Abstract

Additive manufacturing (AM) is widely used in the automotive industry and has been expanded to include aerospace, marine, and rail. High flexibility and the possibility of manufacturing complex parts in AM motivate the integration of additive manufacturing with classical forming technologies, which can improve tooling concepts and reduce costs. This study presents three applications of this integration. First, the possibility of successful utilization of selective laser melting for manufacturing extrusion tools with complex cooling channels and paths for thermocouples is reported, leading to significantly reduced inner die temperatures during the extrusion process. Second, sheet lamination is integrated with laser metal deposition (LMD) to manufacture deep-drawing dies. Promising results are achieved in reducing the stair step effect, which is the main challenge in sheet lamination, by LMD and following post-processing such as milling, ball burnishing, and laser polishing. The new manufacturing route shows that LMD can economically and efficiently reduce the stair step effect and omit the hardening step from the conventional manufacturing process route. Finally, LMD is used to manufacture a hot stamping punch with improved surface roughness by ball burnishing and near-surface complex cooling channels. The experimental results show that the manufactured punch has lower temperatures during hot stamping compared with the conventionally manufactured punch. This study shows the successful integration of AM processes with classical forming processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Hybrid additive manufacturing is defined as the integration of conventional, mostly subtractive, methods with additive manufacturing to overcome the limitations of both processes. The necessity of manufacturing complex tools with multiple functions, such as temperature or force mapping, or regulating the temperature in certain regions of the tool through sophisticated cooling or heating channels, highlights the potential of using additive manufacturing (AM) in tooling, particularly in metal forming. In metal forming processes, such as hot metal extrusion, deep drawing at elevated temperature, and hot stamping, controlling the tool temperature in a short time is essential. Hybrid additive manufacturing offers the possibility of manufacturing such tools with unique properties.

The cooling of hot extrusion dies made of light metals is an effective method for managing heat balance and preventing surface defects [1], such as hot cracks, surface roughening, and grain coarsening after hot extrusion. However, inserting conformal cooling channels close to the main forming zone, which provides the shortest heat conduction path from the forming zone to the cooling zone, is difficult or even impossible for profiles and dies with highly complex geometries. The use of additive manufacturing technologies is a promising approach to allow conformal cooling, while the structure of the die is not weakened like in the case of subtractive manufactured cooling channels [2].

One possible way of manufacturing tools with complex cooling/heating channels is the usage of sheet lamination or layer laminated manufacturing (LLM). However, the application of sheet lamination in rapid tooling, e.g. for deep drawing dies, is limited due to the segregated surface, also known as the stair-step effect. Different pre/post processing techniques, such as the application of an intermediate layer [3], chamfering [4], machining [5], galvanizing [6], and ball burnishing [7], have been used for reducing the stair-step effect. However, these processes either require significant effort and energy to achieve the desired surface roughness or result in surface roughness and hardness that are inadequate for tooling purposes. In 1997, for the first time, the application of laser cladding or laser metal deposition (LMD) was briefly reported as a means to reduce or even eliminate the stair-step effect on a macroscopic scale [8]. According to DIN EN ISO ASTM 52900 [9], directed energy deposition (DED) is an AM process in which the applied energy source melts the filling material. The creation of parts in the DED process is accomplished by melting materials as they are being deposited. Laser metal deposition (LMD) is a subcategory of DED in which a laser beam is used to melt metals and direct energy into a concentrated region where the substrate and the deposited powder melt. Deep drawing, a common forming process in the automotive industry, has to be optimized for the realization of the rapid tooling concept. Not only must the deep drawing machines be robust to increase productivity, but also the tooling production, which is one of the most time-consuming steps [10], need to be optimized. The production of deep drawing tools by combining sheet lamination and LMD can reduce processing time.

