Abstract

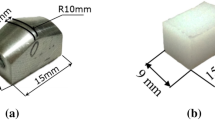

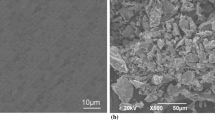

High-Density Polyethylene (HDPE) wear debris generated in the hip joint prothesis leads to its loosening. The aim of this study was to evaluate the potential of Squid Pen (SP) on the tribological and physicochemical properties of HDPE matrix. Biocomposites filled with 0, 5, 10, 15 and 20 wt. % SP were elaborated by hot compression molding. Wear tests were carried out using a reciprocating pin-on-disc tribometer. Rockwell hardness, Fourier-Transform infra-red (FTIR) analysis, Scanning Electron Microscopy (SEM) of the biocomposite were analysed. FTIR analysis results of the biocomposites showed that an increase in the crystallinity rate was obtained with the addition of SP filler. Only 10 wt. % of SP has a significant effect on the hardness of the composite. The correlation between the friction coefficient and the wear resistance of the composite was investigated. The 5 wt. % SP-HDPE biocomposite has the lowest friction coefficient value with a decrease in the specific wear rate, compared to the unfilled HDPE. The SEM results showed that SP wear debris played an important role as a third roller body at the interface reducing the friction coefficient of the composite. It was concluded that the HDPE biocomposite could be successfully reinforced with 5 wt. % of SP.

Similar content being viewed by others

Data Availability

The data that support the findings of this article are available in Journal of Bionic Engineering website (Springer) with the DOI of the article.

References

Buciumeanu, M., Araujo, A., Carvalho, O., Miranda, G., Souza, J. C. M., Silva, F. S., & Henriques, B. (2017). Study of the tribocorrosion behaviour of ti6al4v–ha biocomposites. Tribology International, 107, 77–84.

Friedrich, K. (2018). Polymer composites for tribological applications. Advanced Industrial and Engineering Polymer Research, 1, 3–39.

Al-allaq, A. A., Kashan, J. S., El-Wakad, M. T., & Soliman, A. M. (2021). Multiwall carbon nanotube reinforced ha/hdpe biocomposite for bone reconstruction. Periodicals of Engineering and Natural Sciences, 9, 930–939.

Arumugam, S., Kandasamy, J., Shah, A. U. M., Sultan, M. T. H., Safri, S. N. A., Majid, M. S. A., Basri, A. A., & Mustapha, F. (2020). Investigations on the mechanical properties of coconut and sisal fiber composites for bone fracture fixation applications. Polymers, 12, 2–19.

Hidaka, R., Matsuda, K., & Kawano, H. (2021). Rapid destruction of the hip joint after acetabular fracture in an elderly patient. Arthroplasty Today, 11, 122–126.

Kumar, R. M., Gupta, P., Sharma, S. K., Mittal, A., Shekhar, M., Kumar, V., Manoj, K. B. V., Roy, P., & Lahiri, D. (2017). Sustained drug release from surface modified uhmwpe for acetabular cup lining in total hip implant. Materials Science and Engineering C, 77, 649–661.

Vadivel, H. S., Bek, M., Šebenik, U., Perše, L. S., Kádár, R., Emami, N., & Kalin, M. (2021). Do the Particle Size, molecular weight, and processing of uhmwpe affect its thermomechanical and tribological performance? Journal of Materials Research and Technology, 12, 1728–1737.

Wang, H. T., Li, J., Ma, S. T., Feng, W. Y., Wang, Q., Zhou, H. Y., Zhao, J. M., & Yao, J. (2018). A Study on the prevention and treatment of murine calvarial inflammatory osteolysis induced by ultra-high-molecular-weight polyethylene particles with neomangiferin. Experimental and Therapeutic Medicine, 16, 3889–3896.

Hossin, M. A., Shaqsi, N. H. K., Touby, S. S. J., & Sibani, M. A. (2021). A Review of polymeric chitin extraction, characterization, and applications. Arabian Journal of Geosciences, 14, 1–8.

Plumlee, K., & Schwartz, C. J. (2009). Improved wear resistance of orthopaedic uhmwpe by reinforcement with zirconium particles. Wear, 276, 710–717.

Mindivan, F., & Çolak, A. (2021). Tribo-material based on a uhmwpe/rgoc biocomposite for using in artificial joints. Journal of Applied Polymer Science, 138, 1–13.

Sidia, B., & Bensalah, W. (2021). Tribological and mechanical behaviors of mollusk shell-ultrahigh molecular weight polyethylene bio-composite. Polymer Composites, 42, 3206–3215.

