Abstract

According to fossil evidence, the Initial Upper Paleolithic (IUP) refers to archaeological assemblages associated with the early dispersal of Homo sapiens across Eurasia. These assemblages are often described as exhibiting a combination of Middle and Upper Paleolithic typo-technological features or, more broadly, as a technology in progression from the former to the latter. Genetic evidence indicates that as members of our species moved across Europe and Asia, they encountered Neanderthal, Denisovan, and possibly other local populations. At the Eurasian scale, the IUP shows considerable variation, but to what extent this corresponds to a relatively unified cultural package strictly associated with our species, or a suite of unrelated technologies reflecting the complex dynamics of a global population turnover, remains unclear. Like most archaeological assemblages, however, the IUP illustrates a combination of adaptive and normative behaviors, along with some stochastic variation. Here, we investigate what drives typo-technological variation within an IUP assemblage to identify traits relevant for larger scale inter-regional comparisons. Specifically, we describe a lithic assemblage dated to ca. 45 ka cal BP from the site of Tolbor-16 in northern Mongolia. We identify three defining aspects of the IUP at the site, namely variation in core shape and size, patterns of blade core reduction, and the presence of Middle Paleolithic typo-technological features. Our goal is to clarify the influence of dynamic reduction processes on assemblage composition and, within the variation observed, to identify typo-technological features that are relevant for inter-regional comparisons and scenarios of population dispersal.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

By the Early Upper Paleolithic (EUP), a new set of behaviors is widely documented among the representatives of our species in Eurasia (Bar-Yosef, 2007; Conard & Bolus, 2003; D’Errico et al., 1998; Kozlowski & Otte, 2000; Le Brun-Ricalens & Bordes, 2007; Mellars, 2006; Nigst et al., 2014; Teyssandier et al., 2010; Tsanova et al., 2012). The pivotal period that precedes this definite shift in the archaeological record, however, documents not only Homo sapiens dispersals but also the replacement of Neanderthals, Denisovans, or other unknown human taxa at a continental scale (e.g., Higham et al., 2014). By contrast, assemblages clustered unevenly in Eurasia show a mosaic of derived and archaic behavioral traits. In most cases, the taxonomic identity of the human groups behind the different “traditions” is unclear, and the combination of Middle (MP) and Upper Paleolithic (UP) traits is often interpreted as a local “transition” (Hublin, 2015). Conceptually, the Initial Upper Paleolithic (IUP) is an alternative to the label “transitional” as it does not necessarily imply a progressive, regional emergence of derived UP traits and is consistent with scenarios of H. sapiens population movements (Kuhn, 2003). Rather, the IUP could also represent a cultural phenomenon on its own, with the possibility of contact between IUP populations and other human taxa (Greenbaum et al., 2019). When integrating the notion of IUP into complex scenarios laid out by fossil and genetic analyses, conceptual challenges meet descriptive ones, and identifying relevant features to discriminate between local transitions, contact between populations, or large-scale demic dispersals is still a work in progress (Kuhn & Zwyns, 2014).

Originally, changes observed in lithic techno-typology defined the IUP (Marks & Ferring, 1988). At Boker Tachtit, in the Negev, Marks & Volkman (1983) recognized a form of continuity across layers 1–4, dated between 50 and 44.3 ka cal BP (Boaretto et al., 2021). Volkman (1983) nonetheless described a technological shift from bidirectional toward unidirectional blade production and the disappearance of specific tool types such as the Emireh point. The outcome of such a shift (layer 4) was labelled as IUP to signal the beginning of the Upper Paleolithic (Marks, 1990). Later, Kuhn and colleagues (Kuhn et al., 1999, 2001) extended the definition to southwest Asian assemblages showing combinations of MP and UP typo-technological features, such as Levallois types and volumetric blade production. To the west, it would extend to central Europe with Bohunician assemblages based on their overall similarities with the Emiran (from the lower levels at Boker Tachtit) (Hoffecker, 2009; Hublin, 2012; Svoboda, 2001; Tostevin, 2000). Today, the definition of the IUP has grown even larger and includes any assemblages showing formal bone tool production, ornaments, H. sapiens remains, or lithics exhibiting MP/UP features and dated to before 40 ka or predating the local EUP. The case of the Bachokirian is of particular interest. Discovered in Bulgaria, it was successively described as a possible origin for the Aurignacian (Kozlowski & Otte, 2000), as an MP assemblage (Teyssandier, 2003, 2007; Tsanova, 2006; Tsanova & Bordes, 2003), before being dated to 45–42 ka cal BP and re-assigned again to the IUP (Fewlass et al., 2020; Hublin et al., 2020; Martisius et al., 2022; Pederzani et al., 2021; Smith et al., 2021). In addition, associated human remains from several individuals at Bacho-Kiro yielded Homo sapiens aDNA sequences with recent Neanderthal ancestors that have no identified descendants in western Eurasia but do have descendants in the east Asia (Hajdinjak et al., 2021). It is also worth noting that in western Eurasia, other coeval techno-complexes that do not fit the conservative definitions of IUP are or could be associated with early movements of Homo sapiens populations (e.g., Slimak et al., Mylopotamitaki et al., 2024). Asian IUP sites along the steppe belt, once considered evidence for local transitions (e.g., Derevianko & Volkov, 2004; Derevianko, 2010), are now contemporaneous with early Homo sapiens fossil evidence in the region (Fu et al., 2014). The latter testify to movements of populations across Eurasia that are coeval with age estimates for a Denisovan introgression event into our lineage ca. 47–45 ka (Huerta-Sánchez et al., 2014; Zhang et al., 2018, 2021, 2022). Although direct associations between archaeological assemblages and human fossils or sediment aDNA are lacking (e.g., Kot et al., 2022), the Asian IUP is consistent with scenarios of modern human dispersal eastward into Siberia, Mongolia, and even North China (Barzilai, 2022; Brantingham et al., 2001; Li et al., 2019; Madsen et al., 2014; Rybin et al., 2023; Shichi et al., 2023; Zwyns, 2012, 2021).

From this summary come three main observations. First, core reduction patterns and MP typo-technological features were instrumental in differentiating the IUP from what precedes and what follows. Second, understanding the IUP sensu lato means considering complex scenarios of human dispersals and encounters between human species. Third, it is unclear whether the IUP as we know it represents a cultural link between assemblages, if it is the result of convergences or complex interactions between human fossil species or a combination of these mechanisms (Kuhn & Zwyns, 2014; Goder-Goldberger & Malinsky-Buller, 2022). Without a better understanding of what causes variations within (Li et al., 2020) and between assemblages (Kuhn & Zwyns, 2018), “variability” alone does not support nor does it invalidate any of the proposed scenarios.

Research Questions

Given that variability (or the lack thereof) within and between assemblages is instrumental for different scenarios of dispersal, transition, and contacts between hominins, it seems necessary to explore where it comes from and what may generate typo-technological variations. Central to these questions is what Dunnell (1978) framed as the style/function dichotomy. Because these two notions often coexist within a given object, or trait (Sackett, 1977, 1986), they are considered here as the two ends of a spectrum (Bettinger et al., 1996). The more functional the traits, the more they are indicative of adaptive processes—hence increasing the possibility of convergence (analogies). Conversely, features that are more neutral may reflect social norms and indicate population history (homologies) (Kuhn & Zwyns, 2014). Here, we deliberately focus on three specific aspects of assemblage composition that are foundational to the concept of IUP and highlight variation relevant to large-scale comparisons:

-

Variation in core size, shape, and method of reduction: Levallois types or technology, volumetric blade productions, and, in some cases, small blades/bladelets are among the many key features coexisting in the IUP (e.g., Kuhn & Zwyns, 2014; Kuhn et al., 1999; Leder, 2016; Li et al., 2020; Odsuren et al., 2023; Peng et al., 2014; Rybin & Khatsenovich, 2018; Slavinsky et al., 2016; Volkman, 1983; Goder-Goldberger, et al., 2023; Kadowaki et al., 2021). This is sometimes interpreted as a form of complexity (Perreault et al., 2013), or as reflecting an intermediate taxonomic position between MP and UP (Brantingham et al., 2001, 2004; Derevianko et al., 2000; Goebel, 1999; Goebel et al., 1993; Kuhn et al., 1999). The shift toward small laminar elements, or more broadly “miniaturization,” is considered an evolutionary trend or a punctual adaptation (Elston & Kuhn, 2002; Režek et al., 2018). Either way, these features underline the need for a better understanding of what drives core reduction modalities beyond the use of core typologies. At Boker Tachtit, cores vary from the treatment of surfaces to volumes (Goder-Goldberger et al., 2023). Based on refitted sequences, Volkman (1983) notes, however, that discarded core types may be misleading because their morphology merely illustrates the end of a long reduction process. In the Middle Paleolithic, shifts in reduction methods during core reduction are well documented in various instances (e.g., Baumler, 1988; Di Modica & Bonjean, 2006; Dibble, 1995). The so-called “Frison effect” is one way to explore variation in core shape within and between assemblages (Frison, 1968; Jelinek, 1976) as reflecting functional constraints. According to Dibble (1995), there are reasons to question the assumption that core shapes/types represent distinct, unvarying, and normative strategies of core reduction. Hence, the question: are variations in IUP core types representative of specific, independent reduction sequences coexisting in the assemblage (e.g., “mental template”); or alternatively, do they reflect adaptive choices in a continuum of reduction?