The conventional method of manufacturing cooling channels in hot stamping tools involves segmenting the tool and drilling holes, which can result in leakages and low flexibility regarding the channel size and location due to the limited accessibility. Additive manufacturing of hot stamping tools provides the advantage of increased flexibility regarding the channel geometry and proximity to the tool surface (e.g., in order to avoid hot spots). By means of LMD thin layers of dense and wear-resistant metals can be deposited on components (e.g., forming tools), resulting in enhanced performance and lifetime [11]. However, a general drawback of the DED process is the poor resolution and surface finish, with a roughness of more than 25 µm in most cases. This fact indicates that the post-processing of tool surfaces manufactured by DED is necessary. Ball burnishing is a promising post-processing procedure that can reduce surface roughness, as demonstrated in the application of deep drawing dies with thermally sprayed hard metal coatings [12]. By these processes, defined textures can be applied to tool surfaces. Thus, the material flow and the heat transfer can be influenced by hot stamping as it is shown for the application with aluminum sheets and milled textures [13]. Investigations on efficient hot stamping tools are highly relevant for the automotive industry due to the increasing use of hot-stamped steel parts in vehicles [14]. While some preliminary investigations have been conducted on hot stamping tools with integrated cooling channels manufactured by LMD, no real forming tools have been applied yet [15].

Combining additive manufacturing with conventional tooling can mitigate the limitations of conventional forming tools and enhance the robustness of the manufactured parts. Hence, three applications of hybrid additive manufacturing for the production of forming tools are investigated in this paper. In the following, the feasibility of using selective laser melting, laser metal deposition, and sheet metal lamination for the production of hot metal extrusion dies, deep-drawing dies, and hot stamping punches will be sequentially explored.

2 AM for Hot Aluminum Extrusion Dies with Conformal Cooling Channels

Two different additive manufacturing processes were developed and applied for the manufacturing of extrusion dies with conformal cooling channels [16]. Due to differences in the processes, the sheet metal lamination method is used for the manufacturing of plain or geometrical simple parts, like the die cap of an extrusion die, and the powder metallurgy-based method (Selective Laser Melting—SLM) is used to build geometries with higher complexity, such as the mandrel of an extrusion die, as shown in Fig. 1. These additively manufactured die parts were used in combination with conventionally manufactured die elements to create the prototype die sets.

2.1 Influence of Stair Step Effect on Material Flow in Hot Metal Extrusion

In sheet lamination, the stair step effect occurs on a macroscopic scale ranging from 0.1 to 1.0 mm, whereas in SLM, it occurs on a microscopic scale, typically around 30 µm. For the latter, the influence of surface topology on the material flow was investigated by visioplastic analysis in a die for simple rod extrusion. The conical-shaped prechamber was divided into two halves, one machined (post-processed) and the other rough (as laser melted by SLM), as shown in Fig. 2(a). A billet, prepared with indicator pins perpendicular to the main axis of the billet was partially extruded through this die [17]. After extrusion, the billet was ejected and cut along the plane containing the indicator pins. Metallographic analysis reveals that the rough surface in the prechamber generated by the additive manufacturing process (SLM) has no influence on the material flow behavior, as it is similar to the opposite (machined) surface, as shown in Fig. 2(b). Hence, in regard to the material flow, a post-processing process like machining is not required in hot metal extrusion.

a AM die for visioplastic analysis of the material flow, b Longitudinal cross section of the billet [16]

2.2 Extrusion Dies Manufactured by Selective Laser Melting

A mandrel for an extrusion die, as shown in Fig. 3(a), was manufactured in a powder bed of CL50WS (similar to the hot working steel 1.2709) in a nitrogen atmosphere by using a laser cusing machine m3 linear (by Concept Laser GmbH). The fabrication of the die, with a volume of 116 cm3 and a deposition rate of 3.8 cm3/h, took around 30 h (1580 layers with a layer thickness of 30 μm). The fitting surfaces and die bearings were afterward mechanically refinished (EDM/machining). The mandrel was heat treated (aging at 500 °C for 8 h) to a final hardness of 55 HRC [16].

Due to the special design of the trial extrusion press, a supply of the cooling medium and the measuring setup is only possible from the exit end face of the die. For feeding the coolant into the mandrel, a multidirectional course of the cooling channel through the mandrel was designed. The cooling channel is located in two opposing arms of the mandrel's cross-shaped bridge, while the other two arms contain a channel system for thermocouples (TC), as illustrated in Fig. 3(b).

Thermocouples were placed in close proximity to the die bearings on the surface. To prevent a pull-out and damage to the thermocouples caused by potential contact between the extrudate and the thermocouples, particularly during the beginning of the extrusion process, small deflectors were added to the nose of the mandrel, as shown in Fig. 3(a).

