Abstract

For the first time, micromixing characterization for the Villermaux–Dushman reaction could be performed with a non-reactive viscous medium at viscosities up to 2 Pas. As viscous medium, sucrose solution was used with the benefit of being a Newtonian fluid with tuneable viscosity. Due to the higher viscosities in comparison to established media for micromixing investigations, a new protocol for the experimental implementation was developed. Micromixing experiments were conducted and the applicability of viscous sucrose solutions was proven in a stirred tank reactor. Major challenges in characterizing micromixing efficiency in high viscous solution were consolidated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

For the production of many specialty chemicals temperature, pressure, concentrations, catalysis or solvents can have a strong influence on the quality of the final product [1, 2]. In the case of mixing sensitive reactions, efficient mixing is additionally to consider.

The origin of mixing efficiency can be for example the impeller type, the place of injection, the impeller speed or in the case of tubular reactors the type of winding or the type of static mixing elements [3, 4]. Moreover, at critical conditions where a thermal runaway is occurring the injection place of a stopper solution must be set in a way that mixing, in this case micromixing, can be achieved as fast as possible. Especially in the case of polymerization reactions, mixing efficiency has a strong influence on the product [5, 6]. Bad mixing conditions at the feed point of monomer and initiator can lead to fouling in the reactor in continuous radical polymerization [7]. In the case of e.g. polymerization reactions, the viscosity grows several magnitudes higher and mixing processes can become extremely difficult. Micromixing characterization at viscosities up to some 100 Pas are incredibly challenging and have not been conducted so far [8]. On the one hand, a suitable viscous medium must be selected and on the other hand, a compatible test reaction and a suited protocol for micromixing characterization must be found to operate in the selected viscous medium [9].

To characterize micromixing efficiency, various chemical test reactions have been developed such as the azo-coupling of 1-naphthol with diazotized sulphuric acid (Bourne reaction) [10] or the iodide–iodate test reaction also known as the Villermaux–Dushman reaction [11] which is extensively applied to characterize batch and continuous reactors. The Villermaux–Dushman reaction was first developed for a stirred tank reactor but later has been transferred to continuous reactors. In flow chemistry, micromixers and millireactors have been mainly the central point of attention when micromixing characterization is performed in continuous reactors [12,13,14,15,16].

Originally, the Villermaux–Dushman reaction was developed for water solutions but was later transferred for viscous solutions using glycerin–water solutions or hydroxyethyl cellulose as a thickener allowing micromixing characterization at viscosities up to 200 mPas [2, 17]. However, in various chemical processes such as polymerization reactions, the viscosity increases by several orders of magnitude and has a major influence on polymerization processes [18]. This requires a deep understanding of micromixing effects at elevated viscosities. In this work, sucrose solution is discussed as a test fluid for micromixing experiments which offers micromixing characterization at viscosities up to 2 Pas. Micromixing characterization in viscous solutions is demonstrated in a stirred tank reactor to investigate its feasibility and to set the foundation for prospective experiments in continuous reactors.

Villermaux–Dushman reaction

The Villermaux–Dushman reaction is a parallel competing test reaction which consists of a comproportionation reaction yielding iodine from iodide and iodate and an acid–base reaction in a borate buffer.

Boric acid is classified as toxic for reproduction by the CLP Regulation and REACH, it has also a limited solubility in water and other potential media [19, 20]. Therefore, the borate buffer was replaced by a new promising buffer which is a phosphate buffer [9, 21].

The modified Villermaux-Dushman reaction can be written as

Iodine further reacts into triiodide which can photometrically be detected at 353 nm.

A definition of the segregation index is similar to a borate buffer but the \( {\mathrm{H}}_2\mathrm{B}{\mathrm{O}}_3^{-} \) specie is substituted with \( \mathrm{HP}{\mathrm{O}}_4^{2-} \). The yield under imperfect mixing conditions \( \mathrm{Y} \) can be written as

The yield of the reaction \( {Y}_{ST} \) under total segregation can be expressed as

Thus, the segregation index can be defined as

The iodine concentration can be deduced from mass balance equations of the Dushman reaction.

The equilibrium constant K for reaction (iii) in water at 25 °C is given by literature [22].

Though, it should be mentioned that it is uncertain if the acid–base reaction only occurs with the \( \mathrm{HP}{\mathrm{O}}_4^{2-} \) species or with both the \( \mathrm{HP}{\mathrm{O}}_4^{2-} \) and \( {\mathrm{H}}_2\mathrm{P}{\mathrm{O}}_4^{-} \) species and further investigations must be conducted [23].