-

Bidirectional blade reduction: Unidirectional and bidirectional blade reduction strategies (namely the use of a single, or two opposed striking platforms) are often presented as different core reduction strategies, corresponding to different core shapes and producing blades that are somewhat distinct. As described above, the original definition of IUP stems from a gradual shift from bi- to unidirectional reduction patterns (Barzilai, 2022; Marks, 1990; Marks & Volkman, 1983; Volkman, 1983), while in the IUP of Central and East Asia, bidirectional blade production is among the most common features identified in IUP contexts (Li et al., 2020; Odsuren et al., 2023; Rybin, 2004; Slavinsky et al., 2016; Zwyns, 2012). Two additional characteristics are often recognized, namely the large size and the Levallois characteristics (i.e., convergent dorsal pattern) of some of the blades. While it is commonly accepted that size is a contingency of raw material availability/transport and that Levallois blanks can be obtained by non-Levallois technologies, in what sense core reduction is “bidirectional” is far less clear. As for core shape, one can imagine core rotations in economic terms (increasing core productivity) (Dibble, 1995), instead of an independent and distinct reduction system (Boëda, 1988). Hence, we formulate the following question: in IUP assemblages, is bidirectional flaking a way to optimize blank productivity per core, does it serve another functional purpose (such as obtaining a specific type of blank), or is it a normative choice?

-

Typological variation and transitional status: A combination of MP and UP traits typically characterizes the tool inventory of many IUP sites and is foundational to the concept of the IUP (Barzilai, 2022; Kuhn, 2003; Marks & Ferring, 1988; Rybin, 2014). It is therefore essential to clarify what typological “transitional” traits are and what they mean at the assemblage level. Does the occurrence of MP tool types in IUP assemblages reflect an economic strategy, archaic features inherited from a recent ancestor, and/or contacts with other human groups? What constitutes relevant similarities (or differences) pertaining to the recognition of the IUP is key to drawing evolutionary interpretations between assemblages (Kuhn & Zwyns, 2014, 2018; Zwyns, 2021).

Overall, the research questions highlighted above aim at exploring intra-assemblage variability in a dynamic way that extends beyond typo-technological classification. We consider that processes of core reduction, flaking patterns, and plesiomorphic typological features may lean toward either end of a functional/neutral gradient. Their position on that spectrum will determine how informative they are in evaluating assemblage relatedness. This approach is used to formulate hypotheses and predictions before looking at the material of Tolbor-16, while also using examples from the Gorny-Altai and the Transbaikal.

Material

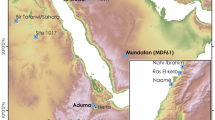

The material described here is from Tolbor-16 (AH6—see below). Although part of the assemblage description is already published elsewhere (Zwyns et al., 2019—Supplementary information 5), we present here a holistic analysis of the assemblage integrating published and unpublished descriptions to address specific questions. Additional material from Kamenka A-C, in the Transbaikal (Lbova, 2000; Zwyns & Lbova, 2019), and Kara-Bom OH5-OH6, in the Altai (Derevianko et al., 1998; Zwyns, 2012), is used for comparative purposes (Fig. 1).

Map of the main IUP sites identified between the Gorny-Altai and Mongolia. 1, Luotuoshi; 2, Ush-Bulak; 3, Malo Yaloman, Cave; 4, Kara-Bom, 5, Ust-Karakol-1 and Denisova Cave; 6, Kara-Tenesh; 7, Derbina sites; 8, Arembovski; 9, Makarovo IV; 10, Khotyk; 11, Barun-Alan sites; 12, Kamenka and Varvarina Gora; 13, Tolbaga; 14, Podzvonkaya; 15, Egiin-Gol sites (Dörölj 1–2); 16, Tolbor-16 and Tolbor-4; 17, Tsatsyn Ereg; 18, Mojlt’yn-Am; 19, Chiken sites; 20, Tsagan-Agui; 21, Shuiddonggou 1; 22, Khanzat-1; 23, Khavsgayt (and Salkhit); 24, Rashaan Khad; 25, Otson Tsokhio; Geo-atlas background map

Site Location and Environmental Setting

Tolbor-16 (N 49° 13′ 621″; E 102° 55′ 381″) is an archaeological site located in the Northern Hangai, along the western flank of the Tolbor valley (Ikh-Tulbuurin-Gol, 1154 m asl). It takes part in a rich concentration of Paleolithic sites found along the valley flanks of the Selenge tributaries. Surrounded by forest-steppe landscapes, it lies at the junction between a deep rill coming down from the Shar Khad Mountain and the valley’s open grassland (Fig. 2A). The rill activates during snowmelt and heavy rain, eroding Pleistocene deposits and exposing Paleolithic stone artifacts. It was tested in 2010 and recognized as a potential stratified site based on two 2 × 1 m test pits (named here Pit 1 and Pit 2) along the current slope and separated by 35 m (Fig. 2D, E).

A Location of Tolbor-16 site. B Contours of Pit 1. C Southwest corner of Pit 1, with stratigraphic drawing overlay. Solifluction lobes are color-codded, and AH6 is in the lowest lobe (unit 3c—green). In Pit 1, material from AH6 is partly redeposited in AH5 (unit 3b—brown). D Position of the main excavation pits along the slope, in cross-section, and in plan. E Contour of Pit 4. F 1-m projection of all piece-plotted lithic artifacts (> 2 cm) on the North Wall. The sample from AH6 is in red. G 3D projection of the AH6 sample and stratigraphic drawing overlay, from Agisoft Photoscan with projections from NewPlot (McPherron & Dibble, 2002) and MeshLab; drawings by C. H. Paine)

Pit 1 revealed an artifact concentration between approximately 1.70 and 2.00 m from the ground surface (Gladyshev et al., 2013). Between 2011 and 2016, 12 m2 was excavated bringing the total surface to 14 m2 (Fig. 2A) (Zwyns et al., 2014, 2019). Six archaeological horizons (AH) are identified within three lithological units (see below). The material associated with Archaeological Horizon 6 (AH6) belongs to the lowest concentration, but solifluction brought artifacts probably originating from the same layers into AH5 (and maybe AH4). Pit 4 was first opened in 2013 with a trench of 4 × 1 m located upslope, along a meander, and it was extended to a surface of 15 m2 in 2014. No archaeological material was found below AH6 after further testing the erosional surface of the meander below Pit 4 and testing below the lowest concentration in Pit 1 (Fig. 2E).

The material was collected with the help of a total station, EDM CE, and New-Plot GIS software to geoposition artifacts bigger than 2 cm in length and, when possible, to measure the orientation and inclination of their long axis (McPherron & Dibble, 2002). The station was set up to have a maximum of 5 mm error relative to reference points located > 3 m outside of the excavation area. Within lithological units, we excavated sediments by arbitrary spits of ca. 5-cm thickness and dry-sieved using a 4- and 2-mm mesh (for more details, see Zwyns et al., 2019).

