Abstract

The synthesis of trisubstituted isoxazoles generally requires multiple individual chemical steps, making them amenable to improvements in efficiency by telescoping as a multistep flow process. Three steps (oximation, chlorination and cycloaddition) were developed in continuous flow mode, aiming to function as an high-yielding and efficient sequence. We demonstrate this sequence using two aldehyde starting materials of interest: one carbocyclic and one heterocyclic. Between these two substrates, significant differences in solubility and reactivity necessitated modifications to the route. Most notably, the chlorination step could be carried out using either an organic N-Cl source (applicable for the carbocyclic aldehyde) or Cl2 generated on-demand in a flow setup (applicable for the heterocyclic aldehyde). By selecting the most effective method for each substrate, good yields could be achieved over the telescoped sequence.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Isoxazoles are a class of 5-membered heterocycles that are of significant interest in medicinal chemistry and are present in numerous marketed drugs [1, 2]. Although the chemistry of isoxazoles is well-established and a plethora of routes for their synthesis have been reported [3,4,5], these are mostly focused on forming mono- or disubstituted derivatives. The synthesis of fully substituted (trisubstituted) isoxazoles is more challenging, especially since the regioselectivity of commonly-used 1,3-dipolar cycloadditions varies depending on the electronic properties of the two substrates. This results in different possible products, which further complicates the matter of synthesizing such heterocycles.

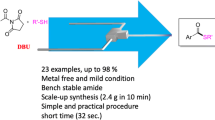

The target isoxazole substrates 5 and 7 were trisubstituted, with an electron withdrawing ester/acid group in the 4-position (Scheme 1a). Reported methods to generate this substitution pattern are limited, particularly with an electron withdrawing group in this position. The most commonly-reported route to such isoxazoles is the addition of an electron rich olefin or alkyne to a chloroxime [6, 7]. In the case of target compounds 7, an enamine formed from a 1,3-dicarbonyl would deliver the correct regioselectivity [8].

The corresponding synthetic sequence to 5 consists of three steps: oxime formation, chlorination and cycloaddition (Scheme 1b) [9,10,11]. First, the oxime 2 is formed by simple reaction of the corresponding aldehyde 1 with hydroxylamine. Chlorination with an electrophilic chlorine source then provides the chloroxime 3. This chloroxime should be reacted onward without isolation, where possible, due to the possibility of hydrolysis or other decomposition under certain conditions. Enamine 6 as a cycloaddition partner provides the required electronic configuration for the reaction to proceed with the desired regiochemistry to product 5. This cycloaddition is proposed to occur via gradual release of an unstable nitrile oxide intermediate, 4 [12]. Direct synthesis of such intermediates has been demonstrated in select cases [13, 14], but is generally unfavorable due to their poor stability.

When considering this synthetic sequence on large scale, several problems were identified. First, the formation of oxime 2, although a simple transformation, requires phase separation to remove inorganic by-products, which limits the overall rate of processing and could be improved by continuous operation. Chlorination to form 3 was addition-limited, due to exothermicity. It was proposed that this issue could be solved by performing the chemistry in flow, whereby the larger surface area enables more effective heat transfer, neutralizing any threat of a thermal runaway or selectivity degradation [15]. The synthesis of isoxazoles in flow has been reported several times, capitalizing on the ability to access high temperatures in a straightforward manner [16]. Flow isoxazole syntheses include the cyclization of 1,3-diketones with hydroxylamine [17], cyclization of β-chlorovinyl ketones with sodium azide [18], and synthesis of non-aromatic isoxazole derivatives by cycloaddition of chloroxime with an electron rich olefin [19]. It was also proposed that flow chemistry could expedite the synthesis by straightforward reaction telescoping, leading to an overall more productive reaction sequence [20,21,22,23,24].

Finally, flow would facilitate the use of in situ generated Cl2 as an effective alternative to traditional organic chlorinating agents [25]. The “on-site on-demand generation” of highly reactive reagents, such as Cl2, has been demonstrated as a safe and effective alternative to standard approaches. Using this concept, the transportation, storage and handling of such reactive compounds can be obviated [26, 27]. The concept of chlorine generation and utilization in flow has been reported for a small selection of reactions [28, 29], but to the best of our knowledge never for formation of chloroximes 3, or related intermediates.

