Abstract

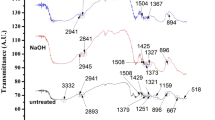

Coir Fibres (CF) and Pineapple Leaf Fibres (PALF) are valuable natural fibres which are abundantly available in Malaysia as agricultural wastes. The aim of this study is to investigate the effects of alkali (6%), silane (2%), and calcium hydroxide (6%) on tensile, morphological, thermal, and structural properties of CF and PALF to improve their interfacial bonding with Polylactic Acid (PLA) matrix. Scanning electron microscopy and Fourier transform infrared spectroscopy were used to observe the effectiveness of the chemical treatments in the removal of impurities. Alkali treated fibres yield the lowest fibre diameter and the highest Interfacial Stress Strength (IFSS). Thermogravimetric Analysis (TGA) shows improved thermal stability in silane treated CF and alkali treated PALF. It is assumed that fibre treatments can help to develop biodegradable CF and PALF reinforced PLA biocomposites for industrial applications.

Similar content being viewed by others

References

Sedan D, Pagnoux C, Smith A, Chotard T. Mechanical properties of hemp fibre reinforced cement: Influence of the fibre/matrix interaction. Journal of the European Ceramic Society, 2008, 28, 183–192.

Majeed K, Jawaid M, Hassan A, Abu Bakar A, Abdul Khalil H P S, Salema A A, Inuwa I. Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Materials & Design, 2013, 46, 391–410.

Li X, Tabil L G, Panigrahi S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. Journal of Polymers and the Environment, 2007, 15, 25–33.

Faruk O, Bledzki A K, Fink H P, Sain M. Biocomposites reinforced with natural fibers: 2000–2010. Progress in Polymer Science, 2012, 37, 1552–1596.

Rachini A, Le Troedec M, Peyratout C, Smith A. Chemical modification of hemp fibers by silane coupling agents. Journal of Applied Polymer Science, 2012, 123, 601–610.

Asim M, Jawaid M, Abdan K, Ishak M R. Effect of alkali and silane treatments on mechanical and fibre-matrix bond strength of kenaf and pineapple leaf fibres. Journal of Bionic Engineering, 2016, 13, 426–435.

Kabir M, Wang H, Lau K, Cardona F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Composites Part B: Engineering, 2012, 43, 2883–2892.

Van Krevelen D W, Te Nijenhuis K. Properties of Polymers: Their Correlation with Chemical Structure; their Numerical Estimation and Prediction from Additive Group Contributions, Elsevier BV, Amsterdam, Neitherlands, 2009.

Ku H, Wang H, Pattarachaiyakoop N, Trada M. A review on the tensile properties of natural fiber reinforced polymer composites. Composites Part B: Engineering, 2011, 42, 856–873.

Arsene M A, Okwo A, Bilba K, Soboyejo A, Soboyejo W. Chemically and thermally treated vegetable fibers for reinforcement of cement-based composites. Materials and Manufacturing Processes, 2007, 22, 214–27.

Van de Weyenberg I, Truong T C, Vangrimde B, Verpoest I. Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Composites Part A: Applied Science and Manufacturing, 2006, 37, 1368–1376.

Lopattananon N, Panawarangkul K, Sahakaro K, Ellis B. Performance of pineapple leaf fiber–natural rubber composites: The effect of fiber surface treatments. Journal of Applied Polymer Science, 2006, 102, 1974–1984.

Tserki V, Panayiotou C, Zafeiropoulos N. A study of the effect of acetylation and propionylation on the interface of natural fibre biodegradable composites. Composites Part A: Applied Science and Manufacturing, 2005, 36, 1110–1118.

Zhandarov S, Mäder E. Characterization of fiber/matrix interface strength: Applicability of different tests, approaches and parameters. Composites Science and Technology, 2005, 65, 149–160.

Arbelaiz A, Cantero G, Fernandez B, Mondragon I, Ganan P, Kenny J. Flax fiber surface modifications: Effects on fiber physico mechanical and flax/polypropylene interface properties. Polymer Composites, 2005, 26, 324–332.

Yu L, Dean K, Li L. Polymer blends and composites from renewable resources. Progress in Polymer Science, 2006, 31, 576–602.