Stratigraphy and Chronology

At T16, unit 1 corresponds to the Holocene soil complex and includes one or more chernozem or kastanozem-type soils. Unit 2 is a layer of loess and reworked loess that sits on the top of unit 3, a soliflucted diamict of laminar silt with gravel and cobbles. The material presented here as IUP is from AH6, the lowermost of the identified horizons, which occur within unit 3 (Zwyns et al., 2019). Sedimentologically, stratigraphically, and chronologically, the sequences at Pits 1 and 4 correlate well (Fig. 2C, G). In both pits, the IUP deposits are housed within a laminar silt (called unit 3c, color-coded green) subjected post-depositionally to at least one episode of solifluction. This is overlain by another laminar silt with abundant cobbles (called unit 3b, color-coded yellow–brown) which contains AH5 Early Upper Paleolithic material. This laminar silt was likewise subjected to a post-depositional episode of solifluction which, based on the archaeology within it, may in places have involved the uppermost part of the underlying AH6 as well as AH5. Overlying this in both pits (albeit only in a few small patches in Pit 4) is a gravelly silt with a less distinctly laminar character than the underlying units (color-coded blue), likewise subjected to an episode of post-depositional solifluction.

Polymineral post-IR IRSL, quartz OSL, and radiocarbon dates were used to date the deposits and archaeology. Luminescence dates obtained on samples collected from Pits 1, 2, and 3 provided a chronological framework for sediment deposition, while measurements obtained on both quartz and polymineral (feldspar-dominated) fine-grained aliquots provide independent age control. Bones are rarely preserved but their distribution tightly coincides with the archaeological occupations, and samples from cultural layers AH2 through AH6 in Pits 1 and 4 were collected for radiocarbon dates. The results indicate that the human occupation at T16 took place during the Late Pleistocene, during marine oxygen isotope stage (MIS) 3 and MIS2. AH2 is assigned to MIS2 while AH3 and AH5 date between 35.1 and 38.5 ka. The IUP material from AH6 is dated to 42.5–45.6 ka cal BP by radiocarbon (Zwyns et al., 2019).

Methods

Sampling Procedure

Geological evidence points to low-energy deposition, but post-depositional processes may still have impacted the site’s stratigraphy. Deflation or slopewash could potentially have depleted fine matrix material from archaeological horizons, resulting in time-averaging issues or palimpsests (although there is no specific evidence to suggest this), and in a scenario where successive occupations are not well stratified, localized mixing of AH is possible, even without active solifluction, as erosion and gravity work to level the undulating soliflucted surface. Here, we specifically sampled lithic material coming from solifluction lobe 3c attributed to AH6 (Zwyns et al., 2019). Hence, the material presented here derives from a surface of 15 m2 in the lowest archaeological deposit. The upper limit of lobe 3c has been drawn arbitrarily based on field observations and projections of piece-plotted artifacts (< 2 cm) on a 3D model of Pit 4. Figure 2F and G illustrate the distribution of the AH6 and the distribution of AH1-AH5. Bone distribution is in close association with artifacts from AH6 and the sediment bulk samples (Zwyns et al., 2019). While this sampling strategy does not guarantee 100% integrity, it minimizes the risk of including intrusive material in the analysis.

Material Description

The sample (Table 1) is first described in detail and the terminology used for the description is standard (Boëda, 1995; Inizan et al., 1995; Pelegrin, 1995; Pigeot, 1987; Tixier, 1963). A sub-sample including all the cores described here and a selection of blanks, flakes, and tools was 3D-scanned using Einscan-SE and the associated software EXscan 3.1.0.1. All cores were scanned 4 to 6 times using a turntable, with 16 stops, while blanks, flakes, and tools were scanned using 8 stops. The automatic alignment was based on salient features, and the mesh was built watertight and in high definition. Meshlab software was used for rendering and snapshots. Volumes and surfaces were calculated in EXscan based on measures from the models, while quantitative and qualitative attributes were collected using an E4-Microsoft Access database and digital calipers and following the protocols described elsewhere (Zwyns & Lbova, 2019). Core fragments or hypothetical preforms are not included in the volume analyses. The quantitative data is described with the help of standard univariate statistics and non-parametric tests (the significance threshold adopted is 0.05, before the Bonferroni correction).

Addressing Research Questions

Specific analyses are put forward to address the questions listed above. In addition, the results of these analyses on material from Pit 1 and Pit 4 are summarized in a comprehensive model based on the concept of the reduction sequences (Bar-Yosef & Van Peer, 2009; Boëda, 1995; Boëda et al., 1990; Geneste, 1985; Pelegrin, 1995; Schlanger & Sinclair, 1990; Sellet, 1993).

-

Question 1—Are variations in core type representative of specific, independent reduction sequences coexisting in the assemblage (e.g., “mental template”); or alternatively, do they reflect situational choices in a continuum of reduction?

Because shape categories are partly defined based on size, using linear measurements to address this question would lead to circular reasoning. Instead, core volume is used as a unit under the simplifying assumptions that equal raw material volume is available for all core categories and that larger volumes are preferred. The first assumption is acceptable given the raw material abundance in the valley, and the second assumption is plausible for all shape categories except for Mode B (core on blades). Identified as ad hoc as part of a branching/recycling reduction sequence, the latter should have smaller volumes than cores reduced from nodules, cobbles, or slabs. Therefore, Mode B cores are used here as a control sample. We set basic predictions for two arbitrary models. The first one implied that the main core categories correspond to distinct reduction sequences, starting from raw material collection to exhaustion, and would result in an overlap in terms of volume distribution across the board. The second implied that shapes reflect different stages of exhaustion in a single sequence, which would lead to a monotonic decrease in volumes across categories.

-

Question 2—Is bidirectional flaking a way to optimize blank productivity per core, does it serve another functional purpose (such as obtaining a specific type of blank), or is it a normative choice?

Bidirectional flaking is addressed by comparing the width and thickness of blades grouped per dorsal pattern (uni- or bidirectional). The basic assumptions are that cores started with a similar size; the sample of blades available is representative of the range of sizes originally produced, and length, width, and thickness of blades are dependent variables. Predictions are that if bidirectional flaking is a strategy to increase productivity (number of blades per core), we expect that unidirectional blades would be larger on average than the bidirectional ones. Given the rate of fragmentation, we compare width and thickness instead of length, because they are dependent variables. In addition, we controlled for the effect of fragmentation on the recognition of bidirectional scars, platform preparation, degree of edge convergence, and retouch per scar pattern.

-

Question 3—Does the occurrence of MP tool types reflect an economic strategy, archaic features inherited from a recent ancestor, and/or contacts with other human groups?

To address the issue of MP tool types, we provide a qualitative assessment of the type of blanks on which they are produced. We compare this with the overall debitage to identify specific production sequences, curation, and/or recycling processes.

Material Description

Raw Material

The lithic assemblage is mainly produced on a medium to fine grain, local, cryptocrystalline raw material for which the primary sources occur, in the whole valley, as sub-vertical up-lifted bands. Although the raw material has been described as sedimentary rocks (e.g., mudstone), the stratigraphic position of the outcrop, sandwiched between basaltic layers, suggests that at least part of the material studied is better described as effusive (or metamorphic) rocks. Secondary sources consist of nodules distributed along the streams and canyons around the site or are currently buried under the alluvial deposits of the Tolbor River. Based on the examination of the cortex preserved, it seems that a substantial part of the raw material was collected in secondary deposits. Although the use of fine grain chert, flint, or jasper-like material possibly exotic to the valley is reported during the later phases of the Upper Paleolithic, it is absent in the coarse fraction of the AH6 sample (> 2 cm) and extremely rare in the screen.

A light blue patina, semi-extensive with root-like patterns, alters most of the archaeological material. Seventy-nine percent of the blades (N = 165) and 80% of the flakes (N = 125) show calcium-carbonate concretions on one and more rarely (4% and 11% respectively) on both faces.

Cores and Preforms

Two main categories of cores can be distinguished based on the type of material used: Mode A (N = 26) refers to cores on blocks, slabs, and nodules (or possibly massive flakes—although this could not be observed) and Mode B groups cores on blades (N = 8).

Mode A cores have in common the frequent use of two opposed platforms, a relatively broad flaking surface extending on at least a broad and a narrow face as opposed to a flat back. The latter is often shaped by the removal of large flakes, perpendicular to the axis of the main flaking surface. Three main groups can be identified based on overall shapes: prismatic, ogival/cuboid, and cubic cores (Fig. 3). A little overlap between shape categories is observed, suggesting the occurrence of intermediate shapes and relatively loose boundaries between shape categories.

