Abstract

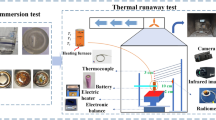

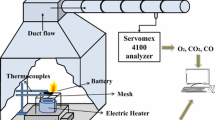

The seawater immersion test is one of the essential indicators for evaluating the safety of lithium-ion batteries (LIBs). In this work, 3.5 wt% salt in water as surrogate seawater was used in LIB immersion experiments, and the combustion behaviors, surface temperature, mass loss, and heat flux during thermal runaway (TR) of LIBs were analyzed after different immersion duration (tim, 0 h, 2 h, 3 h, 6 h), to evaluate the thermal stability of cells. The experimental results showed that the fire behavior of the 21700 cylinders with 50% state of charge (SOC) was less severe than that with 100% SOC. For 100% SOC cells, the maximum temperature decreased sharply suffering tim of 6 h, whose temperature of TR (Ttr) was lower than that of 50% SOC cells, and the maximum battery surface temperature (Tmax) was higher than that of the 50% SOC cases. Total mass loss (TML) decreased with the increase of tim for 100% and 50% SOC batteries, which of 50% SOC LIBs was much lower than that of 100% SOC LIBs. For LIBs after different tim, the heat flux presented almost the same tendency during combustion tests. This work further investigated the TR characteristics of 21700 cylinders after immersion, which could help improve LIB safety.

Graphical abstract

The burning behaviors of 21700 cylinders after different immersion duration were investigated, which might help evaluate the fire risk of batteries and improve safety

Similar content being viewed by others

References

Kim S, Kim J-S, Miara L, Wang Y, Jung S-K, Park SY, Song Z, Kim H, Badding M, Chang J, Roev V, Yoon G, Kim R, Kim J-H, Yoon K, Im D, Kang K (2022) High-energy and durable lithium metal batteries using garnet-type solid electrolytes with tailored lithium-metal compatibility. Nat Commun 13:1883. https://doi.org/10.1038/s41467-022-29531-x

Sun P, Bisschop R, Niu H, Huang X (2020) A review of battery fires in electric vehicles. Fire Technol 56:1361–1410. https://doi.org/10.1007/s10694-019-00944-3

Huang Y, Tang Y, Yuan W, Fang G, Yang Y, Zhang X, Wu Y, Yuan Y, Wang C, Li J (2021) Challenges and recent progress in thermal management with heat pipes for lithium-ion power batteries in electric vehicles. Sci China Technol Sc 64:919–956. https://doi.org/10.1007/s11431-020-1714-1

Peng Z, Jiang Q, Peng P, Li F-F (2021) NH3-activated fullerene derivative hierarchical microstructures to porous Fe3O4/N-C for oxygen reduction reaction and Zn-air battery. Eng Sci 14:27–38. https://doi.org/10.30919/es8d1311

Dang C, Mu Q, Xie X, Sun X, Yang X, Zhang Y, Maganti S, Huang M, Jiang Q, Seok I, Du W, Hou C (2022) Recent progress in cathode catalyst for nonaqueous lithium oxygen batteries: a review. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-022-00500-8

Hou C, Wang B, Murugadoss V, Vupputuri S, Chao Y, Guo Z, Wang C, Du W (2020) Recent advances in Co3O4 as anode materials for high-performance lithium-ion batteries. Eng Sci 11:19–30. https://doi.org/10.30919/es8d1128

Patil SS, Bhat TS, Teli AM, Beknalkar SA, Dhavale SB, Faras MM, Karanjkar MM, Patil PS (2020) Hybrid solid state supercapacitors (HSSC’s) for high energy & power density: an overview. Eng Sci 12:38–51. https://doi.org/10.30919/es8d1140

Hu X, Wu H, Liu S, Gong S-M, Du Y, Li X, Lu X, Qu J (2021) Fabrication of organic shape-stabilized phase change material and its energy storage applications. Eng Sci. https://doi.org/10.30919/es8d474

Lu X, Liu H, Murugadoss V, Seok I, Huang J, Ryu JE, Guo Z (2020) Polyethylene glycol/carbon black shape-stable phase change composites for peak load regulating of electric power system and corresponding thermal energy storage. Eng Sci 9:25–34. https://doi.org/10.30919/es8d901