2.3 Hybrid Extrusion Dies

One of the major technological advantages of additive manufacturing against conventional processes is the nearly unlimited geometrical complexity of the parts to be produced. However, there are also disadvantages associated with laser melting, such as high production times and costs. To address this, in addition to the previously described strategies, a hybrid tooling concept was developed and tested, in which the limitations resulting from technological constraints of the investigated rapid tooling technologies were circumvented and experimentally implemented by a smart combination of the processes. A hybrid tooling element means in this case the combination of conventionally manufactured standardized tooling elements with flexibly designed or product-adapted shaping tooling elements through rapid tooling processes. Figure 4 shows a proven example of such a concept. A mandrel tip with cooling channels, consisting of 480 layers of 30 μm each, made of 1.2709 was “printed” by SLM on a conventionally manufactured tool bridge made of 1.2343 tool steel. The tool was subsequently tempered and aged.

a Conventionally manufactured tool bridge, b Hybrid mandrel with AM-made mandrel tip [16]

The tool geometry follows mainly the concept presented in Sect. 2.2; however, the cooling medium is guided through multiple bent brass tubes through the conventionally manufactured tool bridge. These tubes are inserted into corresponding cavities in the tool and are covered with a cap (refer to Fig. 5).

Mandrel with isolated coolant supply and cap: a Schematic, b Real [19]

The hybrid tool described above was successfully used in combination with a conventionally manufactured die cap to produce a hollow profile with a square cross-section (18 × 18 × 1 mm3) in testing extrusion trials [19]. The die cap was able to withstand the acting forces and provided a cooling effect that was comparable to the corresponding concept presented in Sect. 2.2.

2.4 Extrusion Dies Manufactured by Layer Laminated Manufacturing

For the manufacturing of an extrusion die cap with integrated cooling channels, the sheet lamination method was applied. Steel sheet lamellas were cut in a CNC laser-cutting center (Trumpf TL 1005) according to the die cap geometry. The lamellas of the die were cut from sheets of hot working steel 1.2343/H11 (heat treated to 54 HRC) with a thickness of 1 mm (welding chamber, cooling channel lamellas) and 2 mm (die bearing lamella), as shown in Fig. 6.

The stacked lamellas are supported by a 19 mm thick backer platen made conventionally of the hot working steel 1.2343/H11, as shown in Fig. 7(a) by machining and EDM. The cooling channels were aligned around the circumference of the square die opening directly behind the die-bearing lamella. To keep each laminae as one single unit, the cooling channels have been split into two lamellas, as depicted in Fig. 7(b), resulting in a labyrinth like path of the coolant through the two lamellas.

For the experimental investigation of the potential of die cooling in hot extrusion, extrusion trials were carried out at different extrusion speeds, with and without applying cooling. The results of using the die cap based on sheet lamination with integrated cooling channels (as presented in Sect. 2.4), in combination with a conventional manufacture mandrel, are presented below. Starting at a low profile’s exit speed, the extrusion speed was increased successively from trial to trial and the surfaces of the profiles were analyzed regarding surface defects, especially the formation of hot cracks. As billet material, the difficult-to-extrude aluminum alloy EN AW-7075 was chosen which was preheated to 440 °C. Die and container temperatures were set to 450 °C. A square hollow profile (22 × 22 × 1 mm3) with an extrusion ratio of R = 38:1 was extruded on a 10 MN direct extrusion press (SMS) with an inner container diameter of 105 mm. Water (18 °C, 1.8 L/min) was chosen as the cooling medium. Without cooling, hot cracks occurred at profile exit speeds between 1 m/min and 1.25 m/min, as illustrated in Fig. 8. With rising extrusion speed, the size and dimension of the hot cracks increased. By applying die cooling, profiles can be manufactured at an exit speed of around 3.1 m/min without surface defects. This means that approximately three times higher productivity can be achieved without any thermally induced surface defects on the extrudate. The extrusion forces at an extrusion speed of 3 m/min, at the end of extrusion of a billet, were 4.95 MN without cooling and increased by 17% up to 5.8 MN with die cooling.

Extension of the process limits in hot aluminum extrusion of EN AW-7075 by using an inner die water cooling [16]

The described application in hot metal extrusion is an example where the stair-step effect, commonly associated with most additive manufacturing technologies, only requires local reworking. The following sections will look at use cases where extensive reworking is necessary.

3 Hybrid Additive Laminated Tooling

There are various methods for the production of deep drawing dies. The most traditional method is machining the target geometry from a block or bar. This can be done by traditional methods such as milling or turning, or by electrical discharge machining. However, electrical discharge machining is used for very complex geometries and shapes with high hardness of raw material. All methods, especially electrical discharge machining, are highly time-consuming. Therefore, using the additive manufacturing method can speed up the process.

