Abstract

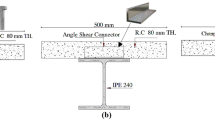

Poor quality of construction materials and ineffective design of structural members are primary reasons for fast deterioration of flexural capacity of existing steel reinforced cement concrete (RCC) beam. Beam strengthening methods are applied to prevent further distress in the existing structural element. This article presents the results of an experimental study on the performance of strengthened simply supported 1200 mm long rectangular low strength (low ultimate compressive strength) RCC beams tested in flexure under 4-point bending. The unstrengthened RCC beam (control beam, CB) has been strengthened in this study by attaching additional concrete layer at underside (tension side) of the existing CB. The additional cement concrete layer (FSM layer) is bonded to the existing bottom surface of the CB using epoxy adhesive and steel shear keys. The FSM concrete layer is longitudinally reinforced using steel rebar (FSM steel) to withstand bending stress. This method is regarded as far surface mounted (FSM) reinforcement for flexural strengthening of the existing RCC beam (Strengthened beam, SB). This research investigates the effectiveness of using the FSM technique by performing laboratory tests to observe the expected change in the flexural capacity, deflection and failure mode of the SB relative to the unstrengthened CB. This research also investigates the expected shear transfer between the CB bottom and the FSM concrete layer with consideration for the use of shear keys of different diameters as fasteners, and application of epoxy as a bonding material. The effect of using a 1200 mm long (equal to the length of CB) FSM steel of Ø12 mm in the 62.5 mm thick FSM concrete layer was examined in case A tests. Steel shear key of Ø10 mm and length of 150 mm was used in case A tests for increasing the bond between the CB bottom concrete and the FSM concrete layer. The length of steel shear keys used in the subsequent tests was kept the same. Epoxy and surface roughness at the interface of the CB bottom—FSM layer were used. The mid-span deflection and peak bending moment observed in the SB is compared with those observed in the CB. It is noted that the ratio of the measured deflections SB/CB when beam fails in case A is in the range of 0.4–0.6 and the ratio of peak bending moments SB/CB is in the range of 2.7–3.1. The effect of using a 1200 mm long FSM steel of Ø12 mm (greater than the FSM steel diameter in case A) was investigated in case B tests. Thickness of the FSM concrete layer was of 62.5 mm that is the same as the thickness of the FSM layer in case A. A steel shear key of Ø12 mm (greater than case A tests) and epoxy adhesive were used in case B tests. The ratio of the two deflections SB/CB for case B is 0.5 when beam fails. The ratio of peak bending moments SB/CB for case B is in the range of 2.9–3. The effect of position of the FSM steel in the FSM concrete layer was investigated in case C tests by first decreasing the thickness of the FSM layer from 62.5 mm (the same thickness as in case A) to 37.5 mm. In the next case D tests of the SB specimens, the thickness of the FSM concrete layer was increased from 62.5 mm (case A) to 82.5 mm. For both case C and D tests, the steel shear key of Ø8 mm (smaller diameter than case A, and case B) was used. Epoxy adhesive and the surface roughness were used in both cases. For case C, the ratio of the two observed deflections SB/CB is close to 0.6 when beam fails. The ratio of peak bending moments SB/CB in case C is in the range of 2.4–2.6. The ratio of the observed deflections SB/CB in case D is close to 0.5 when beam fails. The ratio of peak bending moments SB/CB in case D is in the range of 2.8–3.1. The effect of length of the FSM layer was investigated in case E and F tests using a reduced length of the FSM concrete layer. Like case A to D tests, no adhesives were used in case E and case F tests to investigate the variation in deflection and peak bending moment capacity values. For case F tests, the steel shear key of Ø12 mm was used. This diameter of steel shear key is the same as the diameter of shear key used in case B but higher than the diameter of shear key used in case E tests. In case E tests, length of the FSM concrete layer was 700 mm that is shorter than the 1200 mm long CB used in case A to D tests. In the next case F tests, length of the FSM concrete layer was further reduced to 350 mm. This length of the FSM layer is shorter than the 700 mm long FSM layer used in case E. In case F tests, diameter of the FSM steel was 10 mm. The FSM steel was placed in the 62.5 mm thick FSM concrete layer (the same thickness as in case A and case B). The observed SB/CB ratio for deflection in case E tests is in the range of 0.4–0.50. The maximum calculated SB/CB ratio for bending moment capacity in case E is 2.5 when peak moment arises. Debonding of FSM layer in case E was observed when the load carrying capacity of SB specimen was almost zero. The ratio of the two deflections SB/CB for case F is in the range of 0.5–0.6 when beam fails. The ratio of bending moments SB/CB in case F is in the range of 1.8–2.2 when the peak bending moment arises. The experimental results provide evidence that flexural capacity of the SB specimens in comparison with the control beams have increased while mid-span deflection of the SB specimens have decreased due to the increased initial stiffness of the SB specimens. Owing to the ease of the FSM method, and smaller deflection ratio with higher peak moment ratio the FSM method yields, the FSM method is preferred for strengthening the control beams.

Similar content being viewed by others

References

Abdzaid, H. M., & Kamonna, H. H. (2019). Flexural strengthening of continuous reinforced concrete beams with near-surface-mounted reinforcement. Practice Periodical on Structural Design and Construction, 24(3), 04019014. https://doi.org/10.1061/(ASCE)SC.1943-5576.0000428

Ahmed, K. S., Habib, M. A., & Asef, M. F. (2021b). Flexural response of stainless steel reinforced concrete beam. Structures, 34, 589–603.