Micromixing in viscous solution

A number of researches have been performed in viscous solution. The first micromixing characterization in a viscous medium using the Villermaux–Dushman reaction was the study of micromixing processes in glycerin–water solution [2]. Further researches followed in glycerin–water solutions in different reactor types, e.g. bed reactors and rotating packed bed microfluidic chambers [24, 25]. Glycerin–water solution is a Newtonian fluid and allows a micromixing characterization up to 170 mPas. Furthermore, Guichardon et al. performed kinetic investigation of the Dushman reaction and confirmed a fifth-order rate law in glycerin–water solution.

The reaction constant k depended on the ionic strength \( \upmu \) and the dielectric constant \( {\upvarepsilon}_{\mathrm{r}} \) of the glycerin–water solution. It could be numerically described up to an ionic strength \( \upmu \) of 0.166 mol L− 1 and a glycerin mass fraction of 75.9 % by the following equation.

At higher ionic strength, they presented an empirical relationship of the reaction rate constant by using a kinetic parameter as a function of the glycerin mass fraction. As an acid, they used sulphuric acid and potassium sulphate as a salt. Sulphate ions can act as a base and alter the investigation of the ionic strength on the reaction rate constant. In addition, they measured the development of the equilibrium constant K for reaction (iii) with higher glycerin mass fraction consequently with higher viscosities. An increase of K could be observed. For a glycerin mass fraction of 0 %, K is 736 L mol-1 and for a mass fraction of 80 %, K is around 7200 L mol-1 [2]. The two parameters, they investigated were the influence of the injection time and of the stirring speed on the micromixing efficiency up to 170 mPas. Whereas these parameters could be enough for low viscosities, this will change at higher viscosities. This will be discussed in Chap. 3.1.

Next to glycerin–water solution, carboxymethyl cellulose (CMC) and hydroxyethyl cellulose (HEC) were used frequently at low mass fractions up to 0.2 %, where they still behave Newtonian. CMC has the disadvantage that the viscosity depends on many factors such as concentration, temperature, and pH value [26]. Both, CMC and HEC, behave non-Newtonian at mass fractions above 0.2 % where shear-thinning behaviour can be observed [27, 28]. HEC does not show a pH dependency of the viscosity but Newtonian behaviour can only be sustained up to a viscosity of 50 mPas. Kunowa et al. have performed micromixing experiments in HEC in a borate buffer. They could observe higher absorbances with increasing HEC mass fraction [17]. Pinot et al. have conducted micromixing experiments in HEC in a phosphate buffer. They have proven applicability of a phosphate buffer in micromixing experiments, though they stated the difficulty of the non-Newtonian behaviour at higher HEC mass fractions [9].

Sucrose solution as a new viscous medium for micromixing characterization

For the Villermaux-Dushman reaction, a proper viscous medium should fulfil several requirements.

-

Be chemical inert towards the reactants and reactive products.

-

Not interfering in the chemical analysis of the reactive product.

-

Set a wide range of viscosity.

-

Be soluble for all the reactants.

-

Have a Newtonian behaviour through large shear rates.

-

No change in viscosity at different pH values.

-

Allow kinetic investigation of the Dushman reaction at different viscosities.

A promising viscous medium for micromixing characterization with the Villermaux–Dushman reaction is sucrose solution (α-D-glucopyranosyl-β-D-fructofuranose). The main advantages of sucrose solutions are Newtonian behaviour, chemical inertness towards the reactants and a tuneable range of viscosities up to 2 Pas. Sucrose is a disaccharide composed of D-fructofuranose and D-glucopyranose which is bonded through a 1,2-α,β-glycosidic bond. Thus, both functional groups, the formyl and ketone group, are bonded which is why sucrose is a non-reducing sugar (Fig. 1).

Glucose solution, invert sugar solution or malt syrup cannot be used for micromixing characterization since they do not fulfil the requirement for a viscous test fluid to be chemical inert. Glucose reacts with triiodide in a redox reaction yielding iodide and gluconic acid altering the triiodide concentration, which is obtained in micromixing characterization. Though Pinot et al. have stated, that with sucrose parasite reaction like the hydrolysis through the injected acid could occur [9], we could not observe this at experimental conditions for micromixing characterization when diluted sulphuric acid is used at 25 °C. Further investigations were conducted in Chap. 3.3. Characterization of the properties of sucrose solutions were conducted and the results are presented in the supplement information.