Core shape variations. Scatter plots comparing the length/thickness and width/thickness ratios (Eerkens & de Voogt, 2022). Length and thickness are measured as the longest and shortest sides. The x axis represents the ratio of length to thickness (L:T), with low L:T indicating a shorter, thicker shape and a high L:T indicating a longer, thinner shape. The y axes represent the same calculation but use width in place of length. The two axes-axis meet where the ratio is 1:1, in other words where a hypothetical cube-shaped artifact would plot. Complex hulls show the shape categories; prismatic (1), cuboid/ogival (2), cubic (3), burin-core (4); the two cubic blade cores (5) and a sample of three prismatic bladelet cores from the EUP in Pit 1, as a comparative sample (6)

Prismatic cores (N = 8) (Fig. 4; SI1) are bidirectional blade cores that are exploited from a main flaking surface that extends from a narrow to a broad face, following a frontal or semi-turning progression. A back-and-forth motion between the two surfaces means that the reduction is mostly taking place at the intersection between two planes. One of the flanks often shows blade removals while the other still bears cortex, a postero-lateral crest, or orthogonal removals giving the core an asymmetrical cross-section. Although most examples are reduced from two opposed platforms, one is often larger than the other. It suggests differences in functions between the two and/or successive phases of reduction. The backs of the core are flat, cortical, or prepared by the removal of large flakes. There is no median posterior crest, because its position is shifted toward one of the flanks, opposite to the flaking surface (cfr. the postero-lateral crest mentioned above). As a management of lateral convexities, it points toward the intersection between two surfaces as part of the core-producing blades.

Cuboid/ogivals (N = 9) (Fig. 5; SI2) are elongated narrow blade cores that have been reduced on at least 3 of their four faces, often leaving the back as the only surface that has not produced blades. Following Volkman’s terminology (1983), the cores show a “spin” of two opposed striking platforms (moving side-to-side, from broad to narrow face) by also a “tumble” of the core (moving end-to-end, with platform and flaking surfaces moving in the opposite direction). Essentially, they follow the same reduction principles as the prismatic ones but in a more extensive fashion. Two successive phases of asymmetrical reduction take place, and the volume is reduced in its thickness more than its length. What remains at the end of the process is an elongated “stick-shape” core, often preserving a striking platform larger than the other, but also an angle between the striking platform and the flaking surface that is still suitable for flaking purposes and points toward the last phase of reduction.

Cubics (N = 8) (Fig. 6; SI3) show more variability in the treatment of flaking surfaces than the other categories and they are shorter. Based on their last observable removals, some of the cubic cores could be characterized as flake cores, but when a main flaking surface is still identifiable, the conception is clearly volumetric, and the general reduction pattern is asymmetrical or semi-turning. Just like other blade cores, they may preserve cortex on one of their narrow faces, even when showing evidence of frequent core rotations. None of the specimens observed are clear examples of hierarchical surface conception, such as observed in the Levallois method, nor do they show any resemblance with an alternate/discoid pattern. Instead, debordant flakes are used to maintain lateral convexities and the flaking takes place from two opposed platforms at once, on the same flaking surface.

Two cubic cores (one from each pit) (Fig. 7 (1, 2)) show a more intensive use of a broad face as a flaking surface, a morphology often described as “flat-faced cores,” and produced blades until discarded. The remaining length of the flaking surface, the number of scars, and the lack of cortex point toward a relatively advanced stage of reduction.

Numbers 1 and 2 are Mode A cubic cores with blade removals (aka. “flat-faced cores”); number 1 is from Pit 1 AH5; 2 is from Pit 4 AH6. Mode B cores. 1, 3, burin-core with bidirectional longitudinal removals along one edge; 2, burin-core with removals along both edges; 4, 5 burin-cores in the early stages of reduction (note the setup of two opposed platforms); 6, truncated-facetted, burin-core wit asymmetrical cross-section. All Mode B cores are from Pit 4 AH6, except for number 8 that comes from Pit 1 AH6

Mode B cores are blades (N = 8) (Fig. 7 (3–9); SI4), or laminar flake blanks, that are turned into volumetric cores producing small blades and bladelets. From burin-cores, small blades/bladelets are detached from one or two opposed platforms, following the longest axis of a thick blade segment (> 10 mm) (Zwyns et al., 2012). Depending on their degree of reduction, such artifacts fall into different burin types (burin on truncation, dihedral, or polyhedral). One is flaked on the dorsal face of the blade (truncated-faceted), and another shows a flaking surface extending from the narrow to the dorsal face, like on Mode A cores. Classic burin-cores show combinations of striking platform preparations, with one shaped by lateral removal perpendicular to the blade, as opposed to another one prepared by a truncation. Just like for the larger cores, there seems to be an alternating use of the platforms, with one remaining larger than the other at the time of discard.

To summarize, two main categories of core are identified depending on whether they are reduced from raw material nodules (Mode A) or if they are re-knapped thick blades (Mode B). In the former mode, different types are distinguished based on core shapes, though they share the same kind of asymmetrical reduction patterns (Fig. 8). Whether these categories represent distinct, independent reduction sequences, or different steps in a single core reduction process, is discussed below. With the latter, core variants overlap with tool types, such as burins (on breakage, truncation, dihedral, or polyhedral) or truncated-facetted pieces. The burin-cores derive from a recycling of technical blades coming from the blade production processes.

Simplified core reduction pattern. 1, ACR from the Asian IUP (adapted from Boëda’s Roc-de-Combe type) (Boëda, 1990), blades are removed between two surfaces. (A, E) Axis of core reduction. (B) Motion around the flaking surface. (C)Technical flakes (debordant) for the management of lateral convexities. (D) Core geometry. (F) Crest. (G) Posterior crest. (H) Intersection between two surfaces. 2, two ACR phases on one core (cuboid-ogival configuration); 3, prismatic core; 4, cuboid-ogival core; 5, cubic core; burin-core (frontal reduction pattern)

Blade Blanks and Retouched Blades

Fragmentation

The frequency of unretouched flakes and blades is relatively even, with blades slightly more represented (N = 173; 53%) (Table 2). Considering the minimum number of individuals (sum of platform blanks) or including the fragments, retouched blades represent about a third of all blades (N = 38, 36%; N = 83, 32%, respectively). To evaluate the number of blades per core, we divided the sum of the core and preforms by the number of retouched and unretouched blade blanks. A ratio of 15 blades per core derives from the whole sample, but it drops to a ratio of 5/blades per core when considering the MNIs for blades and blade tools—reflecting the fact that over 90% of blades are fragments. Naturally, these numbers may also reflect the import/export of artifacts in the excavated area. Retouched flake frequencies are generally low (N = 32; 36%), but they rise in the MNI (N = 21; 65%). This, along with the observation that most of the flakes are proximal fragments and complete flakes (N = 74; 88%), suggests a visibility bias when differentiating flake fragments from lithic shatter. In addition to the Mode B cores described above, numerous blade fragments show impact points, chipping, and flexion fractures on the snapped surface (Fig. 9). We also find numerous blade segments like those described by Slavinski and colleagues (2019) in the Siberian Altai. Considered a whole, the sample shows a high fragmentation rate that may reflect trampling (or other post-depositional processes) and/or intentional snapping procedures.

Pit 4 AH6. Blade fragments showing features consistent with an intentional fragmentation. 1, 2, and 5 show impact points on breakage planes; 1, 3, and 4 are “butterfly-like” fragments as described by Slavinsky et al. (2019); 2 and 5 show notches near the breakage plane

Length, Width, and Thickness

With only 22 complete blades, the length of the blades shows a relatively similar distribution for retouched and unretouched specimens, and the whole set ranges between 35 and about 130 mm (Table 3). Unretouched blades show double the variance observed in retouched blades. Complete flakes range between 15 and 66 mm in length. Blade width distribution is unimodal. While retouched blades are significantly wider than unretouched ones (U = 5060, p = 0.00013) (Figs. 10 and 15A), they also show less variation. The coefficient of variation is 41.4 and 29.1 respectively, and the Fligner-Killeen test suggests that the difference is statistically significant (T = 46.736, E(T) = 80.433, z = − 3.3871, p = 0.00035). Flakes show a smaller difference between the retouched and unretouched categories, showing that larger flakes are more likely to be retouched. The same observations are made on the thickness, and retouched blades are significantly thicker and more standardized than unretouched ones. These differences are reduced but still hold when comparing MNIs.