The hybrid additive laminated tooling process route for deep drawing applications is initially presented in Ref. [20] and shown in Fig. 9. The process starts with the cutting of sheets with varying thicknesses, which are then stacked in a suitable order. The generated stair-step effects are reduced by laser metal deposition (LMD) and the surface roughness of the deposited area is improved by milling, ball burnishing, or laser polishing. The development of such a tool requires a systematic design, which will be presented in the subsequent sections.

3.1 Tool Design

Sheet lamination offers widely different combinations of thicknesses and materials. There are, using three sheet thicknesses (0.5 mm, 1.0 mm, and 2 mm) to manufacture a die with a tool radius of 8 mm offers 4930 possibilities. However, selecting the appropriate sheet combination is a multi-objective task that considers factors such as energy consumption, sheet materials, and application of functional elements like sensors or cooling channels. To achieve low form deviation (ΔR), better surface roughness, and a strong weld track, selecting the proper filling strategy and process parameters for laser metal deposition is crucial. For instance, filling the area A1 in Fig. 10(a) and subsequently filling the A2 (one-step filling strategy) leads to thermal deformation of the substrate sheet, which results in form deviation (ΔR) in the tool radius.

Therefore, the following two-step strategy, as shown in Fig. 10(b), is used. As a first step, the sheets are joined together by bonding tracks, and the filling step is applied to reduce the stair-step areas. An example of selecting the proper process parameters during the laser metal deposition (LMD) is shown in Fig. 11. It shows the inappropriate selection of the process parameters during the LMD (here low laser power, P) leads to insufficient weld strength.

The deep drawing process must not cause the tool sheets to fracture or plastify. A semi-analytical method based on classical beam theory for a simplified model is developed and explained in Ref. [20] to study the von Mises stress distribution in a thickness direction. It is shown that high-strength sheets need to be used for bottom sheets near the die support. Two different strategies are followed for cutting the tool sheets in the design step. In the first strategy, the sheets’ corner edges were in contact with nominal radius, named as without offset. In the second strategy, all sheets except the cover and final sheet are offset by minus 1 mm with respect to the nominal die radius R, as shown in Fig. 12(a). For the case with offset, two different deposition strategies are studied. In the first strategy, the whole stair step volume are filled with tracks parallel to the bonding tracks. In the second strategy, the filling step is divided into two steps: an initial linear smoothing step and a final smoothing step, i.e., a radial bidirectional smoothing step. The with-offset strategy provides a generally homogenous surface with better surface roughness and lower shape inaccuracy compared with the without-offset strategy. Different bidirectional filling along the radius improves the average surface roughness (Ra) by 35% due to more continuous deposition. However, the manufacturing time was three times higher and the laser nozzle lifetime was shorter than in the unidirectional case.

3.2 Tool Wear Test

Deep drawing experiments were conducted with an eccentric press for two different deep drawing radii, 6 and 8 mm, respectively. For the forming experiments, the three sheet thicknesses (0.5 mm, 1 mm from HC420LA, and 2 mm from S355MC material) were laser cut and stacked as shown in Fig. 13(a), to generate the laminated die with a radius of 8 mm (die). For the wear resistance test, the HC380LA high-strength steel blank with a thickness of 1 mm was used. Two different powders Ferro 55 and 316L-Si were used for reducing the stair step effect by LMD. The deposition was performed by a Lasertec 65 3D hybrid machine by Sauer GmbH/DMG MORI AG. The depositions were done with a laser spot diameter of 1.6 mm.

The deep drawing was performed for 1000 strokes using dies manufactured from HC420LA and S355MC lamellas in combination with the LMD of Ferro 55 powder. The results were compared with those obtained using a conventional die, as illustrated in Fig. 14. The change in surface roughness Rz (maximum height) is calculated as:

After each 200 deep drawing strokes, R ′z of the die is measured.

The surface roughness of the dies was measured using KEYENCE's VR-5000 profilometer according to DIN 4288, with a cut-off length of 0.8 mm. The surface roughness was measured in the radius direction with 7 lines at intervals of 5 pixels.