Results and discussion

Oxime formation

The initial formation of oxime 2a was achieved by condensation of the aldehyde 1a with hydroxylamine. In order to expedite the purification of this reaction and facilitate possible telescoping, a biphasic reaction was envisaged. Therein, the organic phase, containing only the desired product 2a (as a mixture of isomers, E/Z ~ 92:8 by HPLC area), could be separated using a hydrophobic membrane. This organic phase could then be used directly in the next step, or solvent simply removed to yield product 2a.

Following initial batch screening (see SI Sect. 3.1.1), ethyl acetate (EtOAc) was selected as the most suitable solvent, providing excellent yield in a short reaction time, at high concentrations up to 4 M. The rate of this reaction in batch was found to be highly dependent on the mixing efficiency, resulting in some reproducibility issues when performing optimization. This further highlights the benefit of transferring such a biphasic reaction to flow, where more material can be produced by extended operation, without changing the reactor geometry.

When transferring these conditions to flow (Scheme 2), feed concentrations of 3 M could be successfully employed (4 M was not used in flow due to solubility restrictions). By incorporating a 2.8 bar back pressure regulator (BPR, idex) after the reactor coil, the reaction could be heated to 100 °C without solvent evaporation. Under these conditions, a stable segmented flow regime was formed, yet interphase mixing was sufficient for reaction completion to be achieved within 10 min residence time.

After leaving the reactor and cooling to room temperature, the slug flow passed through the BPR to a membrane separator (Zaiput, SEP-10) equipped with a hydrophobic membrane (OB400). The two phases were separated with excellent efficiency, providing an ethyl acetate stream in which solely the desired product 2a was dissolved. This successful phase separation was thought to benefit from the higher ionic strength of the aqueous phase, bestowed by the NaCl formed during NH2OH·HCl neutralization in the feed. Using the optimized conditions, the reaction output was collected at steady state for 170 min, allowing 23.1 g (98% yield) of oxime 2a to be isolated after solvent evaporation.

Due to the poor solubility of the pyridine-based oxime product 2b (solubility in EtOAc ≈ 0.07 M, see SI Sect. 3.1.2), it was not possible to carry out the transformation in an equivalent biphasic flow setup. Since this reaction could be performed suitably in batch, the required material for onward reaction development was synthesized in batch (EtOAc/H2O at 75 °C for 1 h), providing 85% yield on multigram scale.

Chlorination (Organic chlorine source)

A key decision in the synthetic route was surrounding the conditions for formation of chloroxime intermediate 3a - a transformation that requires an electrophilic chlorine source. Although a range of reagents have been reported in this transformation [30], this role is often fulfilled by N-chlorosuccinimide (NCS), due to its commercial availability and ease of handling [31]. Nevertheless, we assessed alternative reagents and determined 1,3-dichloro-5,5-dimethylhydantoin (DCH), containing two N-Cl equivalents, to be more effective per equivalent of Cl (88% vs. 75% yield). Trichloroisocyanuric acid (TCIA), with three N-Cl equivalents, was found to be marginally less effective (65% yield). In a small screen of solvents, acetonitrile (MeCN) was found to be most suitable to affecting the transformation in a short reaction time. Details can be found in the Supporting Information, Sect. 3.2.1.

The developed batch chlorination could be transferred to flow in a straightforward manner using substrate 2a (Scheme 3). After simply tuning the temperature and residence time, the desired product was formed in 96% HPLC assay yield (vs. biphenyl as the internal standard) in a residence time of just 5 min. Due to the intent to telescope directly into the cycloaddition step, the isolation of 3a was not studied in detail.

Batch chlorination of the analogous pyridine oxime substrate 2b could not be achieved with the same success, however, with incomplete reaction observed even after 30 min. Furthermore, the low solubility in MeCN led to an inhomogeneous reaction mixture, which would be unsuitable for onward processing in flow. Accordingly, an alternative method was sought.