Thakur V K, Thakur M K, Gupta R K. Review: Raw natural fiber–based polymer composites. International Journal of Polymer Analysis and Characterization, 2014, 19, 256–271.

Kalia S, Kaith B, Kaur I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites - A review. Polymer Engineering & Science, 2009, 49, 1253–1272.

Torres F, Cubillas M. Study of the interfacial properties of natural fibre reinforced polyethylene. Polymer Testing, 2005, 24, 694–698.

Eichhorn S J, Baillie C A, Zafeiropoulos N, Mwaikambo L Y, Ansell M P, Dufresne A, Entwistle K M, Herrera-Franco P J, Escamilla G C, Groom L, Hughes M, Hill C, Rials T G, Wild P M. Current international research into cellulosic fibres and composites. Journal of Materials Science, 2001, 36, 2107–2131.

Sawpan M A, Pickering K L, Fernyhough A. Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Composites Part A: Applied Science and Manufacturing, 2011, 42, 888–895.

Sawpan M A, Pickering K L, Fernyhough A. Effect of fibre treatments on interfacial shear strength of hemp fibre reinforced polylactide and unsaturated polyester composites. Composites Part A: Applied Science and Manufacturing, 2011, 42, 1189–1196.

Yan L, Chouw N, Yuan X. Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment. Journal of Reinforced Plastics and Composites, 2012, 31, 425–437.

Wang B, Panigrahi S, Tabil L, Crerar W. Pre-treatment of flax fibers for use in rotationally molded biocomposites. Journal of Reinforced Plastics and Composites, 2007, 26, 447–463.

Tserki V, Zafeiropoulos N, Simon F, Panayiotou C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Composites Part A: Applied Science and Manufacturing, 2005, 36, 1110–1118.

Rao K M M, Rao K M, Prasad A R. Fabrication and testing of natural fibre composites: Vakka, sisal, bamboo and banana. Materials & Design, 2010, 31, 508–513.

Satyanarayana K G, Arizaga G G, Wypych F. Biodegradable composites based on lignocellulosic fibers - An overview. Progress in Polymer Science, 2009, 34, 982–1021.

Cheung H Y, Ho M P, Lau K T, Cardona F, Hui D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Composites Part B: Engineering, 2009, 40, 655–663.

Rahman M M, Khan M A. Surface treatment of coir (Cocos nucifera) fibers and its influence on the fibers’ physicomechanical properties. Composites Science and Technology, 2007, 67, 2369–2276.

Nam T H, Ogihara S, Tung N H, Kobayashi S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly (butylene succinate) biodegradable composites. Composites Part B: Engineering, 2011, 42, 1648–1656.

Islam M N, Rahman M R, Haque M M, Huque M M. Physico-mechanical properties of chemically treated coir reinforced polypropylene composites. Composites Part A: Applied Science and Manufacturing, 2010, 41, 192–198.

Petchwattana N, Covavisaruch S. Mechanical and morphological properties of wood plastic biocomposites prepared from toughened poly (lactic acid) and rubber wood sawdust (Hevea brasiliensis). Journal of Bionic Engineering, 2014, 11, 630–637.

Saba N, Paridah M, Jawaid M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Construction and Building Materials, 2015, 76, 87–96.

Yan L, Chouw N, Jayaraman K. Flax fibre and its composites–A review. Composites Part B: Engineering, 2014, 56, 296–317.

Law K N, Daud W R W, Ghazali A. Morphological and chemical nature of fiber strands of oil palm empty-fruit-bunch (OPEFB). BioResources, 2007, 2, 351–362.

Summerscales J, Dissanayake N P, Virk A S, Hall W. A review of bast fibres and their composites. Part 1–Fibres as reinforcements. Composites Part A: Applied Science and Manufacturing, 2010, 41, 1329–1335.

Gu H. Tensile behaviours of the coir fibre and related composites after NaOH treatment. Materials & Design, 2009, 30, 3931–3934.

Rosa M F, Chiou B S, Medeiros E S, Wood D F, Williams T G, Mattoso L H C, Orts W J, Imam S H. Effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresource Technology, 2009, 100, 5196–2202.

Arrakhiz F, El Achaby M, Kakou A C, Vaudreuil S, Benmoussa K, Bouhfid R, Fassi-Fehri O, Qaiss A. Mechanical properties of high density polyethylene reinforced with chemically modified coir fibers: Impact of chemical treatments. Materials & Design, 2012, 37, 379–383.