The results show that, although the surface roughness of the conventional die, milled out of steel 1.2379 (X155CrVMo12-1) and hardened with the hardness of 642 ± 13 HV10, is better even after 1000 strokes, the dies produced by the hybrid method have lower wear compared with the conventional die, which is more than 60% of the initial condition. Therefore, it could be concluded that the die wear in the hybrid method is significantly lower than in the conventional method. However, it needs to be considered that the maximum surface roughness of the conventional die (Rz = 9.3 µm) is better than the surface roughness of the hybrid additive laminated tooling (Rz = 21.7 µm), even after 1,000 cups. The wear test for hybrid tools was extended to 10,000 strokes for both laser polishing and ball burnishing post-processing methods. The results of die radius change and die surface roughness change for both methods are shown in Fig. 15.

The die radius decrease, or macroscopic wear, after increasing the surface is caused by high abrasion of the die, resulting in a smaller die radius and roughness. Overall, the die radius change after 10,000 strokes is around 6.2% (R = 7.87 mm) for the laser-polished die and around 6.5% (R = 7.71 mm) for the ball-burnished die, as shown in Fig. 15(a). The surface roughness change, or the microscopic wear, shows that the die surface roughness post-processed by ball burnishing increases around 35% (Rz = 24.94 µm), whereas the value for laser polishing is approximately 29% (Rz = 16.15 µm) after 5,000 strokes. After wear, the surface roughness improves, and the final surface roughness is about Rz = 13.24 µm, as shown in Fig. 15(b).

3.3 Demonstrator

The hybrid method offers high flexibility in the manufacturing of complex shapes and free forms in a short time. As a demonstrator, a deep drawing die made of two different powders (Ferro 55 and 316L-Si) was manufactured, and DC06 and HC380LA blanks with a thickness of 1 mm were deep drawn, as shown in Fig. 16. The deep drawing results demonstrate the feasibility of fabricating a massive deep drawing die without hardening. The surface roughness Rz (maximum height) of the deep-drawn demonstrator out of HC380LA is only 3% better than that of DC06. It also enables the use of dissimilar deposited materials to adjust the surface roughness and heat transmission coefficient in the effective contact area of the tool.

The hybrid method also offers the possibility of manufacturing complex heating and cooling channels, as well as the insertion of load sensors. A related concept to the demonstrator is depicted in Fig. 17.

The high flexibility of the LMD offers the possibility of manufacturing complex cooling channels for hot stamping tools with different forms, which will be elaborated upon subsequently.

4 Hot Stamping Tools with Near-Surface Cooling Channels

Laser metal deposition (LMD) enables the production of even more complex geometries. In the current case, this is shown through the manufacturing of near-surface cooling channels for a hot stamping tool.

4.1 Development of Cooling Channels for LMD

Within the scope of preliminary investigations, different cooling channel geometries are analyzed regarding their suitability of being manufactured by LMD on the one hand. On the other hand, the cooling channels have to exhibit a sufficient cooling capacity in hot stamping tools. Besides others, such as square, triangular, and round cooling channels, the drop-shaped cooling channel is investigated (as shown in Fig. 18). This shape is found to represent a good compromise between the two important aspects of manufacturability by LMD and cooling capacity in hot stamping [21]. The round and square cooling channels cannot be manufactured by the LMD process because the support of overhangs is missing.

The laser deposition of the cooling channels is performed with the same machine as in Sect. 3, with a laser spot diameter of 3 mm.

For the use of drop-shaped cooling channels in a hot stamping tool manufactured by LMD, various channel widths and distances are investigated. This is relevant regarding the surface roughness of the tool surface, as shown in Fig. 19. Due to the high roughness of the tool surfaces after the LMD process, subsequent ball burnishing is applied to level the roughness peaks, resulting in a reduction of up to 50% in the roughness value Rz.

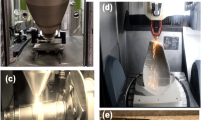

4.2 Application in a Cooled Hot Stamping Punch

For the application of additively manufactured cooling channels in a hot stamping tool, the geometry of a hat profile is chosen as a workpiece. The upper part of the punch and its cooling channels are manufactured by LMD (via Lasertec 65 3D) using the tool steel powder (Ferro 55 by voestalpine). The cooled upper part of the punch is deposited on a pre-machined base material (1.2367) to save time and costs (Fig. 20). Besides the proximity of the cooling channels to the surface of the tool, another advantage of the additive manufacturing method is that the cooling channel system is continuous and requires only one inlet and one outlet for the water coolant. In contrast, conventionally manufactured cooling channels require one inlet and outlet for each cooling channel.