Chlorination (Cl2 generator)

As an alternative to N-Cl reagents, direct oxidation to the nitrile oxide 4a was attempted using NaOCl. Although this reaction proceeded rapidly, the resulting product was found to be unstable, providing unsatisfactory yields (Table S3.2.10). This was particularly true when telescoping with the cycloaddition step. The literature describes a dimerization of such nitrile oxide intermediates, meaning that only substrates with ortho substitution are sufficiently stable for onward reaction [13].

Building on the idea of using NaOCl as a readily available oxidant, it was found that adding HCl to these reactions resulted in good yields of the desired chloroxime intermediate 3a [32]. We turned to our previous work on chlorine generators in flow, which would serve in this case as a highly reactive source of electrophilic Cl [28]. We opted to build a setup in which the Cl2 gas would be dissolved in EtOAc, to improve the safety profile (i.e., avoid producing Cl2 as a gas) and ensure compatibility with the next reaction step (Scheme 4a). Aqueous solutions of HCl (6 M) and NaOCl (1.75 M) were mixed in a T-mixer (0.5 mm aperture), using ~ 4 equiv HCl, followed by a short coil to ensure complete mixing of the two streams. A stream of EtOAc was then added, with a 0.5 mL piece of perfluoroalkoxy alkane (PFA) tubing to allow extraction of Cl2 and formation of a stable segmented flow regime.

To test the compatibility of this approach with the two oxime substrates, the output of the chlorine generator was first added to a flask containing the oxime 2a, imitating gradual addition in a batch reaction (Scheme 4b). Gratifyingly, this provided full conversion of the starting material within 5 min after complete Cl2 addition and 96% HPLC assay yield. Similarly, oxime 2b, dissolved in MeOH, displayed high reactivity with no remaining starting material detected 5 min after Cl2 addition was completed (Scheme 4c).

Chlorination of oximes using Cl2 generator. (a) Schematic of Cl2 generator: Cl2 formed by oxidation of chloride, followed by extraction into EtOAc and phase separation. (b) Chlorination of carbocyclic oxime 2a. (c) Chlorination of heterocyclic oxime 2b. Reaction performance was assessed by the complete consumption of starting material 2b, by GC-FID analysis

An interesting observation was made when performing these gradual addition experiments. Reactions with both substrates formed a thick precipitate during the addition period, which then redissolved once > 1 equiv Cl2 was added. This was attributed to reaction of the oxime 2 with HCl generated during the reaction, resulting in the corresponding oxime HCl salt. This could be explained by a significant solubility difference between the oximes 2 and chloroximes 3, which remained soluble, even when additional Cl2 equivalents (up to 3) were added. This observation was vital for transferal to flow, whereby an excess of Cl2 should be maintained at all times. Poor mixing or pump pulsation could feasibly cause instantaneous disruption of this stoichiometry, and should be avoided as far as possible.

Cycloaddition

The cycloaddition of chloroximes across a double bond is accepted to proceed via nitrile oxide intermediate 4, which can readily be liberated from chloroxime 3 in the presence of base. However, as discussed above, this intermediate 4 has poor stability and tends to dimerize readily in solution. This became apparent when attempting reactions using a stoichiometric quantity of base (Et3N or N,N-diisopropylethylamine, DIPEA), which led to < 50% yield of 5a from the DCH-produced chloroxime intermediate 3a (Table S3.2.4).

Instead, it was postulated that the pyrrolidine released during reaction with enamine 6 would act as a gradual release of base as the reaction progressed. Therefore, the generated HCl could be consumed without forming large quantities of the unstable nitrile oxide 4. To examine the transformation in detail, batch experiments were carried out (Table 1) using both substrates 2a and 2b.

Since the chlorination step had already been demonstrated to be effective in a range of solvents (Table S3.2.3), the two steps were telescoped to examine the effect of solvent on the cycloaddition. Polar solvents DMF, EtOH and MeCN (entries 1, 2 and 4) provided good results, whilst the reaction proved to be sluggish in EtOAc (entry 3). MeCN was selected in place of EtOH for onward experiments for reasons of improved DCH solubility (for improved compatibility with the previous chlorination step). When transferring the reaction to flow, it would be desirable for the reaction to take place within a shorter time. To increase reaction rate, the equivalents of enamine 6 were increased (entries 5 and 6), which lead to 79% yield within 15 min. To further accelerate the reaction, the temperature was raised to 80 °C providing excellent yield of 5a with a reaction time of just 5 min (entries 7 and 8).