Experimental section

Materials and methods

The following chemicals were used for experiments without further purification: \( \mathrm{KI} \) (Carl Roth, ACS reagent grade), \( {\mathrm{KIO}}_3 \) (Carl Roth, ACS reagent grade), \( \mathrm{NaOH} \) (Carl Roth, ACS reagent grade) and \( \mathrm{Na}{\mathrm{H}}_2{\mathrm{PO}}_4\cdot 2{\mathrm{H}}_2\mathrm{O} \) (Carl Roth, ACS reagent grade). All solutions were prepared from demineralized water (conductivity 0.8 µS/cm). Diluted sulphuric acid solution was prepared from concentrated sulphuric acid and demineralized water. Iodate solutions were prepared from dried and powdered \( {\mathrm{KIO}}_3 \). \( \mathrm{NaOH} \) solution was prepared from sodium hydroxide. The concentration was determined by triple titration. \( \mathrm{Na}{\mathrm{H}}_2{\mathrm{PO}}_4 \) solution was prepared from \( \mathrm{Na}{\mathrm{H}}_2{\mathrm{PO}}_4\cdot 2{\mathrm{H}}_2\mathrm{O} \).

The rheological properties of sucrose solution were investigated by individual measurements with AR-G2 (TA Instruments) with a 60 mm 2° cone at 25 °C. The viscosities of the bulk solutions which were used for micromixing experiments were determined with a ViscoQC 300 R viscometer (Anton Paar) with a cylinder beaker geometry (CC18) at 25 °C. The density of sucrose solutions were determined with a pycnometer (Neubert–Glas Gbr).

UV–Vis analysis was performed with a Cary®50 spectrometer (Varian). The absorbances were either measured with a falcata immersion probe with variable tip length (Falcata Lab, 661.622, Hellma) or a quartz cuvette (d = 10 mm). The absorbance of triiodide in sucrose solution obeys to the Lambert–Beer law. The extinction coefficient of \( {\mathrm{I}}_3^{-} \) in 1400 mPas sucrose solution was determined as 2705(± 25) m²/mol for a 10 mm pathlength. Micromixing experiments were conducted in a 1.5 L double-wall reaction vessel. The reaction volume was 1 L. The internal temperature was measured with a PT100 sensor and kept constant at 25 °C using a thermostat (Julabo F-30 C). During experiments, a nitrogen atmosphere was set. The acid was injected by a syringe pump (LSP01-1 A, Longer Pump) and the reaction solution was mixed with an agitator (IKAVISC MR-D1, IKA–Labortechnik). A paravisc impeller (EKATO Rühr- und Messtechnik) was used for mixing. A sketch of the experimental setup is given in Fig. 2.

Preparation of the bulk solution and viscous sulphuric acid

The preparation of the experimental solution requires several steps and needs some precautions. Most important, all vessels and storing reservoirs for sucrose solution should be kept as dust free as possible to avoid crystallization through nucleation. Sucrose solution was prepared with commercially available sucrose from Nordzucker AG by heating the desired amount of sucrose and demineralized water at 105 °C in a pot. The sucrose solution was cooled down in a round-bottomed flask in a heating cabinet to 25 °C to reduce the chance of spontaneous crystallization. Potassium iodide, potassium iodate, sodium dihydrogen phosphate and sodium hydroxide are difficult to solve in concentrated sucrose solution. Therefore, 0.2 mol L− 1 \( {\mathrm{KIO}}_3 \) (ρ = 1.03 g/cm³ at 25 °C), 4 mol L− 1 \( \mathrm{Na}{\mathrm{H}}_2{\mathrm{PO}}_4\cdot 2{\mathrm{H}}_2\mathrm{O} \) (ρ = 1.33 g/cm³ at 25 °C) and 4.12 mol L− 1 \( \mathrm{NaOH} \) (ρ = 1.15 g/cm³ at 25 °C) stock solutions were prepared in demineralized water. First, a concentrated buffer is prepared by mixing \( \mathrm{Na}{\mathrm{H}}_2{\mathrm{PO}}_4\cdot 2{\mathrm{H}}_2\mathrm{O} \) and \( \mathrm{NaOH} \) solutions. Then, \( \mathrm{KI} \) is dispensed as a powder and the required amount of sucrose solution is added and mixed. Finally, \( {\mathrm{KIO}}_3 \) solution is added and the bulk is homogenously mixed. This sequence of preparation prevents an early formation of triiodide. The concentrations and viscosity for the experimental micromixing characterizations are given in Table 1.