Sidia, B., & Bensalah, W. (2020). Tribological properties of high density polyethylene based composite: The effect of mollusc shell particles under dry condition. Journal of Composite Materials, 55, 55–60.

Fouad, H., Elleithy, R., & Alothman, O. Y. (2013). Thermo-mechanical, wear and fracture behavior of high-density polyethylene/hydroxyapatite nano composite for biomedical applications: Effect of accelerated ageing. Journal of Materials Science and Technology, 29, 573–581.

Dweiri, R. (2021). Processing and characterization of surface treated chicken eggshell and calcium carbonate particles filled high-density polyethylene composites. Materials Research, 24, 24–30.

Jeong, S. H., Kim, J. K., Lim, Y. W., Hwang, H. B., Kwon, H. Y., Bae, B. S., & Jin, J. (2018). Squid pen-inspired chitinous functional materials: Hierarchical chitin fibers by centrifugal jet-spinning and transparent chitin fiber-reinforced composite. APL Materials, 6, 6–12.

Cuong, H. N., Minh, N. C., Hoa, N. V., & Trung, T. S. (2016). Preparation and characterization of high purity β-chitin from squid pens (loligo chenisis). International Journal of Biological Macromolecules, 93, 442–447.

Satitsri, S., & Muanprasat, C. (2020). Chitin and chitosan derivatives as biomaterial resources for biological and biomedical applications. Molecules, 25, 25–35.

Kasprzak, D., & Galiński, M. (2021). DMSO as an auxiliary solvent in the fabrication of homogeneous chitin-based films obtaining from an ionic liquid process. European Polymer Journal, 158, 1–9.

Shavandi, A., Bekhit, A. E. D. A., Sun, Z., Ali, A., & Goululd, M. (2015). A novel squid pen chitosan/hydroxyapatite/β-tricalcium phosphate composite for bone tissue engineering. Materials Science and Engineering C, 55, 373–383.

Azadi, M., Teimouri, A., & Mehranzadeh, G. (2016). Preparation, characterization and biocompatible properties of β-chitin/silk fibroin/nanohydroxyapatite composite scaffolds prepared using a freeze-drying method. RSC Advances, 6, 7048–7060.

Braguin, L. M. N., Silva, C. A. J., Berbel, L. O., Viveiros, B. V. G., Rossi, J. L., Costa, I., & Saiki, M. (2021). A study on corrosion resistance of iso 5832–1 austenitic stainless steel used as orthopedic implant. International Journal of Advances in Medical Biotechnology, 3, 23–28.

ASTM. (2008). D785–03-Standard test method for rockwell hardness of plastics and electrical insulating. In Annual Book of ASTM Standards; ASTM International: United States, 1–6.

Borruto, A. (2010). A new material for hip prosthesis without considerable debris release. Medical Engineering and Physics, 32, 908–913.

Mohammed, T. M. (2019). Nanocomposites in total hip joint replacements. Applications of Nanocomposite Materials in Orthopedics. Woodhead Publishing, 221–252.

Zai, W., Wong, M. H., & Man, H. C. (2019). Improving the wear and corrosion resistance of cocrmo-uhmwpe articulating surfaces in the presence of an electrolyte. Applied Surface Science, 464, 404–411.

Huang, J., Qu, S., Wang, J., Yang, D., Duan, K., & Weng, J. (2013). Reciprocating sliding wear behavior of alendronate sodium-loaded uhmwpe under different tribological conditions. Materials Science and Engineering C, 33, 3001–3009.

Zerbi, G., Gallino, G., Fanti, N., & Baini, L. (1989). Structural depth profiling in polyethylene films by multiple internal reflection infra-red spectroscopy. Polymer, 30, 2324–2327.

Florek, M., Fornal, E., Gómezromero, P., Zieba, E., Paszkowicz, W., Lekki, J., Nowak, J., & Kuczumow, A. (2009). Complementary microstructural and chemical analyses of sepia officinalis endoskeleton. Materials Science and Engineering C, 29, 1220–1226.

Wang, Q., Li, W., Liu, R. N., Zhang, K., Zhang, H. H., Fan, S. L., & Wang, Z. Y. (2019). Human and non-human bone identification using ftir spectroscopy. International Journal of Legal Medicine, 133, 269–276.

Kourkoumelis, N., Zhang, X., Lin, Z., & Wang, J. (2019). Fourier transform infrared spectroscopy of bone tissue: Bone quality assessment in preclinical and clinical applications of osteoporosis and fragility fracture. Clinical Reviews in Bone and Mineral Metabolism, 17, 24–39.