Dorsal Pattern

The blade dorsal faces include both unidirectional and bidirectional patterns (Table 4; Figs. 11 and 12). The numerous undetermined specimens reflect how fragmentation affects the recognition of bidirectional dorsal patterns, while differences between MNI and the whole sample suggest that bidirectional blades are usually more numerous among fragments. Essentially, the coexistence of bi- and unidirectional blades suggests a core reduction involving two opposed platforms and alternate short sequences of flaking. When the whole sample is considered, bidirectional blades are well represented among the retouched tools. The situation changes when we look at the MNI where unidirectional blades dominate both in retouched and unretouched categories. It shows that the recognition of bidirectional dorsal pattern is affected by the high rate of fragmentation and/or that proximal fragments tend to show less evidence of bidirectional dorsal scars.

Assuming that they are not all imported, the good representation of crested blades reflects the intensity of core reduction at the site. The lack of initial crests and core preparation flakes and the good representation of second crests suggest the import of semi-prepared cores from an unknown distance (arguably, the initial flaking could occur not further than a few meters away). This corroborates the low frequency of primary or secondary cortex on both blade and flake blanks. Notable is the occurrence of small size crests (close to the 12 mm width cut-off), linked with the production of small blades/bladelet, and blades or laminar flakes with orthogonal removals on one side. Morphologically, the latter are like second/third crests but seem to reflect posterior removal covering one of the flanks. Given that all categories of blades have been retouched, import–export of technical blanks cannot be ruled out.

Platform Type

Platform preparations often depend on object categories (Table 5). Plain, facetted, and dihedral convex platforms (in that order) are the most frequent among unretouched blades, while dihedral and faceted platforms stand out among blade tools. Flakes show little preparation, which is consistent with the general lack of technological investment observed in the overall sample.

The external platform edge is prepared using various methods that we categorized into six main groups: no preparation (1), light abrasion (2), strong abrasion (3), pecking (4) (Fig. 13e, f), flaking (5), and trimming (6) (Table 6; Fig. 13c, d). Notable is the marginal faceting (flaking from the dorsal face toward the platform) (Fig. 13e) and the pecking that occurs in high frequencies in the IUP from the Altai and the Baikal region (Slavinsky et al., 2017; Zwyns, 2012; Zwyns & Lbova, 2019), but also known in western Russia (Nehoroshev, 1999) and in the Levant (Kadowaki, 2017; Ohnuma, 1988). Defined respectively as a faceting or a hammering of the platform edge, it can be combined with a prominent plain, dihedral, or facetted platform (Fig. 13c–f).

Pit 4 AH6. Close-up on platform preparations and breakage planes. a Plane platform; b cortical platform; c plane platform with lateral trimming; d plane platform with marginal faceting (perpendicular to the dorsal face); e plane platform with pecking; f facetted platform with pecking; g point of percussion on opposed breakage planes (same as Fig. 9 (2))

Platform thicknesses are within the expected range of direct percussion with a stone hammer (> 4 mm on average, according to Pelegrin, 1995) (Table 7; Fig. 14A). It is particularly true for the retouched blades that have the thickest platforms in the sample. It is notable, however, that the use of such percussion technique is not spatially or temporally specific. Given the standard deviations observed and the lack of reliable experimental referential for this raw material, the use of other techniques (e.g., soft stone hammer) cannot be ruled out.

Pit 4 AH6. A Platform thickness. Note the thicker platform for retouched blades, aligning with the facetted platforms. B Close-up on percussion marks suggesting this ogival/cuboid core was used as a hammer/retoucher (same as Fig. 5 (5))

Flaking Technique

Our interpretation of the flaking techniques is approached here using the data presented above, namely platform morphology, external platform edge, and impact points and lips. Platforms are generally thick (> 4 mm), especially for retouched blades. Faceted platforms are rare among flakes, but one blade platform out of four is faceted. Along with dihedral preparations, this treatment accounts for half of the retouched blades. Hence, it is reasonable to suggest that the use of a mineral hammer extends to the production of blades.

External platform edges lack thin abrasion but frequently show heavy battering, flaking (from the dorsal face toward the platform), and trimming (from the platform toward the dorsal face) (Fig. 12). Such preparations are often (but not only) associated with the production of massive blades (Slavinsky et al., 2017). Like overhang removal, it prepares the core edge for direct percussion using a hard hammer and the associated compression force. Two of the cores from our sample show evidence of percussion that is consistent with their use as “retoucher” and could be associated with such striking platform preparation of other cores (Fig. 14A). No clear correlation can be established between platform and edge preparation beyond the fact that plain and faceted platforms are more likely to show a visible preparation of the edge.

More than half the blades show impact points on their platform, while it is far less frequent on flakes. This feature is usually associated with the use of a stone hammer (Anoikin et al., 2019). The presence of an identifiable lip, a feature associated with a greater shearing force, occurs on about half of the blades observed, while it is much less common on flakes (with the exception of the retouched flakes). Prominent bulbs are common but do not occur systematically.

Hence the assemblage shows a complex of features that is not easy to interpret. Parts of it (platform thickness, impact point, prominent bulb) are consistent with the use of stone hammers, a technique known in most Paleolithic assemblages. Other features (battered, flaked, or trimmed external platform edge, strong abrasion, lip) could be consistent with the use of a soft, or hard, stone hammer, and cannot, therefore, distinguish between these methods. Some features could also indicate an occasional use of organic hammer (tangential percussion, soft abrasion, thin platform) (Pelegrin & Inizan, 2013) but not only are these features rare in the assemblage, they may also occur in association with different types of percussion (Driscoll & García-Rojas, 2014; Kharevich et al., 2022). Finally, following the discovery of a metasomatite stone cobble in the IUP assemblage of Tolbor-4, Kharevich and colleagues (2021) have produced an experimental series of blades from mudstone nodules collected in the primary deposits exposed next to the site. Testing for different types of hammers, including organic and mineral (with different degrees of hardness), they suggest that the coexistence of features described above and observed in the IUP from Tolbor-4 can be replicated more accurately using metasomatite than any of the other materials tested.

Profile, Cross-Section, and Asymmetry

Blade cross-sections are mostly trapezoidal, triangular, or polyhedral and bear two or more previous blade removals on the dorsal face (Table 8). Half of the retouched blades have a trapezoidal cross-section and come from a relatively advanced stage of core reduction (“plein debitage”). This is consistent with the lack of cortical blank in the tool category (N = 1, Table 4). The triangular category includes crested blades, while polyhedral sections also include technical blades with more intricate patterns on the dorsal face.

When it could be determined, blade profiles tend to be straight (Table 9). Straight profiles accounted for more than a third of the whole blade assemblage, retouched or not. To this can be added blades with a slight curvature. The difference between the whole sample and the MNI for retouched blades merely indicates the difficulty to find drawing a line between straight and slightly curved blades, given the minimum keel necessary for successful blade production. Although it is not a reliable predictor, the curvature is usually less pronounced in bidirectional core reduction than in unidirectional one.

The asymmetry is defined here as the cross-section of blanks with an angle ≥ 70° relative to the ventral face along one of the unretouched edges (natural back, debordant, side blades) (Table 10). The right/left edge is identified with the platform placed below. Notable is that backed blades are at least as numerous as flatter ones. This pattern is more clearly expressed in MNI and among retouched blades, and overall, it is consistent with a core reduction taking place at the intersection between two surfaces. It also indicates that, beyond the technical role of such blades for the management of lateral convexities, they are frequently also used as tools.

Summary

The assemblage documents a technology geared toward the production of blades of various sizes, and most of the cores preserve evidence of repeated blade removals. Cores are produced either on nodules/cobbles (Mode A) or on thick technical blades (Mode B) (Fig. 15). Although they can be grouped in different shape categories, Mode A cores share a basic setup that points toward a volumetric reduction, the use of two opposed platforms and semi-circular reduction pattern. The latter is oriented off-axis, with the exploitation of a surface located at the intersection of a broad and a narrow face. On the cuboid/ogival core, the system is duplicated leaving only the back of the core without negatives of long removals. The back is usually flat, prepared or not, with a posterior crest located on one of the extremities, at the intersection with the flank. The absence of methods based on the exploitation of hierarchical surfaces (e.g., Levallois) is notable, along with the lack of evidence for sequences geared exclusively toward flake production. The blade production relies on the use of crests, side blades, and tablets for the management of convexities and platforms, respectively (Fig. 16). Mode B burin-cores and associated spalls are well represented, but vary in shape, size, and reduction modalities. Typologically, they include smaller versions of the asymmetrical reduction observed in Mode A, truncated-facetted, and polyhedric burins, aka the typical burin-core.