The preparation steps are demonstrated with the preparation of 4200 mL experimental sucrose solution with a viscosity of 2144 mPas at 25 °C. First, a 78.7 % sucrose solution is prepared by heating 1221 g water and 4508 g sucrose at 105 °C until sucrose is completely dissolved. The density of the prepared solution is measured to be 1.397 g/cm³ at 25 °C. In a 5 L beaker, 44.1 mL (50.7 g) 4.12 mol L− 1 NaOH and 47.7 mL (63.6 g) 4 mol L− 1 NaH2PO4·2H2O is mixed by slewing and 8.134 g of KI is dissolved in the concentrated buffer. The amount of sucrose solution is given by the difference of the final experimental solution and the added volumes of stock solutions so far. Thus, 4059 mL (5671 g) 78.7 % sucrose solution is added in the beaker and the solution is mixed with a paravisc impeller. While mixing 49.0 mL (50.71 g) 0.2 mol L1 KIO3 is added and the mixture is homogenously mixed. The resulting experimental solution has a volume of 4204 mL (5844 g) at a density of 1.390 g/cm³ and viscosity of 2144 mPas at 25 °C.

Viscous 0.5 M sulphuric acid was freshly prepared before the start of the micromixing experiment. For this, 12 mL 2 mol L− 1 H2SO4 was added in a 50 mL graduated flask and filled up with 1300 mPas viscous sucrose solution. The final viscosity of the 0.5 mol L− 1 sulphuric acid solution was then 92 mPas (1.33 g/cm³).

Experimental procedure for micromixing experiments

For each micromixing experiment, the according mass for 1 L was removed from the prepared stock solution and transferred carefully in the reaction vessel in a way that bubble entrainment is minimised. The internal temperature was set to be 25 °C. A 6 mL syringe was filled up with 2 mL (2.06 g) of 0.5 mol L− 1 sulphuric acid and mounted on the syringe pump. A nitrogen atmosphere was set, and the desired injection time and impeller speed were adjusted. The micromixing experiment begins with the start of the acid injection. After the acid injection, the agitator was operated for one more minute to ensure a homogenous dispersion of the formed triiodide. A sample was taken from the bulk solution and UV–Vis measurement was conducted in a 10 mm quartz cuvette for each experiment three minutes after the end of injection. The decrease in absorbance of the measured triiodide in the buffered sucrose solution was approximately 0.5 %/min. In glycerin–water solution, a reduction of triiodide could be measured as well which was 0.15 %/min [2]. A detailed explanation for the phenomenon should be part of further investigations. Above an impeller speed of 180 rpm, the formation of strong turbulent vortices hindered micromixing experiments for the characterization in water (run 1) and for the experiment at 2144 mPas (run 5) massive entrainment of bubbles hindered UV–Vis measurements.

Results

Properties of sucrose solution

Rheological properties of sucrose have been investigated by food scientists and the sugar industry. In the supplement information, the rheological properties of sucrose solutions, the development of the viscosity and density against the mass fraction are given and compared to the National Bureau of Standards [29] and Nordic Sugar [30].

The viscosity is strongly influenced by the temperature. Therefore, it is important to keep the temperature at a constant value. Sucrose solutions show Newtonian behaviour at shear rates above 10 s− 1. For experimental procedures, the density of sucrose solution is particularly important to know. The reason will be discussed in the "Experimental section". Between a mass fraction of 65 and 80 %, the density \( \uprho \) and mass fraction of sucrose solution \( {\mathrm{w}}_{\mathrm{sucrose}} \) can be approximated by Eq. 8 at 25 °C.

Heating sucrose solution requires precaution measurements. Above a temperature of 120 °C, thermal hydrolysis of sucrose occurs and a shift from a light yellow to a strong yellow colour can be observed. Furthermore, sucrose solution tends to spontaneously crystallize over a mass fraction of 72 %, since it becomes supersaturated and a spontaneous or induced crystallization can occur [30, 31].