Hou C, Hou J, Zhang H, Ma Y, He X, Geng W, Zhang Q (2020) Facile synthesis of LiMn0.75Fe0.25PO4/C nanocomposite cathode materials of lithium-ion batteries through microwave sintering. Eng Sci 11:36–43. https://doi.org/10.30919/es5e1006

Tao CF, Ye QP, Wang CM, Qian YJ, Wang CF, Zhou TT, Z.G. (2020) Tang, An experimental investigation on the burning behaviors of lithium ion batteries after different immersion times. J Clean Prod 242:118539. https://doi.org/10.1016/j.jclepro.2019.118539

Zhang L, Zhao C, Liu Y, Xu J, Sun J, Wang Q (2021) Electrochemical performance and thermal stability of lithium ion batteries after immersion. Corros Sci 184:109384. https://doi.org/10.1016/j.corsci.2021.109384

Kumar NP, Patankar VH (2022) Design and development of water-immersible two-channel high-voltage spike pulser for under-water inspection and gauging of pipes. Rev Sci Instrum 93:1014703. https://doi.org/10.1063/5.0072733

Feng XN, Ouyang MG, Liu X, Lu LG, Xia Y, He XM (2018) Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater 10:246–267. https://doi.org/10.1016/j.ensm.2017.05.013

Larsson F, Andersson P, Blomqvist P, Lorén A, Mellander B-E (2014) Characteristics of lithium-ion batteries during fire tests. J Power Sources 271:414–420. https://doi.org/10.1016/j.jpowsour.2014.08.027

Wang Q, Mao B, Stoliarov SI, Sun J (2019) A review of lithium ion battery failure mechanisms and fire prevention strategies. Prog Energ Combust 73:95–131. https://doi.org/10.1016/j.pecs.2019.03.002

Spotnitz R, Franklin J (2003) Abuse behavior of high-power, lithium-ion cells. J Power Sources 113:81–100. https://doi.org/10.1016/S0378-7753(02)00488-3

Bandhauer TM, Garimella S, Fuller TF (2011) A critical review of thermal issues in lithium-ion batteries. J Electrochem Soc 158:R1–R25. https://doi.org/10.1149/1.3515880

Wang F, Ke X, Shen K, Zhu L, Yuan C (2021) A critical review on materials and fabrications of thermally stable separators for lithium-ion batteries. Adv Mater Technol-Us. https://doi.org/10.1002/admt.202100772

Wu Y, Liu X, Wang L, Feng X, Ren D, Li Y, Rui X, Wang Y, Han X, Xu G-L, Wang H, Lu L, He X, Amine K, Ouyang M (2021) Development of cathode-electrolyte-interphase for safer lithium batteries. Energy Storage Mater 37:77–86. https://doi.org/10.1016/j.ensm.2021.02.001

Ghiji M, Edmonds S, Moinuddin K (2021) A review of experimental and numerical studies of lithium ion battery fires. Appl Sci Basel 11. https://doi.org/10.3390/app11031247

Chen Y, Kang Y, Zhao Y, Wang L, Liu J, Li Y, Liang Z, He X, Li X, Tavajohi N, Li B (2021) A review of lithium-ion battery safety concerns: the issues, strategies, and testing standards. J Energy Chem 59:83–99. https://doi.org/10.1016/j.jechem.2020.10.017

Song L, Zheng Y, Xiao Z, Wang C, Long T (2022) Review on thermal runaway of lithium-ion batteries for electric vehicles. J Electron Mater 51:30–46. https://doi.org/10.1007/s11664-021-09281-0

Chen Y (2022) Recent advances of overcharge investigation of lithium-ion batteries. Ionics 28:495–514. https://doi.org/10.1007/s11581-021-04331-3

An Z, Jia L, Ding Y, Dang C, Li X (2017) A review on lithium-ion power battery thermal management technologies and thermal safety. J Therm Sci 26:391–412. https://doi.org/10.1007/s11630-017-0955-2