A Thickness of burin-cores on blades compared with retouched and unretouched blades. B Dorsal cortex frequency on unidirectional and bidirectional blades (unretouched and retouched combined). Note that the lack of extensive cortex on is expected bidirectional blades, given the higher number of removal scars

The size of blanks produced ranges from large blades to bladelets (width ≤ 12 mm), with examples of convergent, sub-parallel, and parallel edges present. Dorsal patterns show comparable occurrences of uni- and bidirectional dorsal patterns among unretouched blades, and the latter can be difficult to identify due to the high rate of fragmentation. Notable is the higher frequency of retouched bidirectional blades. Overall, the assemblage appears as a blade production workshop. Cortex proportions and crest frequencies suggest that (semi-)prepared cores were introduced and reduced until exhaustion. Platform preparations indicate the occasional use of marginal and complete faceting. The latter are thicker than the plain platforms on average, and we note that thick platforms are prevalent among the retouched tools. Tools are often more robust than the unretouched blanks, perhaps indicating that a selection process takes place based on the size of the blanks. The high rate of fragmentation and the absence of refitted sequences prevent an accurate estimate of the core productivity. Based on the number of negatives and the size of the cores, we suspect that the ratio of five blades per core calculated from the blank MNI is an underestimation and may reflect the export of the products to another location.

Results

Core Shape Variation

After removing fragments and setting aside the two cubic “flat-faced cores,” we compared the volumes of 28 cores (SI5). In terms of maximum length and flaking surface length, prismatic and cuboid/ogival cores are similar. Both categories overlap in size with the largest blades from the sample studied. We observe, however, that the average prismatic core volume is larger than all other shape categories, with the broadest variance (Fig. 17A). Cuboid/ogival and cubic flake cores, while having different shapes and producing different blanks, do not differ significantly in terms of volume (U = 22, p = 0.8465). As expected, burin-cores and more generally Mode B cores show a narrow distribution and the smallest volumes. At first glance, differences in volume do not support the prediction that all shape categories are indicators of independent pathways. We note, however, that cuboid/ogival and cubic flake core volumes broadly overlap. Hence, they do not show the monotonic decrease in volume expected in the most straightforward case of a single reduction process. Instead, we observe a more nuanced picture where both predictions are partly fulfilled.

To stay consistent with the data requires the use of a parsimonious model that starts from a prismatic core and integrates reduction sequence and branching events (Fig. 17B). Mode A core reduction would start with large prismatic cores before following one among three different pathways. In the first one, prismatic cores are reduced and do not change shape as their volume decreases, leading to the production of small blades from small prismatic cores, equivalent in size to what large Mode B cores could produce (ca. 85 mm in length, > 12 mm in width). In the second one, cores are reduced faster in thickness than in length, leading to a cuboid/ogival shape and producing small blades at the end of the process. In both cases, the blanks produced range from large/medium to small blades. Cubic flake cores illustrate yet another case, where core length decreases faster than thickness, thereby leading to the production of flakes (cubic) or short blades (flat-faced cores).

To simplify, cuboids/ogival and cubic cores are two categories of shapes that illustrate how a prismatic core can be reduced. In the case of the former, the core is rotated, and asymmetrical reduction happens (at least) twice. Three out of the four faces of the core are used as flaking surfaces while the back remains with relatively little changes. Blades are produced until the end of the process of reduction. In the case of the latter, multiple tablet removals, breakage, or shorter block to start with leads to a cubic shape and, in some cases, to flake production.

Mode B cores producing small blades/bladelets show substantial typological variations, but because they are almost exclusively produced on relatively thick blade/laminar segments (usually over 10 mm in thickness) (Zwyns, 2012) (Fig. 15A), their volume is smaller while other features suggest that blades were occasionally snapped. Qualitatively, some blade segments show a morphology like what Slavinsky and colleagues (2019) identify as evidence for intentional snapping at Kara-Bom, in the Altai. The latter sometimes show clear perpendicular impact points, lateral notches, or small retouch-like removals on the fracture plane (Figs. 9 and 13G, H). Although there is a high rate of fragmentation among blades compared with flakes, the latter do not differ in average thickness and are more compact and naturally less prone to bending/shearing fractures. Based on the observations listed above, we consider that direct percussion, and/or the use of a passive anvil to intentionally fragment the blades, is plausible to the exclusion of other natural causes.

Bidirectional Blade Reduction

As mentioned above, bidirectional blades are well represented among retouched tools (ca. 42% of identified dorsal patterns), with the caveat that over 60% of the blades are fragmented, thereby decreasing the visibility of such dorsal pattern.

When comparing the frequency of bidirectional removals with other IUP assemblages, it is notable that T16 is at the lower end of it, even considering assemblages with similar fragmentation rates such as Kamenka A-C (Table 11). Considering that access to raw material seems to impact the number of blanks produced per core, it is therefore possible that core rotations are an option to increase blank productivity. The example of Kara-Bom OH5/OH6 has closer access to raw material, yet with collection trips that can be as long as 14 km, which stretches the limits of a usual 6–8 km hunter-gatherer foraging radius (Binford, 1979; Kelly, 2007). At high latitude, this distance is difficult to cover during the shortened daylight of a winter day, especially if one considers the time devoted to collecting rocks and the energy spent carrying them. Kara-Bom shows a blade/core ratio similar to T16, but with a much higher frequency of bidirectional removals. Given the possible biases in sampling procedures and excavation methods between these examples, such observations need verification.

When looking at the cortex distribution per dorsal pattern, uni- and bidirectional blanks do not differ significantly except in cases when the cortex covers over 60% of the surface (Fig. 15B). This is not surprising given that dorsal scars from a bidirectional pattern, by default, would tend to cover a broader region of the dorsal surface than a unidirectional one. Although the early stages of blade reduction are not extensively documented in the T16 sample, it suggests that core reduction may start as unidirectional before including the use of an opposed platform. Such a strategy would predict that blades with unidirectional dorsal pattern are larger than the bidirectional ones.

Figure 18 shows the results of a comparison between the widths per binned dorsal patterns (SI5). Unidirectional and bidirectional categories include cases where distal crests, or cortex, are still visible. The crest/cortical group includes initial and second crests (sous-crête), neo-crest, and cortical blades. Other groups have undetermined dorsal patterns. Three different IUP assemblages corresponding to three distinct raw material situations are compared, ranging from local access (Tolbor-16), within the foraging radius (Kara-Bom) and long distance (Kamenka A-C). The results show that in all cases, there is no significant difference in width between uni- and bidirectional blades. Perhaps the most striking difference is in terms of variance and outliers, which are often larger in the bidirectional blades than unidirectional ones. The size of crest blades seems to vary, perhaps because of raw material shortage. Overall, the results do not validate the hypothesis of a bidirectional flaking strategy being aimed at increasing the blank productivity of cores.

Three qualitative categories of blades can be distinguished based on their contour (Zwyns & Lbova, 2019) (Table 12; Fig. 11). Type 1 groups are blades that have convergent edges from the proximal to the distal end; type 2 is convergent from the mesial to the distal end; and type 3 are blades with parallel edges (except a possible convergence at the distal end). Mostly due to the high fragmentation rate, a sample of 32 blades (MNI = 21) could be typed in one of these categories as the whole sample. For both retouched and unretouched blades, type 3 dominates except for the MNI of retouched blades. This suggests either that blade production was aimed at this kind of format, or that other types are missing for other reasons (e.g., export). Considering the asymmetrical pattern of core reduction and the high frequency of naturally backed blanks, this pattern indicates that the role of parallel-edged thick blades cannot be restricted to core management. Instead, they are an integrative part of the tool kit.

Comparing these results with the IUP assemblage of Kamenka A-C leads to several observations. First, debordant/neo-crest blades are the most represented among unretouched blanks in both samples. They are also transformed into retouched tool forms, but at T16, the frequency may be artificially inflated due to fragmentation or blade export. When one considers the MNI blades, convergent blades are as likely to occur among the tools. This is, perhaps, the clearest difference with Kamenka where convergent blanks are lacking compared with sub-parallel blades. The latter, defined as blades that have parallel edges up to the mesial section, are rarely observed at T16. Convergent mesiodistal fragments do occur, but in smaller frequencies than in Kamenka. These results may indicate differences in blank selection or import–export between the sites.