Challenges in micromixing characterization in viscous solution

Investigating micromixing efficiency in viscous solutions is challenging. After injection of acid, the formed triiodide is measured. For this, the formed triiodide must be homogenously mixed in the bulk solution which requires ideal macromixing. Thus, parameters such as impeller type, local injection point and impeller speed must be chosen carefully when characterizing micromixing efficiency at high viscosities. An inappropriate injection point or impeller type can lead to dead zones or the formation of toroidal or turbulent vortices. When aqueous sulphuric acid is mixed in the bulk solution, there is a significant difference in viscosity and density of the two miscible fluids, in which buoyancy effects must be overcome to achieve homogenous mixing. Furthermore, a major challenge is the formation of bubbles in the bulk solution at high impeller speeds which complicates UV–Vis measurements. Therefore, before characterizing micromixing efficiency in viscous solution, macromixing experiments should be conducted to ensure macromixing effects do not alter results from micromixing experiments.

Investigation of triiodide reduction in acidic sucrose solution

For successful micromixing experiments, the hydrolysis of sucrose should be in an acceptable range. Guichardon et al. measured a drop of triiodide absorbances of 3.5 % in 23 min in glycerin–water solution [2] and showed that this drop is acceptable for micromixing characterization. In order to determine the value for sucrose solutions, triiodide was mixed in 200 mL solution containing 66 % sucrose and tempered at 25 °C in a 250 mL vessel. Then, 1 mL of 2 mol L− 1 sulphuric acid was injected in the vessel and absorbances were measured via UV–Vis spectroscopy for 20 min. A small decrease of the triiodide absorbance of 5 % could be noticed. Furthermore, sucrose solution was injected in 2 mol L− 1 sulphuric acid containing triiodide and again a decrease in absorbances of 5 % in 20 min could be observed. The results are in agreement with Nordic Sugar where a full inversion of sucrose occurs at a pH value of 2 after several days at 20 °C [30]. The decrease of triiodide absorbances in sucrose solution are comparable to Guichardon et al. [2].

On the contrary, experiments with diluted perchloric acid lead to a strong decrease of triiodide at 25 °C. Since perchloric acid is comparatively a very strong acid, the hydrolysis of sucrose can even occur at room temperature. Therefore, sulphuric acid is more suitable for micromixing characterization in sucrose solution.

Investigation of critical injection time

The injection time of the acid must be chosen carefully. In the case of a too fast injection, macroscopic plumes of acid can be formed and both macro- and micromixing are measured. To investigate only micromixing efficiency, the injection time is increased to the point where the absorbance does not change with increasing injection time which is referred to as the critical injection time. This procedure is well described by Fournier and Guichardon [11, 32].

In Fig. 3, the critical injection time was determined at a viscosity of 1335 mPas at 120 rpm to be 800 s reaching a constant value. Thus, it can be assumed that micromixing is dominant and macromixing can be neglected. Therefore, all micromixing experiments were performed with an injection time of 800 s.

Influence of the stirring speed on the measured absorbances

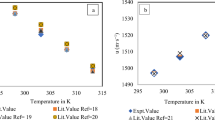

Micromixing experiments were performed at viscosities between 1 and 2144 mPas with aqueous sulphuric acid. The results are presented in Fig. 4.

For comparison, experiments were conducted in water as well. Because of intense turbulent vortices, the impeller speed could only be increased to 180 rpm in case of water. The segregation indices were calculated according to Eq. 3, though it should be kept in mind, that a final definition of the segregation index in a phosphate buffer cannot be given yet, and eventually the results must be recalculated. For that purpose, the corresponding triiodide concentrations are given as well.

The measured segregation indices in water are much lower than in viscous sucrose solution. At low impeller speeds of 120 rpm and 150 rpm, similar segregation indices are measured at viscosities between 119-2144 mPas. The results indicate that micromixing efficiency is improved after a critical impeller speed is achieved which is above 150 rpm. Between 180 and 240 rpm, the segregation indices decrease with higher impeller speeds, which can be explained by better mixing. Furthermore, segregation indices increase with higher viscosities at a given impeller speed.