Zhang QS, Niu JH, Zhao ZH, Wang Q (2022) Research on the effect of thermal runaway gas components and explosion limits of lithium-ion batteries under different charge states. J Energy Storage 45:103759. https://doi.org/10.1016/j.est.2021.103759

Gao S, Zhao X, Fu Q, Zhang T, Zhu J, Hou F, Ni J, Zhu C, Li T, Wang Y, Murugadoss V, Mersal G, Ibrahim M, El-Bahy Z, Huang M, Guo Z (2022) Highly transmitted silver nanowires-SWCNTs conductive flexible film by nested density structure and aluminum-doped zinc oxide capping layer for flexible amorphous silicon solar cells. J Mater Sci Technol 126:152–160. https://doi.org/10.1016/j.jmst.2022.03.012

Liu YH, Niu HC, Li Z, Liu J, Xu CS, Huang XY (2021) Thermal runaway characteristics and failure criticality of massive ternary Li-ion battery piles in low-pressure storage and transport. Process Saf Environ Protect 155. https://doi.org/10.1016/j.psep.2021.09.031

Fang J, Cai JN, He XZ (2021) Experimental study on the vertical thermal runaway propagation in cylindrical lithium-ion batteries: effects of spacing and state of charge. Appl Therm Eng 197:117399. https://doi.org/10.1016/j.applthermaleng.2021.117399

Gao ZH, Rao S, Zhang TY, Gao F, Xiao Y, Shali LF, Wang XX, Zheng YD, Chen YY, Zong Y, Li WF, Chen YP (2022) Bioinspired thermal runaway retardant capsules for improved safety and electrochemical performance in lithium-ion batteries. Adv Sci 9:2103796. https://doi.org/10.1002/advs.202103796

Ouyang D, Weng J, Chen M, Wang J, Wang Z (2022) Electrochemical and thermal characteristics of aging lithium-ion cells after long-term cycling at abusive-temperature environments. Process Saf Environ Prot 159:1215–1223. https://doi.org/10.1016/j.psep.2022.01.055

Said AO, Lee C, Stoliarov SI (2020) Experimental investigation of cascading failure in 18650 lithium ion cell arrays: impact of cathode chemistry. J Power Sources 446:227347. https://doi.org/10.1016/j.jpowsour.2019.227347

Wang Z, Wang J (2020) An experimental investigation of the degradation and combustion behaviors associated with lithium ion batteries after different aging treatments. J Clean Prod 272:122708. https://doi.org/10.1016/j.jclepro.2020.122708

Liu X, Wu Z, Stoliarov SI, Denlinger M, Masias A, Snyder K (2016) Heat release during thermally-induced failure of a lithium ion battery: impact of cathode composition. Fire Saf J 85:10–22. https://doi.org/10.1016/j.firesaf.2016.08.001

Kimura A, Otsuka T (2013) Performance evaluation of differential accelerating rate calorimeter for the thermal runaway reaction of di-tert-butyl peroxide. J Therm Anal Calorim 113:1585–1591. https://doi.org/10.1007/s10973-013-3282-1

Galushkin NE, Yazvinskaya NN, Galushkin DN (2016) Thermal runaway as a new high-performance method of desorption of hydrogen from hydrides. Int J Hydrogen Energ 41:14813–14819. https://doi.org/10.1016/j.ijhydene.2016.07.050

Garcia A, Monsalve-Serrano J, Sari RL, Martinez-Boggio S (2022) Thermal runaway evaluation and thermal performance enhancement of a lithium-ion battery coupling cooling system and battery sub-models. Appl Therm Eng 202:117884. https://doi.org/10.1016/j.applthermaleng.2021.117884

Harrison J, Charles D, Zenker J, Frank E (2019) Using multi-physics system simulation to predict battery pack thermal performance and risk of thermal runaway during eVTOL aircraft operations. Aiaa/Ieee Electric Aircraft Technol Symp (Eats). https://doi.org/10.2514/6.2019-4406

Xie S, Ren LX, Gong YZ, Li MH, Chen XT (2020) Effect of charging/discharging rate on the thermal runaway characteristics of lithium-ion batteries in low pressure. J Electrochem Soc 167:140503. https://doi.org/10.1149/1945-7111/abbfd8