Retouched Tools

It is difficult to identify what types of blanks were targeted and selected for secondary treatment (e.g., retouch) solely based on technological proxies. Here, it is addressed by comparing retouched and unretouched blanks, with the hope to identify potential criteria of selection. At the most basic level, it is notable that ca. 65% of the retouched tools are made on blades (Table 13). It is not surprising given that the well-documented blade production makes up a substantial part of the assemblage, while specific flake production is lacking.

Comparing the width and thickness of the retouched and unretouched blades shows that the retouched ones are larger (and thicker). Although the sample is small, they are not restricted to a specific type of contour and both tools with parallel and convergent edges are common. Typical UP tool types, such as burins, perforators, or retouched bladelets, are rare or absent except for endscrapers on blades and flakes, and truncated blades. A few examples of tools with proximal secondary modifications are observed, by bilateral abrupt retouch (Fig. 11 (11)), Kombewa removals (Fig. 21 (2)), or bilateral direct retouch. Overall, there is a lack of formal, highly curated tools.

Middle Paleolithic typical tool types such as sidescrapers are mostly absent, while notches and denticulates are well represented among both flakes and blades (Figs. 19 and 20). A close examination of the retouched tools across categories reveals that most of the tools are retouched technical flakes linked with the blade reduction process. For example, irregular laminar flakes and debordant blades were often targeted to produce retouch blades, notches, or denticulate while endscrapers were produced on byproduct flakes of crest shaping. There are, naturally, examples of “plein debitage” blades bearing retouch, but they are often fragments. Overall, the technology used at the site allowed for the production of diverse blade types. Some of these blades seem to be under-represented, while technical, often irregular blanks are transformed into informal tools.

Technical and retouched flakes. Bifacial thinning flakes (1, 2); crest-shaping/orthogonal flakes (4, 5, 8, 9); flakes detached from an opposed platform for blade core flaking surface distal management (3, 6, 7); core flanks (10, 11); core tablet (13, same as Fig. 14 (4)). Tool types are piece esquillée endscraper (5); retouched flakes (9, 10); denticulate (12) (drawings by N. Zwyns)

Technical and retouched flakes and blades. Fragment of blades with percussion marks on the breakage plane (3); bidirectional flake (4); proximal blade fragments with bidirectional dorsal pattern (5, 7); cortical blades (8); blades with unilateral orthogonal removals (9, 10). Tool types are piece esquillees (1); fragment of notched tool (2); retouched blades/laminar flakes (3, 8, 9, 12); and denticulate (10) (drawings by N. Zwyns)

We note the occurrence of two bifacial pieces. The first one is a relatively large, asymmetrical bifacial-backed knife produced on what appears to be a massive cortical flake (Fig. 21 (1)). Bifacial thinning removals are around the distal mesiodistal part and inverse flat retouch is more invasive. The tool is off-axis by ca. 45° relative to the axis of flaking. From a techno-functional point of view (Boëda, 2001), mesiodistal direct and alternate retouch identifies the right edge as the last one being active. The extent of the inverse retouch highlights the role of the pointed tip, where symmetry is more prevalent. From a broad typological standpoint, this artifact falls into the Keilmesser category. Well-known in the Middle Paleolithic from Central Europe, these assymetrical bifacial-backed knives are also found in other contexts (Jöris, 2006; Jöris & Uomini, 2019; Marks et al., 2002, Weiss, 2020). The direct position of the retouch, with a mesiodistal localization, a continuous distribution, and a relatively straight delineation of the right edge, the back/based morphology, and the pointed tip suggest a taxonomic position between the Klausseniche (Klausennischemesser) and the Bockstein (Bocksteinmesser) sub-types (Jöris, 2006; Jöris & Uomini, 2019). Because the back almost connects with the distal end, the T16 artifact leans toward the latter. Technologically, this tool is a modified flake; hence, the base is not clearly defined, and the cross-section is plano-convex. Although the raw material appears to be local, only a small number of bifacial thinning/retouch flakes (N = 3) have been identified (with the caveat that bifacial thinning flakes may be difficult to differentiate from crest-shaping flakes).

Another small bifacial piece displays an advanced stage of thinning, but marginal retouch is absent (Fig. 21 (3)). Instead, the lateral edges retain a transversal plane that prevents them from functioning as cutting surfaces. The distal part is broken and missing. From a techno-functional point of view, this object could be interpreted as unfinished, and still in the thinning phase.

Discussion

Do Core Types Correspond to Independent Reduction Sequences?

There are countless descriptions of core shape variability in Paleolithic assemblages, but whether core types are proxies for specific reduction sequences is not a question that is systematically addressed. To the best of our knowledge, these discussions are best exemplified by a debate revolving around the Middle Pleistocene assemblage from level IIa at Biache Saint Vast (France). Interpreted as a specialized hunting camp with easy access to high-quality raw material, level IIa was described by Tuffreau (1988) and Boëda (1988, 1994) as an assemblage with a prevalence of Levallois technology in cores, blanks, and tools. Boëda went on identifying two different variants of Levallois recurrent (Schemas A and B, unidirectional and bidirectional respectively), along with non-Levallois centripetal reductions (Schema C) and other undifferentiated cores and core/tools (Schemas D and E, respectively). He further suggested that these categories correspond to distinct reduction pathways that required specific, yet different, initial setup. Hence, once the reduction started in one schema, it was no longer possible to change to another—thereby explaining why cores were discarded in different shapes. While recognizing the high frequency of Levallois and the schemas described by Boëda, Dibble (1995) challenged these two latter assumptions. Following Frison (1968) and Jelinek (1976), he argued that some of the schemas (or core types) could also correspond to different steps in a reduction sequence.

Such debates had an influence on the study of Middle Paleolithic assemblages elsewhere. Based on flake dorsal cortex and scar patterns, Baumler (1988) suggests that at the site of Zobište, in northern Bosnia, cores that are first reduced from one or two platforms would then be flaked following a centripetal progression prior to discard. Although methods are sometimes correlated with raw material quality (e.g., De Loecker & Roebroeks, 2012), refits from layer 5 in Scladina, in Belgium, show that several methods are sometimes used on cobbles of coarse-grained material such as quartzite (Di Modica & Bonjean, 2006). Although shifts in method during core reduction may occur during the Middle Paleolithic, Kuhn (1995) notes that for the Pontinian, a Middle Paleolithic variant from Italy characterized by its overall small size, there is consistency in methods throughout the reduction process. With size constraints, it is easier to associate some of the core types with independent reduction pathways. The same situation is observed in Montenegro, in the Mousterian layers XVIII-XII of Crvena stijena, and at Bioče layers 2–7, with respect due to the limitation of sample size (Dogandžić & Đuričić, 2017).

Far from being trivial, addressing core shape variability at the assemblage level is central to the recognition of the IUP as a phenomenon distinct from transitional assemblages. At Boker Tachtit, Volkman (1983) describes a system centered around the production of Levallois points. He notes that consistency in core reduction pathways is higher at the top (layer 4) and the bottom (layer 1) of the cultural sequence. In the latter, blades are mostly considered byproducts relative to elongated bidirectional points, seen as a transitional stage from the Middle to Upper Paleolithic technology (Demidenko & Usik, 1993; Teyssandier, 2024). This is one of the reasons why layer 4 was considered the outcome of a transitional process and referred to as IUP (Marks, 1990). At the individual core level, such a shift was described in Kara-Bom, where two cores aimed at the production of Levallois points and blade productions were refitted on a single raw material nodule (Rybin, 2020). The coexistence between a Levallois-like blade technology and sub-volumetric blade reduction is also observed by Li and colleagues (2020) at Shuidonggou locality 1. To document the intra-assemblage variability of this rare example of the IUP in North China, they isolate different core shapes such as Levallois (grouping uni- and bidirectional blade cores and flake cores) and prismatic/subprismatic. Although they note that there are examples of cores that combine the two forms (possibly indicating an asymmetrical reduction method), they do not attempt to test for potential links between the different types in the framework of a continuous process. They note that based on size, simple core forms are unlikely to be the beginning of a blade core reduction process. Albeit their classification systems differ from ours, the variations observed encapsulate most of the specific forms observed in T16 (except cuboids/ogival).