For slow impeller speeds at 120 and 150 rpm, the segregation indices are similar whether the viscosity is 119 mPas or 2144 mPas. This unexpected phenomenon could indicate that increasing micromixing performance can only be achieved after a critical impeller speed is achieved for viscous solutions. However, identical segregation indices at 120 rpm do not necessarily imply same micromixing times. It can be assumed that the kinetics of the acid–base reaction and of the Dushman reaction might be altered with increasing viscosity. Guichardon et al. have shown that for a glycerin–water mixture the global reaction rate equation is according to a fifth-order but the reaction rate constant is altered with the glycerin mass fraction [2]. Similar results might be possible with sucrose solutions. With higher viscosities, the kinetics of the Dushman reaction might be altered into slower reaction rates. In the parallel competing reactions between the acid–base reaction and the Dushman reaction, the acid–base reaction would be then even more favored. If same segregation indices for different viscosities at a given impeller speed are determined, the according micromixing times for the higher viscosity would have to increase. The evaluation of the experimental data requires several kinetic data of each reaction e.g., the kinetics of the acid–base reaction, a comprehensive kinetic investigation of the Dushman reaction at different viscosities and the reaction rate constants for the iodine–triiodide equilibrium reaction. Therefore, the segregation index itself might be insufficient to compare micromixing efficiency at different viscosities. A comparison of calculated micromixing times would be more reasonable which requires not only kinetic data but an adequate micromixing model for viscous solutions.

Micromixing characterization with viscous acidic sucrose solution

In the run 6 and 7, the injected sulphuric acid solution had a viscosity of 92 mPas. The viscous sulphuric has not only a much higher viscosity than aqueous sulphuric acid but the density has increased from 1.03 g/cm³ to 1.33 g/cm³ as well. The results of the micromixing experiments are presented in Fig. 5. For comparison, the results of run 1, 2 and 3 are presented as well.

Generally, the segregation indices with viscous sulphuric acid are lower than with aqueous sulphuric acid. In run 6, the segregation index at 120 rpm is lower than in run 2. The segregation indices match at 180 and 210 rpm. At 240 rpm, a further decrease in absorbance occurs with run 6 compared to run 2. The measured absorbances for run 7 are lower than in run 2 even though the viscosity is about 100 mPas higher.

Experiments with viscous sulphuric acid led to lower absorbances than with aqueous sulphuric acid. When experiments are conducted with aqueous sulphuric acid, buoyancy forces must be overcome. Furthermore, mixing two miscible fluids with significant viscosity differences becomes harder as the differences increase [33, 34]. Moreover, the initial viscosity of the bulk solution decreases over time since the aqueous portion of the bulk solution increases by the injection of aqueous sulphuric acid. All these effects must be considered when micromixing characterization is conducted in viscous solutions. To investigate the single effect of viscosity on micromixing characterization, it is advisable to use viscous sulphuric acid.

Discussion

An interpretation of the experimental data without kinetic data of the Dushman reaction at different viscosities and a suitable micromixing model is difficult. Nevertheless, we want to demonstrate the impact of a change in the reaction rate constant of the Dushman reaction kDushman on micromixing time calculations. As an underlying micromixing model, the incorporation model is selected. Although this model might not be suitable to describe micromixing in viscous solution, it allows to estimate the impact of different reaction rate constants of the Dushman reaction on micromixing time calculations. A description of the model is originally given by Fournier et al. [35]. The micromixing time calculations were performed with an extended incorporation model for sulphuric acid according to Arian and Pauer with the given concentration from Table 1 [23]. It can be assumed that for high viscosities the Dushman reaction is slowed down even further, resulting in a reduction of the reaction rate constant with higher viscosities but probably not significantly effecting the acid–base reaction. Therefore, the segregation index was exemplary calculated for different percentages of the reaction rate constant kDushman. The results of the calculations are given in Fig. 6.

The left figure shows that micromixing times at the same segregation index change if the reaction rate constant of the Dushman reaction is altered to slower values. On the right figure, micromixing times were calculated for a segregation index XS of 0.15. For this, the values for the reaction rate constant kDushman were set between 10 and 100 % of its original value. The difference in micromixing times can differ by an order of magnitude for the same segregation index if the reaction rate constant kDushman is slowed down significantly. The results of the micromixing time calculations indicate that similar segregation indices in viscous solutions do not necessarily correspond to same micromixing efficiencies. A shift of the Dushman reaction to slower reaction rates with increasing viscosity could explain the similar measured triiodide concentrations at 120 and 150 rpm.

Conclusions

Micromixing characterizations were performed at viscosities up to 2 Pas. A procedure to produce the viscous bulk solution and a protocol for micromixing characterization in viscous solution were proposed. Sucrose solution is a promising viscous medium with the advantage of being a Newtonian fluid with tunable viscosities. Furthermore, micromixing experiments with viscous sulphuric acid were conducted for the first time. The micromixing experiments were conducted in a stirred tank reactor to show a proof of concept. A transfer to continuous reactors should be possible allowing micromixing characterization of milli- and microflow reactors as well as static mixers at different viscosities.