Jia Z, Huang Z, Zhai H, Qin P, Zhang Y, Li Y, Wang Q (2022) Experimental investigation on thermal runaway propagation of 18,650 lithium-ion battery modules with two cathode materials at low pressure. Energy. https://doi.org/10.1016/j.energy.2022.123925

Fu YY, Lu S, Shi L, Cheng XD, Zhang HP (2018) Ignition and combustion characteristics of lithium ion batteries under low atmospheric pressure. Energy 161:38–45. https://doi.org/10.1016/j.energy.2018.06.129

Chen MY, Liu JH, He YP, Yuen R, Wang J (2017) Study of the fire hazards of lithium-ion batteries at different pressures. Appl Therm Eng 125:1061–1074. https://doi.org/10.1016/j.applthermaleng.2017.06.131

Xie S, Sun J, Chen XT, He YH (2021) Thermal runaway behavior of lithium-ion batteries in different charging states under low pressure. Int J Energy Res 45:5795–5805. https://doi.org/10.1002/er.6200

Wang HB, Du ZM, Liu L, Zhang ZL, Hao JY, Wang QZ, Wang S (2020) Study on the thermal runaway and its propagation of lithium-ion batteries under low pressure. Fire Technol 56:2427–2440. https://doi.org/10.1007/s10694-020-00963-5

Huang ZH, Shen T, Jin KQ, Sun JH, Wang QS (2022) Heating power effect on the thermal runaway characteristics of large-format lithium ion battery with Li(Ni1/3Co1/3Mn1/3)O-2 as cathode. Energy 239:121885. https://doi.org/10.1016/j.energy.2021.121885

Bai JL, Wang ZR, Gao TF, Bai W, Wang JL (2021) Effect of mechanical extrusion force on thermal runaway of lithium-ion batteries caused by flat heating. J Power Sources 507:230305. https://doi.org/10.1016/j.jpowsour.2021.230305

Liu PJ, Li YQ, Mao BB, Chen M, Huang ZH, Wang QS (2021) Experimental study on thermal runaway and fire behaviors of large format lithium iron phosphate battery. Appl Therm Eng 192:116949. https://doi.org/10.1016/j.applthermaleng.2021.116949

Zhang L, Li YQ, Duan QL, Chen M, Xu JJ, Zhao CP, Sun JH, Wang QS (2020) Experimental study on the synergistic effect of gas extinguishing agents and water mist on suppressing lithium-ion battery fires. J Energy Storage 32:101801. https://doi.org/10.1016/j.est.2020.101801

Wang Z, Yang H, Li Y, Wang G, Wang J (2019) Thermal runaway and fire behaviors of large-scale lithium ion batteries with different heating methods. J Hazard Mater 379:120730. https://doi.org/10.1016/j.jhazmat.2019.06.007

Ping P, Kong DP, Zhang JQ, Wen RX, Wen J (2018) Characterization of behaviour and hazards of fire and deflagration for high-energy Li-ion cells by over-heating. J Power Sources 398:55–66. https://doi.org/10.1016/j.jpowsour.2018.07.044

Li KJ, Xu CS, Wang HB, Jin CY, Rui XY, Chen SQ, Feng XN, Fan LY, Ouyang MG (2022) Investigation for the effect of side plates on thermal runaway propagation characteristics in battery modules. Appl Therm Eng 201:117774. https://doi.org/10.1016/j.applthermaleng.2021.117774

Jiang ZY, Qu ZG, Zhang JF, Rao ZH (2020) Rapid prediction method for thermal runaway propagation in battery pack based on lumped thermal resistance network and electric circuit analogy. Appl Energy 268:115007. https://doi.org/10.1016/j.apenergy.2020.115007

Huang Z, Shen T, Jin K, Sun J, Wang Q (2022) Heating power effect on the thermal runaway characteristics of large-format lithium ion battery with Li(Ni1/3Co1/3Mn1/3)O2 as cathode. Energy 239:121885. https://doi.org/10.1016/j.energy.2021.121885