Karthikeyan A, Balamurugan K. Effect of alkali treatment and fiber length on impact behavior of coir fiber reinforced epoxy composites. Journal of Scientific & Industrial Research, 2012, 71, 627–631.

Kabir M, Wang H, Lau K, Cardona F. Tensile properties of chemically treated hemp fibres as reinforcement for composites. Composites Part B: Engineering, 2013, 53, 362–368.

Mukhopadhyay S, Fangueiro R, Arpac Y, Sentürk Ü. Banana fibers–variability and fracture behaviour. Journal of Engineered Fibers & Fabrics, 2008, 3, 39–45.

Hossain M K, Dewan M W, Hosur M, Jeelani S. Mechanical performances of surface modified jute fiber reinforced biopol nanophased green composites. Composites Part B: Engineering, 2011, 42, 1701–1707.

Le Troedec M, Sedan D, Peyratout C, Bonnet J P, Smith A, Guinebretiere R, Gloaguen V, Krausz P. Influence of various chemical treatments on the composition and structure of hemp fibres. Composites Part A: Applied Science and Manufacturing, 2008, 39, 514–522.

Paiva M, Ammar I, Campos A, Cheikh R B, Cunha A. Alfa fibres: Mechanical, morphological and interfacial characterization. Composites Science and Technology, 2007, 67, 1132–1138.

Saw S K, Sarkhel G, Choudhury A. Surface modification of coir fibre involving oxidation of lignins followed by reaction with furfuryl alcohol: Characterization and stability. Applied Surface Science, 2011, 257, 3763–3769.

Das M, Chakrabarty D. Thermogravimetric analysis and weathering study by water immersion of alkali treated bamboo fibres. BioResources, 2008, 3, 1051–1062.

Puglia D, Monti M, Santulli C, Sarasini F, De Rosa I M, Kenny J M. Effect of alkali and silane treatments on mechanical and thermal behavior of Phormium tenax fibers. Fibers and Polymers, 2013, 14, 423–427.

Meon M S, Othman M F, Husain H, Remeli M F, Syawal M S M. Improving tensile properties of kenaf fibers treated with sodium hydroxide. Procedia Engineering, 2012, 41, 1587–1592.

Ibrahim N A, Hadithon K A, Abdan K. Effect of fiber treatment on mechanical properties of kenaf fiber-ecoflex composites. Journal of Reinforced Plastics and Composites, 2010, 29, 2192–2198.

Mishra S, Mohanty A, Drzal L T, Misra M, Parija S, Nayak S K, Tripathy S S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Composites Science and Technology, 2003, 63, 1377–1385.

Nirmal U, Singh N, Hashim J, Lau S T, Jamil N. On the effect of different polymer matrix and fibre treatment on single fibre pullout test using betelnut fibres. Materials & Design, 2011, 32, 2717–2726.

Sedan D, Pagnoux C, Chotard T, Smith A, Lejolly D, Gloaguen V, Krausz P. Effect of calcium rich and alkaline solutions on the chemical behaviour of hemp fibres. Journal of Materials Science, 2007, 42, 9336–9342.

Rosa M F, Chiou B S, Medeiros E S, Wood D F, Mattoso L H C, Orts W J, Imam S H. Biodegradable composites based on starch/EVOH/glycerol blends and coconut fibers. Journal of Applied Polymer Science, 2009, 111, 612–618.

Santos E F, Mauler R S, Nachtigall S M. Effectiveness of maleated-and silanized-PP for coir fiber-filled composites. Journal of Reinforced Plastics and Composites, 2009, 28, 2119–2129.

Acknowledgment

The authors wish to thank the Ministry of Higher Education (Malaysia) for financial support (CSFP-2015) of the first author’s PhD study. The authors are also grateful to UPM for providing Putra grant GP-IPS /2017/9520200.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siakeng, R., Jawaid, M., Ariffin, H. et al. Effects of Surface Treatments on Tensile, Thermal and Fibre-matrix Bond Strength of Coir and Pineapple Leaf Fibres with Poly Lactic Acid. J Bionic Eng 15, 1035–1046 (2018). https://doi.org/10.1007/s42235-018-0091-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-018-0091-z