Following this success with substrate 2a, similar optimization was attempted with substrate 2b. Unfortunately, this substrate was found to react significantly slower in all three examined solvents (entries 9–11). Considering also the previously-observed poor chlorination performance of this substrate with DCH, the reaction was instead attempted using in-situ generated Cl2 (Scheme 5).

The oxime substrate 2b was combined in flow with the solution of Cl2 in EtOAc (as described above, Scheme 4) and allowed to react, forming 3b in a 2 mL coil at room temperature (4.7 min residence time). The resulting stream was then introduced to a batch vessel containing enamine 6 in MeOH. Additional base (DIPEA) was required in this instance, to neutralize the HCl formed in the chlorination step. After reacting for 1 h at 50 °C in batch, the desired isoxazole product 5b was successfully formed with 95% HPLC area.

Telescoping and isolation

Finally, in order to demonstrate the optimal synthetic procedure for both substrates, telescoped reactions from the oxime starting materials 2 were performed on multigram scale. Although it would be possible to also include the oxime formation step (particularly for oxime 2a, which used the Cl2 generator with EtOAc as reaction solvent) in the telescoped sequence, this was not performed due to practical reasons and equipment constraints. Oxime 2a was reacted using the Cl2 generator, but was observed to require more than 13.3 min residence time in the cycloaddition step, so was collected and reacted onwards in batch for 2 h (section S1.12). Conversely, when using DCH to form the chloroxime 3a, superior results were obtained (Scheme 6a).

To isolate a larger quantity of material, a multigram quantity of oxime 2a was processed. Chloroxime 3a was formed by simply mixing 2a with DCH (both in MeCN) and heating to 50 °C for 10 min (a lower temperature and longer residence time, compared to the previous conditions, Scheme 3). The preformed enamine cycloaddition partner 6 was then added as a separate stream, which was heated to 80 °C for 13.3 min to form isoxazole ester product 5a. For ease of isolation, this product was further functionalized to its corresponding carboxylic acid 7a by hydrolysis in batch. Upon acidification with HCl, 7.54 g of the desired product precipitated, providing 76% yield over 3 steps. With additional development, this hydrolysis step could likely be transferred to flow. However, due to the use of multiple unit operations (e.g., pH adjustments and extractions), it was performed in batch for this study.

As previously discussed, oxime 2b performed poorly in chlorination reactions with DCH. Therefore, the telescoped procedure for this substrate was carried out using the Cl2 generator (Scheme 6b). The stream of Cl2 (~ 1 M in EtOAc) was mixed with oxime 2b, requiring only a short residence time at room temperature to form the chloroxime 3b. Introducing a stream of enamine 6 and DIPEA formed the desired isoxazole ester 5b after 13.3 min residence time at 80 °C. As for the other substrate, the product was isolated as the corresponding carboxylic acid 7b after ester hydrolysis. In this case, citric acid was used for acidification in place of HCl, to ensure that the pyridine moiety was not protonated. A 1.85 g quantity of acid 7b was isolated, corresponding to 65% yield over 3 steps.

Conclusion

We have described the development of a multistep flow procedure for the synthesis of two trisubstituted isoxazoles, both featuring a carboxylic acid substituent. The syntheses were carried out in four steps from the corresponding commercially available aldehyde substrates. The carbocyclic aldehyde could be reacted to its corresponding oxime derivative in a facile manner, using a biphasic flow regime, which enabled an efficient continuous aqueous wash and phase separation. On the other hand, the heterocyclic analogue presented a challenge for such biphasic flow processing, due to its poor solubility in apolar organic solvents.