Feng XN, Sun J, Ouyang MG, Wang F, He XM, Lu LG, Peng HE (2015) Characterization of penetration induced thermal runaway propagation process within a large format lithium ion battery module. J Power Sources 275:261–273. https://doi.org/10.1016/j.jpowsour.2014.11.017

Zhang FS, Feng XN, Xu CS, Jiang FC, Ouyang MG (2022) Thermal runaway front in failure propagation of long-shape lithium-ion battery. Int J Heat Mass Transf 182:121928. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121928

Fu YY, Lu S, Li KY, Liu CC, Cheng XD, Zhang HP (2015) An experimental study on burning behaviors of 18650 lithium ion batteries using a cone calorimeter. J Power Sources 273:216–222. https://doi.org/10.1016/j.jpowsour.2014.09.039

Zou K, Li Q, Lu S (2022) An experimental study on thermal runaway and fire behavior of large-format LiNi0.8Co0.1Mn0.1O2 pouch power cell. J Energy Storage 49:104138. https://doi.org/10.1016/j.est.2022.104138

Wang Z, Ouyang D, Chen M, Wang X, Zhang Z, Wang J (2019) Fire behavior of lithium-ion battery with different states of charge induced by high incident heat fluxes. J Therm Anal Calorim 136:2239–2247. https://doi.org/10.1007/s10973-018-7899-y

Ouyang DX, Chen MY, Wang J (2019) Fire behaviors study on 18650 batteries pack using a cone-calorimeter. J Therm Anal Calorim 136:2281–2294. https://doi.org/10.1007/s10973-018-7891-6

Wang QS, Huang PF, Ping P, Du YL, Li K, Sun JH (2017) Combustion behavior of lithium iron phosphate battery induced by external heat radiation. J Loss Prevent Proc 49:961–969. https://doi.org/10.1016/j.jlp.2016.12.002

Mao BB, Chen HD, Cui ZX, Wu TQ, Wang QS (2018) Failure mechanism of the lithium ion battery during nail penetration. Int J Heat Mass Transf 122:1103–1115. https://doi.org/10.1016/j.ijheatmasstransfer.2018.02.036

Hu DZ, Chen G, Tian J, Li N, Chen L, Su YF, Song TL, Lu Y, Cao DY, Chen S, Wu F (2021) Unrevealing the effects of low temperature on cycling life of 21700-type cylindrical Li-ion batteries. J Energy Chem 60:104–110. https://doi.org/10.1016/j.jechem.2020.12.024

Qiu Y, Jiang F (2022) A review on passive and active strategies of enhancing the safety of lithium-ion batteries. Int J Heat Mass Transf 184. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122288

Ouyang D, Chen M, Huang Q, Weng J, Wang Z, Wang J (2019) A review on the thermal hazards of the lithium-ion battery and the corresponding countermeasures. Appl Sci Basel 9. https://doi.org/10.3390/app9122483

Chen S, Gao Z, Sun T (2021) Safety challenges and safety measures of Li-ion batteries. Energy Sci Eng 9:1647–1672. https://doi.org/10.1002/ese3.895

Chen HD, Buston JEH, Gill J, Howard D, Williams RCE, Vendra CMR, Shelke A, Wen JX (2020) An experimental study on thermal runaway characteristics of lithium-ion batteries with high specific energy and prediction of heat release rate. J Power Sources 472:228585. https://doi.org/10.1016/j.jpowsour.2020.228585

Quinn JB, Waldmann T, Richter K, Kasper M, Wohlfahrt-Mehrens M (2018) Energy density of cylindrical li-ion cells: a comparison of commercial 18650 to the 21700 cells. J Electrochem Soc 165:A3284–A3291. https://doi.org/10.1149/2.0281814jes

Girones A, Mateo A, Llanes L, Anglada M, DeLuccia J, Laird C (2003) Evaluation of fatigue damage for duplex stainless steels in aggressive environments by means of an electrochemical fatigue sensor (EFS). Int J Fatigue 25:1189–1194. https://doi.org/10.1016/S0142-1123(03)00119-1

Safizadeh F, Sorour N, Ghali E, Houlachi G (2018) Corrosion behavior of Fe-Mo and Fe-Mo-P cathodic coatings in the simulated electrolyte for sodium chlorate production. Electrochim Acta 269:340–349. https://doi.org/10.1016/j.electacta.2018.03.019