The interpretation of the segregation index requires several kinetic data and a micromixing model for viscous fluids. A kinetic investigation of the Dushman reaction and further micromixing characterizations in sucrose solution will be the main purpose of a future paper.

References

Roessler A, Rys P (2001) Wenn die Rührgeschwindigkeit die Produktverteilung bestimmt: Selektivität mischungsmaskierter Reaktionen. Chem Unserer Zeit 35:314–323. https://doi.org/10.1002/1521-3781(200110)35:5<314:AID-CIUZ314>3.0.CO;2-D

Guichardon P, Falk L, Villermaux J (1997) Extension of a chemical method for the study of micromixing process in viscous media. Chem Eng Sci 52:4649–4658. https://doi.org/10.1016/S0009-2509(97)85419-X

Fang JZ, Lee DJ (2001) Micromixing efficiency in static mixer. Chem Eng Sci 56:3797–3802. https://doi.org/10.1016/S0009-2509(01)00098-7

Jasińska M (2015) Test reactions to study efficiency of. Chem Process Eng 36:171–208. https://doi.org/10.1515/cpe-2015-0013

Bally F, Serra CA, Hessel V et al (2011) Micromixer-assisted polymerization processes. Chem Eng Sci 66:1449–1462. https://doi.org/10.1016/j.ces.2010.07.026

Oechsler BF, Melo PA, Pinto JC (2017) Micromixing effects on the dynamic behavior of continuous free-radical solution polymerization tank reactors. Appl Math Modell 42:346–362. https://doi.org/10.1016/j.apm.2016.10.019

Bayer T, Pysall D, Wachsen O (2000) Micro mixing effects in continuous radical polymerization. In: Ehrfeld W (ed) Microreaction Technology: Industrial Prospects. Springer Berlin Heidelberg, Berlin, pp 165–170

Pippel W (1978) Verweilzeitanalyse in technologischen Strömungssystemen. Akademieverlag, Berlin

Pinot J, Commenge J-M, Portha J-F et al (2014) New protocol of the Villermaux–Dushman reaction system to characterize micromixing effect in viscous media. Chem Eng Sci 118:94–101. https://doi.org/10.1016/j.ces.2014.07.010

Bourne JR, Kozicki F, Rys P (1981) Mixing and fast chemical reaction—I. Chem Eng Sci 36:1643–1648. https://doi.org/10.1016/0009-2509(81)80008-5

Fournier M-C, Falk L, Villermaux J (1996) A new parallel competing reaction system for assessing micromixing efficiency—Experimental approach. Chem Eng Sci 51:5053–5064. https://doi.org/10.1016/0009-2509(96)00270-9

Kölbl A, Kraut M, Schubert K (2008) The iodide iodate method to characterize microstructured mixing devices. AlChE J 54:639–645. https://doi.org/10.1002/aic.11408

Kockmann N, Kiefer T, Engler M et al (2006) Convective mixing and chemical reactions in microchannels with high flow rates. Sens Actuators B 117:495–508. https://doi.org/10.1016/j.snb.2006.01.004

Kashid M, Renken A, Kiwi-Minsker L (2011) Mixing efficiency and energy consumption for five generic microchannel designs. Chem Eng J 167:436–443. https://doi.org/10.1016/j.cej.2010.09.078

Gobert SRL, Kuhn S, Braeken L et al (2017) Characterization of milli- and microflow reactors: mixing efficiency and residence time distribution. Org Process Res Dev 21:531–542. https://doi.org/10.1021/acs.oprd.6b00359

Panić S, Loebbecke S, Tuercke T et al (2004) Experimental approaches to a better understanding of mixing performance of microfluidic devices. Chem Eng J 101:409–419. https://doi.org/10.1016/j.cej.2003.10.026

Kunowa K, Schmidt-Lehr S, Pauer W et al (2007) Characterization of mixing efficiency in polymerization reactors using competitive-parallel reactions. Macromol Symp 259:32–41. https://doi.org/10.1002/masy.200751305

Moritz HU (1989) Increase in viscosity and its influence on polymerization processes. Chem Eng Technol 12:71–87. https://doi.org/10.1002/ceat.270120112

European Parliament (2008) Regulation (EC) No 1272/2008 of the European Parliament and the Council: CLP, vol 2008