During the hot stamping tests, the temperature of the punch was measured by thermocouples located 2 mm beneath the surface. The following three cases are compared:

-

A conventionally manufactured punch (material 1.2367) with two drilled cooling channels with a diameter of 8 mm, a distance between channels of 12 mm, and a distance to the tool surface of approx. 15 mm (originating from manufacturing restrictions due to deep-hole drilling).

-

An additively manufactured punch with a distance of the drop-shaped cooling channels to the surface of approx. 4.5 mm without post-processed surface.

-

An additively manufactured punch with a distance of the drop-shaped cooling channels to the surface of approx. 4.5 mm and ball burnished surface. The width of the drop-shaped channels is 6 mm and the distance between the channels is 8 mm (this applies to the case above as well).

After four continuously formed specimens, the temperature of the punch differs according to the cooling channel configuration and the tool surface. By using the additively manufactured punch with the ball burnished surface, the temperature is reduced by up to 40% compared with the conventionally manufactured punch, as shown in Fig. 21. The additively manufactured punch without a post-processed surface also shows a temperature reduction. Nevertheless, due to the higher roughness of the additively manufactured surfaces, it is deduced that the heat transfer is decreased compared with the conventionally manufactured punch. This results in a lower contribution of the tool material to the cooling capacity during the quenching phase. However, this drawback can be compensated for by using near-surface cooling channels in combination with the additively manufactured punch.

As a result, the near-surface cooling channels manufactured by LMD provide the opportunity to prevent an extensive heating-up of the tools on an industrial production scale, which leads to the advantages of reducing cycle times and avoiding hot spots. Since the experiments were conducted on a research scale, they give a clear indication of the mentioned aspects. However, on an industrial scale, the number of formed parts would be higher.

Another potential application of the LMD process is the manufacturing of textures on tool surfaces. This is done on the blank holder to analyze the influence on heat distribution and the material flow of the blank (Fig. 22).

Through this process, several effects can be achieved in the forming result of the hat profile, including:

-

Reduction of springback (as shown in Fig. 23)

-

Prevention of orange peel in the profile’s wall (as shown in Fig. 24)

-

Possibility of producing ductile part areas by the use of two-sided textures through delayed cooling

The use of a textured blank holder in the formation of a hat profile results in a reduction of up to six times in springback compared with those formed without texturing. The reason for this is that the texturing creates a homogeneous temperature field in the hat profile, which is beneficial regarding the formation of residual stresses to prevent undesirable springback.

A potential reason for the appearance of the orange peel is the inhomogeneous grain size distribution across the part. This is caused by early cooling-down of certain areas of the hat profile, particularly the flange. However, a minor drawback of the used texture is the local appearance of slight scratches on the inside of the hat profile. This can be prevented if the welding tracks are ball burnished, for example.

These positive effects regarding the use of textured blank holders derive from the more homogeneous temperature distribution during the hot stamping procedure compared with the non-textured tool. Consequently, this prevents certain areas of the blank from cooling down faster than others, thereby maintaining a more homogeneous material flow between the flange and the wall. This is indicated in the temperature of the flange, which is higher by approx. 40% in the case of the textured blankholder after the forming and holding stage (as shown in Fig. 25). Thus, the material flow is preserved for a longer duration, resulting in a more homogeneous formation of the part.

In summary, additively manufactured tools provide the advantage of more efficient cooling for the top of the hat profile through near-surface channels, while also preventing premature cooling of parts like the flanges through the use of textured surfaces. This results in improved process efficiency, with lower cycle times and prevention of overheated tools, while also supporting material flow from the flanges.

