Abstract

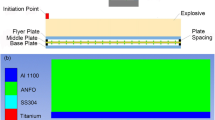

Two types of titanium/steel composite plates with the same thickness were manufactured by parallel explosive welding and double vertical explosive welding and rolling, respectively. The comparative analysis of microstructure showed that the interface of double vertical explosive welding plate (B plate) tended to be straight while the interface of parallel explosive welding plate (A plate) was wavy bonding. Defects near the interface of B plate were extruded, and the thickness of the diffusion layer of B plate was thicker under the effects of preheating temperature and press-working. Comparative tests of mechanical properties indicated that the tensile shear strength of B plate was lower while its micro-hardness was higher. Specimens of these two types of plates were neither separated nor cracked after bending up to 180° in the three-point bending test. From the microstructural observation of tensile fracture characteristics, A plate had strong toughness fracture while B plate had mainly ductile fracture with cleavage fracture as the supplement. Macroscopically, the tensile strength of the latter was 7.9% less than that of the former. However, both satisfied the Chinese standard of tensile strength.

Similar content being viewed by others

References

W.G. Zhai, Properties and Bonding Interface Microstructure of Titanium–Steel and Copper–Steel Composite Plates with Explosive Welding, Nanjing University of Aeronautics and Astronautics, Nanjing, 2013.

F. Findik, Mater. Des. 32 (2011) 1081–1093.

Y.J. Li, The Welding Technology of Advanced Materials, Chemical Industry Press, Beijing, 2012.

B.H. Shao, K. Zhang, Engineering Application and Principle of Explosive Welding, Press of Science and Technology of Dalian, Dalian, 1987.

N. Kahraman, B. Gülenç, F. Findik, J. Mater. Process. Technol. 169 (2005) 127–133.

C.G. Shi, Y. Wang, S.J. Li, J. You, J. Iron Steel Res. Int. 21 (2014) 625–629.

S.A.A.A. Mousavi, P.F. Sartangi, Mater. Des. 30 (2009) 459–468.

P. Manikandan, K. Hokamoto, M. Fujita, J. Mater. Process. Technol. 195 (2008) 232–240.

S. Saravanan, K. Raghukandan, K. Hokamoto, Arch. Civ. Mech. Eng. 16 (2016) 563–568.

Z.Y. Zhang, L. Peng, J.M. Wang, Procedia Eng. 16 (2011) 14–17.

C.G. Shi, Y. Wang, L.S. Zhao, J. Iron Steel Res. Int. 22 (2015) 949–953.

C.G. Shi, J. You, Explosive Mater. 37 (2008) No.3, 28–30.

C.G. Shi, The Lower Bound Theorem and Double Vertical Method of Explosive Welding, Metallurgical Industry Press, Beijing, 2015.

M.X. Xie, L.J. Zhang, G.F. Zhang, Mater. Des. 87 (2015) 181–197.

S.M. Walley, Metall. Mater. Trans. A 38 (2007) 2629–2654.

Y.M. Zheng, R.G. Huang, S.H. Chen, Trans. Nonferrous Metal Soc. China 8 (1998) No.S1, 239–243.

T. Momono, T. Enjo, K. Ikeuchi, ISIJ Int. 30 (1990) 978–984.

M. Acarer, B. Demir, Mater. Lett. 62 (2008) 4158–4160.

F. Findik, R. Yilmaz, T. Somyurek, Sci. Res. Essays. 6 (2011) 4141–4151.

Y. Sun, D. Zhang, L.J. Wu, Journal of East China University of Science & Technology 38 (2012) 652–656.

Y.M. Zheng, The Principle and Application of Explosive Welding and Metallic Composite, Central South University Press, Wuhan, 2007.

Acknowledgements

This project was sponsored by the National Natural Science Foundation of China (No. 51541112) and Special Fund Achievement Transformation Projects in Jiangsu of China (No. BA2012030).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, X., Shi, Cg., Ge, Yh. et al. Comparison of microstructure and mechanical properties of titanium/steel composite plates by two manufacturing processes. J. Iron Steel Res. Int. 25, 347–356 (2018). https://doi.org/10.1007/s42243-018-0038-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0038-y