(2009) Regulation (EC) No 1907/2006 of the European Parliament and of the Council: REACH, vol 2006

Baqueiro C, Ibaseta N, Guichardon P et al (2018) Influence of reagents choice (buffer, acid and inert salt) on triiodide production in the Villermaux–Dushman method applied to a stirred vessel. Chem Eng Res Des 136:25–31. https://doi.org/10.1016/j.cherd.2018.04.017

Palmer DA, Ramette RW, Mesmer RE (1984) Triiodide ion formation equilibrium and activity coefficients in aqueous solution. J Solution Chem 13:673–683. https://doi.org/10.1007/BF00650374

Arian E, Pauer W (2021) Contributions to the kinetics of the iodide–iodate test reaction for micromixing time calculation with extended incorporation models. Chem Eng Sci 136U:116549. https://doi.org/10.1016/j.ces.2021.116549

Jiao W, Liu Y, Qi G (2012) Micromixing efficiency of viscous media in novel impinging stream-rotating packed bed reactor. Ind Eng Chem Res 51:7113–7118. https://doi.org/10.1021/ie202586f

Chen Y-S, Liu H-S, Lin C-C et al (2004) Micromixing in a rotating packed bed. J Chem Eng Jpn/JCEJ 37:1122–1128. https://doi.org/10.1252/jcej.37.1122

Bourne JR, Hilber CP, Petrozzi S (1989) The influence of viscosity on micromixing in turbulent flows. Chem Eng Process Process Intensif 25:133–139. https://doi.org/10.1016/0255-2701(89)80003-0

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym Sci 286:1173–1180. https://doi.org/10.1007/s00396-008-1882-2

Del Giudice F, Tassieri M, Oelschlaeger C et al (2017) When microrheology, bulk rheology, and microfluidics meet: broadband rheology of hydroxyethyl cellulose water solutions. Macromolecules 50:2951–2963. https://doi.org/10.1021/acs.macromol.6b02727

Bates FJ (1942) Polarimetry, saccharimetry and the sugars, (United States. National Bureau of Standards. Circular C440). U.S. Goverment Printing Office, Washington

Nordic Sugar A/S The functional properties of sugar - on a technical level. https://www.nordicsugar.com/fileadmin/Nordic_Sugar/Brochures_factsheet_policies_news/Download_center/Functional_properties_of_sugar_on_a_technical_level/Functional_prop_on_tech_level_uk.pdf. Accessed 23 Apr 2020

Mathlouthi M, Reiser P (eds) (1995) Sucrose: Properties and Applications. Springer US, Boston

Guichardon P, Falk L (2000) Characterisation of micromixing efficiency by the iodide–iodate reaction system. Part I: experimental procedure. Chem Eng Sci 55:4233–4243. https://doi.org/10.1016/S0009-2509(00)00068-3

Rożeń A, Bałdyga J (2004) Instability of the couette flow of two liquids differing in viscosities. Inzynieria Chemiczna i Procesowa 25:439–454

Burmester SSH, Rielly CD, Edwards MF (1992) The mixing of miscible liquids with large differences in density and viscosity. In: Moreau R, King R (eds) Fluid Mechanics of Mixing, vol 10. Springer, Dordrecht, pp 83–90

Fournier M-C, Falk L, Villermaux J (1996) A new parallel competing reaction system for assessing micromixing efficiency—Determination of micromixing time by a simple mixing model. Chem Eng Sci 51:5187–5192. https://doi.org/10.1016/S0009-2509(96)00340-5

Acknowledgements

We thank Tobias Leistner for the investigation of the rheological properties and density of sucrose solutions. We thank Ezgi Köz for assisting in the micromixing experiments.

Funding

Open Access funding enabled and organized by Projekt DEAL. The work has partially been funded by the German Federal Ministry for Economic Affairs and Energy as part of the ENPRO Initiative (KoPPonA 2.0, FKZ: 03EN2004M).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Sucrose solution as a new viscous medium for determining micromixing efficiency is proposed.

• Determination of micromixing efficiency up to 2 Pas.

• Application examples for micromixing experiments with viscous acid were conducted.

Supplementary Information

ESM 1

(DOCX 195 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Arian, E., Pauer, W. Sucrose solution as a new viscous test fluid with tunable viscosities up to 2 Pas for micromixing characterization by the Villermaux–Dushman reaction. J Flow Chem 11, 579–588 (2021). https://doi.org/10.1007/s41981-021-00158-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-021-00158-1