Next, a chlorination of the oxime was carried out using either an N-Cl source (DCH), or Cl2 generated in situ. The carbocyclic oxime performed far more favorably with the N-Cl source, whereas both substrates underwent rapid reaction with Cl2. The Cl2 method, however, generated an equivalent of HCl, which had to be quenched with added base in the subsequent reaction step. Here, the use of flow technology facilitated a rapid chlorination in a safe manner, by the chemical generator concept. Finally, the cycloaddition was performed using an enamine partner, wherein the pyridine-derived chloroxime proved to be a more reactive coupling partner. Flow processing allowed higher temperature to be used, resulting in a shorter reaction time than in batch. Both substrates could be processed efficiently on gram scale, with the chlorination-cycloaddition step telescoped in flow, followed by batch hydrolysis for isolation. This represents an efficient flow-enabled method for the synthesis of trisubstituted isoxazoles, which can be challenging to synthesize by alternative methods.

References

Agrawal N, Mishra P (2018) The synthetic and therapeutic expedition of isoxazole and its analogs. Med Chem Res 27:1309–1344

Taylor RD, Maccoss M, Lawson A (2014) D. G. Rings in Drugs. J Med Chem 57:5845–5859

Hu F, Szostak M (2015) Recent developments in the synthesis and reactivity of isoxazoles: Metal Catalysis and beyond. Adv Synth Catal 357:2583–2614

Morita T, Yugandar S, Fuse S, Nakamura H (2018) Recent progresses in the synthesis of functionalized isoxazoles. Tetrahedron Lett 59:1159–1171

Das S, Chanda K (2021) An overview of metal-free synthetic routes to isoxazoles: the privileged scaffold. RSC Adv 11:32680–32705

Zhou X, Xu X, Shi Z, Liu K, Gao H, Li W (2016) Enolate-mediated 1,3-dipolar cycloaddition reaction of β-functionalized ketones with nitrile oxides: direct access to 3,4,5-trisubstituted isoxazoles. Org Biomol Chem 14:5246–5250

Kesornpun C, Aree T, Mahidol C, Ruchirawat S, Kittakoop P (2016) Water-assisted Nitrile Oxide cycloadditions: synthesis of Isoxazoles and Stereoselective syntheses of Isoxazolines and 1,2,4-Oxadiazoles. Angew Chem Int Ed 55:3997–4001

Nakamura M, Kurihara H, Suzuki G, Mitsuya M, Ohkubo M, Ohta H (2010) Isoxazolopyridone derivatives as allosteric metabotropic glutamate receptor 7 antagonists. Bioorg Med Chem Lett 20:726–729

Buettelmann B, Cecere G, Fasching B, Zbinden G, Hernandez K, Knust M, Koblet H, Pinard E, Thomas A (2019) New isoxazolyl ether derivatives as GABA A alpha 5 PAM, WO2019/238633A1

Buettelmann B, Cecere G, Fasching B, Zbinden G, Hernandez K, Knust M, Koblet H, Pinard E, Thomas A (2018) New isoxazolyl ether derivatives as GABA A alpha5 PAM, WO2018/104419A1

Dott P, Hanlon SP, Hildbrand S, Iding H, Thomas A, Waldmeier P (2013) Process for the Preparation of Isoxazolyl-Methoxy-Nicotinic Acids, WO2013/057123A1

Jager V, Colinas PA (2002) Nitrile Oxides. in Synthetic Applications of 1,3-Dipolar Cycloaddition Chemistry Toward Heterocycles and Natural Products (eds. Padwa, A. & Pearson, W. H.) 361

Gütz C, Stenglein A, Waldvogel SR (2017) Highly modular Flow cell for Electroorganic Synthesis. Org Process Res Dev 21:771–778

Genin MJ, Bueno AB, Agejas J, Manninen PR, Bocchinfuso W, Montrose-Rafizadeh C, Cannady E, Jones T, Stille J, Raddad E, Reidy C, Cox A, Michael M, Michael L (2015) Discovery of 6-(4-{[5-Cyclopropyl-3-(2,6-dichlorophenyl)isoxazol-4-yl]methoxy}piperidin-1-yl)-1-methyl-1 H -indole-3-carboxylic Acid: a novel FXR agonist for the treatment of Dyslipidemia. J Med Chem 58:9768–9772

Plutschack MB, Pieber B, Gilmore K, Seeberger PH (2017) The Hitchhiker’s guide to Flow Chemistry. Chem Rev 117:11796–11893

