on iron ore oxidized pellets. J. Cent. South Univ. Technol. 17, 732–737 (2010). https://doi.org/10.1007/s11771-010-0548-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-010-0548-7