Abstract

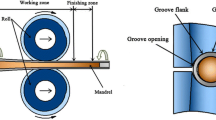

As the process parameters of pilger cold-rolled seamless steel tubes are basically based on experience leading to the generation of defects, 304 stainless steel was chosen and the important process parameters including the feed, rotation angle and Q value (the ratio of the length of the deformation section to that of the finishing section) were selected to analyze the effect of different process parameters on the tube forming process and rules. The results show that during the cold rolling process, the rolling force, the equivalent stress of the tube, the residual stress and the springback of the external diameter increased with the increase in the feed rate and the rotation angle and the decrease in Q value. Increasing the feed quantity and decreasing Q value will lead to the decrement in the roundness of the pipe. After comprehensive evaluation of the advantages and disadvantages, a set of optimal parameters are selected to carry out the experiment. The residual stress and the outer diameter of the finished products were measured. The results of the measurement and the numerical simulation results are within reasonable range, and the accuracy of the numerical simulations and the influence of the process parameters on the pilger cold rolling are further verified.

Similar content being viewed by others

References

D. Sornin, E.A. Pachón-Rodríguez, E. Vanegas-Márquez, K. Mocellin, R. Logé, J. Mater. Eng. Perform. 25 (2016) 4059–4069.

K.S. Ragger, S. Primig, R. Daniel, R. Kaiser, J. Paal, C. Mitterer, B. Buchmayr, Mater. Charact. 128 (2017) 257–268.

Y. Azizoğlu, M. Gärdsback, B. Sjöberg, L. Lindgren, Procedia Eng. 207 (2017) 2370–2375.

H. Stinnertz, Tube Pipe Technol. 87 (1988) 27–31.

B. Lodej, K. Niang, P. Montmitonnet, J.L. Aubin, J. Mater. Process. Technol. 177 (2006) 188–191.

J. Osika, W. Libura, J. Mater. Process. Technol. 34 (1992) 325–332.

S. Ukai, S. Mizuta, T. Yoshitake, T. Okuda, M. Fujiwara, S. Hagi, T. Kobayashi, J. Nucl. Mater. 283 (2000) 702–706.

C. Zheng, H.W. Song, S.Y. Deng, S.H. Zhang, Procedia Eng. 207 (2017) 2346–2351.

H.Q. Zhang, X.F. Wang, B.L. Wei, H. Li, Int. J. Adv. Manuf. Technol. 92 (2017) 2169–2183.

Y. Barzegar, R.J. Nedoushan, A. Razazzade, M. Farzin, D. Banabic, Proc. Romanian Acad. Ser. A 17 (2016) 267–276.

P. Montmitonnet, D. Farrugia, J.L. Aubin, F. Delamare, Wear 152 (1992) 327–342.

H. Abe, T. Nomura, Y. Kubota, J. Mater. Process. Technol. 214 (2014) 1627–1637.

D. Pociecha, B. Boryczko, J. Osika, M. Mroczkowski, Arch. Civil Mech. Eng. 14 (2014) 376–382.

F.Y. Yan, Pass design of LG730 cold-rolling pilger mill and its finite element simulation in the rolling process, Yanshan University, Qinhuangdao, China, 2015.

X.F. Zhou, Forg. Stamp. Technol. 37 (2012) No. 3, 55–58.

H. Abe, M. Furugen, J. Mater. Process. Technol. 212 (2012) 1687–1693.

S.N. Randall, H. Prieur, Iron Steel Eng. 2 (1967) 109–117.

H. Abe, T. Iwamoto, Y. Yamamoto, S. Nishida, R. Komatsu, J. Mater. Process. Technol. 231 (2016) 277–287.

T. Fan, Research on three-roller cold rolling process of 302 stainless steel tube, Shenyang Ligong University, Shenyang, China, 2012.

J.L. Liu, W.D. Zeng, Z.L. Du, H. Tao, J.H. Xi, Y. Shu, J.Z. Yang, Titan. Ind. Prog. 32 (2015) 3 21–25.

L. Huang, Z. Xu, C. Dai, S. X. Hui, W.J. Ye, G. Wang, S.S. Xie, H.W. Li, Rare Metal Mater. Eng. 42 (2013) 524–529.

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China (Grant No. U1710113), the China Postdoctoral Science Foundation (Grant No. 2017M622903), the National Key Research and Development Program of Shanxi Province (Grant No. 201703D121008), the Project of Excellent Graduate Innovation in Shanxi (Grant No. 2017SY077) and the Graduate Innovation Funding Scheme for “Heavy Machinery” (Grant Nos. 20172001 and 20172004) for financial support and authorization to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chu, Zb., Xue, Zy., Zhang, D. et al. Parameters of cold pilgering of seamless steel tube. J. Iron Steel Res. Int. 26, 593–601 (2019). https://doi.org/10.1007/s42243-019-00269-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00269-z