5 Economic Evaluation

For an economic evaluation of the hybrid additive manufacturing of laminated tooling, a comparison is made with fully deposited tooling using laser metal deposition. Since the technological, economic, and energetic evaluation is highly dependent on part geometry, a generalized academic geometry is used to ensure comparability with other processes. It is assumed, as shown in Fig. 26(a) that the semi-finished product is a cuboid (side length a) with a square base and a certain thickness (c as length/thickness ratio). The semi-finished product is made up of a finite number of sheets (n) of the same thickness (t). In the center of the cuboid is a cylindrical hole (diameter d) whose volume represents the relative amount of scrap in the semi-finished product (X) as illustrated in Fig. 26(a). A systematic and detailed analysis is provided in Ref. [22]. A comparison of the resulting energy consumption of the entire process chain is shown in Fig. 26(b). The calculation takes into account the energy for steel production, further processing into sheet metal, laser cutting of the sheet metal, and the corresponding post processes. Fully additive manufacturing followed by milling as mentioned is an alternative to prototyping for complex geometries. Figure 26(b) shows that LMD followed by milling (as post-processing) consumes significantly more energy than the hybrid additive laminated tooling process. The total production time of LMD (plus milling) is significantly higher than for the hybrid process, as shown in Fig. 26(b). In the calculation of the production time, the external production of the sheets and the raw material are not considered.

Comparison of the hybrid process with a fully manufactured part from LMD plus milling: a Assumed geometry for calculations, b Total energy consumption and production time [22]

6 Conclusions

The utilization of selective laser melting and layer laminated manufacturing in the production of extrusion die components provides the possibility to integrate multidirectional cooling channels and thermocouples for temperature measurement into hot extrusion dies near the forming zone. Empirical studies have demonstrated that the implementation of inner die cooling can substantially decrease the exit temperature of the profile. The developed tooling technology exhibits significant potential for increasing the production speed in hot aluminum extrusion.

The combination of sheet lamination and laser metal deposition (LMD) has been demonstrated to enable the manufacture of complex die geometries beyond simple axially symmetrical dies. This is due to the relative simplicity of manufacturing the lamellae and the LMD process's ability to fill steps with quasi-any geometry between the lamellae. The process has a lower carbon footprint than tools manufactured entirely using LMD, since only small parts of the tool are processed using the LMD process. In addition, the new process is much faster due to the significantly lower amount of powder processed. The presented investigations have shown the feasibility of manufacturing cooling channels by LMD in hot stamping tools, which contributes to an improved hot stamping process. The manufactured punch exhibits the durability to withstand the forces in hot stamping. Additionally, the near-surface cooling channels are able to keep the punch temperature at a steady lower temperature compared with the conventionally manufactured punch, thus preventing extensive heating up of the tool. The additively manufactured textures can influence the heat balance in the formed part and homogenize the material flow during forming. Furthermore, locally ductile areas can be manufactured using such textures. These findings demonstrate the feasibility of manufacturing hot stamping tools by LMD, which serves as a foundation for further developments to increase the efficiency of the hot stamping process.

It is shown that hybrid additive manufacturing has the potential to improve the tooling design of different forming tools.

Abbreviations

- AM:

-

Additive manufacturing

- DED:

-

Directed energy deposition

- LLM:

-

Layer laminated manufacturing

- LMD:

-

Laser metal deposition

- SLM:

-

Selective laser melting

References

Akeret, R.: Die produktivität beim strangpressen von aluminium-werkstoffen—einfluss von werkstoff und verfahren. Z. Met. 62(6), 451–456 (1971)

Hölker, R., Jäger, A., Ben Khalifa, N., Tekkaya, A.E.: New concepts for cooling of extrusion dies manufactured by rapid tooling. Key Eng. Mater. 491, 223–232 (2012)

Kleiner, M., Krux, R.: Entwicklung eines verfahrens zur schnellen herstellung von tief- und streckziehwerkzeugen aus blechlamellen für die prototypen- und kleinserienfertigung. Forschungsberichte für die Praxis, Stahl-Zentrum Düusseldorf, Nr. P384 (2001)

Walczyk, D.F., Hardt, D.E.: Rapid tooling for sheet metal forming using profiled edge laminations-design principles and demonstration. J. Manuf. Sci. Eng. 120(4), 746–754 (1998)

Kunieda, M., Nakagawa, T.: Manufacturing of laminated deep drawing dies by laser beam cutting. Adv. Technol. Plast. 1, 520–525 (1984)

Himmer, T., Techel, A., Nowotny, S., Beyer, E.: Recent developments in metal laminated tooling by multiple laser processing. Rapid Prototyp. J. 9(1), 24–29 (2003)

Hiegemann, L., Agarwal, C., Weddeling, C., Tekkaya, A.E.: Reducing the stair step effect of layer manufactured surfaces by ball burnishing. In: Proceedings of the AIP Conference: 190002 (2016)

Erasenthiran, P., Ball, R., Jungreuthmayer, C., O’Neill, W., Steen, W.M.: Laser step shaping for laminated object manufacturing parts. In: Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Laser Institute of America, pp. 84–92 (1997)