Ahmed, K. S., & Riaz, M. (2017). Interface dependency of reinforced concrete jacketing for column strengthening. Mist International Journal of Science and Technology. https://doi.org/10.47981/j.mijst.05(01)2017.128(%p)

Ahmed, K. S., Shahjalal, M., Siddique, T. A., & Keng, A. K. (2021a). Bond strength of post-installed high strength deformed rebar in concrete. Case Studies in Construction Materials, 15, e00581.

Attari, N., Amziane, S., & Chemrouk, M. (2012). Flexural strengthening of concrete beams using CFRP, GFRP and hybrid FRP sheets. Construction and Building Materials, 37, 746–757. https://doi.org/10.1016/j.conbuildmat.2012.07.052

Badawi, M., & Soudki, K. (2009). Flexural strengthening of RC beams with prestressed NSM CFRP rods—Experimental and analytical investigation. Construction and Building Materials, 23(10), 3292–3300.

Bilotta, A., Ceroni, F., Nigro, E., & Pecce, M. (2015). Efficiency of CFRP NSM strips and EBR plates for flexural strengthening of RC beams and loading pattern influence. Composite Structures, 124, 163–175.

Blaschko, M. (2003). Bond behaviour of Cfrp strips glued into slits. Fibre-Reinforced Polymer Reinforcement for Concrete Structures (pp. 205–214). Bilfinger Berger AG, Department of Civil Engineering.

Darain, K. M. U., Jumaat, M. Z., Shukri, A. A., Obaydullah, M., Huda, M. N., Hosen, M. A., & Hoque, N. (2016). Strengthening of RC beams using externally bonded reinforcement combined with near-surface mounted technique. Polymers, 8(7), 261. Retrieved from https://www.mdpi.com/2073-4360/8/7/261

De Laura, L., & Antonio, N. (2002). Bond between near-surface mounted fiber-reinforced polymer rods and concrete in structural strengthening. ACI Structural Journal. https://doi.org/10.14359/11534

El-Hacha, R., & Gaafar, M. (2011). Flexural strengthening of reinforced concrete beams using prestressed, near-surface-mounted CFRP bars. PCI Journal, 56(4), 134–151.

Focacci, F., Nanni, A., & Bakis, C. E. (2000). Local bond-slip relationship for FRP reinforcement in concrete. Journal of Composites for Construction, 4(1), 24–31. https://doi.org/10.1061/(ASCE)1090-0268(2000)4:1(24)

Foraboschi, P. (2015). Analytical model to predict the lifetime of concrete members externally reinforced with FRP. Theoretical and Applied Fracture Mechanics, 75(2015), 137–145.

Foraboschi, P. (2022). Strengthening of reinforced concrete beams subjected to concentrated loads using externally bonded fiber composite materials. Materials, https://www.mdpi.com/1996-1944/15/6/2328

Imjai, T., Setkit, M., Garcia, R., & Figueiredo, F. P. (2020). Strengthening of damaged low strength concrete beams using PTMS or NSM techniques. Case Studies in Construction Materials, 13, e00403. https://doi.org/10.1016/j.cscm.2020.e00403

Khalifa, A. M. (2016). Flexural performance of RC beams strengthened with near surface mounted CFRP strips. Alexandria Engineering Journal, 55(2), 1497–1505. https://doi.org/10.1016/j.aej.2016.01.033

Ombres, L. (2011). Flexural analysis of reinforced concrete beams strengthened with a cement based high strength composite material. Composite Structures, 94(1), 143–155. https://doi.org/10.1016/j.compstruct.2011.07.008

Önal, M. M. (2014). Strengthening reinforced concrete beams with CFRP and GFRP. Advances in Materials Science and Engineering, 2014, 967964. https://doi.org/10.1155/2014/967964

Sharaky, I. A., Reda, R. M., Ghanem, M., Seleem, M. H., & Sallam, H. E. M. (2017). Experimental and numerical study of RC beams strengthened with bottom and side NSM GFRP bars having different end conditions. Construction and Building Materials, 149, 882–903. https://doi.org/10.1016/j.conbuildmat.2017.05.192

Sharaky, I. A., Torres, L., Comas, J., & Barris, C. (2014). Flexural response of reinforced concrete (RC) beams strengthened with near surface mounted (NSM) fibre reinforced polymer (FRP) bars. Composite Structures, 109, 8–22. https://doi.org/10.1016/j.compstruct.2013.10.051

Shariff, F. U., Anand, V. N., & Balaji, N. C. (2021). Flexural strengthening of RC beams using near surface mounted—Glass fiber reinforced polymer strips. AIP Conference Proceedings, 2327(1), 020014. https://doi.org/10.1063/5.0039665

Täljsten, B., Carolin, A., & Nordin, H. (2003). Concrete structures strengthened with near surface mounted reinforcement of CFRP. Advances in Structural Engineering, 6(3), 201–213. https://doi.org/10.1260/136943303322419223

Tetta, Z. C., Koutas, L. N., & Bournas, D. A. (2015). Textile-reinforced mortar (TRM) versus fiber-reinforced polymers (FRP) in shear strengthening of concrete beams. Composites Part b: Engineering, 77, 338–348. https://doi.org/10.1016/j.compositesb.2015.03.055

Vieira, M. M., Santosa, A. R. S., Mont’alvernel, M., Bezerral, M., & Montenegro, C. S. (2016). Experimental analysis of reinforced concrete beams strengthened in bending with carbon fiber reinforced polymer. IBRACON Structures and Materials Journal, 9(1), 123–152.

Funding

This research was fully funded through a Ministry of Education of Bangladesh Government Grant PS20191098.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Talukder, M.K., Haque, M.N. Experimental investigation of flexural capacity and deflection of low strength RCC beam strengthened with flexural steels and steel shear key. Asian J Civ Eng 24, 29–56 (2023). https://doi.org/10.1007/s42107-022-00484-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-022-00484-2