Hessel V, Kralisch D, Kockmann N, Noël T, Wang Q (2013) Novel process windows for enabling, accelerating, and uplifting flow chemistry. Chemsuschem 6:746–789

Rodriguez A, Juan A, Gómez M, Moreno A, de la Hoz A (2012) Continuous-flow microliter microwave irradiation in the synthesis of isoxazole derivatives: an optimization procedure. Synthesis 44:2527–2530

Koo H, Kim HY, Oh K (2019) Continuous Flow synthesis of isoxazoles via Vinyl Azides from Friedel-Crafts Acylation of alkynes: a modulated troubleshooting optimization Approach. Org Lett 21:10063–10068

Castellano S, Tamborini L, Viviano M, Pinto A, Sbardella G, Conti P (2010) Synthesis of 3-aryl/benzyl-4,5,6,6a-tetrahydro-3a H-pyrrolo[3,4-d]isoxazole derivatives: a comparison between conventional, microwave-assisted and flow-based methodologies. J Org Chem 75:7439–7442

Britton J, Raston CL (2017) Multi-step continuous-flow synthesis. Chem Soc Rev 46:1250–1271

Bloemendal VRLJ, Janssen MACH, van Hest JCM, Rutjes FP (2020) J. T. continuous one-flow multi-step synthesis of active pharmaceutical ingredients. React Chem Eng 5:1186–1197

Jiao J, Nie W, Yu T, Yang F, Zhang Q, Aihemaiti F, Yang T, Liu X, Wang J, Li P (2021) Multi-step continuous‐Flow Organic synthesis: opportunities and challenges. Chem Eur J 27:4817–4838

Webb D, Jamison TF (2010) Continuous flow multi-step organic synthesis. Chem Sci 1:675–680

Pieber B, Gilmore K, Seeberger PH (2017) Integrated flow processing — challenges in continuous multistep synthesis. J Flow Chem 7:129–136

Cantillo D, Kappe CO (2017) Halogenation of organic compounds using continuous flow and microreactor technology. React Chem Eng 2:7–19

Dallinger D, Gutmann B, Kappe CO (2020) The Concept of Chemical generators: On-Site On-Demand production of Hazardous reagents in continuous Flow. Acc Chem Res 53:1330–1341

Zalesskiy SS, Kitson PJ, Frei P, Bubliauskas A, Cronin (2019) L. 3D designed and printed chemical generators for on demand reagent synthesis. Nat Commun 10:6–13

Strauss FJ, Cantillo D, Guerra J, Kappe CO (2016) A laboratory-scale continuous flow chlorine generator for organic synthesis. React Chem Eng 1:472–476

Leung GYC, Ying STR, Chia E, Chen A, Log G, Ramalingam B (2023) Safe and on-demand protocol for the continuous generation of SO2 and Cl2 for subsequent utilization in organic synthesis. J Flow Chem. https://doi.org/10.1007/s41981-023-00280-2

Kumar V, Kaushik MP (2006) A novel one-pot synthesis of hydroximoyl chlorides and 2-isoxazolines using N-tert-butyl-N-chlorocyanamide. Tetrahedron Lett 47:1457–1460

Gołȩbiewski WM, Gucma M (2007) Applications of N-chlorosuccinimide in organic synthesis. Synthesis 3599–3619

Shtaiwi M, Wentrup C (2002) Iminopropadienones from dioxanediones, isoxazolopyrimidinones, pyridopyrimidinones, and pyridopyrimidinium olates. J Org Chem 67:8558–8565

Acknowledgements

The Research Center Pharmaceutical Engineering (RCPE) is funded within the framework of COMET – Competence Centers for Excellent Technologies by BMK, BMAW, Land Steiermark and SFG. The COMET program is managed by the FFG. This article was published open access through support by the University of Graz.

Funding

Open access funding provided by University of Graz.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Prieschl, M., Sulzer, N., Sedelmeier, J. et al. Leveraging flow chemistry for the synthesis of trisubstituted isoxazoles. J Flow Chem 13, 405–411 (2023). https://doi.org/10.1007/s41981-023-00288-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-023-00288-8