DIN 52900: DIN EN ISO/ASTM 52900 Fundamentals and vocabulary. Beuth Verlag GmbH, Berlin (2021)

Vieira, A.M., Silva, F.J.G., Campilho, R.D.S.G., Ferreira, L.P., Sá, J.C., Pereira, T.: SMED methodology applied to the deep drawing process in the automotive industry. In: 30th International Conference on Flexible Automation and Intelligent Manufacturing (FAIM2021), 1416–1422, Athens, 15–18 June 2021

Gibson, I., Rosen, D., Stucker, B.: Directed energy deposition processes. In: Gibson, I., Rosen, D., Stucker, B. (Eds.), Additive Manufactur Tech, 2nd ed. Springer, pp. 245–268, (2015)

Hiegemann, L., Weddeling, C., Ben Khalifa, N., Tekkaya, A. E.: Control of the material flow in deep drawing by the use of rolled surface textures. In: 6. Öffentl. Koll. SFB 708, pp. 33–45 (2013)

Zheng, K., Politis, D.J., Lin, J., Dean, T.A.: An experimental and numerical investigation of the effect of macro-textured tool surfaces in hot stamping. Int. J. Mater. Form. 10, 241–254 (2017)

Mori, K., Bariani, P.F., Behrens, B.A., Brosius, A., Bruschi, S., Maeno, T., Merklein, M., Yanagimoto, J.: Hot stamping of ultra-high strength steel parts. CIRP Ann. Manuf. Technol. 66, 755–777 (2017)

Cortina, M., Arrizubieta, J.I., Calleja, A., Ukar, E., Alberdi, A.: Case study to illustrate the potential of conformal cooling channels for hot stamping dies manufactured using hybrid process of laser metal deposition (LMD) and milling. Metals 8, 102 (2018). https://doi.org/10.3390/met8020102

Hölker R.: Additiv hergestellte Werkzeuge mit lokaler Innenkühlung zur Produktivitätssteigerung beim Aluminium-Strangpressen, Shaker Verlag, ISBN 978–3-8440-3149-2, Dissertation, Technical University of Dortmund (2014)

Hölker, R., Haase, M., Ben, K.N., Tekkaya, A.E.: Hot extrusion dies with conformal cooling channels produced by additive manufacturing. Mater. Today Proc. Part A 2(10), 4838–4846 (2015)

Hölker, R., Jäger, A., Ben, K.N., Tekkaya, A.E.: Controlling heat balance in hot aluminum extrusion by additive manufactured extrusion dies with conformal cooling channels. Int. J. Precis. Eng. Manuf. 14(8), 1487–1493 (2013)

Hölker, R., Tekkaya, A.E.: Advancements in the manufacturing of dies for hot aluminum extrusion with conformal cooling channels. Int. J. Adv. Manuf. Technol. (2015). https://doi.org/10.1007/s00170-015-7647-4

Dardaei Joghan, H., Hahn, M., Sehrt, J.T., Tekkaya, A.E.: Hybrid additive manufacturing of metal laminated forming tools. CIRP Ann. 71(1), 225–228 (2022). https://doi.org/10.1016/j.cirp.2022.03.018

Komodromos, A., Kolpak, F., Tekkaya, A.E.: Manufacturing of integrated cooling channels by directed energy deposition for hot stamping tools with ball burnished surfaces. Berg Huettenmaenn Monatsh. 167(9), 428–434 (2022). https://doi.org/10.1007/s00501-022-01264-w

Dardaei Joghan, H., Hahn, M., Aboola, O.E., Tekkaya, A.E.: Ressourcen and manufacturing technology evaluation of hybrid additive metal laminated tooling for forming. Mater. Res. Proc. 28, 21–30 (2023)

Acknowledgements

This work was carried out within the projects 198180216, 426515407 and 417202720 funded by the German Research Foundation (DFG). The financial support is greatly acknowledged. The authors also thank Mr. Gabriel Marín for his considerable support in the conduction and analysis of the hot stamping tests and surface roughness measurements.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dardaei Joghan, H., Hölker-Jäger, R., Komodromos, A. et al. Hybrid Additive Manufacturing of Forming Tools. Automot. Innov. 6, 311–323 (2023). https://doi.org/10.1007/s42154-023-00239-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42154-023-00239-y