Kobrina, Y., Turunen, M. J., Saarakkala, S., Jurvelin, J. S., HautaKasari, M., & Isaksson, H. (2010). Cluster analysis of infrared spectra of rabbit cortical bone samples during maturation and growth. The Analyst, 12, 3147–3155.

Chaber, R., Łach, K., Depciuch, J., Szmuc, K., Michalak, E., Raciborska, A., Koziorowska, A., & Cebulski, J. (2017). Fourier transform infrared (ftir) spectroscopy of paraffin and deparafinnized bone tissue samples as a diagnostic tool for ewing sarcoma of bones. Infrared Physics and Technology, 85, 364–371.

Lavall, R. L., Assis, O. B. G., & CampanaFilho, S. P. (2007). β-Chitin from the pens of loligo sp.: Extraction and characterization. Bioresource Technology, 98, 2465–2472.

Cortizo, M. S., Berghoff, C. F., & Alessandrini, J. L. (2008). Characterization of chitin from illex argentinus squid pen. Carbohydrate Polymers, 74, 10–15.

Youn, D. K., No, H. K., & Prinyawiwatkul, W. (2013). Preparation and characteristics of squid pen β-chitin prepared under optimal deproteinisation and demineralisation condition. International Journal of Food Science and Technology, 48, 571–577.

Stark, N. M., & Matuana, L. M. (2004). Surface chemistry changes of weathered hdpe/wood-flour composites studied by xps and ftir spectroscopy. Polymer Degradation and Stability, 86, 1–9.

Hamzah, M., Khenfouch, M., Rjeb, A., Sayouri, S., Houssaini, D. S., Darhouri, M., & Srinivasu, V. (2008). Surface chemistry changes and microstructure evaluation of low density nanocluster polyethylene under natural weathering: a spectroscopic investigation. Journal of Physics: Conference Series, Johannesburg, South Africa, 1–14.

Grigoriadou, I., Pavlidou, E., Paraskevopoulos, K. M., Terzopoulou, Z., & Bikiaris, D. N. (2018). Comparative study of the photochemical stability of hdpe/ag composites. Polymer Degradation and Stability, 153, 23–36.

Salem, A., Bensalah, W., & Mezlini, S. (2019). Tribological investigation of hdpe-cuttlebone and hdpe-red coral composites. Journal of Bionic Engineering, 16, 1068–1079.

Gibson, L. J., Ashby, M. F., & Harly, B. A. (2010). Cellular materials in nature and medicine (pp. 300–320). Cambridge University Press.

Hermán, V., González, G., Noris-Suárez, K., Albano, C., Karam, A., Romero, K., Yndriago, L., Marquez, A., & Lozada, L. (2015). Biocompatibility studies of hdpe–ha composites with different ha content. Polymer Bulletin, 72, 3083–3095.

Hussein, A. A., Salim, R. D., & Sultan, A. A. (2015). Water absorption and mechanical properties of high—density polyethylene/egg shell composite. Journal of Basrah Researches, 37, 36–42.

Tasdemir, M., & Ersoy, S. (2014). Friction and wear performance of hdpe/talc-calcium carbonate polymer composites against sliding distance and applied load. Romanian Journal of Materials, 44, 257–264.

Yuan, S., Li, Y., Zhang, Q., Wen, J., & Zhu, Z. F. (2018). The tribological properties of pp/epdm/caco3 composites modified by hdpe. Conference Series: Materials Science and Engineering, 381, 1–5.

Denape, J. (2015). Third body concept and wear particle behavior in dry friction sliding conditions. Key Engineering Materials, 640, 1–12.

Oladele, I. O., Olajide, J. L., & Amujede, M. (2016). Wear resistance and mechanical behaviour of epoxy/mollusk shell biocomposites developed for structural applications. Tribology in Industry, 38, 347–360.

Salari, M., Taromsari, S. M., Bagheri, R., & Sani, M. A. F. (2019). Improved wear, mechanical, and biological behavior of uhmwpe-hap-zirconia hybrid nanocomposites with a prospective application in total hip joint replacement. Journal of Materials Science, 54, 4259–4276.

Acknowledgements

The authors are grateful to the University of Monastir and the Ministry of Higher Education and Scientific Research—Tunisia for their support (LGM: LAB-MA-05). We would like to thank Mr. Didier VOILLEMIN, manager of the company C2T Implants for his great cooperation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sidia, B., Bensalah, W. Tribological and Physicochemical Analysis of Squid Pen High-density Polyethylene Biocomposite for Medical Application. J Bionic Eng 19, 1481–1492 (2022). https://doi.org/10.1007/s42235-022-00217-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-022-00217-w