Dong P, Wang D, Yao Y, Li X, Zhang Y, Ru J, Ren T (2017) Stabilizing interface layer of LiNi0.5Co0.2Mn0.3O2 cathode materials under high voltage using p-toluenesulfonyl isocyanate as film forming additive. J Power Sources 344:111–118. https://doi.org/10.1016/j.jpowsour.2017.01.116

Delichatsios MA (1993) Transition from momentum to buoyancy-controlled turbulent jet diffusion flames and flame height relationships. Combust Flame 92:349–364. https://doi.org/10.1016/0010-2180(93)90148-V

Chen MY, Yuen R, Wang J (2017) An experimental study about the effect of arrangement on the fire behaviors of lithium-ion batteries. J Therm Anal Calorim 129:181–188. https://doi.org/10.1007/s10973-017-6158-y

Liu C, Huang Q, Zheng K, Qin J, Zhou D, Wang J (2020) Impact of lithium salts on the combustion characteristics of electrolyte under diverse pressures. Energies 13(20). https://doi.org/10.3390/en13205373

Qin J, Liu C, Huang Q (2020) Simulation on fire emergency evacuation in special subway station based on Pathfinder. Case Stud Therm Eng 21. https://doi.org/10.1016/j.csite.2020.100677

Liu C, Xu D, Weng J, Zhou S, Li W, Wan Y, Jiang S, Zhou D, Wang J, Huang Q (2020) Phase change materials application in battery thermal management system: a review. Materials (Basel) 13(20):1-. https://doi.org/10.3390/ma13204622

Huang Q, Glazier SL, Louli AJ, McArthur M, Liu C, Schrooten J, Dahn JR (2020) Effects of graphite heat-treatment temperature on single-crystal Li[Ni5Mn3CO2]O2/graphite pouch cells. J Electrochem Soc 167(8). https://doi.org/10.1149/1945-7111/ab9381

Xu D, Huang G, Guo L, Chen Y, Ding C, Liu C (2022) Enhancement of catalytic combustion and thermolysis for treating polyethylene plastic waste. Adv Compos Hybrid Mater 5:113–129. https://doi.org/10.1007/s42114-021-00317-x

Liu C, Zheng K, Zhou Y, Zhu K, Huang Q (2021) Experimental thermal hazard investigation of pressure and EC/PC/EMC mass ratio on electrolyte. Energies 14(9). https://doi.org/10.3390/en14092511

Funding

This work was financially supported by the Guangdong Basic and Applied Basic Research Foundation (2021B1515130008), the Open Project Program of the State Key Laboratory of Fire Science (No. HZ2020-KF01), Anhui Province Outstanding Young Talents Support Program (No.gxyqZD2022058), and the Project of Anhui Jianzhu University 2019 Talent Research Program under No. 2019QDZ21. The authors acknowledge the financial support of Taif University Researchers Supporting Project number (TURSP-2020/158), Taif University, Taif, Saudi Arabia, National Natural Science Foundation of China (No. 51906238), Natural Science Foundation of Shanxi Province (No. 20210302123017), Research Project Supported by Shanxi Scholarship Council of China (No. 2022-139), and Fund Program for the Scientific Activities of Selected Returned Overseas Professionals in Shanxi Province (No. 20220012).

Author information

Authors and Affiliations

Contributions

Chao Ding: formal analysis, writing—original draft. Nannan Zhu: data curation. Xuehui Wang: methodology, validation. A. Alhadhrami: visualization. M.H.H. Mahmoud: investigation. Mohamed M. Ibrahim: software. Que Huang: project administration, writing—review and editing. Changcheng Liu: supervision. Mina Huang: resources. Jian Wang: conceptualization, funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ding, C., Zhu, N., Wang, X. et al. Experimental study on the burning behaviors of 21700 lithium-ion batteries with high specific energy after different immersion duration. Adv Compos Hybrid Mater 5, 2575–2588 (2022). https://doi.org/10.1007/s42114-022-00536-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-022-00536-w