Just like the examples above, the T16 material shows a relative consistency in the use of the asymmetrical method of reduction. Besides the “typical” examples showing the use of a narrow and a broad flaking surface, other shapes occur in the absence of long refitted sequences, yet whether these shapes correspond to independent methods of reduction was unclear. We compared the volume (a metric independent of the shape and reduction methods) across categories while setting basic predictions for two arbitrary models. The first one implied that the main core categories correspond to distinct reduction sequences, starting from raw material collection to exhaustion, and would result in an overlap in terms of volume distribution across the board. The second implied that shapes reflect different stages of exhaustion in a single sequence, which would lead to a monotonic decrease in volumes across categories. These predictions both occur to some degree, and the results of these exploratory analyses suggest that a more nuanced model is required to make sense of the bulk of qualitative and quantitative observations.

We put forward a model centered around the production of blades as a primary goal and relying on a basic prismatic core setup. The core reduction may continue along the same lines until exhaustion or branch off toward a narrower shape due to a change of orientation, or toward a cubic shape due to platform rejuvenation. A relatively consistent reduction method is used regardless of the differences in core shapes; therefore, we consider that distinct core types do not necessarily correspond to distinct reduction sequences per se. They may represent branching events in a Markov decision process (Muller et al., 2017), with points of no return. Turning a cubic core back into a prismatic or cuboid/ogival shape would become too costly at a certain point of the process. Conversely, turning a core into a cubic shape might be easier and perhaps less costly. Overall, our model integrates both original predictions, with a reduction system that sometimes branches into sequences of decision-making responding to predictable or stochastic changes. Whether or not core shapes reflect what is known as a “mental template” is more difficult to assess. To be consistent with the model, the templates must be defined as modalities combined in a resilient reduction process (as opposed to the dogmatic application of a formula). Repeating the latter may be interpreted as a learning experience from which expectations arise in terms of technical constraints, byproducts, and accidents, along with pre-conceptualized technological solutions.

Variations in core shape and size in this case may be partly due to the dynamic nature of a reduction process. Although there is consistency in the flaking technology within (and between) IUP assemblages, diversity in core shape does not necessarily index for specific chaîne opératoire (Dibble, 1995). Consequently, core typology may be useful as a classification tool, but it is not as accurate as an indicator of technological diversity as it is illustrating flexibility around a general concept of reduction (Moore, 2011). It is not trivial when it comes to discussing the coexistence of flake and blade cores, or Levallois-like cores in an IUP context. It also suggests that to quantify the complexity of such dynamic systems, it is important to integrate the consistency of a reduction method, which gives weight to the notion of hierarchical complexity (Haidle, 2014; Muller et al., 2017; Stolarczyk & Schmidt, 2018). Systems based on categorical data such as procedural units may tend to amplify “complexity” when different core shapes are used as proxies for flaking methods (Oswalt, 1976; Perreault et al., 2013).

Is Bidirectionality a Way to Optimize the Blank Production?

The bidirectional character of the blade production has been central to the definition of the IUP since the first use of the concept. Originally, Marks considered the IUP as the result of the transition from bidirectional toward unidirectional flaking (Marks & Volkman, 1983). For layer 4 at Boker Tachtit, Volkman (1983) notes that the short removal sequences involved in the production of Levallois points may vary too. The different pathways he described, however, are often organized around bidirectional predetermining lateral flakes/blades to set up the convergent guiding ridges. First described as a Levallois reduction (Marks & Kaufman, 1983), it was recently reconsidered as a non-Levallois “surficial” concept (Goder-Goldberger et al., 2023). Although later iterations of the definition are more flexible (Bar-Yosef & Kuhn, 1999; Kuhn et al., 1999), the vast majority of what is called IUP in Central and East Asia includes a substantial share of bidirectional blanks (Belousova & Rybin, 2016; Derevianko et al., 2000, 2007; Peng et al., 2014; Rybin, 2004; Slavinsky et al., 2016; Vasiliev & Rybin, 2009; Zwyns, 2012; Zwyns & Lbova, 2019).

At T16, the reduction is mostly bidirectional, but pending long refit sequences, the role of the two opposed platforms remains unclear. With one larger than the other, it could indicate either a different role for each, such as a main platform to strike blades, and an opposed one for the management of distal convexities, or simply alternate removal sequences. A simple test was presented here considering core rotations to increase productivity. The “Frison effect” may not be the most compelling explanation for the reasons listed above. However, it is parsimonious and can be tested upfront with a straightforward prediction: unidirectional blades should be larger if the core reduction started unidirectionally. In fact, uni- and bidirectional blades have roughly the same size (with or without the inclusion of bladelets) and the data does not validate such a hypothesis. Instead, IUP assemblages considered here show bidirectional removals early in the reduction process (Fig. 18). The results raise questions regarding the role of such a strategy.

A first possibility is what Pelegrin (1995) described as distal management of laminar flakes (and their dorsal negatives on longer blades) in a Châtelperronian context. It is associated with an asymmetrical core reduction similar to the Asian IUP (Roc-de-Combe method sensu Boëda, 1990) and is otherwise mostly unidirectional. At T16, such flakes and dorsal scars occur only occasionally. In fact, blade dorsal patterns often show opposed removals covering the whole length of the blade (and not just the distal part), further suggesting that direction shifts are frequent. A second possibility is that removals from an opposed platform may be associated with the Y-shape dorsal pattern typical of convergent blanks. As described by Marks & Kaufman (1983) in the layer 4 of Boker Tachtit, opposed platforms are involved in the production of convergent blanks. Secondary platforms are used for preparing the detachment of points (removing “predetermining” flakes, sensu Boëda, 1994) coming from primary platforms (aka “predetermined” flake). We note that the asymmetrical reduction method represented at T16, like what Boëda described as the Roc-de-Combe method (1990), overlaps with the non-Levallois surficial concept reported by Goder-Goldberger et al. (2023) in the AH-B (tentatively correlated with the layer 2 of Marks’s excavation by the same authors). While the data at hand does not show a specific association with convergent blanks, it is difficult to test this idea due to fragmentation and the lack of refits. In general, Asian IUP assemblages show a high frequency of “Levallois-like” blades while offering few examples of genuine Levalloisian technology (Kharevich et al., 2022; Shunkov et al., 2019). Absent at T16, examples of Levallois nevertheless exist elsewhere (Rybin & Khatsenovich, 2018), but their connection with blade production is far from clear.

Combined with a percussion with more compression than shearing force, bidirectionality may be one of the technological solutions to produce robust blades with a relatively straight profile. Core flaking surfaces and blades from T16 have little keel (longitudinal convexity) compared with generic UP blade production. The latter is often geared toward the production of thinner, sharper blades through tangential percussion with organic or soft stone hammers. In unidirectional examples, it tends to show a more pronounced curvature on both flaking surface and blades. Evidence for intentional fragmentation may support this idea, as it seems to isolate thick segments with straight profiles. Based on qualitative observations, this hypothesis requires a test that is beyond the scope of our paper. Overall, the hypotheses described above are not mutually exclusive and may coexist at T16 or elsewhere. It comes out of our analyses that bidirectionality is a technical decision independent of a straightforward need for productivity, or a reduction effect. The rate of fragmentation and the lack of refits, however, prevent us from fully addressing the function of this trait. Overall, it is probably misleading to isolate bidirectional flaking from its technological context. When combined with asymmetrical and burin, and burin-core reduction methods, however, it may illustrate a combination of functional and “neutral” features worth using (in combination with others) for long-distance comparisons.

IUP assemblages compared here illustrate different constraints in raw material availability and properties, in contiguous yet distant regions. In all three cases, dorsal patterns indicate frequent core rotations starting early in the reduction process. As Vasiliev & Rybin (2009) suggested for the site of Tolbaga, in the Transbaikal, T16 cores are as likely to be finished by unidirectional flaking. Assuming that there is a functional meaning to such a strategy, it could increase control on the contour (e.g., convergent guiding scars) or on the profile (e.g., straight) of the blades. To our knowledge, such an association between flaking patterns is hypothetical, and not clearly expressed in the T16 data set. Granted that other functional roles should be explored, it cannot be excluded that this trait expresses normative behaviors. Along with other patterns of core reduction (asymmetrical, and burin-core reduction), such normative behaviors are key to address the unity of IUP as a large-scale phenomenon through long-distance comparisons. Rare in the context of blade production, neutral traits are the most informative when it comes to measuring the degree of relatedness between assemblages (Dunnell, 1978, 2006; Sackett, 1977, 1986).